Experience issue 2023

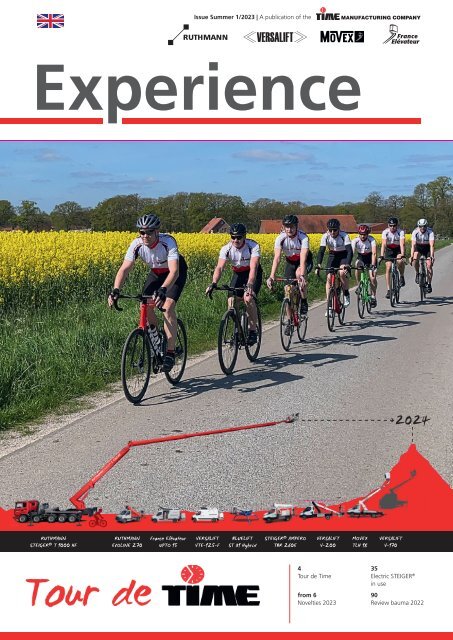

Dear customers, partners and readers, After the successful bauma 2022 in Munich, we are now also appearing in our Experience for the first time with all the new brands of the TIME Group. You will find 92 pages of news and information about the products of RUTHMANN, VERSALIFT, France Elévateur and MOVEX. With this issue, which we will launch at APEX 2023, we would also like to announce an outstanding new product: We are very pleased to present the new T 1000 HF on pages 4 - 5 as the goal of our “Tour de TIME” for 2024, with which RUTHMANN will again crack the 100-meter mark and offer the most innovative and flexible equipment in this class. You will certainly read a lot of outstanding things about this in the coming years. Not quite as high, but still just as great, are the other machines in this issue. Benefit from our Experience and read about the many positive experiences our customers have had with the new innovative electric drives and how well they work in practice. We would also like to take this opportunity to thank our colleagues who, with their innovative thinking, enjoyment of their work and outstanding personal commitment, continue to optimize our products and make them the best on the global market. We hope you enjoy reading this issue. Your TIME Management Team: Kim Bach Jensen (TIME Europe), Uwe Strotmann (RUTHMANN), Charles Goffin (France Elévateur)

Dear customers, partners and readers,

After the successful bauma 2022 in Munich, we are now also appearing in our Experience for the first time with all the new brands of the TIME Group. You will find 92 pages of news and information about the products of RUTHMANN, VERSALIFT, France Elévateur and MOVEX. With this issue, which we will launch at APEX 2023, we would also like to announce an outstanding new product: We are very pleased to present the new T 1000 HF on pages 4 - 5 as the goal of our “Tour de TIME” for 2024, with which RUTHMANN will again crack the 100-meter mark and offer the most innovative and flexible equipment in this class. You will certainly read a lot of outstanding things about this in the coming years. Not quite as high, but still just as great, are the other machines in this issue. Benefit from our Experience and read about the many positive experiences our customers have had with the new innovative electric drives and how well they work in practice. We would also like to take this opportunity to thank our colleagues who, with their innovative thinking, enjoyment of their work and outstanding personal commitment, continue to optimize our products and make them the best on the global market. We hope you enjoy reading this issue.

Your TIME Management Team:

Kim Bach Jensen (TIME Europe), Uwe Strotmann (RUTHMANN), Charles Goffin (France Elévateur)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Issue Summer 1/<strong>2023</strong> | A publication of the<br />

