Binder1 Inner_JRD

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SOCIETY<br />

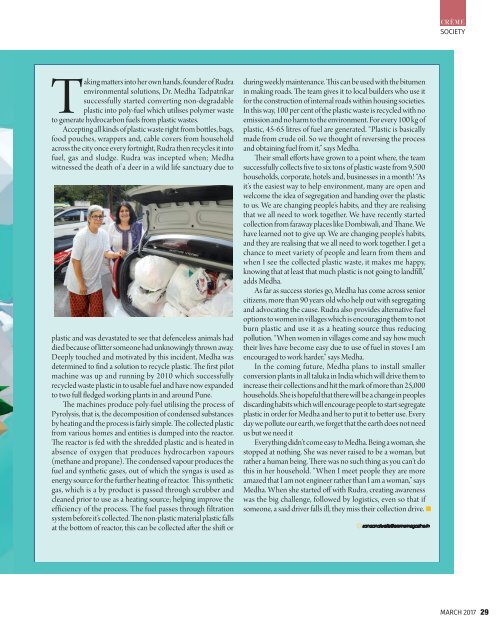

Taking matters into her own hands, founder of Rudra<br />

environmental solutions, Dr. Medha Tadpatrikar<br />

successfully started converting non-degradable<br />

plastic into poly-fuel which utilises polymer waste<br />

to generate hydrocarbon fuels from plastic wastes.<br />

Accepting all kinds of plastic waste right from bottles, bags,<br />

food pouches, wrappers and, cable covers from household<br />

across the city once every fortnight, Rudra then recycles it into<br />

fuel, gas and sludge. Rudra was incepted when; Medha<br />

witnessed the death of a deer in a wild life sanctuary due to<br />

plastic and was devastated to see that defenceless animals had<br />

died because of litter someone had unknowingly thrown away.<br />

Deeply touched and motivated by this incident, Medha was<br />

determined to find a solution to recycle plastic. The first pilot<br />

machine was up and running by 2010 which successfully<br />

recycled waste plastic in to usable fuel and have now expanded<br />

to two full fledged working plants in and around Pune.<br />

The machines produce poly-fuel utilising the process of<br />

Pyrolysis, that is, the decomposition of condensed substances<br />

by heating and the process is fairly simple. The collected plastic<br />

from various homes and entities is dumped into the reactor.<br />

The reactor is fed with the shredded plastic and is heated in<br />

absence of oxygen that produces hydrocarbon vapours<br />

(methane and propane). The condensed vapour produces the<br />

fuel and synthetic gases, out of which the syngas is used as<br />

energy source for the further heating of reactor. This synthetic<br />

gas, which is a by product is passed through scrubber and<br />

cleaned prior to use as a heating source; helping improve the<br />

efficiency of the process. The fuel passes through filtration<br />

system before it’s collected. The non-plastic material plastic falls<br />

at the bottom of reactor, this can be collected after the shift or<br />

during weekly maintenance. This can be used with the bitumen<br />

in making roads. The team gives it to local builders who use it<br />

for the construction of internal roads within housing societies.<br />

In this way, 100 per cent of the plastic waste is recycled with no<br />

emission and no harm to the environment. For every 100 kg of<br />

plastic, 45-65 litres of fuel are generated. “Plastic is basically<br />

made from crude oil. So we thought of reversing the process<br />

and obtaining fuel from it,” says Medha.<br />

Their small efforts have grown to a point where, the team<br />

successfully collects five to six tons of plastic waste from 9,500<br />

households, corporate, hotels and, businesses in a month! “As<br />

it’s the easiest way to help environment, many are open and<br />

welcome the idea of segregation and handing over the plastic<br />

to us. We are changing people’s habits, and they are realising<br />

that we all need to work together. We have recently started<br />

collection from faraway places like Dombiwali, and Thane. We<br />

have learned not to give up. We are changing people’s habits,<br />

and they are realising that we all need to work together. I get a<br />

chance to meet variety of people and learn from them and<br />

when I see the collected plastic waste, it makes me happy,<br />

knowing that at least that much plastic is not going to landfill,”<br />

adds Medha.<br />

As far as success stories go, Medha has come across senior<br />

citizens, more than 90 years old who help out with segregating<br />

and advocating the cause. Rudra also provides alternative fuel<br />

options to women in villages which is encouraging them to not<br />

burn plastic and use it as a heating source thus reducing<br />

pollution. “When women in villages come and say how much<br />

their lives have become easy due to use of fuel in stoves I am<br />

encouraged to work harder,” says Medha.<br />

In the coming future, Medha plans to install smaller<br />

conversion plants in all taluka in India which will drive them to<br />

increase their collections and hit the mark of more than 25,000<br />

households. She is hopeful that there will be a change in peoples<br />

discarding habits which will encourage people to start segregate<br />

plastic in order for Medha and her to put it to better use. Every<br />

day we pollute our earth, we forget that the earth does not need<br />

us but we need it<br />

Everything didn’t come easy to Medha. Being a woman, she<br />

stopped at nothing. She was never raised to be a woman, but<br />

rather a human being. There was no such thing as you can’t do<br />

this in her household. “When I meet people they are more<br />

amazed that I am not engineer rather than I am a woman,” says<br />

Medha. When she started off with Rudra, creating awareness<br />

was the big challenge, followed by logistics, even so that if<br />

someone, a said driver falls ill, they miss their collection drive.<br />

sanaanalwalla@crememagazine.in<br />

MARCH 2017 29