KOMA

Cabinet Systems - Koma-epaper.com

Cabinet Systems - Koma-epaper.com

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

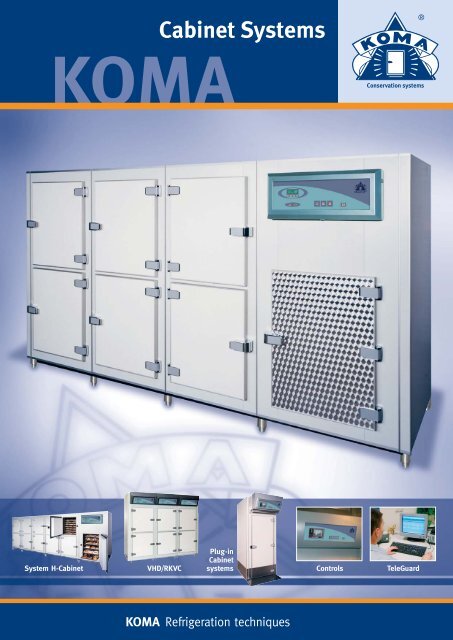

<strong>KOMA</strong><br />

Cabinet Systems<br />

®<br />

Conservation systems<br />

System H-Cabinet<br />

VHD/RKVC<br />

Plug-in<br />

Cabinet<br />

systems<br />

Controls<br />

TeleGuard<br />

<strong>KOMA</strong> Refrigeration techniques

®<br />

Conservation systems<br />

Introduction<br />

<strong>KOMA</strong> refrigeration technique – we<br />

are committed to our name. Powerful<br />

refrigeration technique, the<br />

appropriate room climate for every<br />

product, state-of-the-art air flow<br />

systems according to the <strong>KOMA</strong>-TLR-<br />

Formula, variable sizes, components<br />

of leading manufacturers as well as<br />

the fact, that every system is<br />

customized, planned, projected and<br />

installed are basis for supply of best<br />

possible quality.<br />

Our optimal control and regulation<br />

of the fundamental conditions<br />

according to the <strong>KOMA</strong>-TLR-Formula<br />

temperature, air and relative air<br />

humidity ensures well-balanced<br />

cooling and fermentation climates.<br />

Our cabinet systems provide custom<br />

solutions for confectioneries, bakeries<br />

as well as gastronomy. They include<br />

conservation cabinets such as deep<br />

freezer rooms with or without blast<br />

freezing cases, dough conditioning<br />

cabinets, cream-climate cabinets with<br />

high air humidity and other plug-in<br />

systems.<br />

POWERFUL REFRIGERATION TECHNIQUE<br />

ALL COMPONENTS<br />

FROM ONE SOURCE<br />

<strong>KOMA</strong> employs its own field service<br />

staff – trained service technicians,<br />

ideal supply of individual parts and<br />

the planning is in our own hands.<br />

The world nowadays is online – and<br />

so are we. Let all facility be monitored.<br />

All failures are reported to our<br />

monitoring-department and processed<br />

immediately. 24 hours a day, 365<br />

days a year. Further information can<br />

be found on the following pages.<br />

You are looking for something special?<br />

You have an exact idea of what the<br />

temperature curve of your dough<br />

refrigeration and conditioning system<br />

should look like ? Our new SunRiser<br />

controls implement your specification<br />

at one hundred per cent. Please feel<br />

free to call us, we will be happy to<br />

support and inform you.<br />

On the following pages we want to<br />

present you our product range. If<br />

there are any questions left and<br />

should you require further<br />

information, we will be available<br />

with all our knowledge at any time.<br />

Please contact our indoor service<br />

team under (+31) (0)475-474700.<br />

Of course, the responsible sales<br />

representative for your region is also<br />

available for an appointment on<br />

site. We will be happy to provide<br />

you with the contact.<br />

Modern<br />

production<br />

plants for<br />

insulation<br />

panels, control<br />

engineering<br />

and<br />

refrigerationtechnical<br />

components in<br />

Roermond, NL.<br />

CONTENTS<br />

H-cabinets<br />

(80/20 System) Page 3<br />

· Dough Deep Freezing Cabinets<br />

with Blast Freezing Section in<br />

variable sizes, (-18°C/-38°C)<br />

VHD-JetStream Page 4<br />

· Dough Deep Freezing<br />

Cabinets in variable sizes,<br />

(-18°C/-28°C)<br />

RKVC-Variotherm Page 4<br />

(-28 °C/+25 °C)<br />

· Cabinet System with<br />

variable temperature range<br />

for each section<br />

Plug-in Cabinet systems<br />

Page 5<br />

· SDCC-SunRiser/Recovery<br />

· SVHD-2E (Deep Freezing<br />

Room-hatch system)<br />

· SKHV-2 (Cream-Climate<br />

Cabinet-hatch system)<br />

Controls Page 6<br />

· SunRiser Touch Screen<br />

Control<br />

· MonoCell AT Computer<br />

Control for storage cabinets<br />

TeleGuard Page 7<br />

· TeleGuard remote monitoring<br />

· KRASS software for data<br />

recording and analysis<br />

2

System H-cabinet<br />

®<br />

Conservation systems<br />

Conservation cabinet featuring<br />

storage- and blast freezing technique<br />

for packed and<br />

unpacked<br />

goods, baked<br />

and partly<br />

baked products,<br />

fresh dough<br />

portions, hot<br />

products, meat,<br />

fish and all<br />

other sensitive<br />

foods.<br />

All <strong>KOMA</strong><br />

cabinets are<br />

