Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

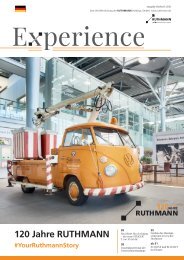

MESSAGE FROM THE MANAGEMENT<br />

TBR 250 – HAS NOW ARRIVED<br />

... THIS MONUMENTAL FEAT WAS ACHIEVED<br />

THROUGH RUTHMANN’S INTERNALLY<br />

DESIGNED “WEIGHT WATCHER” PROJECT.<br />

| 4

MESSAGE FROM THE MANAGEMENT<br />

pictured: (f.l.t.r.) Uwe Strotmann, Rolf Kulawik, Uwe Stapper and Nico Krekeler<br />

Dear customers, business partners, and readers,<br />

The fourth <strong>Experience</strong> edition will be available in time for APEX <strong>2017</strong> in Amsterdam<br />

Introducing our customers to the newest developments – the STEIGER® TBR 250 and ECOLINE RS 240<br />

this time around – has already become a real tradition.<br />

As promised, we will once again be unveiling revolutionary innovations<br />

The following pages not only describe these innovations in greater detail but you will also find a lot<br />

of interesting information about our RUTHMANNSTEIGER®, CARGOLOADER®, and ECOLINE/BLUELIFT<br />

product lines.<br />

<strong>2017</strong> has been an extremely busy and successful year for us so far. We would like to thank our customers<br />

for the many orders they have placed. We are deeply committed to providing the best products and service<br />

available in the industry.<br />

RUTHMANN customers can look forward many interesting developments for the remainder of the year.<br />

