M/s. API Ispat & Powertech Private Limited, Vill ... - Seiaacg.org

M/s. API Ispat & Powertech Private Limited, Vill ... - Seiaacg.org

M/s. API Ispat & Powertech Private Limited, Vill ... - Seiaacg.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

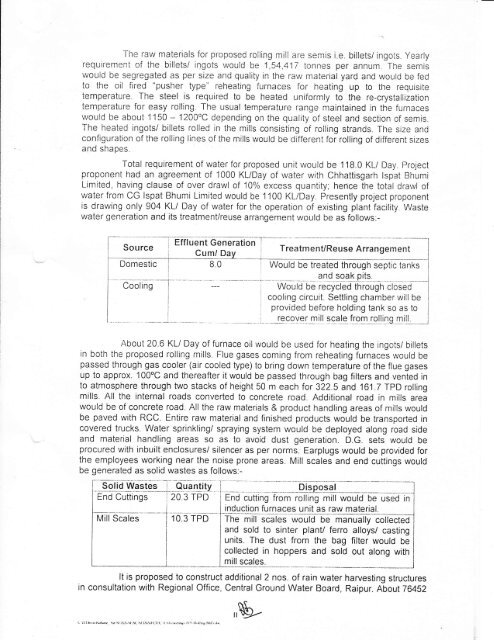

The raw materials for proposed rolling mill are semis i.e. billetsl ingols, Yearlyrequirement of the billets/ ingots would be 1,54,4'17 tonnes per annum The semiswould be segregated as per size and quality in the raw material yard and would be fedto the otl fired "pusher type" reheating furnaces for heating up to the requisitetemperature. The steel is required to be heated uniformly to the re-crystallizationtemperature for easy rolling The usual temperature range maintained in the furnaceswould be about 1150 - 1200"C depenciing on the quality of steel and section of semis.The heated ingots/ billets rolled in the mills consisting of rolling strands. The size andconfiguration of the rolling lines of the mills would be different for rolling of different srzesand shapesTotal requirement of water for proposed unit would be 118.0 KU Day. Projectproponent had an agreement of 1000 KL/Day of water with Chhattlsgarh lspat Bhumi<strong>Limited</strong>, having clause of over drawl of 10% excess quantity; hence the total drawl ofwater from CG lspat Bhumi <strong>Limited</strong> would be 1100 KL/Day. Presently project proponentis drawing only 904 KL/ Day of water for the operation of existing plant facility Wastewater generation and its treatment/reuse arrangement would be as follows:-i Effluent GenerationDomestic-IlCoolrnt -TIlIiITreatmenUReuse ArrangementWould be treated through septic tanks_ __et9Jga(ptls__ _ ,Would be recycled through closedcooling circuit. Settling chamber will beprovided before holding tank so as to10.3 TPDEnd cutting tom Alhng mill would be used il1induction furnaces unit as raw materialThe mill scales would be manually collectedand sold to sinter planV ferro alloys/ castingunits. The dust from the bag filter would becollected in hoppers and sold out along withmill scales.It is proposed to construct additional 2 nos. of rain water harvesting structuresin consultation with Regional Office, Central Ground Water Board, Raipur. About 7645?,,brJ) I lr\< r,urr(- \, v i/."\.V n\ \' r A J ( 1 ( ."",'.,."t,..,i,u.nt,nr V,," r.About 20.6 KL/ Day of furnace oil would be used for heating the ingots/ billetsin both the proposed rolling mills. Flue gases coming from reheating furnaces would bepassed through gas cooler (air cooled type) to bring down temperature of the flue gasesup to approx. 1OO.C and thereafter itwould be passed through bag filters and vented into atmosphere through two stacks of height 50 m each for 322.5 and 161.7 TPD rollingmills All the internal roads converted to concrete road. Additional road in mills areawould be of concrete road. All the raw materials & product handling areas of mills wouldbe paved with RCC. Entire raw material and finished products would be transported incovered trucks. Water sprinkling/ spraying system would be deployed along road sideand material handling areas so as to avoid dust generation. D.G. sets would beprocured with inbuilt enclosures/ silencer as per norms. Earplugs would be provided forthe employees working near the noise prone areas. Mill scales and end cuttings wouldbe generated as solid wastes as follows:-

![[Medical college and Hospital] - Seiaacg.org](https://img.yumpu.com/52174544/1/184x260/medical-college-and-hospital-seiaacgorg.jpg?quality=85)