manufactured in our own cabinetpanel<br />

plant. The insulation is made<br />

of polyurethane-hard-foam (CFC-free,<br />

high-pressure foamed) and is<br />

manufactured according to the<br />

sandwich-technique and the conical<br />

bracketing-technique.<br />

The modular design of two<br />

superposed hatches per section allows<br />

for optimal fitting to your available<br />

space.<br />

Even years later, the system may be<br />

upgraded by extension of another<br />

section as well as in terms of an<br />

refrigeration technical upgrade or<br />

extension.<br />

H-10<br />

The H-cabinet is mounted on<br />

adjustable stainless steel feet in order<br />

to avoid any extensive ground work.<br />

The inside design is stainless steel.<br />

The edges of each of the cases are<br />

rounded. A water drain is integrated<br />

inside. Thus, the H-cabinet meets the<br />

highest demands in terms of hygiene.<br />

During blast freezing of products, the<br />

cabinet provides approx. 80% of the<br />

capacity for the blast freezing section<br />

while 20% of the power are delivered<br />

to the remaining storage sections.<br />

All this is coordinated by the <strong>KOMA</strong><br />

MonoCell AT computer control.<br />

The refrigeration cycle includes<br />

components of premium quality<br />

according to the stringent Dutch STEKstandard.<br />

Separately installed halfhermetic<br />

reciprocating compressors<br />

as well as premium quality evaporatorand<br />

condenser techniques ensure<br />

sufficient refrigeration<br />

capacity whenever<br />

demanded.<br />

HN-cabinet for branches H1-blast freezer Stainless steel<br />

inside/rounded edges<br />

3

®<br />

Conservation systems<br />

VHD-JetStream<br />

VHD-6<br />

Storage technique for packed and<br />

unpacked products, baked and partly<br />

baked products, fresh dough<br />

portions, hot products, meat, fish and<br />

all other sensitive foods.<br />

The modular design (two hatches per<br />

section) allows for optimal fitting of<br />

the VHD cabinet to the requirements<br />

on site. Up to five sections may be<br />

integrated into one system. The<br />

mounting on adjustable stainless<br />

steel feet avoids any extensive ground<br />

work.<br />

The cabinet may be connected to a<br />

provided drainage connection or, on<br />

demand, it will be delivered with a<br />

melt water receptacle in order to<br />

avoid extra work.<br />

The inside design is stainless steel.<br />

The edges of each of the sections<br />

are rounded so that the VHD-cabinet<br />

meets the highest<br />

hygienic demands.<br />

The refrigeration cycle<br />

includes components of<br />

premium quality according to the<br />

stringent Dutch STEK-standard.<br />

Separately installed<br />

half-hermetic<br />

reciprocating<br />

compressors as<br />

well as premium<br />

quality evaporatorand<br />

condenser<br />

techniques ensure<br />

sufficient<br />

refrigeration<br />

capacity whenever<br />

demanded.<br />

RKVC-6<br />

4

Plug-in systems<br />

®<br />

Conservation systems<br />

SVHD-2<br />

The SVHD-2 is mounted on adjustable<br />

stainless steel feet in order to any<br />

extensive ground work.<br />

The inside design is stainless steel.<br />

The edges of each of the sections<br />

are rounded. A water drain is<br />

integrated inside. Thus, the SVHD-2<br />

meets the highest demands in terms<br />

of hygiene.<br />

The system provides 2 hatches 62 x<br />

75 cm for trays or baskets 60 x 40<br />

and 60 x 80 respectively. Compact<br />

refrigeration technique allows for<br />

variable applications on minimum<br />

space.<br />

Fully automatic<br />

Retarder<br />

prover system<br />

“Populair”<br />

This is a plug-in system and therefore ready-to-use, so it can<br />

be connected to any common 230 V power socket. Hence, the<br />

SVHD-2 is dedicated for both, production as well as for use at<br />

the sales point.<br />

Possible temperature ranges:<br />

· Deep freezing: -18°C/-28°C · Recovery: -18°C/+15°C<br />

· Cold storage: +2°C/+8°C · Cream-climate: +2°C/+8°C<br />

SVHD-2<br />

Fully automatic<br />

Retarder prover<br />

system “Populair”<br />

On smallest space, the ready-to-use<br />

fully automatic fermentation system<br />

“Populair” offers the sophisticated<br />

technique of our “big” fully automatic<br />

SunRiser dough conditioning system.<br />

· Computer control SunRiser AT<br />

· Evaporator technique exclusively<br />

designed for <strong>KOMA</strong> with different fin<br />

