You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>aim</strong>: <strong>zero</strong> <strong>emissions</strong>

Kaizen<br />

“Continuous improvement. As no process can ever<br />

be declared perfect, there is always room for improvement.”

Table of Contents<br />

Aim: <strong>zero</strong> <strong>emissions</strong>, <strong>zero</strong> waste 4<br />

Towards the ultimate Eco-car 7<br />

Clean manufacturing 10<br />

Green technologies 11<br />

The 3 Rs: Reduce, Reuse, Recycle 18<br />

The next horizon 21<br />

September 2006 edition

Residential<br />

(CO 2 )<br />

Aim:<br />

<strong>zero</strong> <strong>emissions</strong>, <strong>zero</strong> waste<br />

There are over 200 million cars in use on Europe’s roads<br />

today, providing freedom of mobility to every type of driver.<br />

European CO2 <strong>emissions</strong> World by CO2<br />

sector emmisions (2004) by sector*<br />

Yet cars are also widely associated with being harmful to the<br />

planet’s ecosystem. This can range from global warming and<br />

Petroleum<br />

refining (CO 2 )<br />

Commercial/<br />

Institutional (CO 2 )<br />

5%<br />

12%<br />

Manufacturing Industries<br />

and Construction (CO 2 )<br />

Other<br />

4%<br />

16%<br />

9%<br />

Carbon Dioxide (CO 2 )<br />

Particulate Matter (PM)<br />

Nitrogen Oxides (NOx)<br />

Volatile Organic<br />

Compounds (VOCs)<br />

Carbon Monoxide (CO)<br />

24%<br />

30%<br />

* Source EEA (European Environment Agency) Technical Report 6/2006<br />

VEhiClE<br />

Emissions<br />

greenhouse gases to smog, noise and landfill pollution. In<br />

recent years, the automobile industry has made great progress<br />

in reducing the environmental burden of motor vehicles.<br />

Transportation (CO 2 )<br />

a “greenhouse gas” that can contribute<br />

to global warming.<br />

found in soot from factories and car<br />

exhaust amongst others. Can cause<br />

respiratory diseases.<br />

causes acid rain. Also generates ozone<br />

that can contribute to photochemical<br />

smog and global warming.<br />

hydrocarbons from industrial<br />

processes, factories and cars.<br />

Contribute to smog.<br />

harmful to humans, can be fatal; now<br />

largely eliminated from car exhaust<br />

<strong>emissions</strong>.<br />

Electricity and Heat<br />

Production (CO 2 )<br />

Life cycle <strong>emissions</strong><br />

Carbon Dioxide<br />

Particulate Matter<br />

Nitrogen Oxides<br />

Volatile Organic Compounds<br />

Carbon Monoxide<br />

hOw dO CARS AffECT<br />

thE EnvironmEnt?<br />

Manufacturing<br />

Energy, Water,<br />

Waste, Landfill, Emissions<br />

End of Life<br />

Waste, Landfill

&<br />

How do cars affect the environment?<br />

Vehicle manufacturing consumes raw materials and energy, while cars<br />

produce exhaust <strong>emissions</strong> and have to be disposed of properly at the<br />

end of their lives. Reducing the impact of each of these processes is a key<br />

challenge for <strong>Toyota</strong>.<br />

Motor vehicles interact with the<br />

environment throughout their entire<br />

lifecycle – from their initial design and the<br />

way they are manufactured, to their use<br />

on the road and their eventual disposal<br />

when no longer needed.<br />

When driving, car engines release<br />

<strong>emissions</strong> into the air, influencing the<br />

chemical composition of the atmosphere<br />

we breathe and indirectly affecting<br />

weather patterns around the globe. The<br />

challenge is: How can these <strong>emissions</strong><br />

be further reduced?<br />

A second environmental impact comes<br />

from the fact that vehicles are made out of<br />

metals, plastics and other manufactured<br />

materials. Can cars be designed so<br />

that they can be recycled more easily<br />

and comprehensively? And automotive<br />

factories use energy and materials to<br />

manufacture new vehicles, and produce<br />

waste as a by-product. How can<br />

factories be designed to respond more<br />

efficiently to environmental constraints?<br />

For <strong>Toyota</strong>, minimizing these kinds of<br />

environmental impact has long been<br />

a top priority at every level of the<br />

company’s organisation and activity. The<br />

company’s environmental policy forms<br />

part of a much wider vision of sustainable<br />

development, one of the cornerstones of<br />

global economic thinking for the future.<br />

And building completely recyclable cars<br />

with <strong>zero</strong> <strong>emissions</strong> is <strong>Toyota</strong>’s foremost<br />

challenge for the years to come.<br />

Both…and morE!<br />

Much of the debate surrounding sustainable mobility, or<br />

the development of the ultimate eco-car, places a cleaner<br />

environment in opposition to economic and industrial<br />

growth. The thinking goes: you can only have one or the<br />

other, but not both. It is in <strong>Toyota</strong>’s corporate culture to work hard when<br />

confronted with these challenges, to try and achieve both and more!

