Decontamination in primary care dental practices - Gov.uk

Decontamination in primary care dental practices - Gov.uk

Decontamination in primary care dental practices - Gov.uk

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

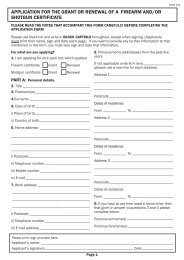

5 Sett<strong>in</strong>g up a decontam<strong>in</strong>ation area5 Sett<strong>in</strong>g up a decontam<strong>in</strong>ation area5.1 There is a clear need to maximise the separation ofdecontam<strong>in</strong>ation work from cl<strong>in</strong>ical activity with<strong>in</strong>the constra<strong>in</strong>ts of space and room availability.Where <strong>in</strong>struments are reprocessed <strong>in</strong> the sameroom as the patient treatment area, the reprocess<strong>in</strong>garea should be as far from the <strong>dental</strong> chair aspracticality allows. As <strong>dental</strong> <strong>practices</strong> progresstowards higher standards, remov<strong>in</strong>g thedecontam<strong>in</strong>ation process from the treatment roomshould be a priority. For example layouts, seeFigures 1–3.5.2 If decontam<strong>in</strong>ation has to be carried out <strong>in</strong> apatient treatment room, to m<strong>in</strong>imise the risks bothto the patient and of cross-contam<strong>in</strong>ation of<strong>in</strong>struments, appropriate controls should be <strong>in</strong>place. Uncontrolled procedures that generate therisk of exposure to aerosol dispersion or splashes(such as manual wash<strong>in</strong>g, the use of an ultrasoniccleaner without a sealed chamber (or lid) or theopen<strong>in</strong>g of decontam<strong>in</strong>ation equipment) shouldNOT take place while the patient is present.5.3 Regardless of the choice of location used for thereprocess<strong>in</strong>g facilities, a dirty-to-clean workflowshould be ma<strong>in</strong>ta<strong>in</strong>ed so that used <strong>in</strong>strumentsare at a lower risk of com<strong>in</strong>g <strong>in</strong>to contact withdecontam<strong>in</strong>ated <strong>in</strong>struments. This requires awell-developed rout<strong>in</strong>e for surface clean<strong>in</strong>g/decontam<strong>in</strong>ation with<strong>in</strong> the facilities:Ventilation<strong>in</strong>putVentilationextraction oroutputWash-handbas<strong>in</strong>(optional)OUT(optional,dependentupon spaceand layout)Inspectionand storageCLEANZONEInspectand,whereapplicable,packSterilizerDIRTYZONEDeliverWash-handbas<strong>in</strong>OUTINKeyR<strong>in</strong>s<strong>in</strong>gs<strong>in</strong>kUltrasoniccleaner(optional)Wash<strong>in</strong>gs<strong>in</strong>kInstrument flowAirflowNotes1. The use of an ultrasonic cleaner is optional. Where such a cleaner is not provided,handl<strong>in</strong>g difficulties will be reduced by sit<strong>in</strong>g the wash<strong>in</strong>g s<strong>in</strong>k near to the r<strong>in</strong>s<strong>in</strong>g s<strong>in</strong>k orby comb<strong>in</strong><strong>in</strong>g both s<strong>in</strong>ks through the <strong>in</strong>stallation of a double-bowl s<strong>in</strong>k assembly.2. Practices may <strong>in</strong>crease the number of sterilizers if capacity and service cont<strong>in</strong>uitydictates.Figure 1 Example layout for essential quality requirements29