That’s a promise!<br />

Your RUTHMANN management team<br />

| 5

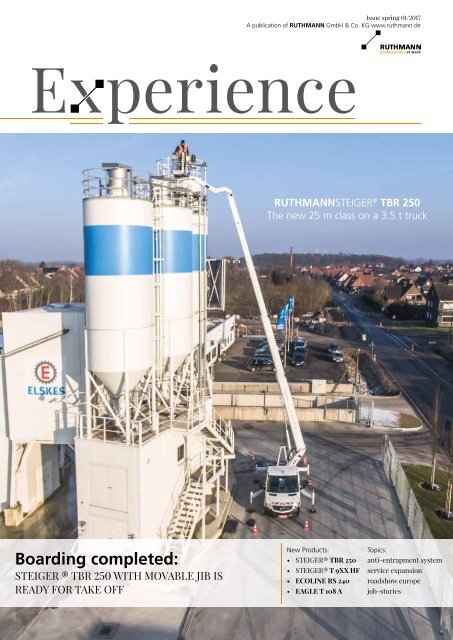

COVER STORY<br />

chassis, EURO 6 chassis in the<br />

3.5 t category are now heavier<br />

than ever before The brand new<br />

STEIGER® TBR 250 fulfils all of<br />

the abovementioned<br />

requirements. This monumental<br />

feat was achieved through our<br />

internally designed “weight<br />

watcher” project. The<br />

revolutionary “space-frame<br />

design” tower and multi-beveled<br />

telescopic boom have also been<br />

optimized.<br />

Our new model – featuring a<br />

boom system made of high tech,<br />

fine-grained steel and movable<br />

jib (RÜSSEL®) – is able to<br />

provide a remarkable 24.5 m<br />

working height. It can be driven<br />

by anyone with a valid B/3<br />

passenger car driver’s license.<br />

Substitute for 7.49 t<br />

The STEIGER® TBR 250 is the<br />

ideal substitute for aerial work<br />

platforms with similar working<br />

heights in the 7.49 t category.<br />

With its 230-kg basket load<br />

capacity, 185° jib (RÜSSEL®)<br />

swiveling range, and 5° permissible<br />

setup inclination, this exciting,<br />

new model has what it takes to<br />

carry out daily tasks with<br />

maximum efficiency.<br />

Its innovative boom system, with<br />

internal telescopic cylinders and<br />

power supply, provides an<br />

amazing 16.5 m lateral outreach<br />

at 100 kg basket load.<br />

The 2 x 85° basket rotation<br />

mechanism and innovative<br />

slip-resistant aluminum floor<br />

and steps, have further enhanced<br />

the level of efficiency and safety<br />

on this STEIGER ® model.<br />

This innovative truck-mounted<br />

aerial work platform also features<br />

a convenient and extremely<br />

practical interchangeable work<br />

basket system. Operators can<br />

use either the aluminum or<br />

synthetic basket, depending on<br />

the assignment. With the doubleinsulated<br />

synthetic basket and<br />

standard secondary “boom to<br />

chassis” insulation, assignments<br />

can safely be carried out on live<br />

(to 1000V) power lines. The<br />

control panel – known as the<br />

COCKPIT – is also available on<br />

this model. It is another example<br />

of technological perfection at its<br />

finest. Our time-tested, ultramodern<br />

control technology is<br />

incorporated in the COCKPIT<br />

for easy, safe, and intuitive<br />

STEIGER® operation.<br />

Sustainability is underpinned by<br />

the many identical parts found<br />

on STEIGER® models in the TB/<br />

TBR series. This modular concept<br />

offers our customers many<br />

advantages when it comes to<br />

maintenance, repair, and parts<br />

availability,<br />

Chassis factor<br />

The TBR 250 can me mounted<br />

onto a variety of different trucks.<br />

In the 3.5 t category alone,<br />

customers can choose either the<br />

Mercedes-Benz Sprinter, Nissan<br />

Capstar, Renault, or Iveco Daily.<br />

Other customer wishes –<br />

including all-wheel drive and/or<br />

chassis with greater payload<br />

capacity – are optionally available<br />

in higher weight categories. The<br />

short wheelbase featured on this<br />

new STEIGER® model, facilitates<br />

easy handling in cramped and<br />

congested inner-city traffic<br />

conditions handling. •<br />

Incredible<br />

lateral outreach,<br />

sturdy, versatile,<br />

and agile…are<br />

just some of the<br />

attributes that have<br />

captivated<br />

RUTHMANN<br />

STEIGER® TBR 250<br />

customers since<br />

sales were<br />

launched at the<br />

end of 2016.<br />

| 7

T 9XX HF<br />

62°<br />

72°

T 9XX HF

BLUELIFT<br />

advantageous when working on<br />

sensitive floors (non-marking<br />

rubber tracks are available) but<br />

also when carrying out<br />

assignments on unpaved surfaces.<br />

The SA 11 is so light that it can be<br />

towed on standard trailers. No<br />

trucks necessary! Many types of<br />

passenger cars (with hitches) are<br />

able to do the job.<br />

The BLUELIFT SA 11 has so many<br />

other beneficial features. The<br />

SA 11 is the newest and smallest<br />

model in the BLUELIFT trackdrive<br />

product line. With the<br />

addition of the SA 11,<br />

RUTHMANN now offers<br />

professional track-drive<br />

platforms with working heights<br />

that range from 11 m to 26 m. All<br />

models in this series are ultracompact<br />

and the various types<br />

of motors available are based on<br />

user experience and customer<br />

preferences.<br />

RUTHMANN provides the best<br />

after-sales service in the industry<br />

and the BLUELIFT track-drive<br />

product line, is no exception.<br />

The company-owned service<br />

centers, more than 100 service<br />

employees, and many mobile<br />

workshops (Servicepoints)<br />

guarantee the highest levels of<br />

customer satisfaction. Of<br />

course, our excellent spare parts<br />

distribution center in<br />

Gescher-Hochmoor (Germany)<br />

also plays a major role. •<br />

Safe working conditions<br />

for BLUELIFT operators<br />

RUTHMANN PRESENTS THE<br />

“ANTI-ENTRAPMENT SYSTEM”<br />

The fundamental goal of RUTHMANN BLUELIFT track-drive work<br />

platforms: maximum safety when working up high. A newly<br />

developed system will further enhance the level of safety at the job<br />

site.<br />

It is unfortunate that work-platform<br />

related accidents, resulting in<br />

personal injury, continue to occur.<br />

Operators in the work basket risk<br />

getting squished between objects<br />

such as branches and steel beams.<br />

RUTHMANN has taken it upon itself<br />

to avoid these types of accidents.<br />

In order to prevent mishaps of this<br />

kind, BLUELIFT customers will<br />

soon be able to order the optional<br />

and innovative “anti-entrapment<br />

system”. A cross brace with touchsensors<br />

– mounted in front of the<br />

control panel in the work basket –<br />

immediately halts all work platform<br />

