Drive technology for AC and DC

Drive technology for AC and DC

Drive technology for AC and DC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

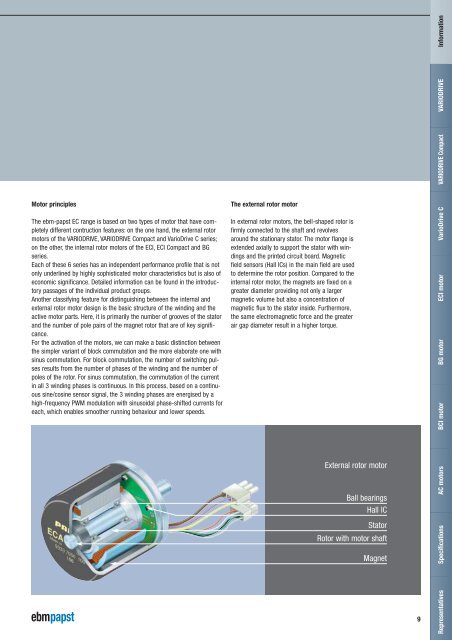

VARIODRIVE CompactVARIODRIVEIn<strong>for</strong>mationMotor principlesThe ebm-papst EC range is based on two types of motor that have completelydifferent contruction features: on the one h<strong>and</strong>, the external rotormotors of the VARIODRIVE, VARIODRIVE Compact <strong>and</strong> Vario<strong>Drive</strong> C series;on the other, the internal rotor motors of the ECI, ECI Compact <strong>and</strong> BGseries.Each of these 6 series has an independent per<strong>for</strong>mance profile that is notonly underlined by highly sophisticated motor characteristics but is also ofeconomic significance. Detailed in<strong>for</strong>mation can be found in the introductorypassages of the individual product groups.Another classifying feature <strong>for</strong> distinguishing between the internal <strong>and</strong>external rotor motor design is the basic structure of the winding <strong>and</strong> theactive motor parts. Here, it is primarily the number of grooves of the stator<strong>and</strong> the number of pole pairs of the magnet rotor that are of key significance.For the activation of the motors, we can make a basic distinction betweenthe simpler variant of block commutation <strong>and</strong> the more elaborate one withsinus commutation. For block commutation, the number of switching pulsesresults from the number of phases of the winding <strong>and</strong> the number ofpoles of the rotor. For sinus commutation, the commutation of the currentin all 3 winding phases is continuous. In this process, based on a continuoussine/cosine sensor signal, the 3 winding phases are energised by ahigh-frequency PWM modulation with sinusoidal phase-shifted currents <strong>for</strong>each, which enables smoother running behaviour <strong>and</strong> lower speeds.The external rotor motorIn external rotor motors, the bell-shaped rotor isfirmly connected to the shaft <strong>and</strong> revolvesaround the stationary stator. The motor flange isextended axially to support the stator with windings<strong>and</strong> the printed circuit board. Magneticfield sensors (Hall ICs) in the main field are usedto determine the rotor position. Compared to theinternal rotor motor, the magnets are fixed on agreater diameter providing not only a largermagnetic volume but also a concentration ofmagnetic flux to the stator inside. Furthermore,the same electromagnetic <strong>for</strong>ce <strong>and</strong> the greaterair gap diameter result in a higher torque.BCI motorBG motorECI motorVario<strong>Drive</strong> CExternal rotor motorBall bearingsHall ICStatorRotor with motor shaftMagnet9Representatives Specifications <strong>AC</strong> motors