<strong>Experience</strong><br />

2024<br />

RUTHMANN<br />

STEIGER® T 1000 HF<br />

RUTHMANN<br />

ECOLINE 270<br />

France Elévateur<br />

UPTO 15<br />

VERSALIFT<br />

VTE-125-F<br />

BLUELIFT<br />

ST 31 Hybrid<br />

STEIGER® AMPERO<br />

TBR 260E<br />

VERSALIFT<br />

V-200<br />

MOVEX<br />

TLH 18<br />

VERSALIFT<br />

V-170<br />

4<br />

Tour de Time<br />

from 6<br />

Novelties <strong>2023</strong><br />

35<br />

Electric STEIGER ®<br />

in use<br />

90<br />

Review bauma 2022

NEW@TIME-GROUP …<br />

ECOLINE 270<br />

France Elévateur UPTO 15<br />

VERSALIFT VTE-125-F<br />

Working height:<br />

27 m<br />

Reach:<br />

16 m<br />

Further information: Page 26<br />

Working height:<br />

1.,1 m<br />

Reach:<br />

9.1 m<br />

Further information: Page 10<br />

Working height:<br />

12.3 m<br />

Reach:<br />

7 m<br />

Further information: Page 32<br />

STEIGER ® T 230 XS<br />

STEIGER ® AMPERO TBR 260 E<br />

VERSALIFT V-200<br />

Working height:<br />

23 m<br />

Reach:<br />

18.1 m<br />

Further information: Page 18<br />

Working height:<br />

26 m<br />

Reach:<br />

17 m<br />

Further information: Page 6<br />

Working height:<br />

19.9 m<br />

Reach:<br />

14 m<br />

Further information: Page 28<br />

MOVEX TLRH 18<br />

BLUELIFT ST 31 HYBRID<br />

Working height:<br />

18 m<br />

Reach:<br />

9.4 m<br />

Further information: Page 12<br />

Working height:<br />

31 m<br />

Reach:<br />

18 m<br />

Further information: Page 12<br />

| 2

GREETING<br />

<strong>Experience</strong><br />

GREETING<br />

Dear customers, partners and readers,<br />

After the successful bauma 2022 in Munich, we are now also appearing in<br />

our <strong>Experience</strong> for the first time with all the new brands of the TIME Group.<br />

You will find 92 pages of news and information about the products of RUTH-<br />

MANN, VERSALIFT, France Elévateur and MOVEX.<br />

With this <strong>issue</strong>, which we will launch at APEX <strong>2023</strong>, we would also like to announce<br />

an outstanding new product: We are very pleased to present the new<br />

T 1000 HF on pages 4 - 5 as the goal of our “Tour de TIME” for 2024, with<br />

which RUTHMANN will again crack the 100-meter mark and offer the most<br />

innovative and flexible equipment in this class. You will certainly read a lot of<br />

outstanding things about this in the coming years. Not quite as high, but still<br />

just as great, are the other machines in this <strong>issue</strong>. Benefit from our <strong>Experience</strong><br />

and read about the many positive experiences our customers have had with<br />

the new innovative electric drives and how well they work in practice.<br />

We would also like to take this opportunity to thank our colleagues who, with<br />

their innovative thinking, enjoyment of their work and outstanding personal<br />

commitment, continue to optimize our products and make them the best on<br />

the global market.<br />

From left to right: Charles Goffin, Martin<br />

Christiansen, Uwe Strotmann, Jay Jeffrey<br />

and Kim Bach Jensen at bauma 2022.<br />

We hope you enjoy reading this <strong>issue</strong>.<br />

Your TIME Management Team: Kim Bach Jensen (TIME Europe),<br />

Uwe Strotmann (RUTHMANN), Charles Goffin (France Elévateur)<br />

CONTENTS<br />

4 ................Innovations presented and in use<br />

49 ................TIME Service<br />

53 ................Handover<br />

62 ................Training<br />

67 ................Research<br />

68 ................Recruiting<br />

73 ................Living & Working<br />

78 ................Internal<br />

83 ................Classic<br />

84 ................Internal II<br />

89 ................Fairs<br />

| 3

<strong>Experience</strong><br />

TOUR DE TIME<br />

Tour de<br />

Tour de Time - a short journey through the new products of the Time Group,<br />

which since June 2022 also includes France Elévateur and MOVEX, in<br />

addition to RUTHMANN and VERSALIFT. Join us on our journey through<br />

Europe, discover the new products and climb to new heights with us today.<br />

In 2024, we will break the 100-metre barrier again and present the new<br />

RUTHMANN STEIGER ® T 1000 HF to you. The 100-metre STEIGER ® with<br />

RUTHMANN HighFlex technology will be unique in its class in terms of flexibility.<br />