6<br />

• Follow the traffic flow and anticipate<br />

what is going to happen in front<br />

of you.<br />

• Change up to a higher gear early:<br />

a higher gear always means a lower<br />

engine speed and lower fuel<br />

consumption<br />

Responsibility<br />

through<br />

innovation<br />

One of the<br />

world’s leading<br />

automobile manufacturers, <strong>Toyota</strong> sold some 8.1 million<br />

vehicles* in 200 , marketing them in over 1 0 countries.<br />

<strong>Toyota</strong> is one of the leading automotive brands in Europe,<br />

where it has been selling cars since the early 1960s<br />

and has invested over €6 billion since 1990. From its<br />

headquarters in Brussels, Belgium, the company overseas<br />

its eight European production sites, large R&D facilities<br />

and design, logistics, training and service centres. In total,<br />

<strong>Toyota</strong> employs some ,000 people in Europe, including<br />

retailers.<br />

* <strong>Toyota</strong>, Lexus, Hino & Daihatsu combined<br />

• A constant speed can give<br />

lower fuel consumption.<br />

• Don’t use your car to travel short<br />

distances<br />

• If possible, switch off your engine if<br />

you have to wait longer than<br />

0 seconds<br />

• Follow the manufacturer’s<br />

instructions and have your car<br />

serviced regularly<br />

• Check your tyre pressures on a<br />

monthly basis<br />

• Keep your windows closed and use<br />

the ventilation system<br />

• Only use electrical accessories (air<br />

conditioning, rear screen heater,<br />

etc.) when necessary, as they<br />

consume energy<br />

toyota’s Eco-drivE tips<br />

• Extra weight results in additional<br />

energy consumption (10% for<br />

ski boxes on the roof, up to<br />

0% more for a cycle rack<br />

on the roof). Remove them<br />

after use.<br />

• Plan your route in advance so<br />

you do not make unnecessary<br />

detours.<br />

• Avoid driving in town,<br />

where fuel consumption is<br />

twice as high as on the<br />

motorway.<br />

• Use of equipment such as<br />

cruise control, or a display<br />

which shows current<br />

consumption, can lead to<br />

fuel savings of up to 10%.<br />

In addition to a reputation for technological innovation,<br />

superior quality and manufacturing expertise, <strong>Toyota</strong> fully<br />

assumes its corporate responsibility for the environment<br />

and for the communities in which it operates.<br />

This commitment translates into a comprehensive vision<br />

of sustainable mobility. <strong>Toyota</strong>’s extensive Research and<br />

Development programmes examine every aspect of<br />

vehicle design, performance, safety and the information<br />

infrastructure that will underpin driving tomorrow. Finding<br />

and implementing solutions that make cars less of an<br />

environmental burden is one of the central foundations of<br />

sustainable mobility.

CNG<br />

Compressed<br />

Natural Gas<br />

Alternative<br />

Fuel Engines<br />

Towards the ultimate<br />

Eco-car<br />

Alternative<br />

Fuel HV<br />

Hybrid Technology<br />

Biofuels<br />

Synthetic Fuels<br />

In 2020 it is estimated there will be some 1.2 billion cars on the<br />

road, nearly twice the current number. Car makers must make the<br />

right decisions today to ensure that this growth does not lead to<br />

a drastic increase in exhaust <strong>emissions</strong> and the greenhouse gas<br />

carbon dioxide (CO 2 ). <strong>Toyota</strong>’s approach to exhaust <strong>emissions</strong><br />

is to explore simultaneously a broad variety of solutions for<br />

developing cleaner, greener vehicles. The reason is that different<br />

countries and communities have different driving conditions,<br />

available fuel, vehicle infrastructure and legislation.<br />

Diesel<br />

Engines<br />

Diesel Hybrid<br />

Vehicle<br />

Diesel Particulate<br />

NOx Reduction<br />

Common Rail Direct Injection<br />

Plug-in HV<br />

Diesel HV THS II<br />

DPNR<br />

Common Rail DI<br />

FCHV<br />

Fuel Cell<br />

Hybrid<br />

Vehicle<br />

<strong>Toyota</strong><br />

Hybrid System<br />

D-4<br />

Direct Injection<br />

4-Stroke Petrol Engine<br />

VVT-i<br />

Variable Valve<br />

Timing with Intelligence<br />

Lean-Burn<br />

Gasoline<br />

Engines<br />

<strong>Toyota</strong> is committed<br />

to developing hybrid<br />

systems as the core<br />

technology for ecocars,<br />

combining different<br />

power sources<br />

in ways that maximize<br />

the strengths of each.<br />

EV<br />

Electric<br />

Vehicle<br />

Electrical<br />

Energy

8<br />

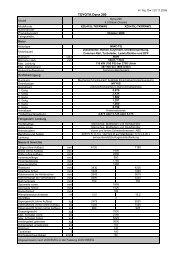

EURO 3<br />

EURO 4<br />

<strong>Toyota</strong> is investing in all these technologies in parallel.<br />

Each forms a step forward towards the ultimate eco-car.<br />

This ideal target would generate <strong>zero</strong> 1997<strong>emissions</strong><br />

from its<br />

engine, and be totally recyclable. Kyoto But Protocol while pursuing this<br />

ideal, it is important to meet thedrafted real needs of society1998<br />

today and tomorrow, and therefore <strong>Toyota</strong>’s approach<br />

Date of application<br />

After 1/1/2000<br />

1/1/2005<br />

Petrol (in grammes/km)<br />

100<br />

80<br />

60<br />

40<br />

20<br />

&<br />

One of the most promising technologies for reducing<br />

<strong>emissions</strong> in conventional cars is known as hybrid<br />

technology, since it advantageously combines the<br />

benefits of two types of power source instead of relying<br />

on just one. For example, a petrol engine can be<br />

combined with an electric motor.<br />

In certain contexts of vehicle use, other<br />

types of low-emission engine technologies<br />

are also proving effective, although they<br />

are not yet as mature or versatile as petrol<br />

and diesel-powered engines. These include<br />

fuel cells (where hydrogen is used to generate<br />

electricity) and compressed natural gas engines.<br />

EU directives on<br />

exhaust emission limits<br />

CO NOx + HC<br />

EURO 3 EURO 4<br />

How can the environmental impact of a car be measured?<br />

Provided we look at the whole lifecycle of a car, we can accurately<br />

measure its overall impact in terms of materials, production, <strong>emissions</strong><br />

