FALL 2016

Distributor's Link Magazine Fall Issue 2016 / Vol 39 No4

Distributor's Link Magazine Fall Issue 2016 / Vol 39 No4

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

130<br />

THE DISTRIBUTOR’S LINK<br />

LAURENCE CLAUS FUNDAMENTALS OF THREAD FORMING SCREWS - PART 1 from page 24<br />

Distributors, especially those working with customers<br />

utilizing thread forming screws or a diverse selection<br />

of fasteners, should have one or more individuals<br />

available to provide their customers with knowledge about<br />

or application engineering assistance regarding thread<br />

forming. Although this may sound like a daunting challenge<br />

considering the wide variety of materials and selection<br />

of thread forming screws on the market, much of the<br />

“science” is actually the same regardless of the material<br />

being fastened into. Once these foundational concepts<br />

are understood, they can be applied to understanding<br />

more specific and focused applications like thread forming<br />

into plastics, light metals, and mild steel.<br />

This series of articles will look at these subjects.<br />

The remainder of this article will look at the universal<br />

fundamentals of thread forming. Part 2 will explore thread<br />

forming in thermoplastics and thermosets. Part 3 will<br />

explore thread forming in mild steel and light metals.<br />

Naturally what is presented in this series will be universal<br />

concepts. There are always exceptions and every project<br />

is unique onto itself, however, having<br />

this fundamental understanding may arm<br />

you with enough knowledge to look at<br />

applications in a new way and provide<br />

your customer with potential cost saving<br />

and performance enhancing solutions.<br />

Part 1- Fundamentals Of Thread<br />

Forming<br />

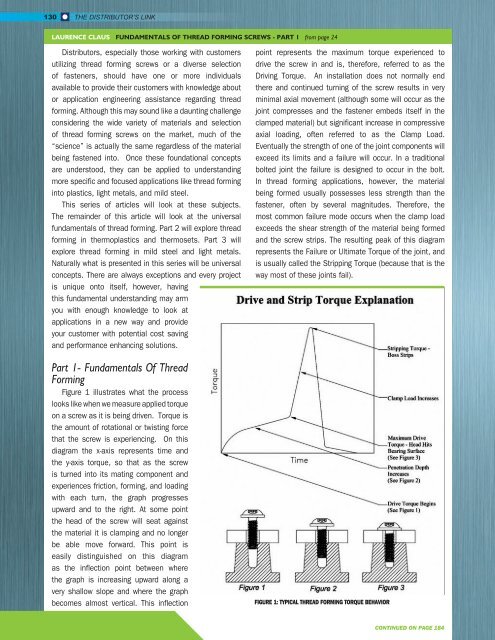

Figure 1 illustrates what the process<br />

looks like when we measure applied torque<br />

on a screw as it is being driven. Torque is<br />

the amount of rotational or twisting force<br />

that the screw is experiencing. On this<br />

diagram the x-axis represents time and<br />

the y-axis torque, so that as the screw<br />

is turned into its mating component and<br />

experiences friction, forming, and loading<br />

with each turn, the graph progresses<br />

upward and to the right. At some point<br />

the head of the screw will seat against<br />

the material it is clamping and no longer<br />

be able move forward. This point is<br />

easily distinguished on this diagram<br />

as the inflection point between where<br />

the graph is increasing upward along a<br />

very shallow slope and where the graph<br />

becomes almost vertical. This inflection<br />

point represents the maximum torque experienced to<br />

drive the screw in and is, therefore, referred to as the<br />

Driving Torque. An installation does not normally end<br />

there and continued turning of the screw results in very<br />

minimal axial movement (although some will occur as the<br />

joint compresses and the fastener embeds itself in the<br />

clamped material) but significant increase in compressive<br />

axial loading, often referred to as the Clamp Load.<br />

Eventually the strength of one of the joint components will<br />

exceed its limits and a failure will occur. In a traditional<br />

bolted joint the failure is designed to occur in the bolt.<br />

In thread forming applications, however, the material<br />

being formed usually possesses less strength than the<br />

fastener, often by several magnitudes. Therefore, the<br />

most common failure mode occurs when the clamp load<br />

exceeds the shear strength of the material being formed<br />

and the screw strips. The resulting peak of this diagram<br />

represents the Failure or Ultimate Torque of the joint, and<br />

is usually called the Stripping Torque (because that is the<br />

way most of these joints fail).<br />

FIGURE 1: TYPICAL THREAD FORMING TORQUE BEHAVIOR<br />

CONTINUED ON PAGE 184