Join us and follow the progress of its development on our social media<br />

channels.<br />

RUTHMANN<br />

ECOLINE 270<br />

France Elévateur<br />

UPTO 15<br />

VERSALIFT<br />

VTE-125-F<br />

| 4

TOUR DE TIME<br />

<strong>Experience</strong><br />

2024<br />

VERSALIFT<br />

V-170<br />

BLUELIFT<br />

ST 31 Hybrid<br />

STEIGER®<br />

AMPERO TBR 260E<br />

VERSALIFT<br />

V-200<br />

MOVEX<br />

TLH 18<br />

| 5

<strong>Experience</strong><br />

NOVELTY<br />

THE LATEST E-STEIGER ® GENERATION<br />

ON IVECO-EDAILY CHASSIS:<br />

THE STEIGER ® AMPERO TBR 260 E<br />

A new dream team at RUTHMANN: the proven, 100% electric RUTHMANN Ampero on the series chassis of<br />

the new IVECO eDaily. The Ampero TBR 260 E is based on the STEIGER ® TBR 260 and is considered the highest<br />

and most powerful truck platform on the market in this electric class. The latest generation offers 26 metres<br />

of working height and a whopping 17 metres of range. With one battery charge, 150 km of travel and 30 full<br />

work cycles are possible - that’s more than enough for a day’s work.<br />

THE RUTHMANN E-DRIVE OFFERS<br />

30 FULL WORK CYCLES<br />

The all-electric E-STEIGER ® Ampero<br />

TBR 260 E has a unique concept: The<br />

built-in battery of the IVECO eDaily<br />

can be used for the travel drive and at<br />

the same time for the STEIGER ® drive.<br />

Regardless of whether it is a 5.2 or<br />

7.0 t chassis - the AMPERO TBR 260 E<br />

drives and operates quietly and with<br />

zero emissions. It extends the proven<br />

concept of the Ampero TBR 250 E<br />

with improved performance data<br />

and standard chassis. The working<br />

platform and the electric motor of<br />

the chassis are powered by a 74 kWh<br />

battery, which is charged with a standard<br />

commercial charging cable. The<br />

charging port is located in the radiator<br />

grille of the IVECO eDaily. It takes one<br />

hour to fully charge the battery via DC<br />

at 80 kW, and four hours via AC at 22<br />

kW.<br />

THE E-MOTOR OFFERS MANY<br />

STRONG ADVANTAGES<br />

The electric drive offers many advantages<br />

over a conventional combustion<br />

engine: the electric motor has a high<br />

torque and demonstrates efficient<br />

engine braking, e.g. when driving<br />

downhill with energy recovery. The<br />

vehicle gets by with fewer moving<br />

parts, such as the alternator and<br />

gearbox, which increases the service<br />

life. Running costs are also significantly<br />

lower.<br />

QUIET OPERATION WITHOUT<br />

EMISSIONS<br />

The STEIGER ® Ampero TBR 260 E has<br />

excellent performance data. Thanks<br />

to the almost silent drive, it opens<br />

up new fields of application: Work<br />

at night or in the vicinity of hospitals<br />

and old people’s homes as well as in<br />

residential areas. It can also be used in<br />

enclosed indoor areas without additional<br />

measures, ideal e.g. for exhibition<br />

centres or extensive production<br />

sites.<br />

The STEIGER ® Ampero TBR 260 E has a<br />

74 kWh battery. It supplies the working platform<br />

and the electric motor of the chassis. It<br />

takes one hour to fully charge the battery via<br />

DC with 80 kW, and four hours via AC with<br />

22 kW.<br />

| 6

NOVELTY<br />

<strong>Experience</strong><br />

The proven, 100 % electric RUTHMANN Ampero is available on the series chassis of the new IVECO eDaily. The Ampero TBR 260 E is based on<br />

the STEIGER ® TBR 260 HV5 and is currently the highest and most powerful truck platform on the market in this electric class.<br />