and end-of-life. This Life Cycle Assessment then makes it easier to<br />

produce cleaner cars according to clear targets.<br />

EU Directive:<br />

sets emission targets<br />

for new cars as of<br />

2005 (Euro 4)<br />

NOx<br />

2.30 0.20 0.15<br />

1.00 0.10 0.08<br />

For Petrol cars<br />

is to deploy the appropriate engine technology to<br />

produce... the right car for the right place at the right<br />

time.<br />

EURO 3<br />

EURO 4<br />

2006<br />

All <strong>Toyota</strong> engines meet<br />

Euro 4 Directive for<br />

<strong>emissions</strong><br />

Date of application<br />

After 1/1/2000<br />

CO NOx<br />

2008/9<br />

European, Japanese and<br />

Korean car makers to<br />

reduce average CO2<br />

to 140 g/km<br />

Diesel (in grammes/km)<br />

NOx + HC Particulate<br />

Matter<br />

0.64 0.50 0.56 0.05<br />

1/1/2005 0.50 0.25 0.30 0.025<br />

CO<br />

HC + NO x<br />

PM<br />

NO x

how environmental<br />

is your car?<br />

To achieve lower <strong>emissions</strong> and greener vehicles on the<br />

way toward the ultimate eco-car, it is essential to measure<br />

progress. <strong>Toyota</strong> has therefore developed its Ecological<br />

Eco-VAS<br />

at work<br />

When a new <strong>Toyota</strong> vehicle is<br />

planned, the Chief Engineer sets<br />

quantitative targets for reducing its<br />

environmental impact. Assessment covers a wide range<br />

of items. It starts with materials – including the elimination<br />

of substances of concern such as lead or chrome<br />

– components and production methods. It continues<br />

by examining fuel efficiency and <strong>emissions</strong> during the<br />

vehicle’s use. And it factors in the amount of materials that<br />

can be recovered on disposal, as well as overall reduction<br />

of <strong>emissions</strong> throughout the vehicle’s life cycle.<br />

All findings from these assessments are kept in a computer<br />

database that can be accessed to compare and contrast<br />

progress in reaching Eco-VAS targets, and confirm the<br />

environmental conformity of a new vehicle based on the<br />

concept of total Life Cycle Assessment (LCA).<br />

Vehicle planning<br />

Eco-VAS at work<br />

Designing and<br />

prototype building<br />

Vehicle Assessment System, or Eco-VAS. This is a<br />

comprehensive approach to assessing a vehicle’s whole<br />

life cycle – from production, through use to disposal – in<br />

terms of its impact on the environment, starting at the<br />

early stages of development, before the vehicle is actually<br />

built. <strong>Toyota</strong> began using Eco-VAS in 200 , bringing the<br />

system to a high level of implementation in 200 .<br />

By enabling development teams to evaluate the<br />

environmental impact of a new vehicle ahead of its actual<br />

production, it will be easier for <strong>Toyota</strong> to ensure constant<br />

step by step improvements on the road to the ultimate<br />

eco-car.<br />

Production<br />

Target setting Target-achievement<br />

Target-achievement status check<br />

Evaluation-results feedback<br />

status con�rmation<br />

9

The production of vehicles, engines and transmissions in<br />

factories inevitably has an impact on the environment. To<br />

ensure that car manufacturing can make more with less,<br />

<strong>Toyota</strong> developed its world-famous <strong>Toyota</strong> Production<br />

System (TPS) several decades ago. Over the years, TPS<br />

has also evolved to include new environmental targets.<br />

It is now applied in <strong>Toyota</strong>’s production facilities all over<br />

Europe.<br />

toyota’s production system...<br />

• eliminates waste<br />

• reduces energy usage<br />

• minimises use of raw materials<br />

• delivers standardised quality<br />

by...<br />

• applying best practice in<br />

all processes (“Yokoten”)<br />

• continuous improvement<br />

(“Kaizen”)<br />

• going to the source to find the<br />

facts (“Genchi Genbutsu”)<br />

• just-in-time production, by<br />

‘pulling’ products through the<br />

production line<br />

• active involvement from<br />

all team members<br />

10<br />

Greener<br />

manufacturing<br />

in the <strong>Toyota</strong> Prius<br />

Clean<br />

manufacturing<br />

Constant efforts to improve standards<br />

throughout the workplace have radically<br />

reduced the environmental impact of<br />

production at our plants.<br />

Since 2001:<br />

• Total energy usage per car has<br />

been reduced by 37% across all of<br />

<strong>Toyota</strong>’s European manufacturing<br />

plants.<br />

• Water usage has been reduced in<br />

Europe by 34%.<br />

• Packaging waste has been reduced<br />

through the full use of returnable or<br />

recyclable packaging.<br />

• Volatile organic compound<br />

<strong>emissions</strong> per square metre of<br />

painted surface have been reduced<br />

by 21%.<br />

Aim: <strong>zero</strong> <strong>emissions</strong><br />

through TPS<br />

For example: <strong>Toyota</strong>’s vehicle plants in both the U.K. and France, have achieved the<br />

ambitious target of delivering <strong>zero</strong> waste to landfill.* Applying TPS principles, staff<br />

carefully examined how production waste was created, and invented appropriate<br />

solutions to reduce, reuse or recycle all the ‘waste’ materials generated. This has resulted<br />

in a 73% reduction of waste going to landfill since 2001.<br />

The manufacturing process for the new Prius model has been organized to reduce the amount of energy needed<br />

for building the car. CO 2 <strong>emissions</strong> during the manufacturing process are cut by 31% compared to the previous<br />

