FALL 2016

Distributor's Link Magazine Fall Issue 2016 / Vol 39 No4

Distributor's Link Magazine Fall Issue 2016 / Vol 39 No4

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

8<br />

THE DISTRIBUTOR’S LINK<br />

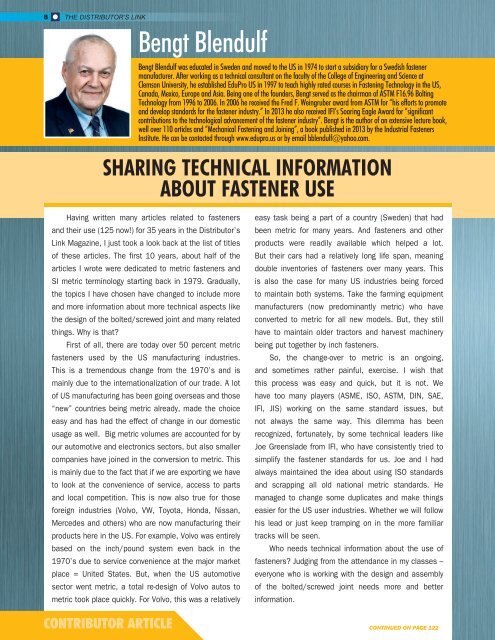

Bengt Blendulf<br />

Bengt Blendulf was educated in Sweden and moved to the US in 1974 to start a subsidiary for a Swedish fastener<br />

manufacturer. After working as a technical consultant on the faculty of the College of Engineering and Science at<br />

Clemson University, he established EduPro US in 1997 to teach highly rated courses in Fastening Technology in the US,<br />

Canada, Mexico, Europe and Asia. Being one of the founders, Bengt served as the chairman of ASTM F16.96 Bolting<br />

Technology from 1996 to 2006. In 2006 he received the Fred F. Weingruber award from ASTM for “his efforts to promote<br />

and develop standards for the fastener industry.” In 2013 he also received IFI’s Soaring Eagle Award for “significant<br />

contributions to the technological advancement of the fastener industry”. Bengt is the author of an extensive lecture book,<br />

well over 110 articles and “Mechanical Fastening and Joining”, a book published in 2013 by the Industrial Fasteners<br />

Institute. He can be contacted through www.edupro.us or by email bblendulf@yahoo.com.<br />

SHARING TECHNICAL INFORMATION<br />

ABOUT FASTENER USE<br />

Having written many articles related to fasteners<br />

and their use (125 now!) for 35 years in the Distributor’s<br />

Link Magazine, I just took a look back at the list of titles<br />

of these articles. The first 10 years, about half of the<br />

articles I wrote were dedicated to metric fasteners and<br />

SI metric terminology starting back in 1979. Gradually,<br />

the topics I have chosen have changed to include more<br />

and more information about more technical aspects like<br />

the design of the bolted/screwed joint and many related<br />

things. Why is that?<br />

First of all, there are today over 50 percent metric<br />

fasteners used by the US manufacturing industries.<br />

This is a tremendous change from the 1970’s and is<br />

mainly due to the internationalization of our trade. A lot<br />

of US manufacturing has been going overseas and those<br />

“new” countries being metric already, made the choice<br />

easy and has had the effect of change in our domestic<br />

usage as well. Big metric volumes are accounted for by<br />

our automotive and electronics sectors, but also smaller<br />

companies have joined in the conversion to metric. This<br />

is mainly due to the fact that if we are exporting we have<br />

to look at the convenience of service, access to parts<br />

and local competition. This is now also true for those<br />

foreign industries (Volvo, VW, Toyota, Honda, Nissan,<br />

Mercedes and others) who are now manufacturing their<br />

products here in the US. For example, Volvo was entirely<br />

based on the inch/pound system even back in the<br />

1970’s due to service convenience at the major market<br />

place = United States. But, when the US automotive<br />

sector went metric, a total re-design of Volvo autos to<br />

metric took place quickly. For Volvo, this was a relatively<br />

CONTRIBUTOR ARTICLE<br />

easy task being a part of a country (Sweden) that had<br />

been metric for many years. And fasteners and other<br />

products were readily available which helped a lot.<br />

But their cars had a relatively long life span, meaning<br />

double inventories of fasteners over many years. This<br />

is also the case for many US industries being forced<br />

to maintain both systems. Take the farming equipment<br />

manufacturers (now predominantly metric) who have<br />

converted to metric for all new models. But, they still<br />

have to maintain older tractors and harvest machinery<br />

being put together by inch fasteners.<br />

So, the change-over to metric is an ongoing,<br />

and sometimes rather painful, exercise. I wish that<br />

this process was easy and quick, but it is not. We<br />

have too many players (ASME, ISO, ASTM, DIN, SAE,<br />

IFI, JIS) working on the same standard issues, but<br />

not always the same way. This dilemma has been<br />

recognized, fortunately, by some technical leaders like<br />

Joe Greenslade from IFI, who have consistently tried to<br />

simplify the fastener standards for us. Joe and I had<br />

always maintained the idea about using ISO standards<br />

and scrapping all old national metric standards. He<br />

managed to change some duplicates and make things<br />

easier for the US user industries. Whether we will follow<br />

his lead or just keep tramping on in the more familiar<br />

tracks will be seen.<br />

Who needs technical information about the use of<br />

fasteners? Judging from the attendance in my classes –<br />

everyone who is working with the design and assembly<br />

of the bolted/screwed joint needs more and better<br />

information.<br />

CONTINUED ON PAGE 122