UNRESTRICTED, OUTSTANDING<br />

PERFORMANCE DATA<br />

Operating the E-STEIGER ® Ampero<br />

TBR 260 E is just as easy as you would<br />

expect from a RUTHMANN STEIGER ® .<br />

With its working height of 26 metres<br />

and a reach of 17 metres, the operating<br />

data is improved by around one<br />

metre compared to the predecessor<br />

STEIGER ® Ampero 250 E. The proven<br />

RÜSSEL ® has a rotation angle of up to<br />

185°, making it easy to work behind<br />

pipes or other obstacles.<br />

The workman basket carries 250 kg<br />

and measures 1.40 x 0.70 metres.<br />

It can be easily replaced by a larger<br />

workman basket measuring 1.60 x 0.7<br />

metres with a reinforced load capacity<br />

of 300 kg.<br />

The flexible support - horizontal and<br />

vertical - of the STEIGER ® AMPERO<br />

TBR 260 E allows the maximum reach,<br />

as it can be supported close to the<br />

object.<br />

The RUTHMANN telescopic construction<br />

made of high-strength finegrained<br />

steel with optimised beam<br />

shape and laser seam is extremely<br />

stable and guarantees maximum reliability<br />

in use.<br />

All these factors make the STEIGER ®<br />

AMPERO TBR 260 E the highest and<br />

most powerful truck working platform<br />

in this electric class on the market.<br />

| 7

<strong>Experience</strong><br />

NOVELTY<br />

VERSALIFT VTA-38-135-H:<br />

A CLASSIC NOW ALSO<br />

FOR EUROPE<br />

VERSALIFT presents the VTA-38-135-H, a proven<br />

pick-up working platform that is now available for<br />

the European market.<br />

Originally launched as the LAT-38-H in 2013, this<br />

impressive working platform has quickly become a<br />

real best-seller in the UK market thanks to its outstanding<br />

performance. In 2021, the platform was<br />

revamped, optimised for even better performance<br />

and re-launched as the VTA-38-135-H. As the most<br />

sought-after pick-up lift in the UK, it is only logical<br />

that this popular platform is now also available in an<br />

EU version.<br />

THE PERFECT LIFT FOR ALMOST ANY TERRAIN<br />

The VTA-38-135-H is an articulated telescopic lift that can<br />

be mounted on both 4x2 and 4x4 pick-up vehicles. With<br />

a working height of 13.6 metres and a horizontal reach of<br />

6.4 metres, the lift offers a maximum load capacity of 230<br />

kg, including two operators and their equipment, with no<br />

restrictions throughout the working area.<br />

Thanks to its compact size, 4x4 design and carefully<br />

thought-out load distribution, the VTA-38-135-H ensures<br />

excellent performance, especially in hard-to-reach areas<br />

where conventional working platforms cannot operate.<br />

The lift features first-class mobility and comfort, making<br />

it an excellent solution for both rough terrain and urban<br />

environments.<br />

Tough as nails: Sensitive parts of the VTA-38-135-H are particularly well<br />

protected against failure.<br />

The VTA-38-135-H achieves a reach of up to 6.4 m. Thanks to its articulated<br />