Prius production plant. Special Eco-plastic made from plants to provide floor mats is used. This further reduces CO 2<br />

<strong>emissions</strong> during manufacturing. The batteries are smaller and more efficient, resulting in 33% less CO 2 <strong>emissions</strong><br />

during manufacturing when compared to the previous generation Prius.<br />

the toyota prius is 90% recycable!<br />

* Zero waste to landfill: less than 3% of 1997 amount of waste disposal to landfill

Green Technologies<br />

Petrol and diesel engines are highly efficient, but they come at a price. They emit CO 2<br />

and other gases and particles that pollute the atmosphere and might influence longer-<br />

term climate patterns. <strong>Toyota</strong> is therefore committed to developing technologies that<br />

reduce <strong>emissions</strong> to much lower levels. Since petrol and diesel engines will probably<br />

continue to form the major source of automotive power in the years to come, a major<br />

effort is being made to reduce the environmental impact of these technologies.<br />

For example, <strong>Toyota</strong> has re-examined the whole structure<br />

of the internal combustion engine to identify specific ways<br />

in which petrol and diesel engines can burn less fuel more<br />

efficiently, and so emit less CO 2 and other unwanted<br />

gases.<br />

This has led to the development of integrated intelligent<br />

technologies that use advanced solutions inside engines<br />

to improve the management of fuel and driving operations.<br />

One of these is Variable Valve Timing-intelligent<br />

(VVT-i), which uses less fuel than comparable petrol<br />

engines and emits less carbon dioxide, nitrogen oxides<br />

and hydrocarbons.<br />

Another is <strong>Toyota</strong>’s Common Rail Diesel technology<br />

(known as D-4D), which injects a precise amount of fuel<br />

directly into the combustion chamber to deliver more<br />

efficient combustion and better fuel economy. These both<br />

help reduce CO 2 levels in exhaust <strong>emissions</strong>.<br />

<strong>Toyota</strong> has also made significant advances in developing engines that are powered by alternative energy<br />

sources. One of the most promising approaches is to combine two different power sources in a single system<br />

to exploit the performance potential of both. This is known as hybrid technology, and forms one of the most<br />

promising development paths on <strong>Toyota</strong>’s eco-car roadmap.<br />

11

Do diesel engines pollute more than petrol engines?<br />

Diesel engines use less fuel and overall produce less CO 2 than petrol<br />

engines. However, they produce more particulate matter and nitrogen<br />

oxides than petrol engines. Advanced technologies can improve the<br />

efficiency and cleanliness of both petrol and diesel engines.<br />

Advancing<br />

with diesel<br />

Mile for mile, diesel engines are more efficient as a power<br />

source than petrol engines. But this efficiency comes at a<br />

price. Diesel exhaust contains higher quantities of Particulate<br />

Matter (mostly consisting of un-burnt carbon compounds), as well<br />

as nitrogen oxide. Over the years, <strong>Toyota</strong> has developed a<br />

number of engine technologies that lower diesel’s impact.<br />

Common Rail Diesel technology (D- D), for example, reduces<br />

CO 2 <strong>emissions</strong>. Special catalysts have been developed to reduce<br />

particulate matter and nitrogen oxides. <strong>Toyota</strong>’s D- D<br />

and exhaust gas recirculation technology help reduce the<br />

presence of hydrocarbons, carbon monoxide and particulate<br />

matter in vehicle exhaust.<br />

In 200 , <strong>Toyota</strong> revolutionised the diesel engine by combining<br />

these different technologies into a single new integrated solution<br />

called <strong>Toyota</strong> Diesel Clean Advanced<br />

Technology (<strong>Toyota</strong> D-CAT). This<br />

advanced concept dramatically<br />

reduces particulate matter and<br />

nitrogen oxides resulting in the<br />

world’s cleanest diesel engine<br />

technology! In 200 , <strong>Toyota</strong> D-CAT<br />

was featured in a brand-new 2.2litre<br />

high-power (1 DIN hp) diesel<br />

engine, built in Poland. <strong>Toyota</strong>’s<br />

new 2.0-litre D- D 12 diesel engine<br />

is available with a diesel particulate<br />

filter, reducing particulate<br />

<strong>emissions</strong> even further.<br />

<strong>Toyota</strong>’s challenge is to ensure that<br />

diesel engines’ <strong>emissions</strong> performance<br />

will eventually be equivalent to<br />

petrol engines.<br />

12<br />

&<br />

The D-4D 2.2-litre, <strong>Toyota</strong> D-CAT engine integrates special technologies<br />

