Handbook of best practices

Handbook%20of%20best%20practices

Handbook%20of%20best%20practices

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

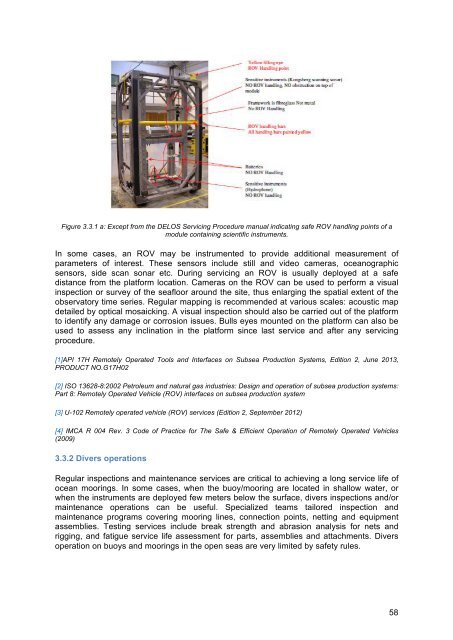

Figure 3.3.1 a: Except from the DELOS Servicing Procedure manual indicating safe ROV handling points <strong>of</strong> a<br />

module containing scientific instruments.<br />

In some cases, an ROV may be instrumented to provide additional measurement <strong>of</strong><br />

parameters <strong>of</strong> interest. These sensors include still and video cameras, oceanographic<br />

sensors, side scan sonar etc. During servicing an ROV is usually deployed at a safe<br />

distance from the platform location. Cameras on the ROV can be used to perform a visual<br />

inspection or survey <strong>of</strong> the seafloor around the site, thus enlarging the spatial extent <strong>of</strong> the<br />

observatory time series. Regular mapping is recommended at various scales: acoustic map<br />

detailed by optical mosaicking. A visual inspection should also be carried out <strong>of</strong> the platform<br />

to identify any damage or corrosion issues. Bulls eyes mounted on the platform can also be<br />

used to assess any inclination in the platform since last service and after any servicing<br />

procedure.<br />

[1]API 17H Remotely Operated Tools and Interfaces on Subsea Production Systems, Edition 2, June 2013,<br />

PRODUCT NO.G17H02<br />

[2] ISO 13628-8:2002 Petroleum and natural gas industries: Design and operation <strong>of</strong> subsea production systems:<br />

Part 8: Remotely Operated Vehicle (ROV) interfaces on subsea production system<br />

[3] U-102 Remotely operated vehicle (ROV) services (Edition 2, September 2012)<br />

[4] IMCA R 004 Rev. 3 Code <strong>of</strong> Practice for The Safe & Efficient Operation <strong>of</strong> Remotely Operated Vehicles<br />

(2009)<br />

3.3.2 Divers operations<br />

Regular inspections and maintenance services are critical to achieving a long service life <strong>of</strong><br />

ocean moorings. In some cases, when the buoy/mooring are located in shallow water, or<br />

when the instruments are deployed few meters below the surface, divers inspections and/or<br />

maintenance operations can be useful. Specialized teams tailored inspection and<br />

maintenance programs covering mooring lines, connection points, netting and equipment<br />

assemblies. Testing services include break strength and abrasion analysis for nets and<br />

rigging, and fatigue service life assessment for parts, assemblies and attachments. Divers<br />

operation on buoys and moorings in the open seas are very limited by safety rules.<br />

58