telescopic design, it also works easily over obstacles.<br />

| 8

NOVELTY<br />

<strong>Experience</strong><br />

Beautiful and powerful: the<br />

VTA-38-135-H is at home in<br />

almost any terrain and the<br />

articulated telescopic design<br />

makes it easy to reach difficult<br />

work sites.<br />

A HYDRAULIC LIFT WITH PRECISION AND PROTECTION<br />

The VTA-38-135-H has a fully hydraulic control system that<br />

is easy to operate and ensures high precision movements.<br />

In addition, all components inside the boom, including the<br />

extension cylinder, are protected to prevent damage from<br />

external influences and shocks.<br />

One of the main advantages of the VTA-38-135-H is its<br />

light weight, which allows it to be easily fitted to a standard<br />

Isuzu D-Max without the need to retrofit the suspension.<br />

This feature makes the lift a cost-effective and<br />

practical solution for companies looking for a reliable and<br />

versatile platform for their fleet.<br />

Ideal for, among other things, maintenance pruning of trees. The allwheel<br />

drive chassis does not stop at rough terrain.<br />

| 9

<strong>Experience</strong><br />

NOVELTY<br />

FRANCE ELÉVATEUR UPTO 15<br />

THE FIRST MODEL OF A NEW GENERATION<br />

The UPTO generation is the result of intensive work by our research and<br />

development department. Our goal at France Elévateur is to offer our<br />

customers ever higher quality products. That is why we have worked to<br />

reduce the weight of the working platform and the energy consumption<br />

in the UPTO range.<br />

Several models from 13 to 18 metres<br />

on van and chassis cabs will form the<br />

UPTO range in the future. Thanks<br />

to the use of new materials and<br />

laser welding technology, the UPTO<br />

series is around 30% lighter than<br />

previous comparable machines. This<br />

enormous weight saving facilitates<br />

material transport and reduces fuel<br />

consumption. The innovative control<br />

technology now also consumes<br />

around 20 % less electrical energy<br />

than before.<br />

| 10

NOVELTY<br />

<strong>Experience</strong><br />

PLENTY OF INTERIOR TRANSPORT<br />

VOLUME<br />

Thanks to the new, ultra-compact<br />

tower in the load compartment, 90%<br />

of the interior volume is retained. In<br />

the UPTO 15, up to 500 kg of payload<br />

is available for large, bulky parts.<br />

Of course, even when the telescopic<br />

boom is not in use, the rear door can<br />

be fully opened on one side to load<br />

and unload the UPTO 15.<br />

UPTO 15 AVAILABLE IMMEDIATELY<br />

The new series starts with the UPTO<br />

15 with a working height of 15.10<br />

metres and a maximum reach of 9.10<br />

metres. With the basket arm, the<br />

UPTO 15 can also reach work sites<br />

behind interfering edges and thus<br />

expands the range of applications<br />

enormously. The stable construction<br />

allows basket loads of up to 230 kg<br />

and the assembly of material by two<br />

persons. At the same time, the basket<br />

can be rotated by 60°.<br />

The new, particularly low basket<br />

threshold in the workman basket<br />

makes it much easier to get in and out.<br />

PLENTY OF COMFORT FOR<br />

DAILY USE<br />

In addition to the above-mentioned<br />

home function, the UPTO 15 also has<br />

an automatic outrigger. At the push of<br />

a button, the machine can be automatically<br />

outriggered and aligned. This<br />

means that work can begin immediately.<br />

EMISSION-FREE OPERATION<br />

ALSO POSSIBLE<br />

With the optionally available Eco-Pack,<br />

it is possible to use the UPTO 15 as a<br />

hybrid working platform. Completely<br />

without CO2 emissions and almost<br />

noiseless, the UPTO 15 can then be<br />

used at night, in narrow pedestrian<br />

zones and even indoors.<br />

In the following you will find the technical<br />

features of UPTO 15, an innovative,<br />

lightweight and handy model:<br />

The advantages of the UPTO 15<br />

at a glance<br />

