The driving force

The driving force. - tretek.no

The driving force. - tretek.no

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

machine specific executions upon request<br />

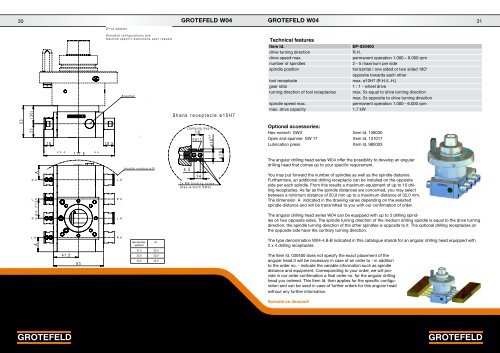

30 Standard configurations and<br />

GROTEFELD W04<br />

53<br />

53<br />

53<br />

53<br />

53<br />

23 23 (30) 23 23 23 (30) (30)<br />

(30)<br />

LI<br />

53<br />

min. 21,5 min. min. 21,5 min. min. 21,5 21,5 21,5 A A A A A<br />

R.H.<br />

R.H.<br />

R.H.<br />

RE<br />

L.H.<br />

L.H. R.H.<br />

L.H.<br />

R.H.<br />

L.H. R.H.<br />

R.H.<br />

RE<br />

L.H.<br />

L.H. R.H.<br />

L.H.<br />

A<br />

A<br />

LI<br />

A<br />

A<br />

L.H.<br />

A<br />

16 18.5<br />

16 18.5<br />

16 57.5 60 18.5<br />

16 57.5 60 18.5<br />

57.5<br />

117.5<br />

60<br />

16 57.5 117.5 60 18.5<br />

117.5<br />

57.5 117.5 60<br />

16 18.5<br />

117.5<br />

57.5 60<br />

23 (30)<br />

min. 21,5 A<br />

R.H.<br />

L.H.<br />

R.H.<br />

L.H.<br />

A<br />

41.5<br />

41.5<br />

41.5<br />

41.5<br />

41.5<br />

83<br />

83<br />

83<br />

83<br />

83<br />

41.5<br />

117.5<br />

83<br />

Drive adapter<br />

Drive adapter<br />

Drive<br />

Standard<br />

adapter<br />

configurations and<br />

Standard machine specific configurations executions and upon request<br />

machine specific executions upon request<br />

Antriebsadapter<br />

Drive adapter<br />

Standardausführungen Drive adapter und<br />

Standard maschinenspezifische configurationsAusführungen<br />

and<br />

machine auf Anfrage specific executions upon request<br />

Standard configurations and<br />

machine specific executions upon request<br />

Breather<br />

Breather<br />

Breather<br />

Entlüftung<br />

Shank receptacle ø10H7<br />

Shank receptacle ø10H7<br />

Shank receptacle ø10H7<br />

clamping depth<br />

Schaftaufnahme clamping 18 depth ø10H7<br />

18<br />

Shank receptacle ø10H7<br />

L.H.<br />

R.H.<br />

clamping depth<br />

SW17<br />

BreatherSW17<br />

18<br />

Einspanntiefe<br />

SW17 18<br />

clamping depth<br />

SW17<br />

ø10 H7 ø10 ø10 H7 ø10 H7 H7<br />

ø19 ø10 ø19 ø19<br />

H7<br />

ø19<br />

trouble contour ø194mm<br />

Shank receptacle ø10H7<br />

clamping depth<br />

18<br />

14<br />

SW17<br />

2x M6 binding screw<br />

2x (Hex-wrench M6 binding 4.5 14<br />

SW3) screw<br />

(Hex-wrench SW3)<br />

2x M6 binding14<br />

screw<br />

(Hex-wrench<br />

4.5<br />

SW3)<br />

trouble contour ø194mm 2x M614<br />

Klemmschraube<br />

trouble contour ø194mm (Innen-6kt.-Schlüssel SW3)<br />

trouble contour ø194mm 2x M6 binding screw<br />

4.5<br />

L.H.<br />

(Hex-wrench SW3)<br />

L.H.<br />

Störkontur ø194mm<br />

14<br />

L.H.<br />

trouble contour ø194mm<br />

LI<br />

R.H.<br />

R.H. L.H.<br />

R.H.<br />

RE<br />

L.H.<br />

R.H. L.H.<br />

L.H.<br />

LI<br />

R.H.<br />

R.H. L.H.<br />

R.H.<br />

RE<br />

R.H.<br />

Breather<br />

4.5<br />

4.5<br />

4.5<br />

18<br />

SW17<br />

14<br />

ø19<br />

Bei Spindelabstand<br />

at spindle distance A =<br />

A= at spindle distance A =<br />

21,5 22,0 at spindle 21,5 distance A 22,0 =<br />

21,5 22,0<br />

22,0 L.H. 22,0 Bei Spindelabstand A =<br />