movements as soon as a touch is<br />

applied. In the first two seconds, the<br />

boom instantly lowers and retracts<br />

itself automatically. In most cases,<br />

the operator is able to free himself<br />

within those initial two seconds.<br />

Should the touch on the cross brace<br />

continue, the controls in the work<br />

basket are cutoff completely and a<br />

visual and audible alarm is sounded.<br />

This is essentially a cry for help and<br />

warns co-workers or passersby of<br />

the emergency. Operators in the<br />

work basket can then receive<br />

immediate attention/first aid.<br />

In case it was shut down<br />

inadvertently, it is important that<br />

the work platform can resume<br />

cross brace<br />

When a touch is applied to the grey cross brace<br />

above the control panel, the controlled movements<br />

of the work platform are automatically deactivated.<br />

The safety mechanism also triggers an optical and<br />

audible alarm to let others know that the operator is<br />

in danger and requires help.<br />

normal operation as quickly as<br />

possible. RUTHMANN’s simple<br />

reset gets things up and running<br />

again in no time.<br />

The anti-entrapment system is an<br />

optional safety system, which in no<br />

way exempts the owner/operator of<br />

complying with standard safety<br />

regulations. Safety instructions<br />

must be adhered to and implemented<br />

at all times. •<br />

| 11

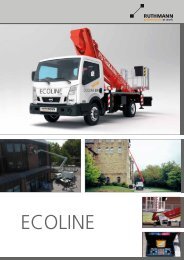

ECOLINE<br />

First Italian RUTHMANN truck-mount<br />

innovation:<br />

THE ECOLINE<br />

RS 240<br />

A year after founding<br />

RUTHMANN Italia S.r.l., the<br />

first new model is making its<br />

debut at the APEX <strong>2017</strong> trade<br />

show in Amsterdam. This new<br />

model is a truck-mounted<br />

articulated work platform<br />

(articulating boom lift truck) on<br />

a 3.5 t chassis. With a working<br />

height of almost 24 m, the new<br />

ECOLINE RS 240 is now the top<br />

model in the thrifty, “lowbudget”<br />

product line.<br />

The working height exceeds the<br />

previous 20 m limit. Customers<br />

at home and abroad have always<br />

wanted an economical alternative<br />

with greater working height on a<br />

3.5 t chassis.<br />

We have responded to this need<br />

by developing a compact,<br />

high-performance model, which<br />

– in addition to the 23.6 m<br />

working height – has so much<br />

more to offer.<br />

Let’s start at the bottom. The<br />

horizontal/vertical support<br />

mechanism is fully variable. The<br />

swiveling range of the turret can<br />

optionally be increased from<br />

360° to 440° (2 x 220°). The<br />

articulating telescopic boom<br />

system – typical for models in<br />

this category – is extremely<br />

sturdy because it is made of<br />

fine-grained steel. The large,<br />

standard aluminum basket (1.3 m<br />

x 0.7 m in size) can rotate 90°<br />

and comes with a 230 V power<br />

supply. The top-quality Hetronic<br />

control system provides safe,<br />

easy, and intuitive handling.<br />

End-position cushioning of the<br />

upper boom and the automatic<br />

start-stop function of the vehicle’s<br />

motor, nicely round off the<br />

many features found on the new<br />

and exciting ECOLINE RS 240.<br />

The “home” function and<br />

automatic set-up/retraction<br />

mechanism are among the other<br />

features optionally available.<br />

The RUTHMANNECOLINE RS<br />

240 – when mounted on a 3.5 t<br />

Nissan Cabstar chassis, for<br />

example – is just 6.91 m long<br />

and 2.56 m high. It is therefore<br />

ideal for assignments in cramped<br />

inner city conditions. However,<br />

because of the short overhangs<br />

in the front and rear of the<br />

vehicle – resulting in larger<br />

approach/departure angles – the<br />

RS 240, in a sense, can also be<br />

characterized an off-road<br />

vehicle<br />

The ECOLINE RS 240 also has<br />

an extraordinary 250-kg basket<br />

load capacity. The lateral outreach<br />

is an amazing 11.4 m at 100 kg,<br />

9.1 m at 200 kg, and 8.3 m at<br />

250 kg.<br />

As with all the other models in<br />

its various series, RUTHMANN<br />

provides ECOLINE RS 240<br />

customers with the best<br />

after-sales service in the entire<br />

work platform industry. The<br />

comprehensive network of<br />

service centers and mobile<br />

workshops are unparalleled in<br />

the low-budget sector. Spare<br />

parts are stocked at the central<br />

warehouse in Gescher-<br />

Hochmoor, Germany. Regardless<br />

of where they are – in Germany<br />

or other parts of the world –<br />

RUTHMANN customers never<br />

have to wait long for parts. •<br />

| 12

ECOLINE<br />

ECOLINE models for Germany<br />

Low budget truck mounts by RUTHMANN<br />

Since the beginning of the year,<br />

more equipment rental<br />

companies have taken delivery<br />

of their very first RUTHMANN<br />

ECOLINE truck mount.<br />

The companies are:<br />

Berning Mietservice (Nordwalde),<br />

Arbeitsbühnenvermietung<br />

Buchtmann (Delmenhorst),<br />

Staufen Baumaschinen Göppingen<br />

und Jens-Karl Lange Industriewartung<br />

AG (Wulften)<br />

The reasons are obvious:<br />

Excellent price-performance<br />

ratio coupled with the best<br />

customer service in the industry.<br />

RUTHMANNSERVICE! •<br />

Equipment rental company – Staufen Baumaschinen<br />

GmbH – is happy to have an ECOLINE 180 in its<br />

rental fleet.<br />

Berning Mietservice from Nordwalde has enhanced its<br />

rental line-up with the ECOLINE 180. From left to right:<br />

Mr. Brueggemann, Mr. Linderskamp, Mr. Scheipers, and<br />

Mr. Olthoff.<br />

| 13

ROADSHOW PART 1<br />

Roadshow<br />

Positive summary from all<br />

across Europe<br />

Over the past few weeks we have been travelling throughout Europe presenting our comprehensive<br />

product portfolio of working platforms to our customers and interested parties.<br />

