In Situ Francis Turbine Blade Replacement due to Gross Cavitation

In Situ Francis Turbine Blade Replacement due to Gross Cavitation

In Situ Francis Turbine Blade Replacement due to Gross Cavitation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

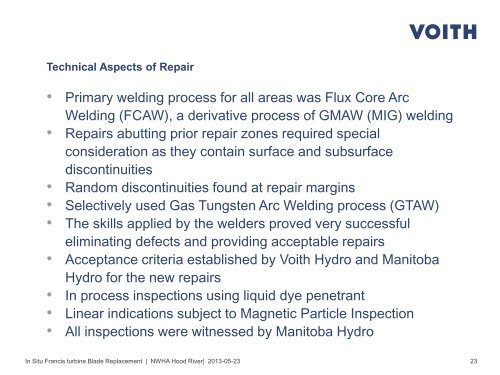

Technical Aspects of Repair<br />

• Primary welding process for all areas was Flux Core Arc<br />

Welding (FCAW), a derivative process of GMAW (MIG) welding<br />

• Repairs abutting prior repair zones required special<br />

consideration as they contain surface and subsurface<br />

discontinuities<br />

• Random discontinuities found at repair margins<br />

• Selectively used Gas Tungsten Arc Welding process (GTAW)<br />

• The skills applied by the welders proved very successful<br />

eliminating defects and providing acceptable repairs<br />

• Acceptance criteria established by Voith Hydro and Mani<strong>to</strong>ba<br />

Hydro for the new repairs<br />

• <strong>In</strong> process inspections using liquid dye penetrant<br />

• Linear indications subject <strong>to</strong> Magnetic Particle <strong>In</strong>spection<br />

• All inspections were witnessed by Mani<strong>to</strong>ba Hydro<br />

<strong>In</strong> <strong>Situ</strong> <strong>Francis</strong> turbine <strong>Blade</strong> <strong>Replacement</strong> | NWHA Hood River| 2013-05-23<br />

23