TIMARIS - Singulus Technologies AG

TIMARIS - Singulus Technologies AG

TIMARIS - Singulus Technologies AG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

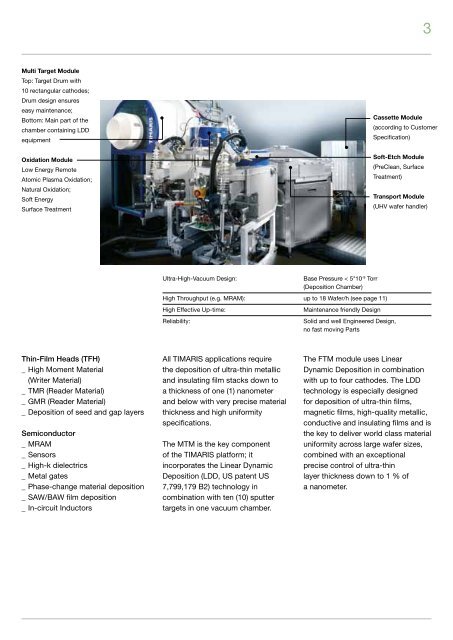

Multi Target Module<br />

Top: Target Drum with<br />

10 rectangular cathodes;<br />

Drum design ensures<br />

easy maintenance;<br />

Bottom: Main part of the<br />

chamber containing LDD<br />

equipment<br />

Oxidation Module<br />

Low Energy Remote<br />

Atomic Plasma Oxidation;<br />

Natural Oxidation;<br />

Soft Energy<br />

Surface Treatment<br />

Thin-Film Heads (TFH)<br />

_ High Moment Material<br />

(Writer Material)<br />

_ TMR (Reader Material)<br />

_ GMR (Reader Material)<br />

_ Deposition of seed and gap layers<br />

Semiconductor<br />

_ MRAM<br />

_ Sensors<br />

_ High-k dielectrics<br />

_ Metal gates<br />

_ Phase-change material deposition<br />

_ SAW/BAW film deposition<br />

_ In-circuit Inductors<br />

Ultra-High-Vacuum Design:<br />

High Throughput (e.g. MRAM):<br />

High Effective Up-time:<br />

Reliability:<br />

All <strong>TIMARIS</strong> applications require<br />

the deposition of ultra-thin metallic<br />

and insulating film stacks down to<br />

a thickness of one (1) nanometer<br />

and below with very precise material<br />

thickness and high uniformity<br />

specifications.<br />

The MTM is the key component<br />

of the <strong>TIMARIS</strong> platform; it<br />

incorporates the Linear Dynamic<br />

Deposition (LDD, US patent US<br />

7,799,179 B2) technology in<br />

combination with ten (10) sputter<br />

targets in one vacuum chamber.<br />

Base Pressure < 5*10-9 Torr<br />

(Deposition Chamber)<br />

up to 18 Wafer/h (see page 11)<br />

Maintenance friendly Design<br />

Solid and well Engineered Design,<br />

no fast moving Parts<br />

3<br />

Cassette Module<br />

(according to Customer<br />

Specification)<br />

Soft-Etch Module<br />

(PreClean, Surface<br />

Treatment)<br />

Transport Module<br />

(UHV wafer handler)<br />

The FTM module uses Linear<br />

Dynamic Deposition in combination<br />

with up to four cathodes. The LDD<br />

technology is especially designed<br />

for deposition of ultra-thin films,<br />

magnetic films, high-quality metallic,<br />

conductive and insulating films and is<br />

the key to deliver world class material<br />

uniformity across large wafer sizes,<br />

combined with an exceptional<br />

precise control of ultra-thin<br />

layer thickness down to 1 % of<br />

a nanometer.