In Situ Francis Turbine Blade Replacement due to Gross Cavitation

In Situ Francis Turbine Blade Replacement due to Gross Cavitation

In Situ Francis Turbine Blade Replacement due to Gross Cavitation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

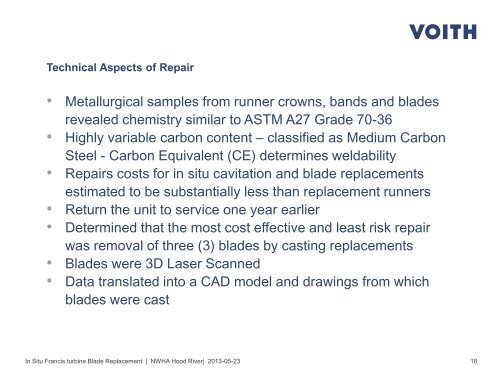

Technical Aspects of Repair<br />

• Metallurgical samples from runner crowns, bands and blades<br />

revealed chemistry similar <strong>to</strong> ASTM A27 Grade 70-36<br />

• Highly variable carbon content – classified as Medium Carbon<br />

Steel - Carbon Equivalent (CE) determines weldability<br />

• Repairs costs for in situ cavitation and blade replacements<br />

estimated <strong>to</strong> be substantially less than replacement runners<br />

• Return the unit <strong>to</strong> service one year earlier<br />

• Determined that the most cost effective and least risk repair<br />

was removal of three (3) blades by casting replacements<br />

• <strong>Blade</strong>s were 3D Laser Scanned<br />

• Data translated in<strong>to</strong> a CAD model and drawings from which<br />

blades were cast<br />

<strong>In</strong> <strong>Situ</strong> <strong>Francis</strong> turbine <strong>Blade</strong> <strong>Replacement</strong> | NWHA Hood River| 2013-05-23<br />

18