We have significantly expanded<br />

our range with the BLUELIFT<br />

spider platforms and the<br />

ECOLINE low-budget truck<br />

platforms. In addition, the<br />

various new STEIGER® models<br />

of course add to our<br />

RUTHMANN innovation<br />

campaign. Most notable are the<br />

3.5 t STEIGER® TBR 250 and TB<br />

290 as well as the newest<br />

HEIGHT performance STEIGER®<br />

T650 HF and T 750 HF.<br />

Consequently, there were and<br />

are ample reasons and<br />

opportunities to make<br />

appointments with potential and<br />

existing customers in order to<br />

discuss new developments and<br />

analyse their requirements.<br />

No matter in which region or<br />

target group we were travelling<br />

through, our guarantee for<br />

success is not just our new,<br />

innovative working platforms<br />

which were developed based on<br />

customer requirements. It also<br />

includes the quality, functionality,<br />

intuitive usability and high<br />

resale value of our machines.<br />

Finally, our success is also based<br />

on customer satisfaction after<br />

purchase. We are happy to<br />

receive constant (inter)national<br />

confirmation that our after-sales<br />

service is better than average in<br />

comparison to that of our<br />

competitors. The availability of<br />

qualified service employees, an<br />

exemplary service hotline that is<br />

free of charge and a proper<br />

parts supply with the best<br />

delivery rate are cited as the<br />

reasons why existing customers<br />

continue to order from us.<br />

Customer statements: “Even for<br />

machines that are older than<br />

15 years you delivered spare<br />

parts within 24 hours.<br />

Impressive!” demonstrates both<br />

our service level and the lifespan<br />

of our machines at the same<br />

time. The fact that we do not rest<br />

on these laurels is documented<br />

in our report on the multimillion<br />

SERVICE expansion<br />

campaign which has been<br />

running since a long time and<br />

will continue to do so. After all,<br />

we want to make the best<br />

service in the industry even<br />

better.<br />

| 14

GLOBAL NEWS<br />

FIRST ECOLINE TRUCK-MOUNTED<br />

AERIAL WORK PLATFORM FOR THE<br />

CZECH REPUBLIC<br />

“ELEKTROLINE a.s.” is the first<br />

company in the Czech Republic<br />

to order one of our new ECOLINE<br />

truck-mounted aerial work<br />

platforms. The prominent,<br />

international company develops,<br />

produces, installs, and maintains<br />

traffic engineering technology<br />

(overhead contact line components,<br />

signaling systems, etc.) on trolley<br />

buses, tramways, and<br />

railway systems.<br />

“ELEKTROLINE a.s.”<br />

employees now have an<br />

ECOLINE RS 200 –<br />

mounted on a Nissan<br />

Cabstar 3.49 t chassis –<br />

to help them carry out<br />

their multi-faceted<br />

assignments. •<br />

Picture: Konnex Trade<br />

FIRST HEIGHT PERFORMANCE<br />

STEIGER ® ON THE JOB IN BULGARIA<br />

There is a wide variety of heavy<br />

equipment – including bucketwheel<br />

and bucket chain<br />

excavators – operating at the<br />

Mini Maritsa Iztok open-pit<br />

lignite (brown coal) mine in<br />

Bulgaria.<br />

To facilitate the smooth and<br />

efficient production process,<br />

these huge machines require<br />

constant care and maintenance.<br />

Professional truck-mounted<br />

aerial work platforms – like<br />

those in our HEIGHT<br />

performance STEIGER®<br />

series – are ideal for<br />

these types of assignments.<br />

Since the beginning of<br />

the year a HEIGHT performanceSTEIGER®<br />

T<br />

400 model has now been<br />

in operation at the lignite<br />

mine in Bulgaria. It is in<br />

operation assisting employees<br />

with intra-company<br />

maintenance and installation<br />

tasks on technical equipment.<br />

Picture: Sava Dimitrov, Manager Bulaccess ltd.<br />

Ongoing inspection work is<br />

primarily carried out on weld<br />

seams, fittings/screw connections,<br />

wires, and cable systems. •<br />

JANNENISKA AT THE VERKOSTO TRADE<br />

SHOW IN TAMPERE, FINLAND<br />

For the first time ever, our Nordic<br />

equipment rental customer<br />

– Janneniska – had its very own<br />

stand at the recently held<br />

"Verkosto Trade Show" (the<br />

event highlights the latest<br />

products, trends, and developments<br />

in the electricity and<br />

telecommunication industries).<br />

Professional visitors and<br />

magazine journalists from near<br />

and far were captivated<br />

by the outstanding<br />

performance capabilities<br />

and versatility of the<br />

company’s STEIGER®<br />

TB 270+. Janneniska also<br />

presented a VERSALIFT®<br />

work platform, mounted<br />

on a VW pick-up truck.<br />

•<br />

Picture: Axel Rask/Time Danmark A/S<br />

| 16

WORLD PREMIERE<br />

FOR THE AMERICAN MARKET<br />

GLOBAL NEWS<br />

Following more than a year of preparation, RUTHMANN and Texas based ReachMaster Inc. are<br />

launching a new truck-mounted lift as the result of a new cooperation between our companies.<br />

Further presentations at the american east coast.<br />

The RUTHMANN Eagle T 108 A<br />

is aimed at the 100+ ft. market<br />

for professionals and can be<br />

driven with a standard American<br />

driver’s license as the unit is<br />

below the CDL* requirements<br />

with a total weight of only<br />

26,001 lbs.<br />

The new unit offers a vertical<br />

work height of 108 ft. and 69<br />

horizontal reach with a 700 lbs.<br />

basket capacity. The lift system<br />

– which is taken from<br />

RUTHMANN’s well-known and<br />

award winning “STEIGER® T<br />

330 HV” line-up - is a 108ft<br />

straight telescopic boom with a<br />

jib arm. The multi-beveled<br />

boom provides incredible<br />

strength and stability, combined<br />

with RUTHMANN ’s highly<br />

* CDL = commercial driver licence<br />

applauded RUTHMANN COCKPIT.<br />

An innovative operational control<br />

system with strong emphasis on<br />

intuitive operation and an informative<br />

full-color display panel,<br />

guiding the operator through<br />

every step of safe operation.<br />

The lift system is shipped<br />

complete from Germany to<br />

ReachMaster Inc. in Texas,<br />

where it is mounted on the<br />

well-proven Ford F650 chassis,<br />

powered by a 6.7-liter Power<br />

Stroke Diesel mated to a<br />

6-speed automatic<br />

transmission.<br />

This unit is the first in a series<br />

of sub-CDL* units planned for<br />

the market under the Eagle<br />

name. As is common practice for<br />

ReachMaster Inc. as an exclusive<br />

specialty lift distributor, the<br />

products are market und their<br />

own brand name rather than a<br />

ReachMaster designation. •<br />

| 17

GLOBAL NEWS<br />

RUTHMANN DELIVERS<br />

ARTICULATED TELESCOPIC WORK<br />

PLATFORM KIT TO AUSTRALIA<br />

Low budget work platforms are gaining in popularity around the<br />

world. This is also the case in Australia. As part of a partnership<br />

between RUTHMANN and Australian work platform manufacturer<br />

– Niftylift – a smart, new approach has been adopted.<br />

The pre-assembled ECOLINE RS 200 boom<br />

system is being shipped from Italy to<br />

Australia where it will be mounted onto<br />

a locally popular truck.<br />

An ECOLINE RS 200 – primarily<br />

developed for European 3.5 t<br />

chassis – will soon be on<br />

assignment in Australia. Niftylift<br />

(Australia) will be mounting the<br />

kit version of the RS 200 onto a<br />

locally popular 4.5 t ISUZU truck.<br />

RUTHMANN is delivering the<br />

ECOLINE RS 200 almost in its<br />

entirety from slew bearing to<br />

work basket, including the<br />

hydraulic, electric, and<br />

control technology.<br />

Niftylift is providing the chassis<br />

for the work platform and will<br />

also develop the appropriate<br />

base frame and stabilizers. •<br />

The ECOLINE RS 200 has compact overall<br />

dimensions. Niftylift is constructing a base<br />

frame with stabilizers for the RS 200 kit from<br />

Italy.<br />

Picture: Kamphuis Arbeitsbühnen-Vermietung<br />

KAMPHUIS – THE DUTCH EQUIPMENT RENTAL COMPANY –<br />

RELIES ON STATE-OF-THE-ART RUTHMANN TECHNOLOGY<br />

“Early adapter” and long-time<br />

business partner – Emiel<br />

Kamphuis – relies heavily on<br />

RUTHMANN’s most up-to-date<br />

STEIGER® developments. Just<br />

recently, Kamphuis took delivery<br />

of a T 750 HF and TB 290. Both<br />

models were ordered long<br />

before they made their debut on<br />

the world stage.<br />

With the current “world champ”<br />

on a 3.5 t chassis, Kamphuis has<br />

the most up-to-date truckmount<br />

technology that can be<br />

driven by anyone with a valid<br />

automobile driver’s license. The<br />

STEIGER® TB 290 offers<br />

Kamphuis rental customers a<br />

working height of almost 29 m.<br />

RUTHMANN’s innovative steel<br />

fabrication and calculation<br />

techniques provide performance<br />

capabilities that until recently,<br />

had only been available in much<br />

heavier truck categories. •<br />

The STEIGER ® TB 290 is the world‘s<br />

best-performing truck-mount on a<br />

3.5 t chassis.<br />

With a 230 km work basket capacity,<br />

there is enough room for 2 operators<br />

and tools.<br />

Kamphuis has provided one of the<br />

first photos of the STEIGER ® T 750 HF in action.<br />

The technicians – equipped with tools and<br />

materials – were safely able to carry out their<br />

installations with utmost efficiency.<br />

Emiel Kamphuis ordered RUTHMANN’s T 750 HF to carry out infrastructure<br />

projects in the Netherlands with maximum effectiveness. With its 75-m working<br />

height, the STEIGER ® T 750 HF provides maximum performance capabilities and<br />

