RCT Reichelt Chemietechnik GmbH + Co. - Thomafluid I (EN)

Thomafluid ® I - Tubings made of elastomers Laboratory Tubings Pressure Tubings Pharmaceutical Tubing Pump Tubings Materials: CR - chloroprene rubber EPdm - ethylene-propylene-diene rubber EPdm/PP - copolymer EVa - ethylene-vinyl-acetate fPm - fluorinated rubber Glass fabric iiR - isobutylene-isoprene-rubber NBR - butadiene-acrylonitrile rubber NR - natural rubber Polyolefine PuR - polyurethane PVC - polyvinyl chloride SBR - styrene-butadiene rubber Silicone

Thomafluid ® I - Tubings made of elastomers

Laboratory Tubings

Pressure Tubings

Pharmaceutical Tubing

Pump Tubings

Materials:

CR - chloroprene rubber

EPdm - ethylene-propylene-diene rubber

EPdm/PP - copolymer

EVa - ethylene-vinyl-acetate

fPm - fluorinated rubber

Glass fabric

iiR - isobutylene-isoprene-rubber

NBR - butadiene-acrylonitrile rubber

NR - natural rubber

Polyolefine

PuR - polyurethane

PVC - polyvinyl chloride

SBR - styrene-butadiene rubber

Silicone

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

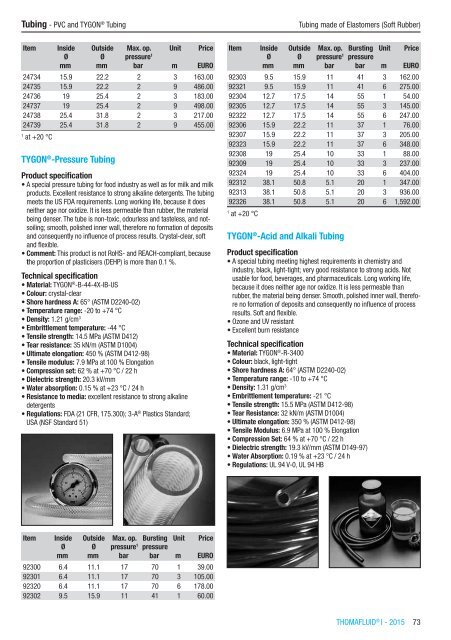

Tubing - PVC and TYGON ® Tubing<br />

Tubing made of Elastomers (Soft Rubber)<br />

Unit Price<br />

Item Inside Outside Max. op.<br />

Ø Ø pressure 1<br />

mm mm bar m EURO<br />

24734 15.9 22.2 2 3 163.00<br />

24735 15.9 22.2 2 9 486.00<br />

24736 19 25.4 2 3 183.00<br />

24737 19 25.4 2 9 498.00<br />

24738 25.4 31.8 2 3 217.00<br />

24739 25.4 31.8 2 9 455.00<br />

1<br />

at +20 °C<br />

TYGON ® -Pressure Tubing<br />

Product specification<br />

• A special pressure tubing for food industry as well as for milk and milk<br />

products. Excellent resistance to strong alkaline detergents. The tubing<br />

meets the US FDA requirements. Long working life, because it does<br />

neither age nor oxidize. It is less permeable than rubber, the material<br />

being denser. The tube is non-toxic, odourless and tasteless, and notsoiling;<br />

smooth, polished inner wall, therefore no formation of deposits<br />

and consequently no influence of process results. Crystal-clear, soft<br />

and flexible.<br />

• <strong>Co</strong>mment: This product is not RoHS- and REACH-compliant, because<br />