bar systems and an integrated stainless<br />

steel condensate tub ensure ideal<br />

evaporator surfaces and avoids<br />

quick icing up.<br />

· Condenser that is separated from<br />

the refrigeration unit, with dust<br />

fleece above the door, maintenancefree<br />

and no cleaning necessary.<br />

· Cooler fans are arranged above the<br />

pressure wall for maximal constancy<br />

Humidification via an interior<br />

evaporation principle allows for equal<br />

fermentation results and energy<br />

savings.<br />

· Plug-in system, ready-to-use (230 V)<br />

· The inside design is stainless steel.<br />

· For racks 620 x 840 x 1750 mm<br />

(L x W x H) and 690 x 840 x 1990<br />

mm (L x W x H) respectively<br />

5

®<br />

Controls<br />

Conservation systems<br />

Today, modern computer controls are<br />

standard on all <strong>KOMA</strong> devices.<br />

SunRiser AT<br />

Units: Populair, fully automatic dough<br />

conditioning system<br />

· All programme sequences are freely<br />

programmable<br />

· Air speeds and humidity are<br />

adjustable in 1%-steps<br />

· Each day can be programmed<br />

freely as part of a week-programme<br />

· TeleGuard remote monitoring<br />

MonoCell AT<br />

Units: H-Cabinet, VHD, RKVC,<br />

SVHD-2<br />

· Blast freezing time and duration<br />

are freely programmable<br />

· Automatic programme selection of<br />

fan impulses for blast freezing and<br />

storage periods<br />

· Free choice of time and the<br />

featured adjustment of defrosting<br />

programmes as part of a weekprogramme<br />

· TeleGuard remote monitoring<br />

6

TeleGuard / KRASS<br />

®<br />

Conservation systems<br />

TeleGuard<br />

Security online for your <strong>KOMA</strong> units.<br />

All of the <strong>KOMA</strong> units can be remotely<br />

monitored via the TeleGuard system.<br />

All of the controls in use with <strong>KOMA</strong><br />

units are compatible with TeleGuard<br />

so that we can guarantee you<br />

maximum security.<br />

Failures are immediately reported to<br />

our monitoring department at our<br />

service headquarters.<br />

The staff is able to establish a direct<br />

connection to your refrigeration unit<br />

in order to take a real time look at<br />

all relevant data or even for editing<br />

purposes. Thus, temperatures and<br />

pressures (high pressure, low<br />

pressure, oil pressure) may be<br />

checked, icing up of the evaporator<br />

can be detected – and, even an open<br />

door is recognized and <strong>KOMA</strong><br />

immediately informs the customer.<br />

Further, our staff is always glad to<br />

assist you in adjusting your unit´s<br />

programming.<br />

KRASS - Software<br />

Our software provides various<br />

possibilities for the recording and<br />

evaluation of the temperature curves.<br />

Whether it chart or table illustration,<br />

temperature recording that meets the<br />

legal requirements (HACCP –<br />

obligation of documentation and<br />

storage). It also allows for control of<br />

the system via a central PC, which<br />

may be located at your Home Office<br />

or any other location.<br />

The software is easy to install on any<br />

standard PC, but we will definitely<br />

assist you with that also.<br />

Just contact us.<br />

MonoCell AT<br />

Units: Blast freezers, KTT, IBF<br />

· Guaranteed quality monitoring and<br />

logical programming.<br />

· Quick cooling time and duration<br />

are freely programmable.<br />

· Air amounts and speeds may be<br />

adjusted in 1%-steps and thus an<br />

ideal adaptation to your quality<br />

demands is ensured.<br />

· Direct intervention at failures.<br />

· Permanent monitoring of all<br />

entered data.<br />

· Automatic backup of all programme<br />

data due to supplementary battery<br />

supply in case of failures, power<br />

breakdowns etc.<br />

· TeleGuard remote monitoring<br />

Note:<br />

Subject to technical modifications and alterations. Illustrations<br />

and charts serve for visualization/illustration purposes and<br />

may change in practice. Status 7/2009.<br />

7

®<br />

Conservation systems<br />

<strong>KOMA</strong> Koeltechnische Industrie B.V.<br />

Energieweg 2 · NL-6045 JE Roermond · Tel.: +31 (0) 475 47 47 00 · Fax: +31 (0) 475 32 54 49<br />

E-Mail: nl-info@koma.com · www.koma.com<br />

<strong>KOMA</strong> subsidiaries in: Belgium, Germany, France, Great Britain, Italy, Spain, U.A.E. (Dubai) and Japan