boom agility on a 4-axle chassis.<br />

| 18

RUTHMANNSERVICE<br />

2016 Service-Center Competition<br />

OUR SERVICE TEAM IN GROSS-GERAU IS TWO-<br />

TIME WINNER<br />

Our annual Service Center<br />

competition was initiated years<br />

ago in order to evaluate the<br />

merits/performance of Station<br />

Managers and their respective<br />

service teams.<br />

For the second year in a row, the<br />

winner is Thomas Heil and his<br />

team from the Groß-Gerau (near<br />

Frankfurt) Service Center.<br />

Second place<br />

went to Station Manager,<br />

Christian Kauschke and his<br />

dedicated staff in Borkheide<br />

while our Service Center in<br />

Hochmoor, headed by Gerd<br />

Decker, placed third.<br />

In 2016, as in 2015, Thomas Heil<br />

and his team achieved the best<br />

overall results in our internal<br />

competition<br />

Congratulations to the winners. •<br />

For the second year in a row,<br />

Thomas Heil (pictured here with<br />

certificate) and his staff in<br />

Groß-Gerau placed first in our<br />

annual Service Center competition.<br />

SERVICEpoint for Lower Franconia<br />

Caption: Matthias Schmitt from the<br />

new “SERVICEpoint Unterfranken”<br />

(Lower Franconia) in front of his<br />

mobile workshop, equipped with<br />

essential spare parts and technical<br />

documentation.<br />

Our service expansion offensive<br />

is running at full speed. The<br />

solid service network in Germany<br />

is being expanded even<br />

further. With the new SERVICEpoint<br />

in Lower Franconia<br />

(Unterfranken), we now have<br />

18 locations in Germany and<br />

Austria.<br />

After some intensive induction<br />

training, our new co-worker<br />

– Matthias Schmitt – will carry<br />

out prompt and cost-effective<br />

safety inspections, maintenance,<br />

and minor repair work on<br />

RUTHMANNSTEIGER®,<br />

BLUELIFT, ECOLINE, and<br />

VERSALIFT® work platforms.<br />

Best of all, customers can take<br />

full advantage of Mr. Schmitt’s<br />

technical know-how right on<br />

their own premises. Our<br />

professional service personnel<br />

provide the best ON-SITE<br />

SERVICES in the industry.<br />

The SERVICEpoint Unterfranken<br />

(Lower Franconia) will be<br />

coordinated by our companyowned<br />

service center in<br />

Gross-Gerau. Mr. Schmitt’s work<br />

assignments are also dispatched<br />

from this location. •<br />

| 20

RUTHMANN<br />

SERVICE

RUTHMANNSERVICE<br />

New brands, new know-how<br />

RUTHMANN’S SERVICE PERSONNEL RECEIVE BLUELIFT<br />

AND ECOLINE TRAINING.<br />

Pictured here<br />

(from left to right):<br />

M. Jöhren, M. Thomas,<br />

G. Marti, and I. Casoli<br />

participating in a lively<br />

exchange of knowledge<br />

service technicians in Germany<br />

and Austria know these units<br />

thoroughly from top to bottom.<br />

Service technicians (f.l.t.r.) : J. Olthoff and F.J. Heisterkamp at the ECOLINE 180<br />