the proportion of plasticisers (DEHP) is more than 0.1 %.<br />

Technical specification<br />

• Material: TYGON ® -B-44-4X-IB-US<br />

• <strong>Co</strong>lour: crystal-clear<br />

• Shore hardness A: 65° (ASTM D2240-02)<br />

• Temperature range: -20 to +74 °C<br />

• Density: 1.21 g/cm 3<br />

• Embrittlement temperature: -44 °C<br />

• Tensile strength: 14.5 MPa (ASTM D412)<br />

• Tear resistance: 35 kN/m (ASTM D1004)<br />

• Ultimate elongation: 450 % (ASTM D412-98)<br />

• Tensile modulus: 7.9 MPa at 100 % Elongation<br />

• <strong>Co</strong>mpression set: 62 % at +70 °C / 22 h<br />

• Dielectric strength: 20.3 kV/mm<br />

• Water absorption: 0.15 % at +23 °C / 24 h<br />

• Resistance to media: excellent resistance to strong alkaline<br />

detergents<br />

• Regulations: FDA (21 CFR, 175.300); 3-A ® Plastics Standard;<br />

USA (NSF Standard 51)<br />

Item Inside Outside Max. op. Bursting Unit Price<br />

Ø Ø pressure 1 pressure<br />

mm mm bar bar m EURO<br />

92303 9.5 15.9 11 41 3 162.00<br />

92321 9.5 15.9 11 41 6 275.00<br />

92304 12.7 17.5 14 55 1 54.00<br />

92305 12.7 17.5 14 55 3 145.00<br />

92322 12.7 17.5 14 55 6 247.00<br />

92306 15.9 22.2 11 37 1 76.00<br />

92307 15.9 22.2 11 37 3 205.00<br />

92323 15.9 22.2 11 37 6 348.00<br />

92308 19 25.4 10 33 1 88.00<br />

92309 19 25.4 10 33 3 237.00<br />

92324 19 25.4 10 33 6 404.00<br />

92312 38.1 50.8 5.1 20 1 347.00<br />

92313 38.1 50.8 5.1 20 3 936.00<br />

92326 38.1 50.8 5.1 20 6 1,592.00<br />

1<br />

at +20 °C<br />

TYGON ® -Acid and Alkali Tubing<br />

Product specification<br />

• A special tubing meeting highest requirements in chemistry and<br />

industry, black, light-tight; very good resistance to strong acids. Not<br />

usable for food, beverages, and pharmaceuticals. Long working life,<br />

because it does neither age nor oxidize. It is less permeable than<br />

rubber, the material being denser. Smooth, polished inner wall, therefore<br />

no formation of deposits and consequently no influence of process<br />

results. Soft and flexible.<br />

• Ozone and UV resistant<br />

• Excellent burn resistance<br />

Technical specification<br />

• Material: TYGON ® -R-3400<br />

• <strong>Co</strong>lour: black, light-tight<br />

• Shore hardness A: 64° (ASTM D2240-02)<br />

• Temperature range: -10 to +74 °C<br />

• Density: 1.31 g/cm 3<br />

• Embrittlement temperature: -21 °C<br />

• Tensile strength: 15.5 MPa (ASTM D412-98)<br />

• Tear Resistance: 32 kN/m (ASTM D1004)<br />

• Ultimate elongation: 350 % (ASTM D412-98)<br />

• Tensile Modulus: 6.9 MPa at 100 % Elongation<br />

• <strong>Co</strong>mpression Set: 64 % at +70 °C / 22 h<br />

• Dielectric strength: 19.3 kV/mm (ASTM D149-97)<br />

• Water Absorption: 0.19 % at +23 °C / 24 h<br />

• Regulations: UL 94 V-0, UL 94 HB<br />

Item Inside Outside Max. op. Bursting Unit Price<br />

Ø Ø pressure 1 pressure<br />

mm mm bar bar m EURO<br />

92300 6.4 11.1 17 70 1 39.00<br />

92301 6.4 11.1 17 70 3 105.00<br />

92320 6.4 11.1 17 70 6 178.00<br />

92302 9.5 15.9 11 41 1 60.00<br />

THOMAFLUID ® I - 2015 73