30 % more payload through use<br />

of HLE 960 steel and laser<br />

welding<br />

Cage arm rotation angle 180°<br />

Working height 15.10 m<br />

Basket load 2 persons/230 kg<br />

Maximum outreach 9.10 m<br />

(80 kg)<br />

Empty weight: 3,000 kg<br />

Double movement<br />

Automatic levelling system<br />

Slope operation up to 15 %<br />

90 % of the internal volume is<br />

retained thanks to the new<br />

ultra-compact barrel<br />

Basket rotation 2 x 60°<br />

The new dual-motion control allows<br />

two movements to be carried<br />

out during operation without loss<br />

of speed, thus saving a lot of time,<br />

especially when the cage has to be<br />

raised and lowered frequently during<br />

operations. The new home function is<br />

then a particularly great relief during<br />

daily use.<br />

| 11

<strong>Experience</strong><br />

NOVELTY<br />

BLUELIFT ST 31 HYBRID<br />

With the new BLUELIFT ST 31 Hybrid, the highest<br />

crawler working platform from the BLUELIFT portfolio<br />

is now also available with the proven BLUE lithium<br />

hybrid drive.<br />

With the new BLUE lithium hybrid drive, it is now also<br />

possible to bring the machine in completely emission-free<br />

without a mains connection, e.g. into buildings, and work<br />

there at heights of up to 31 metres. With its low height<br />

of only 1.99 metres and a width of 1.14 metres, the ST<br />

31 Hybrid fits through many standard doors where other<br />

access solutions have to fit.<br />

The new hybrid drive is available with three different BLUE<br />

lithium battery packs and achieves up to 17 complete,<br />

emission-free work cycles with the largest, 13.4 kWh<br />

battery. At the same time, the work cage can carry a maximum<br />

of 400 kg. The ST 31 Hybrid achieves a lateral reach<br />

of up to 18 metres.<br />

Further information on the<br />

BLUELIFT ST 31 Hybrid and<br />

additional performance data<br />

can be found on the Internet:<br />

For outdoor or off-road use, the proven drive with combustion<br />

engine is also available. The BLUELIFT ST 31 Hybrid is<br />

thus a universal, powerful access solution that can reach<br />

almost all indoor and outdoor work sites.<br />

NEW MOVEX TLRH HYBRID SERIES<br />

With the new hybrid models TLRH<br />

16, TLRH 18 and TLRH 20, MOVEX<br />

now also offers powerful truckmounted<br />

working platforms that<br />

can be used emission-free.<br />

The clean and quiet battery drive is<br />

sufficient for at least one working<br />

day, with the optional battery change<br />

system it is even possible to work<br />

around the clock continuously emission-free.<br />

The machines reach 16.40, 18.00 and<br />

20.10 metres working height and up<br />

to 10.70 metres lateral reach.<br />

The work cage carries a maximum<br />

of 200 kg and is approved for two<br />

persons.<br />

The new MOVEX truck-mounted<br />

working platforms of the TLRH series<br />

are available from TIME-Group sales<br />

in European countries.<br />

Further information on<br />

the equipment and<br />

working diagrams at:<br />

https://movexlift.com/<br />

| 12

NOVELTY<br />

<strong>Experience</strong><br />

NEW: 100 % ELECTRIC VERSALIFT VTL-135-F<br />

AND VTL-145-F ON FORD AND RENAULT<br />

The popular VERSALIFT VTL-135-F and VTL-145-F are<br />

now available as 100% electric on the Ford E-Transit<br />

and Renault Master E-tech vans respectively.<br />

These innovative fully electric lifts are specifically designed<br />

to meet the needs of professionals looking for an efficient<br />

and environmentally conscious solution.<br />

With a working height of 13.5 and 14.4 metres respectively<br />

and a horizontal reach of 8 metres for the VTL-135-F and<br />

8.5 metres for the VTL-145-F, both are real alternatives for<br />

those looking for an all-electric solution. Despite being fully<br />

electric, the VTL-145-F on Renault can be driven with a<br />

class B drivers license.<br />

With a payload of up to 600 kg on the VTL-135-F on Ford<br />