Over the past several months,<br />

our employees have received<br />

professional training in matters<br />

pertaining to the operation and<br />

characteristics of the<br />

RUTHMANNBLUELIFT and<br />

RUTHMANNECOLINE product<br />

lines. Training for our service<br />

employees was provided by our<br />

Italian subsidiary – RUTHMANN<br />

Italia S.r.l. The technical features<br />

and individual components were<br />

presented and analyzed on the<br />

machines themselves.<br />

RUTHMANNSERVICE stands for<br />

uncompromising work platform<br />

safety. Through ongoing service<br />

training, we aim to provide<br />

top-notch service, availability,<br />

and quality on a consistent<br />

basis. This guiding principle also<br />

applies to the BLUELIFT and<br />

ECOLINE product range. It is<br />

therefore imperative that our<br />

Gianni Marti (RUTHMANN<br />

ITALIA General Manager) and<br />

Ivan Casoli (RUTHMANN ITALIA<br />

Service and Development<br />

Manager) were extremely<br />

successful in providing the<br />

essential training for the<br />

ECOLINE and BLUELIFT<br />

product line.<br />

Incidentally, the RUTHMANN<br />

parts assortment now also<br />

includes spare parts for<br />

BLUELIFT and ECOLINE products.<br />

All orders placed by our<br />

global service partners are now<br />

filled centrally through our parts<br />

warehouse in Gescher-<br />

Hochmoor, Germany. •<br />

| 23

CARGOLOADER ®<br />

CARGOLOADER ® –<br />

FAST. VERSATILE, AND EFFICIENT!<br />

NEW: EURO 6<br />

requires no AdBlue<br />

The RCP 50.1 – which fully<br />

complies with the EURO 6<br />

emission standards – has a gross<br />

vehicle weight rating (GVWR)<br />

of 5 t.<br />

With a payload capacity of 2,230 kg,<br />

good can be transported and<br />

loaded/unloaded with maximum<br />

efficiency.<br />

The RCP 50.1 can also be ordered<br />

with a 3.5 t GVWR. It can then be<br />

driven by anyone with a valid<br />

class B automobile driver’s<br />

license. •<br />

NEW CO-WORKER IN OUR CARGOLOADER ® DIVISION<br />

Stephan Gebken - CARGOLOADER ®<br />

Southern Germany and Switzerland<br />

With Stephan Gebken, we have<br />

competent reinforcement in<br />

our CARGOLOADER® division.<br />

Mr. Gebken is the new customer<br />

adviser for Southern Germany<br />

and Switzerland. He gained his<br />

initial experience at<br />

RUTHMANN, having worked<br />

with us from 1992 to 2002.<br />

Trained as an industrial sales<br />

representative in<br />

Gescher-Hochmoor, Stephan<br />

Gebken also earned his degree<br />

in Business Management. He<br />

then honed his skills in the<br />

used-equipment sector and<br />

successful employment in sales.<br />

He also sold liftgates/hydraulic<br />

platforms for 10 years and<br />

worked in the logistics sector<br />

– focusing primarily on semitrailers<br />

for two years afterwards.<br />

Now Stephan Gebken is back<br />

with us at RUTHMANN. We are<br />

happy that our CARGOLOADER ®<br />

customers have a reliable and<br />

competent new professional to<br />

advise and assist them at every<br />

turn. Mr. Gebken is not only an<br />

expert in his field but is also<br />

completely familiar with customer<br />

wishes and requirements.<br />

Contact:<br />

Telephone: +49 2863 204-248<br />

E-mail:<br />

stephan.gebken@ruthmann.de<br />

•<br />

| 24

EXHIBITION REVIEW<br />

LogiMat <strong>2017</strong>: Stuttgart<br />

At the LogiMAT trade show – the biggest international trade fair<br />

for intralogistics solutions and process management – we had the<br />

chance to greet many customers and potential buyers.<br />

LogiMAT has had a very positive<br />

impact on our CARGOLOADER®<br />

product line over the past several<br />

years. The trend continues<br />

unabated in <strong>2017</strong>.<br />

The world-renowned trade fair<br />

– which took place in March<br />

<strong>2017</strong> – was well attended and<br />

our sales team was pleased with<br />

the many orders placed by our<br />

customers. At trade shows and<br />

presentations, our sales team is<br />

always able to explain the<br />

CARGOLOADER®’s operating<br />

principles particularly well.<br />

Our CARGOLOADER® RCP 50<br />

has a gross vehicle weight rating<br />

(GVWR) of 5 t and a maximum<br />

payload capacity of 2,230 kg. The<br />

model fully complies with the<br />

EURO 6 emission standards and<br />

requires no AdBlue (diesel<br />

exhaust fluid).<br />

Customers can also order the<br />

RCP 50 with a 3.5 t GVWR. It can<br />

then be driven by anyone with a<br />

valid class B automobile driver’s<br />

license. •<br />

CONEXPO <strong>2017</strong>: Las Vegas<br />

Every three years, international exhibitors and industry experts meet<br />

in Las Vegas to discover the newest technologies and innovations in<br />

the construction industry. This is the perfect chance to network with<br />

some of the biggest names in the sector but first and foremost, this<br />

world-renowned trade show is a golden opportunity for companies<br />

to present their product range to an international audience.<br />

We were one of 2,500 exhibitors at<br />

this exciting 5-day event. In<br />

keeping with this year's CONEXPO<br />

motto "Imagine what's next", we<br />

launched a brand-new innovation<br />

– the RUTHMANN EAGLE T 108<br />

A. This exciting new model is the<br />

result of a new cooperation with<br />

Texas based ReachMaster Inc..<br />

At our booth in the Gold lot, we<br />

greeted many curious visitors<br />

from across North America,<br />

equipment rental company reps,<br />

as well as end users (i.e. building<br />

façade cleaners, gardener/landscapers,<br />

etc.). Visitors really liked<br />

the fact that the Eagle T 108 A can<br />

be driven with a standard driver’s<br />

license. The enormous working<br />

height and lateral outreach,<br />

coupled with the narrow support<br />

mechanism, also turned a lot of<br />

heads. This is a comprehensive<br />

new package for the US market. In<br />

addition to the new EAGLE T 108<br />

A work platform, we also presented<br />

our RUTHMANN product portfolio.<br />

All in all, CONEXPO <strong>2017</strong> was a<br />

resounding success. We were also<br />

able to establish contacts in Latin<br />

America and further expand our<br />

network of business partners. •<br />

RUTHMANN EAGLE 108 A<br />

is directed at North American<br />

customers<br />

(See page 17)<br />

| 25

CHASSIS VARIATIONS<br />

STEIGER ® T series now with even<br />

more chassis to choose from<br />

T 330 on a Isuzu N-serial chassis<br />

With the addition of the Isuzu N<br />

series, we offer an even wider<br />

selection of chassis for our<br />

STEIGER® T series to 33 m.<br />

The first customer with a<br />

T 330 mounted onto an Isuzu,<br />

is Röttges GmbH from<br />

Mönchengladbach.<br />

Röttges GmbH in<br />

Mönchengladbach is a regional<br />

equipment rental company<br />

specializing in work platforms,<br />

truck cranes, and commercial<br />

vehicles. The company is also an<br />

Isuzu commercial vehicle partner.<br />

This would explain why Röttges<br />

decided to enhance its rental<br />

fleet with an Isuzu truck-mounted<br />

aerial work platform.<br />

STEIGER® T series customers –<br />

T 170 to T 330 – had already had<br />

a wide variety of different makes<br />

and models to choose from.<br />

Most opted for Mercedes-Benz<br />

and MAN trucks in the 7.49 t<br />

category. Now, the Isuzu N<br />

series has also been added.<br />

RUTHMANN also offers<br />

STEIGER® T series customers<br />

trucks with higher tonnage. If<br />

customers require a narrower<br />

support mechanism or considerably<br />

more payload capacity,<br />

Volvo, Scania, or DAF chassis are<br />

the perfect choice.<br />

According to the manufacturer,<br />

Isuzu N- series trucks in the 3.5 t,<br />

5.5 t, and 7.49 t categories are<br />

sturdy, well-made, and very<br />

reliable. They have a warpresistant,<br />

ladder-frame truck<br />

chassis and a high payload<br />

capacity. Isuzu makes<br />

economical, fuel-efficient, and<br />

powerful (up to 190 horsepower)<br />

engines (green environmental<br />

sticker). Isuzu trucks are<br />

equipped with all of the latest<br />

safety features and come with a<br />

3-year warranty. The small<br />

turning circle provides excellent<br />

mobility. Isuzu has features that<br />

customers need and want,<br />

making it the perfect alternative<br />

for RUTHMANNSTEIGER®.<br />

| 26

SPONSORING<br />

TRACK AND FIELD ATHLETES THANK RUTHMANN<br />

RUTHMANN is now the proud<br />

sponsor of the DJK Coesfeld<br />

track and field division. The<br />

team thanked RUTHMANN<br />

owner, Heinz-Jürgen Buss. DJK<br />

division leader – Fabian<br />

Dasbach – stated, “We really<br />

appreciate any support we get<br />

and are honored and proud to<br />

have RUTHMANN on our side.”<br />

From now on, the company’s<br />

30-meter long banner under the<br />

roof in the North Stadium, will<br />

be visible for all to see. •<br />

f. l.t.r.: Werner Rentemeister,<br />

RUTHMANN shareholder Heinz-Jürgen Buss<br />

Picture: DJK Coesfeld<br />

RUTHMANN was sponsor<br />

at K + K Cup <strong>2017</strong><br />

equestrian competition<br />

At the beginning of <strong>2017</strong>, the world-class K+ K Cup equestrian<br />