21,5 22,0 22,0<br />

32,0 24,0 22,0 22,0<br />

21,5 22,0<br />

at spindle 22,0 32,0 distance A 22,0 24,0 =<br />

32,0 24,0<br />

22,0 22,0<br />

32,0 21,5 24,0 22,0<br />

R.H.<br />

32,0 24,0<br />

22,0 22,0<br />

ø10 H7<br />

2x M6 binding screw<br />

(Hex-wrench SW3)<br />

ø19<br />

32,0 24,0<br />

at spindle distance A =<br />

21,5 22,0<br />

22,0 22,0<br />

32,0 24,0<br />

GROTEFELD W04<br />

Technical features<br />

Item Id.<br />

EP-030400<br />

drive turning direction<br />

R.H.<br />

drive speed max.<br />

permanent operation 1.000 – 6.000 rpm<br />

number of spindles<br />

2 - 5 maximum per side<br />

spindle position horizontal / one sided or two sided 180°<br />

opposite towards each other<br />

tool receptacle<br />

max. ø10H7 (R.H./L.H.)<br />

gear ratio<br />

1 : 1 - wheel drive<br />

turning direction of tool receptacles max. 5x equal to drive turning direction<br />

max. 5x opposite to drive turning direction<br />

spindle speed max.<br />

permanent operation 1.000 - 6.000 rpm<br />

max. drive capacity<br />

1,7 kW<br />

Optional accessories:<br />

Hex-wrench SW3 Item Id. 138030<br />

Open end spanner SW 17 Item Id. 131017<br />

Lubrication press Item Id. 980003<br />

<strong>The</strong> angular drilling head series W04 offer the possibility to develop an angular<br />

drilling head that comes up to your specific requirement.<br />

You may put forward the number of spindles as well as the spindle distance.<br />

Furthermore, an additional drilling receptacle can be installed on the opposite<br />

side per each spindle. From this results a maximum equipment of up to 10 drilling<br />

receptacles. As far as the spindle distances are concerned, you may select<br />

between a minimum distance of 20,0 mm up to a maximum distance of 32,0 mm.<br />

<strong>The</strong> dimension A indicated in the drawing varies depending on the selected<br />

spindle distance and will be transmitted to you with our confirmation of order.<br />

<strong>The</strong> angular drilling head series W04 can be equipped with up to 5 drilling spindles<br />

on two opposite sides. <strong>The</strong> spindle turning direction of the medium drilling spindle is equal to the drive turning<br />

direction, the spindle turning direction of the other spindles is opposite to it. <strong>The</strong> optional drilling receptacles on<br />

the opposite side have the contrary turning direction.<br />

<strong>The</strong> type denomination W04-4.8-B indicated in this catalogue stands for an angular drilling head equipped with<br />

2 x 4 drilling receptacles.<br />

<strong>The</strong> Item Id. 030400 does not specify the exact placement of the<br />

angular head.It will be necessary in case of an order to - in addition<br />

to the order no. - indicate the variable information such as spindle<br />

distance and equipment. Corresponding to your order, we will provide<br />

in our order confirmation a final order no. for the angular drilling<br />

head you ordered. This Item Id. then applies for the specific configuration<br />

and can be used in case of further orders for this angular head<br />

without any further information.<br />

Variants on demand!<br />

31