M/s. API Ispat & Powertech Private Limited, Vill ... - Seiaacg.org

M/s. API Ispat & Powertech Private Limited, Vill ... - Seiaacg.org

M/s. API Ispat & Powertech Private Limited, Vill ... - Seiaacg.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

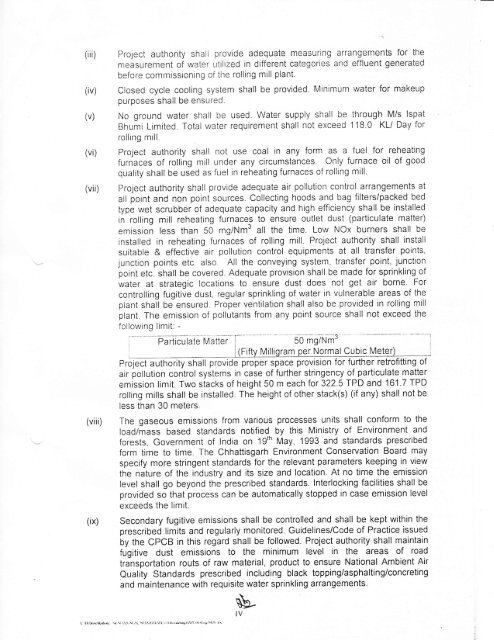

(iii)(iv)(v)(vi)(vii)Prolect authority shail provide adequate measuring arrangements for themeasurement of water utilized in different categories and effluent generatedbefore commissioning of tlre rolling mill plant.Closed cycle cooling system shall be provided. Minimum water for makeuppurposes shall be ensured.No ground water shall bre used. Water supply shall be through M/s lspatBhumi <strong>Limited</strong>. Total water requirement shall not exceed 118.0 KL/ Day forrolling mill.Project authority shall not use coal in any form as a fuel for reheatingfurnaces of rolling mill under any circumstances. Only furnace oil of goodquality shall be used as fuel in reheating furnaces of rolling millProject authority shall provide adequate air pollution control arrangements atall point and non point sources. Collecting hoods and bag filters/packed bedtype wet scrubber of adequate capacity and high efficiency shall be installedin rolling mill reheating furnaces to ensure outlet dust (particulate matter)emission less than 50 mg/Nmr all the time. Low NOx burners shall beinstalled in reheating furnaces of rolling mill. Project authority shall installsuitable & effective air pollution control equipments at all transfer points,junction points etc. also. All the conveying system, transfer point, junctionpoint etc. shall be covered. Adequate provision shall be made for sprinkling ofwater at strategic locations to ensure dust does not get air borne. Forcontrolling fugitive dust, regular sprinkling of water in vulnerable areas of theplant shall be ensured. Proper ventilation shall also be provided in rolling millplant The emission of pollutants from any point source shall not exceed thefollowing iimit. -Particulate Matter-SO mg/Nm:Fiftv Millioram oer Normal Cubic Metereropct zutfrorrty shall provide proper space provision for further retrofltting ofair pollution control systems in case of further stringency of particulate matteremission limit. Two stacks of height 50 m each for 322.5 TPD and 1il.7 fPDrotting mills shall be installed. The height of other stack(s) (if any) shall not beless than 30 meters"(viii) The gaseous emissions from various processes units shall conform to theload/mass based standards notified by this Ministry of Environment andforests, Government of lndia on 19th May, 1993 and standards prescribedform time to time. The Chhattisgarh Environment Conservation Board mayspecify more stringent standards for the relevant parameters keeping in viewthe nature of the industry and its size and location. At no time the emissionlevel shall go beyond the prescribed standards. lnterlocking facilities shall beprovided so that process can be automatically stopped in case emission levelexceeds the limit.(ix) Secondary fugitive emissions shall be controlled and shall be kept within theprescribed limits and regularly monitored. Guidelines/Code of Practice issuedby the CPCB in this regard shall be followed. Project authority shall maintainfugitive dust emissions to the minimum level in the areas of roadtransportation routs of raw material, product to ensure National Ambient AirQuatity Standards prescribed including black topping/asphalting/concretingand maintenance with requisite water sprinkling arrangements.tb-IVllc r I lrh,,d1n'F)W)l 1&{1,,+ \dll, rL

![[Medical college and Hospital] - Seiaacg.org](https://img.yumpu.com/52174544/1/184x260/medical-college-and-hospital-seiaacgorg.jpg?quality=85)