E-Transit, there is enough spare payload to install storage or<br />

a workshop in the back of the van, and to transport materials<br />

and tools. The two person baskets offer a weight limit<br />

of 200 or 230 kg.<br />

VERSALIFT’s user-friendly, intuitive controls with LCD displays<br />

make the lift easy to operate for anyone.<br />

Whether you’re a contractor, electrician or other professional<br />

in need of a reliable electric lift, the Ford E-Transit or<br />

Renault Master E-Tech van mounts are the ideal solution.<br />

These cost-effective lifts are equipped with all the necessary<br />

features to meet your needs.<br />

The VTL-135-F on<br />

the Ford E-Transit van<br />

was exhibited at Vertikal<br />

Days <strong>2023</strong>. With<br />

a working height<br />

of 13.5 metres, it<br />

reaches one metre<br />

less than the VTL-<br />

145-F - but offers up<br />

to 600 kg payload.<br />

Further information<br />

about the new<br />

Versalift VTL-145-F<br />

and VTL-135-F on<br />

Electric Transporterchassis<br />

| 13

<strong>Experience</strong><br />

NOVELTY<br />

MOVEX TLR 16:<br />

AFFORDABLE,<br />

UNIVERSAL AND RELIABLE<br />

| 14

NOVELTY<br />

<strong>Experience</strong><br />

The MOVEX TLR 16 is an affordable truck-mounted<br />

working platform that can be used universally.<br />

It reaches a maximum working height of 16.4 metres<br />

and a lateral outreach of up to 9.7 metres with 80 kg<br />

basket load.<br />

The TLR 16 is robust and reliable and offers numerous<br />

equipment options, e.g. for the maintenance and<br />

servicing of street lighting. The functional design and<br />

easy-to-learn operation also make it ideal for private<br />

users or landlords.<br />

The maximum basket load of the rotatable GRP work basket<br />

is 230 kg. It then reaches its maximum working height<br />

of 16.4 metres with up to 2 persons in the workman basket,<br />

as well as a lateral reach of 6 metres.<br />

The TLR 16 can be mounted on an Iveco 3.5 t chassis, for<br />

example, and then reaches an overall length of 7.37 metres<br />

and an overall width, including the exterior mirrors, of<br />

around 2.2 metres. The overall height is just over 3 metres.<br />

The electro-hydraulic control system is robust and very<br />

easy to learn, even for the inexperienced. Nevertheless, the<br />

MOVEX TLR 16 can be controlled precisely and operated<br />

very safely.<br />

The MOVEX TLR 16 can be conveniently supported and<br />

brought into working position from the work cage or via<br />

an ergonomic control panel on the chassis. Various narrow<br />

support variants are available to enable the machine to be<br />

used in confined conditions.<br />

The MOVEX TLR 16 offers up to 9.7 metres of lateral reach.<br />

For more information, visit movexlift.com<br />

or contact your country’s distributor.<br />

TLR16<br />

18<br />

17<br />

16<br />

15<br />

14<br />

13<br />

12<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

0 1 2 3 4 5 6 7 8 9 10 11 12<br />

The MOVEX<br />

TLR 16 lifts up<br />

to 230 kg at a<br />

working height of<br />

16.2 metres. The<br />

GRP work basket<br />

is approved for 2<br />

persons.<br />

| 15

<strong>Experience</strong><br />

NOVELTY<br />

THE NEW EDITION<br />

OF A CLASSIC:<br />

FRANCE ELÉVATEUR<br />

TOPY 11<br />

The TOPY 11 model on FORD TRANSIT is the latest<br />

generation of this exceptional range. Continuous further<br />

developments have made this working platform<br />

one of the best-selling models. Reliable, robust and<br />

user-friendly are the essential features to meet the<br />

requirements of safe and efficient access technology<br />

at all times.<br />

For more than 20 years, the TOPY from France Elévateur<br />

has been the epitome of a compact, lightweight<br />

and functional truck-mounted working platform. It is<br />

particularly popular with telecommunications companies<br />

and for the installation of signs and surveillance<br />

equipment. Reason enough for the engineers at<br />