competition was held once again at the Münsterland Hall. We were<br />

there as sponsors.<br />

RUTHMANN has its roots in<br />

Germany’s Münsterland. The<br />

region is internationally known<br />

as the "Mecca of equestrian<br />

sports". At the K + K Cup <strong>2017</strong><br />

competition – an annual event<br />

in Münster – we not only<br />

sponsored this year’s Class S<br />

jumping competition but also<br />

handed out the special<br />

award-winning prize. It was not<br />

the rider with the fewest penalty<br />

points (faults) that won but the<br />

rider with the most creative<br />

costume. The winner – Jörg<br />

Oppermann with his show<br />

jumper, “Eckhart” – scored the<br />

most points and received a<br />

high-quality tablet as a reward. •<br />

When it comes to scoring higher, faster, and<br />

further, RUTHMANN is always the right choice.<br />

Pictured here: Show jumping rider, Johannes<br />

Baberg dressed as Stuart the Minion with his<br />

mare, “Daytona.” RUTHMANN’s obstacle/<br />

fence in the jumping course can be seen on the<br />

bottom right.<br />

Picture : Peperhowe (Allgemeine Zeitung,<br />

Coesfeld, 16.01.<strong>2017</strong>)<br />

| 29

RUTHMANN<br />

SERVICE

JOB-STORY<br />

A cut above:<br />

RUTHMANNSTEIGER ® T 360 ON<br />

TREE-CUTTING ASSIGNMENT IN BIELEFELD<br />

Picture: Varnholt, www.gruen-mit-system.de<br />

With its fully-variable support<br />

mechanism and 5°permissible set-up<br />

inclination, the T 360 can carry out<br />

assignments in rough and uneven<br />

terrain just as easily as in cramped and<br />

congested inner-city conditions.<br />

Picture: Varnholt, www.gruen-mit-system.de<br />

Varnholt – Grün mit System – from Gütersloh, offers customers a wide range of services. General<br />

Manager – Heiner Varnholt – and his dedicated staff are highly professional and competent<br />

“systematic green service” specialists. The company focuses on sustainable care and maintenance of<br />

parks, gardens, and other outdoor areas.<br />

Since August 2016, The Varnholt<br />

team has relied on our STEIGER ®<br />

T 360 to carry out assignments<br />

with utmost efficiency. Heiner<br />

Varnholt calls the company’s<br />

sturdy and compact truck<br />

mount, the “all-purpose work<br />

horse.” With the T 360, the<br />

Varnholt team can safely<br />

maneuver to high-up objects<br />

with great precision. Treecutting<br />

assignments in Bielefeld<br />

have never been easier.<br />

Heiner Varnholt made the following<br />

comment: “We are experts<br />

in our field and work systematically<br />

in every aspect of our<br />

business. In our line of work,<br />

proper know-how is just as<br />

important as having the right<br />

Pictured here from left to right: Varnholt employees, Ulrich Verleger, Arnd Bohlmann,<br />