to produce very low NOx and particle <strong>emissions</strong><br />

EGR Valve<br />

Exhaust Port Injector<br />

Variable Nozzle Turbocharger<br />

Air fuel ratio sensor<br />

Oxidation Catalyst<br />

EGR Cooler<br />

Piezoelectric common-rail injection<br />

DPNR Catalyst<br />

High Power Diesel Engine<br />

• 2.2-litre, in-line 4-cylinders<br />

Pressure Difference Sensor<br />

NOx storage reduction catalyst<br />

Gas Temperature Sensors

hybrid<br />

hybrid<br />

Technology<br />

Electric<br />

No single engine technology<br />

or fuel can deliver an optimal<br />

solution to the <strong>emissions</strong><br />

problem. All have their shortcomings.<br />

Petrol engines emit less nitrogen oxides than diesel<br />

engines, and produce insignificant levels of particulate<br />

matter. Diesel engines, on the other hand,<br />

are more fuel efficient and therefore produce less<br />

carbon dioxide than petrol engines. Among non-petroleum<br />

power sources, electric vehicles, for example,<br />

are clean, but cannot deliver satisfying overall<br />

drive performance, acceptable driving range, and have<br />

to be recharged.<br />

But what if it were possible to combine different types<br />

of power sources and make them work together to enhance<br />

their respective benefits and reduce their obvious<br />

shortcomings?<br />

This leap forward has been made through the creation<br />

of <strong>Toyota</strong>’s hybrid technology, now one of the company’s<br />

core vehicle technologies.<br />

If you drive 25,000 km a year in a Prius,<br />

you will save over 1 tonne more<br />

CO2 when compared to a<br />

similarly-sized diesel car.<br />

+<br />

+<br />

+<br />

+<br />

Diesel<br />

or<br />

or<br />

Alternatives<br />

Fuels<br />

Petrol<br />

or<br />

Fuel Cell<br />

Hybrid technology can be applied effectively to improve<br />

the efficiencies of a variety of power trains irrespective<br />

of the type of fuel used (gasoline, diesel, alternative fuels<br />

or fuel cell vehicles).<br />

Hybrids not only deliver lower <strong>emissions</strong> and reduced<br />

fuel consumption, but they are completely silent when<br />

operating electrically and deliver impressive driving performance.<br />

The revolutionary breakthrough achieved by hybrid<br />

technology is the intelligent management of the energy<br />

flows from two different power sources so that each dimension<br />

of driving – acceleration, open road, braking<br />

and stop-and-go – is performed in an optimal way.<br />

This highly innovative solution consists of a petrol engine<br />

designed to minimize fuel consumption, combined<br />

with a <strong>zero</strong>-emission electric motor matched to a nickel<br />

metal hydride electric battery pack to provide additional<br />

power. Both of these power sources work together<br />

under the supervision of a sophisticated power<br />

management controller to deliver maximum overall<br />

driving efficiency.<br />

One tree (1) absorbs around 14kg (2) of CO2<br />

each year. So you'd be doing the annual<br />

workload of a forest with 71 trees.<br />

(1) Measured using Japanese cedar<br />

(2) CO 2 equivalent<br />

1

1<br />

toyota &<br />

hyBrid:<br />

• Launched the world’s first mass-produced hybrid<br />

car (<strong>Toyota</strong> Prius) in 199 .<br />

• Is the world’s leading manufacturer of hybrid<br />

vehicles and has the largest hybrid model line-up.<br />

• Intends to double the number of models in its<br />

hybrid line-up by the early 2010s.<br />

• Over 00,000 hybrid vehicles sold worldwide<br />

(July 2006).<br />

• Over 0,000 hybrid vehicles sold in<br />

Europe (July 2006).<br />

• Target of reaching annual hybrid sales<br />

of 1 million units by the early 2010s.<br />

ordinary driving<br />

Full-throttle<br />

acceleration<br />

deceleration/braking stop-and-go<br />

Runs with electric motor<br />

and engine in most fuel-efficient<br />

configuration<br />

Engine Engine Engine<br />

Engine<br />

Engine power +<br />

electric motor power<br />

Engine Engine Engine<br />

lectric motor Battery BatteryElectric<br />

Battery Electric motor motor Electric motor Battery Electric motor Battery Battery Electric Battery Electric motor motor Electric motor<br />

High fuel-efficiency driving<br />

Battery<br />

Electricity is generated,<br />

and partly recharges the battery<br />

Battery Battery Battery<br />

The <strong>Toyota</strong> Prius has already captured 90%<br />

of the world market for hybrid technology,<br />

having been on the market since 1997.<br />

The Prius was voted the 2005 European<br />

Car of the Year – a strong endorsement for<br />

environmentally beneficial hybrid technology.<br />

Energy recovered<br />

and stored<br />

Prius:<br />

an eco-pioneer<br />

Engine stops automatically,<br />

and can run on electricity alone<br />

Battery Electric motor Battery BatteryElectric Battery Electric motor motor Electric motor<br />

Zero fuel consumption

hybrid<br />

Synergy drive<br />

Hybrid Synergy Drive® (HSD) is the concept behind<br />

the new generation of hybrid vehicles from the <strong>Toyota</strong><br />

brand, including the <strong>Toyota</strong> Prius, the world’s bestselling<br />

hybrid vehicle. HSD combines driving pleasure<br />

and performance with fuel economy, low <strong>emissions</strong><br />

and silent driving. The word “synergy” extends to the<br />

higher synergy between the petrol engine and electric<br />

motor to power the vehicle. The electric motor is now<br />

more powerful, allowing a higher ratio of electrical/<br />

petrol usage. The results are more performance with<br />

greatly improved efficiency.<br />

the benefits of<br />

hybrid synergy drive<br />

in the prius<br />

• Excellent driving performance:<br />

acceleration similar to a mainstream<br />

D-segment (1) diesel engine.<br />

• Low fuel consumption:<br />

. litres/100 km – equivalent<br />

to a B-segment (1) diesel car.<br />

• Lower <strong>emissions</strong>:<br />

CO 2 <strong>emissions</strong> of 10 g/km in the<br />

combined cycle (2) , down from<br />

120 g/km for the previous generation.<br />

• silent driving:<br />

HSD can run on the electric motor only,<br />

offering a completely silent<br />

driving experience.<br />

(1) B-segment cars are compact cars like the <strong>Toyota</strong> Yaris.<br />

