In Situ Francis Turbine Blade Replacement due to Gross Cavitation

In Situ Francis Turbine Blade Replacement due to Gross Cavitation

In Situ Francis Turbine Blade Replacement due to Gross Cavitation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

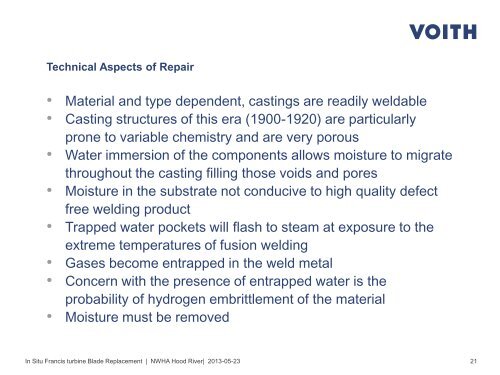

Technical Aspects of Repair<br />

• Material and type dependent, castings are readily weldable<br />

• Casting structures of this era (1900-1920) are particularly<br />

prone <strong>to</strong> variable chemistry and are very porous<br />

• Water immersion of the components allows moisture <strong>to</strong> migrate<br />

throughout the casting filling those voids and pores<br />

• Moisture in the substrate not conducive <strong>to</strong> high quality defect<br />

free welding product<br />

• Trapped water pockets will flash <strong>to</strong> steam at exposure <strong>to</strong> the<br />

extreme temperatures of fusion welding<br />

• Gases become entrapped in the weld metal<br />

• Concern with the presence of entrapped water is the<br />

probability of hydrogen embrittlement of the material<br />

• Moisture must be removed<br />

<strong>In</strong> <strong>Situ</strong> <strong>Francis</strong> turbine <strong>Blade</strong> <strong>Replacement</strong> | NWHA Hood River| 2013-05-23<br />

21