JOURACA_SP_2017

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

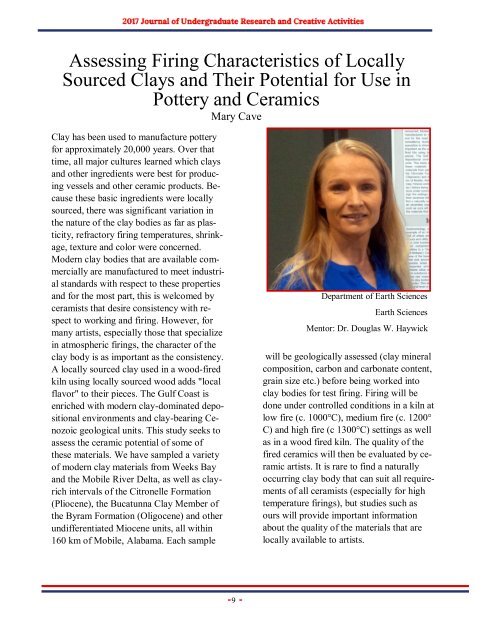

Assessing Firing Characteristics of Locally<br />

Sourced Clays and Their Potential for Use in<br />

Pottery and Ceramics<br />

Mary Cave<br />

Clay has been used to manufacture pottery<br />

for approximately 20,000 years. Over that<br />

time, all major cultures learned which clays<br />

and other ingredients were best for producing<br />

vessels and other ceramic products. Because<br />

these basic ingredients were locally<br />

sourced, there was significant variation in<br />

the nature of the clay bodies as far as plasticity,<br />

refractory firing temperatures, shrinkage,<br />

texture and color were concerned.<br />

Modern clay bodies that are available commercially<br />

are manufactured to meet industrial<br />

standards with respect to these properties<br />

and for the most part, this is welcomed by<br />

ceramists that desire consistency with respect<br />

to working and firing. However, for<br />

many artists, especially those that specialize<br />

in atmospheric firings, the character of the<br />

clay body is as important as the consistency.<br />

A locally sourced clay used in a wood-fired<br />

kiln using locally sourced wood adds "local<br />

flavor" to their pieces. The Gulf Coast is<br />

enriched with modern clay-dominated depositional<br />

environments and clay-bearing Cenozoic<br />

geological units. This study seeks to<br />

assess the ceramic potential of some of<br />

these materials. We have sampled a variety<br />

of modern clay materials from Weeks Bay<br />

and the Mobile River Delta, as well as clayrich<br />

intervals of the Citronelle Formation<br />

(Pliocene), the Bucatunna Clay Member of<br />

the Byram Formation (Oligocene) and other<br />

undifferentiated Miocene units, all within<br />

160 km of Mobile, Alabama. Each sample<br />

Department of Earth Sciences<br />

Earth Sciences<br />

Mentor: Dr. Douglas W. Haywick<br />

will be geologically assessed (clay mineral<br />

composition, carbon and carbonate content,<br />

grain size etc.) before being worked into<br />

clay bodies for test firing. Firing will be<br />

done under controlled conditions in a kiln at<br />

low fire (c. 1000°C), medium fire (c. 1200°<br />

C) and high fire (c 1300°C) settings as well<br />

as in a wood fired kiln. The quality of the<br />

fired ceramics will then be evaluated by ceramic<br />

artists. It is rare to find a naturally<br />

occurring clay body that can suit all requirements<br />

of all ceramists (especially for high<br />

temperature firings), but studies such as<br />

ours will provide important information<br />

about the quality of the materials that are<br />

locally available to artists.<br />

9