D-segment cars are larger, more powerful cars such<br />

as the <strong>Toyota</strong> Avensis.<br />

(2) City and highway driving.<br />

1.5-litre Petrol engine<br />

Uses special technology to<br />

extract more energy from petrol<br />

combustion.<br />

Regenerative braking system<br />

Uses electric motor<br />

as generator to convert<br />

braking energy into electricity.<br />

Inverter<br />

Converts DC from battery to<br />

AC for driving the motor.<br />

Battery<br />

Charged by the engine via the<br />

generator when cruising, and<br />

by electric motor when<br />

braking. Never needs to be<br />

plugged in.<br />

Electric motor<br />

Permanent-magnet<br />

technology to produce 50kW<br />

output.<br />

Power Split Device<br />

Splits power between engine,<br />

motor, generator and wheels.<br />

1

16<br />

lexus<br />

hybrid<br />

drive<br />

The Lexus brand first introduced<br />

hybrid power<br />

trains with the RX 400h<br />

in May 2005. Since<br />

then, Lexus has gained<br />

more ground with its European<br />

hybrid strategy,<br />

both by launching the GS 450h in May 2006 and<br />

presenting the company’s forthcoming flagship,<br />

the LS 600h, in May 2007.<br />

Hybrid technology is attracting customers to the<br />

Lexus brand who are looking for a realistic alternative<br />

to mainstream technology. In addition to the<br />

quietness, smoothness and refinement of hybrid<br />

power trains, Lexus customers appreciate the<br />

powerful and linear acceleration combined with<br />

segment-leading environmental performance. To<br />

reflect the importance of its hybrid strategy, Lexus<br />

has adopted a new brand name that will more<br />

clearly identify its advanced hybrid technology<br />

and philosophy: Lexus Hybrid Drive.<br />

Alternatives<br />

to fossil fuels<br />

The great advantage of alternative energy sources is<br />

that they can drastically cut <strong>emissions</strong> for cars being<br />

driven. However, since many of the technologies<br />

involved are not yet fully mature, and are still too<br />

costly to be implemented into a broad range of<br />

cars, the majority of them require further research<br />

and development before they come to market.<br />

<strong>Toyota</strong> has led the way in developing a number of these alternative technologies as cleaner solutions for<br />

sustainable mobility, and has already proven that innovative solutions can be commercialised for specific uses.

inside an Fchv<br />

CO2 output from oil well to car wheel<br />

Petrol vehicle<br />

Diesel vehicle<br />

Petrol Hybrid<br />

<strong>Toyota</strong> FCHV<br />

(target)<br />

Hydrogen<br />

(Gasoline vehicle = 1)<br />

0 0.2 0.4 0.6 0.8 1.0<br />

Well-to-Tank CO2<br />

Tank-to-Wheel CO2<br />

In the Japanese 10-15 test cycle, <strong>Toyota</strong> in-house testing<br />

FCHV: Hydrogen fuel<br />

Well-to-Tank CO2 = CO2 emitted from the oil well until the fuel arrives at the fuel station<br />

Tank-to-Wheel CO2 = CO2 emitted by a vehicle during use, including refueling<br />

4<br />

3<br />

Water<br />

Air<br />

2<br />

1<br />

1. Fuel cell stack<br />

2. Battery<br />

3. Control unit<br />

4. Motor<br />

hydrogen fuel cells – as pure as water<br />

One of the most promising technologies developed<br />

to use alternative energy is ‘fuel cell’. A fuel<br />

cell works by combining two common elements -<br />

hydrogen and oxygen - to generate electricity that<br />

powers an electric motor. The by-products of this<br />

reaction are only water vapour and heat, making<br />

this technology the ultimate <strong>zero</strong> emission solution<br />

for vehicle use, even though the actual production<br />

process for hydrogen is not emission-free. <strong>Toyota</strong><br />

has been conducting research into fuel cells since<br />

1992. It believes fuel cell driven vehicles will become<br />

a mainstay of mobility in the future.<br />

Vehicles equipped with fuel cells and using <strong>Toyota</strong>’s<br />

hybrid system configuration are 2 - times more<br />

efficient than petrol-powered cars in terms of fuel<br />

tank-to-wheel efficiency.<br />

In 2002, <strong>Toyota</strong> was the first automobile manufacturer<br />

to commercialise Fuel Cell Hybrid Vehicles<br />

(FCHVs) in Japan and the U.S. They are equipped<br />

with the <strong>Toyota</strong> FC Stack, a completely in-house<br />

developed fuel cell. The full commercialisation of<br />

fuel cell vehicles, however, will require the establishment<br />

of a hydrogen supply network similar to that<br />

for petrol and diesel fuel - a large-scale and costly<br />

undertaking. But while the market of fuel cell powered<br />

vehicles is limited for the immediate future, their<br />

potential remains proven and clear.<br />

<strong>Toyota</strong> has been researching a number of other<br />

sources of cleaner fuel for some time now, in its<br />

quest for the ultimate eco-car.<br />

For example, <strong>Toyota</strong> has researched Compressed<br />

Natural Gas (CNG) for over two decades, with<br />

limited-scale commercialisation. Compared to<br />

conventional diesel and petrol vehicles, natural<br />

gas powered vehicles emit very small amounts of<br />

Particulate Matter, and much less carbon dioxide.<br />

However, CNG requires very large storage tanks<br />

for the fuel, and tends to deliver less energy than<br />

conventional fossil fuels, limiting its long-term applications<br />

to very specific driving contexts such as<br />

bus or taxi transport in city centres. Gas-to-Liquid<br />

(GTL) – a synthetic diesel fuel produced from CNG<br />

- is another promising energy alternative, as it uses<br />

existing diesel fuel infrastructures. It provides the<br />

benefit of further <strong>emissions</strong> reduction and the better<br />

fuel economy of the latest clean diesel engines<br />

– such as <strong>Toyota</strong> D-CAT and <strong>Toyota</strong>’s Diesel Particulate<br />