and Robin Schlichting. Solid, compact, efficient, and extremely versatile:<br />

these are the characteristics attributed to the STEIGER ® T 360.<br />

| 32

T 750 HF<br />

First delivery of T 750 HF<br />

GERMAN CRANE RENTAL COMPANY – HÜFFERMANN<br />

KRANDIENST GMBH – LAUNCHES NEW RENTAL CATEGORY<br />

Our STEIGER® T 750 HF is<br />

making inroads into the crane<br />

industry. The T 750 HF – one of<br />

the innovative models in our<br />

(r)evolutionary HEIGHT<br />

performance large-scale series<br />

– has an enormous 75 m<br />

working height. It is therefore<br />

able to carry out assignments<br />

that most often require the<br />

deployment of truck-mounted<br />

cranes. We are pleased to<br />

accompany Hüffermann<br />

Krandienst as it enters the aerial<br />

work platform rental segment.<br />

Vertikal.net commented on the<br />

acquisition: “With the T 750 HF<br />

now in Hüffermann’s rental<br />

lineup, customers across<br />

Germany have immediate access<br />

to a new 75-m STEIGER® truckmounted<br />

lift. The T 750 HF is<br />

ideal for repair and maintenance<br />

assignments on tower silos,<br />

wind turbines, industrial towers,<br />

flare stacks at natural gas<br />

processing plants, etc. Other<br />

tasks include billboard<br />

installation, electricity pylon<br />

construction, high-up electrical<br />

work, building façade cleaning,<br />

and film recording.” •<br />

| 34

COMMITMENT<br />

Nominated for IAPA Award <strong>2017</strong><br />

RUTHMANNSTEIGER® T 510 HF CONTENDER IN LONDON<br />

The IAPA Awards (International<br />

Awards for Powered Access)<br />

– often referred to as the<br />

“Oscars” of the aerial work<br />

platform industry – are internationally<br />

renowned as the<br />

most prestigious and respected<br />

awards in the access industry.<br />

RUTHMANN won awards for 3<br />

consecutive years with our<br />

STEIGER® T 330, T 540, and<br />

T 720 models. Our STEIGER®<br />

T 510 HF – nominated at this<br />

year’s IAPA Awards in London,<br />

England – also picked up the<br />

Spanish Movicarga Award in<br />

2016. The T 510 HF features<br />

a record-breaking 51-m working<br />

height on a 2-axle chassis.<br />

Competitor models only offer 48<br />

m in this category.<br />

The prominent, annual event<br />

took place in London from April<br />

3rd – April 5th. We were not only<br />

there as a nominee but also<br />

participated in the IPAF Summit<br />

which was held at the same time.<br />

The IPAF Summit conference – a<br />

high-profile educational and<br />

networking event – brings<br />

together senior representatives<br />

from across the access<br />

community to discuss and<br />

debate the latest developments<br />

in the industry. Our role as<br />

“supporting sponsor” allowed us<br />

to endorse this all-important<br />

international event and<br />

underscored our global<br />

presence in the truck-mounted<br />

aerial work platform sector. •<br />

RUTHMANN factory shines brightly<br />

CONTINUATION OF THE ECOPROFIT<br />

PROGRAM<br />

Record breaking performance<br />

capabilities - on a 2-axle chassis<br />

We attach great importance to<br />

environmental management.<br />

This is why we are steadily<br />

adopting new measures to<br />

protect the environment.<br />

At the moment, we are replacing<br />

all factory lights with LED<br />

spotlights.<br />

The conversion started in<br />

factory area № 4 (paint shop<br />

and final assembly). HQL (mercury<br />

vapor) lights have been<br />

replaced with LED spotlights<br />

indoors and on the outside<br />

front. The advantages of the<br />

new lighting system are clear.<br />

The electricity consumption<br />

has been reduced by 50% – in<br />

part because the lighting<br />

intensity is automatically<br />

reduced on bright, sunny days.<br />

Optimized lighting in the workplace<br />

has also had a positive<br />

impact on RUTHMANN<br />

employees.<br />

The pilot project was so<br />

successful that the lighting in<br />

area № 3 (assembly and central<br />

warehouse) has also been<br />

converted. LED spotlights are<br />

currently being installed in<br />

area № 2 (service) and the wash<br />

bays in area № 3. •<br />

| 35

ROADSHOW PART 3<br />

FURTHER IN THE NORTH WE COME TO<br />

THE FINAL STATION OF OUR REPORT:<br />

GERMANY<br />

Before Easter, our sales manager<br />

for the Germany area, Volker<br />

Klinkisch, secured a brand-new<br />

model STEIGER® TBR 250 in<br />

order to present his customers<br />

with our newest innovation.<br />

The telescope STEIGER® with<br />

moveable jib, designed for 3.5 t<br />

Euro 6 chassis, reaches a<br />

working height of 24.5 m and has<br />

an outreach of 16.5 m. This<br />

makes it a real alternative to<br />

truck platforms with similar<br />

performance data which, until<br />

now, were only built on 7.49 t<br />

chassis. You can read more about<br />

the new STEIGER ® TBR 250 in<br />

another article in this<br />

<strong>Experience</strong> issue.<br />

Volker Klinkisch<br />

Area Sales Manager<br />

East Germany<br />

Mr Klinkisch’s existing customers,<br />

as well as potential new<br />

customers, displayed their<br />

enthusiasm. The boom system’s<br />

quick speed of movement was<br />

evaluated as entirely positive.<br />

Furthermore, the new<br />

STEIGER® was proven to have a<br />

secure operational feeling due to<br />

soft end cushioning and smooth,<br />

electronic basket levelling.<br />

However, the stability of the<br />

boom is what thrilled the test<br />

participants the most. The<br />

large-scale, multi-edged<br />

telescope boom is<br />

manufactured out of extremely<br />

strong, fine-grained steel. The<br />

concept, which has been tested<br />

for years in other series, also<br />

gives the new STEIGER®<br />

TBR 250 an extremely secure,<br />

yet stable operational feeling.<br />

Mr Klinkisch was pleased with<br />

the lively exchange on the topic<br />

of competitive comparison. It<br />

was heard from the customers<br />

that our STEIGER®, in<br />

comparison to other supplier<br />

models, is probably less likely to<br />

require maintenance and<br />

repairs. Our TBR 250 has one<br />

less telescope element, which<br />

Detailview: RUTHMANNSTEIGER ® TBR 250<br />

led to the recognition that the<br />

inboard power chain with<br />

hydraulic and electric cables<br />

should be less vulnerable in the<br />

middle and long run. The<br />

customers saw a further<br />

advantage in the choice of<br />

material for the boom.<br />

Customers reported on their<br />

negative experiences with<br />

aluminium boom, like those<br />

favoured by our competitors.<br />

| 36

IMPRINT<br />

visit RUTHMANN during the following<br />

exhibitions as well:<br />

24 th -25 th May <strong>2017</strong><br />

SILVERSTONE (Great Britain)<br />

13 th - 16 th June <strong>2017</strong><br />

BERN (Switzerland)<br />

08 th - 09 th September <strong>2017</strong><br />

HOHENRODA (Germany)<br />

05 th - 07 th October <strong>2017</strong><br />

PIACENZA (Italy)<br />

Imprint<br />

„<strong>Experience</strong>“; <strong>Issue</strong>: <strong>Spring</strong> 01/<strong>2017</strong><br />

Publisher:<br />

Ruthmann GmbH & Co. KG.<br />

Address:<br />

Von-Braun-Straße 4<br />

48712 Gescher-Hochmoor<br />

Germany<br />

Telefon: +49 2863 204-0<br />

Telefax: +49 2863 204-5312<br />

www.ruthmann.de<br />

info@ruthmann.de<br />

Editorial office:<br />

RUTHMANN Mediadienst COEmarketing GmbH,<br />

Coesfeld, www.coemarketing.de<br />

Photographic images:<br />

RUTHMANN GmbH & Co. KG, COEmarketing GmbH,<br />

Felbermayr , BRIESE Baumanagement GmbH, IPAF, Landschaftspark<br />

Duisburg Nord, Allgemeine Zeitung Coesfeld,<br />

DJK Coesfeld, Varnholt, Kamphuis Arbeitsbühnen-Vermietung,<br />

Konnex Trade, Bulaccess ltd., Time Danmark A/S<br />

Layout and typesetting:<br />

COEmarketing GmbH, Coesfeld, www.coemarketing.de<br />

Copy-editing and translation:<br />

COEmarketing GmbH, Coesfeld, www.coemarketing.de<br />

Print:<br />

Druckerei Lage, Borken, www.druckerei-lage.de<br />

| 38

RUTHMANNBLUELIFT SA 11<br />

<strong>Experience</strong>_GB_01<strong>2017</strong><br />

NEW<br />

RUTHMANN<br />

SERVICE<br />

RUTHMANNECOLINE RS 240<br />

NEW<br />

RUTHMANN GmbH & Co. KG | www.ruthmann.de