Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

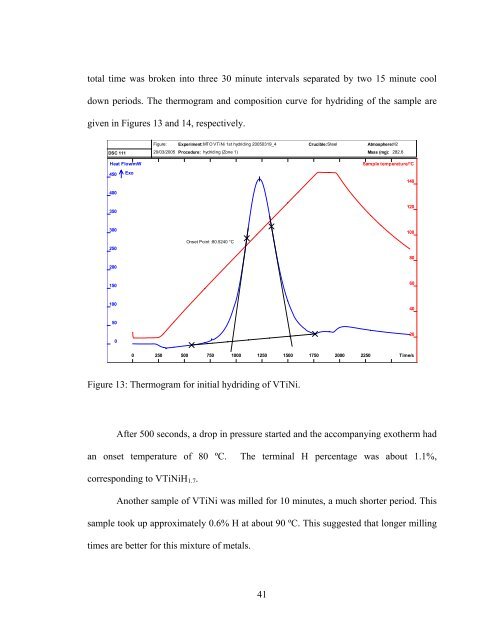

total time was broken into three 30 minute intervals separated by two 15 minute cool<br />

down periods. The thermogram and composition curve for hydriding of the sample are<br />

given in Figures 13 and 14, respectively.<br />

DSC 111<br />

Heat Flow/mW<br />

450 Exo<br />

Figure: Experiment:MTO VTiNi 1st hydriding 20050319_4<br />

Crucible:Steel<br />

Atmosphere:H2<br />

20/03/2005 Procedure: hydriding (Zone 1)<br />

Mass (mg): 282.6<br />

Sample temperature/°C<br />

140<br />

400<br />

350<br />

120<br />

300<br />

250<br />

200<br />

Onset Point :80.5240 °C<br />

100<br />

80<br />

150<br />

60<br />

100<br />

40<br />

50<br />

0<br />

20<br />

0 250 500 750 1000 1250 1500 1750 2000 2250<br />

Time/s<br />

Figure 13: Thermogram for initial hydriding of VTiNi.<br />

After 500 seconds, a drop in pressure started and the accompanying exotherm had<br />

an onset temperature of 80 ºC. The terminal H percentage was about 1.1%,<br />

corresponding to VTiNiH 1.7 .<br />

Another sample of VTiNi was milled for 10 minutes, a much shorter period. This<br />

sample took up approximately 0.6% H at about 90 ºC. This suggested that longer milling<br />

times are better for this mixture of metals.<br />

41