Filter.<br />

<strong>Toyota</strong> also supports the use of alternative fuels including<br />

bio-fuels for cars to help reduce fossil fuel<br />

consumption and to prevent climate change.<br />

Gsi - GEar shiFt indicator<br />

Fuel consumption in vehicles can also be reduced by making more efficient use of existing<br />

technology.The “Gear Shift Indicator” is a good example. It’s a technology that <strong>aim</strong>s to encourage<br />

fuel efficient driving behaviour. It does this by indicating the optimum point to change gear for<br />

eco-driving. By doing so, awareness of fuel efficient driving is increased. Depending on the<br />

circumstances, fuel consumption can be reduced by over %.<br />

1

The 3 Rs:<br />

Reduce, Reuse, Recycle<br />

For car makers, truly sustainable mobility also<br />

means manufacturing vehicles and processing<br />

them at the end of their lifetime in ways that ensure<br />

maximum energy efficiency and minimum waste.<br />

The 2015 target is to have 85% of the vehicle<br />

weight being reused or recycled and 10% energy<br />

recovery, leaving the remaining 5% for disposal.<br />

End-of-life<br />

vehicles<br />

18<br />

&<br />

End-of-life vehicles (ELVs) contain<br />

materials ranging from steel and<br />

rubber to plastic and solvents. Some of these<br />

contain Substances of Concern (SoCs) which<br />

would contaminate the soil and the groundwater<br />

reserves if an ELV is simply thrown away.<br />

<strong>Toyota</strong>’s Eco-VAS (Vehicle Assessment System)<br />

sets targets and consistently tracks measures<br />

for limiting SoCs and reducing other forms of<br />

environmental burden. And further improvements<br />

will follow in the future.<br />

toyota makes vehicle recycling easier:<br />

1. Designing cars for easier recovery.<br />

2. Manufacturing cars with recovery in mind.<br />

3. Recovery of used parts and components that are<br />

replaced during the life of a vehicle.<br />

4. Minimising the remaining waste of an ELV.<br />

How does recycling reduce CO 2 <strong>emissions</strong>?<br />

Making new cars involves the use of many materials, from metals and<br />

synthetic products to cardboard, which all have to be first produced<br />

industrially. By recycling materials where and when appropriate, the<br />

amount of energy used can be reduced, along with factory <strong>emissions</strong>.

