RCT Reichelt Chemietechnik GmbH + Co. - Thomafluid I (EN)

Thomafluid ® I - Tubings made of elastomers Laboratory Tubings Pressure Tubings Pharmaceutical Tubing Pump Tubings Materials: CR - chloroprene rubber EPdm - ethylene-propylene-diene rubber EPdm/PP - copolymer EVa - ethylene-vinyl-acetate fPm - fluorinated rubber Glass fabric iiR - isobutylene-isoprene-rubber NBR - butadiene-acrylonitrile rubber NR - natural rubber Polyolefine PuR - polyurethane PVC - polyvinyl chloride SBR - styrene-butadiene rubber Silicone

Thomafluid ® I - Tubings made of elastomers

Laboratory Tubings

Pressure Tubings

Pharmaceutical Tubing

Pump Tubings

Materials:

CR - chloroprene rubber

EPdm - ethylene-propylene-diene rubber

EPdm/PP - copolymer

EVa - ethylene-vinyl-acetate

fPm - fluorinated rubber

Glass fabric

iiR - isobutylene-isoprene-rubber

NBR - butadiene-acrylonitrile rubber

NR - natural rubber

Polyolefine

PuR - polyurethane

PVC - polyvinyl chloride

SBR - styrene-butadiene rubber

Silicone

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

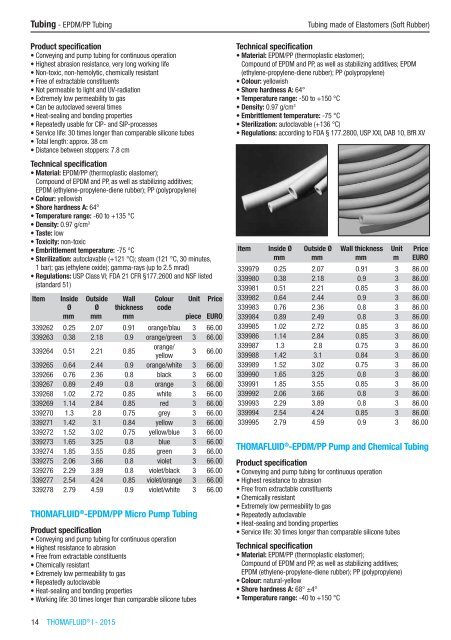

Tubing - EPDM/PP Tubing<br />

Product specification<br />

• <strong>Co</strong>nveying and pump tubing for continuous operation<br />

• Highest abrasion resistance, very long working life<br />

• Non-toxic, non-hemolytic, chemically resistant<br />

• Free of extractable constituents<br />

• Not permeable to light and UV-radiation<br />

• Extremely low permeability to gas<br />

• Can be autoclaved several times<br />

• Heat-sealing and bonding properties<br />

• Repeatedly usable for CIP- and SIP-processes<br />

• Service life: 30 times longer than comparable silicone tubes<br />

• Total length: approx. 38 cm<br />

• Distance between stoppers: 7.8 cm<br />

Technical specification<br />

• Material: EPDM/PP (thermoplastic elastomer);<br />

<strong>Co</strong>mpound of EPDM and PP, as well as stabilizing additives;<br />