The recycling<br />

Process<br />

The European End-of-<br />

Life Vehicle Directive<br />

(Environmental Directive<br />

2000/ /EC) was adopted<br />

by the European Parliament<br />

and Council on September 18, 2000, to improve<br />

the recycling and recovery of ELVs, and<br />

to increase the environmental performance of all<br />

economic players in the processing chain. Since<br />

then, all EU Member States have enacted laws<br />

to implement this Directive.<br />

designing for recycling<br />

In order to simplify the dismantling process, <strong>Toyota</strong><br />

designed a new ‘Easy to Dismantle Mark’.<br />

This mark is added to vehicle parts clearly indicating<br />

certain points that assist in initial dismantling,<br />

such as the positions at which large resin<br />

parts can be easily separated and the locations<br />

at which holes can be drilled for removing fuel.<br />

Cars contain plastics that are hard to recycle.<br />

<strong>Toyota</strong> has therefore developed a special recyclable<br />

plastic called <strong>Toyota</strong> Super Olefin Polymer,<br />

or TSOP, that can be used to make car bumpers<br />

and other parts which can then be recycled<br />

many times over.<br />

IDIS, a practical tool<br />

to dismantle cars<br />

Pioneer Recycling<br />

Plant in Japan<br />

Using shredder<br />

residue effectively<br />

Automobile Recycling<br />

Technical Centre<br />

<strong>Toyota</strong> Prius battery<br />

recycling system<br />

Eco-VAS ‘design<br />

with care’<br />

DISPOSAL<br />

Replacement<br />

remanufactured<br />

parts<br />

Build recoverability<br />

into design<br />

LOPM<br />

DEVELOPMENT PRODUCTION<br />

RECYCLING<br />

RECYCLING<br />

CAR<br />

CAR<br />

USE<br />

Dealer waste<br />

collection system<br />

Design for recycling<br />

Rubber recycling<br />

and reuse<br />

Application of<br />

recycled materials<br />

Greening spare parts<br />

Batteries, tyres, and oil filters all need to be replaced<br />

during a vehicle’s lifetime. <strong>Toyota</strong> has<br />

therefore set up a waste collection system that<br />

retrieves used parts from European dealers and<br />

sends them back for recovery. In addition, <strong>Toyota</strong>’s<br />

remanufactured parts offering now includes<br />

air conditioning compressors, power steering<br />

racks, cylinder heads, starters, automatic transmissions,<br />

alternators, engines and clutch kits.<br />

substances of concern<br />

Lead, together with Mercury, Cadmium and<br />

Hexavalent Chromium, are heavy metals that<br />

cause long-term damage to the environment if<br />

buried unprocessed in landfills. In line with the<br />

year 2000 European Union directive on End-of-<br />

Life Vehicles which limits the use of these Substances<br />

of Concern (SoCs) in materials and vehicle<br />

components starting in 200 , <strong>Toyota</strong> now<br />

uses a number of <strong>zero</strong>-lead car parts and anticorrosion<br />

coatings, mercury-free lighting and<br />

switches, and asbestos-free friction materials<br />

and engine gaskets. It also avoids SoCs in various<br />

kinds of paints and in solvents.<br />

Resin recycling<br />

and reuse<br />

19

20<br />

the end is a new beginning<br />

<strong>Toyota</strong> has created a dedicated Automobile Recycling<br />

Technical Centre in Japan to experiment<br />

with new techniques for dismantling vehicles for<br />

recovery. This has resulted in the construction<br />

of an operational Automobile Shredder Residue<br />

Recycling Plant which in 2001 achieved <strong>Toyota</strong>’s<br />

voluntary goal of developing the technology for<br />

a commercial system to achieve a high recovery<br />

rate for component materials.<br />

Once Europe’s end-of-life cars have been shredded<br />

to extract usable materials, they still leave<br />

2 million tonnes of residue behind. Traditionally<br />

this has been buried in landfill or incinerated. But<br />

the European ELV and Landfill Directives now in<br />

force limit the use of this solution.<br />

Plastic recycled from<br />

polypropylene is used in<br />

four separate parts.<br />

Recycled plastic for the<br />

bumper, instrument panel<br />

and other coverings.<br />

In Japan, <strong>Toyota</strong> has<br />

developed ways of using<br />

certain foam products<br />

found in vehicle<br />

residue to create recycled<br />

soundproofing<br />

products. Thanks to<br />

the high-quality characteristics<br />

of automotive glass, powdered glass<br />

from shredder residue is recycled into tiles for<br />

use in landscaping pavement.<br />

Shredder residue that cannot be recycled can<br />

nevertheless be melted down into extremely<br />

small packs for landfill, reducing once more the<br />

environmental impact of vehicles on future generations.<br />

<strong>Toyota</strong> Avensis<br />

and the 3 Rs<br />

Two parts use plastic<br />

recycled from<br />

production waste.<br />

Renewable materials<br />

(recycled cotton and wool)<br />

for sound absorption and<br />

insulation.

The next horizon<br />

Cars have benefited society for over a century. During this time, car makers have<br />

explored a variety of technologies, and fine-tuned the internal combustion engine into<br />

the high-performance machine we know today. For <strong>Toyota</strong>, the automobile’s future will<br />

be dedicated to improving relations between cars, people and the environment.<br />

<strong>Toyota</strong> has promised to<br />

achieve sustainable mobility.<br />

And our company is<br />

well recognised for its<br />

innovative products<br />

and technologies.<br />

<strong>Toyota</strong> is developing<br />

these advanced<br />

technologies in order<br />

to protect the<br />

environment, and<br />

ensure its continued<br />

growth. Our company<br />

recognises the link between<br />

mobility, a sustainable<br />

environment and economic<br />

growth, and believes that<br />

the growth of our business depends on<br />

the success of sustainable mobility.<br />

Through the concepts it builds today for<br />

tomorrow’s society, <strong>Toyota</strong> is seeking to<br />

expand the scope of personal mobility while<br />

ensuring minimal environmental impact. For<br />

example, <strong>Toyota</strong> has developed the i-swing,<br />

a personal, light-weight mobility vehicle that<br />

creates a seamless transformation between<br />

vehicle and human movement. The batterypowered<br />

i-swing minimizes occupied space<br />

and energy consumption with its ultra compact<br />

size, operating in two-wheel mode when<br />

moving among people in the city and switching<br />

21

22<br />

to three-wheel mode on the road with other vehicles. The driver of the<br />

i-swing can remain in permanent contact with their vehicle through a mobile<br />

phone or a PC, bringing personal mobility to another level.<br />

Beyond its product range, <strong>Toyota</strong> recognises the importance of good<br />

corporate citizenship and is taking concrete steps to positively impact<br />

European society.<br />

In 2002, our company established a fund – the <strong>Toyota</strong> Fund for Europe – to<br />

enhance its good corporate citizenship through social contribution activities<br />

in Europe. The strategic focus of this Fund is linked to our core corporate<br />

sustainability challenges: environment, road safety and technical education.<br />

<strong>Toyota</strong>’s advanced technologies already provide a proven new platform<br />

for building an even wider range of cleaner and more<br />

fuel-efficient engines, while offering an<br />

enticing driving experience.<br />

And other technologies such<br />

as fuel cells promise longterm<br />

alternatives for specific<br />

applications.<br />

With its effective production<br />

methods, leading technology<br />

and constant attention to<br />

customer requirements, <strong>Toyota</strong><br />

is developing many solutions to<br />

the global challenge of sustainable<br />

mobility.<br />

RAiSinG<br />

EnViROnmEnTAl<br />

AwAREnESS<br />

ThROUGh ThE<br />

TOYOTA FunD<br />

FOR EuROPE:<br />

Green pack<br />

Since 2000, <strong>Toyota</strong> has<br />

supported the Regional<br />

Environmental Center for Central<br />

and Eastern Europe in the<br />

development and production of<br />

the Green Pack – a unique multimedia<br />

environmental education<br />

kit designed to be used by<br />

schools.<br />

schools for sustainable<br />

development<br />

In 200 , <strong>Toyota</strong> Europe launched<br />

the Schools for Sustainable<br />

Development programme in<br />

partnership with the NGOs<br />

Groundwork UK and the<br />

Environmental Partnership<br />

(CE Europe). The project <strong>aim</strong>s<br />

to promote local community<br />

environmental actions by giving<br />

schools the opportunity to<br />

make improvements in their<br />

neighbourhoods.<br />

Eco-schools<br />

This project, rolled out in<br />

Western Europe, is <strong>aim</strong>ed at<br />

promoting innovation in schools´<br />

environmental problem solving,<br />

through the awarding of grants<br />

projects on sustainable mobility.

Genchi Genbutsu<br />

“Going to the source to find the facts to make correct decisions,<br />

build consensus and achieve goals.”

<strong>Toyota</strong> Motor Europe<br />

Corporate Affairs<br />

Avenue du Bourget 60 - 1140 Brussels, Belgium<br />

Tel. +32 2 745 21 11 / Fax +32 2 745 20 68<br />

e-mail: pr@toyota-europe.com<br />

www.toyota.eu<br />

This report has been printed on CyclusPrint © paper, produced with 100% recycled pulp and without the use of OBA (Optical Bleaching Agent).