EPDM (ethylene-propylene-diene rubber); PP (polypropylene)<br />

• <strong>Co</strong>lour: yellowish<br />

• Shore hardness A: 64°<br />

• Temperature range: -60 to +135 °C<br />

• Density: 0.97 g/cm 3<br />

• Taste: low<br />

• Toxicity: non-toxic<br />

• Embrittlement temperature: -75 °C<br />

• Sterilization: autoclavable (+121 °C); steam (121 °C, 30 minutes,<br />

1 bar); gas (ethylene oxide); gamma-rays (up to 2.5 mrad)<br />

• Regulations: USP Class VI; FDA 21 CFR §177.2600 and NSF listed<br />

(standard 51)<br />

Item Inside Outside Wall <strong>Co</strong>lour Unit Price<br />

Ø Ø thickness code<br />

mm mm mm piece EURO<br />

339262 0.25 2.07 0.91 orange/blau 3 66.00<br />

339263 0.38 2.18 0.9 orange/green 3 66.00<br />

339264 0.51 2.21 0.85<br />

orange/<br />

yellow<br />

3 66.00<br />

339265 0.64 2.44 0.9 orange/white 3 66.00<br />

339266 0.76 2.36 0.8 black 3 66.00<br />

339267 0.89 2.49 0.8 orange 3 66.00<br />

339268 1.02 2.72 0.85 white 3 66.00<br />

339269 1.14 2.84 0.85 red 3 66.00<br />

339270 1.3 2.8 0.75 grey 3 66.00<br />

339271 1.42 3.1 0.84 yellow 3 66.00<br />

339272 1.52 3.02 0.75 yellow/blue 3 66.00<br />

339273 1.65 3.25 0.8 blue 3 66.00<br />

339274 1.85 3.55 0.85 green 3 66.00<br />

339275 2.06 3.66 0.8 violet 3 66.00<br />

339276 2.29 3.89 0.8 violet/black 3 66.00<br />

339277 2.54 4.24 0.85 violet/orange 3 66.00<br />

339278 2.79 4.59 0.9 violet/white 3 66.00<br />

THOMAFLUID ® -EPDM/PP Micro Pump Tubing<br />

Product specification<br />

• <strong>Co</strong>nveying and pump tubing for continuous operation<br />

• Highest resistance to abrasion<br />

• Free from extractable constituents<br />

• Chemically resistant<br />

• Extremely low permeability to gas<br />

• Repeatedly autoclavable<br />

• Heat-sealing and bonding properties<br />

• Working life: 30 times longer than comparable silicone tubes<br />

Tubing made of Elastomers (Soft Rubber)<br />

Technical specification<br />

• Material: EPDM/PP (thermoplastic elastomer);<br />

<strong>Co</strong>mpound of EPDM and PP, as well as stabilizing additives; EPDM<br />

(ethylene-propylene-diene rubber); PP (polypropylene)<br />

• <strong>Co</strong>lour: yellowish<br />

• Shore hardness A: 64°<br />

• Temperature range: -50 to +150 °C<br />

• Density: 0.97 g/cm 3<br />

• Embrittlement temperature: -75 °C<br />

• Sterilization: autoclavable (+136 °C)<br />

• Regulations: according to FDA § 177.2800, USP XXI, DAB 10, BfR XV<br />

Item Inside Ø Outside Ø Wall thickness Unit Price<br />

mm mm mm m EURO<br />

339979 0.25 2.07 0.91 3 86.00<br />

339980 0.38 2.18 0.9 3 86.00<br />

339981 0.51 2.21 0.85 3 86.00<br />

339982 0.64 2.44 0.9 3 86.00<br />

339983 0.76 2.36 0.8 3 86.00<br />

339984 0.89 2.49 0.8 3 86.00<br />

339985 1.02 2.72 0.85 3 86.00<br />

339986 1.14 2.84 0.85 3 86.00<br />

339987 1.3 2.8 0.75 3 86.00<br />

339988 1.42 3.1 0.84 3 86.00<br />

339989 1.52 3.02 0.75 3 86.00<br />

339990 1.65 3.25 0.8 3 86.00<br />

339991 1.85 3.55 0.85 3 86.00<br />

339992 2.06 3.66 0.8 3 86.00<br />

339993 2.29 3.89 0.8 3 86.00<br />

339994 2.54 4.24 0.85 3 86.00<br />

339995 2.79 4.59 0.9 3 86.00<br />

THOMAFLUID ® -EPDM/PP Pump and Chemical Tubing<br />

Product specification<br />

• <strong>Co</strong>nveying and pump tubing for continuous operation<br />

• Highest resistance to abrasion<br />

• Free from extractable constituents<br />

• Chemically resistant<br />

• Extremely low permeability to gas<br />

• Repeatedly autoclavable<br />

• Heat-sealing and bonding properties<br />

• Service life: 30 times longer than comparable silicone tubes<br />

Technical specification<br />

• Material: EPDM/PP (thermoplastic elastomer);<br />

<strong>Co</strong>mpound of EPDM and PP, as well as stabilizing additives;<br />

EPDM (ethylene-propylene-diene rubber); PP (polypropylene)<br />

• <strong>Co</strong>lour: natural-yellow<br />

• Shore hardness A: 68° ±4°<br />

• Temperature range: -40 to +150 °C<br />

14 THOMAFLUID ® I - 2015