France Elévateur to go back to the drawing board and<br />

revise some of the details of the model.<br />

The TOPY 11 has a 1- or 2-person work basket with a load<br />

capacity of 120 or 200 kg - different versions are available<br />

depending on the market. With its two-part steel telescopic<br />

boom, a working height of 10.25 metres and a lateral<br />

reach of 5 metres are possible.<br />

FAST WORK WITHOUT OUTRIGGER<br />

The TOPY 11 basically does not need any outriggers and is<br />

therefore ready for immediate use. Nevertheless, it achieves<br />

its operating data even with an inclination of up to 15 % in<br />

the longitudinal and 5 % in the transverse axis. This means<br />

that it can also be used on slopes without any problems<br />

and without outrigger<br />

BETTER ERGONOMICS AND HIGHER PAYLOAD<br />

In addition to functionality, special attention was paid to<br />

the controls during the current revision. Parallel to the<br />

ground and basket controls, the control unit in the driver’s<br />

cab has been fundamentally revised. The focus was on<br />

ergonomics and functionality. In addition to some technical<br />

advantages, the new design of the TOPY 11 primarily<br />

brings a reduction in weight. Depending on the equipment,<br />

the payload is now up to 650 kg.<br />

| 16

NOVELTY<br />

<strong>Experience</strong><br />

Is just as fast in action<br />

as it looks: The TOPY<br />

11 requires no outriggers<br />

and is immediately<br />

ready for work<br />

at heights of up to 15<br />

metres.<br />

Here is the TOPY 11<br />

France Elévateur<br />

in action:<br />

EQUIPMENT - TO SUIT ALL NEEDS<br />

In terms of equipment options, the new TOPY 11 scores<br />

with a towing capacity of 2,000 kg, among other things.<br />

In addition, there is a wide range of different tool and<br />

material boxes as well as fold-down tail lifts. The double<br />

insulation against 1,000 V according to DIN VDE0682-742<br />

is also available again as the most requested option.<br />

Depending on the<br />

market, the TOPY 11 is<br />

available with different<br />

basket loads and<br />

reaches. It reaches up<br />

to 6 metres lateral reach<br />

without support.<br />

ALSO AVAILABLE AS HYBRID VERSION<br />

The popular battery package for the platform body is also<br />

represented in the options list. This “hybrid version” makes<br />

the TOPY 11 the ideal working platform, especially in inner-city<br />

areas such as pedestrian zones. As a hybrid version,<br />

the TOPY 11 can be used as an emission-free and almost<br />

noiseless working platform - ideal, for example, when work<br />

has to be done at night.<br />

MERCEDES BENZ OR FORD: THE CHOICE IS YOURS<br />

There are currently two 3.5 t variants to choose from as<br />

carrier vehicles: Mercedes Benz Sprinter and Ford Transit.<br />

On the Ford Transit chassis, the TOPY 11 achieves a payload<br />

of up to 650 kg, ideal for transporting materials and tools<br />

to the site.<br />

With a length of just under 5.90 metres and an overall<br />

height of 2.70 metres, the new TOPY 11 is is one of<br />

the most compact truck mounted platforms on the<br />

market.<br />

| 17

<strong>Experience</strong><br />

NOVELTY<br />

THE ALL-ROUNDER:<br />

THE NEW<br />

STEIGER ® T 230 XS<br />

With the same innovations as in<br />

the successful STEIGER ® T 300 XS,<br />

RUTHMANN has now updated the<br />

STEIGER ® T 230 and presents it as<br />

the STEIGER ® T 230 XS. This true<br />

all-rounder is suitable for landlords,<br />

local authorities, gardeners<br />

and landscapers, building cleaners<br />

and painters. With a working<br />

height of 23.00 metres and the<br />

maximum lateral reach of 18.10<br />

metres with a full 350 kg basket<br />

load, the T 230 XS is up to all challenges.<br />

At the same time, with an<br />

overall length of only 7.59 metres,<br />

it is compact and easy to manoeuvre.<br />

The 7.5 t chassis offers sufficient payload<br />

reserves and reaches a payload<br />

of up to 600 kg. Even with a spacious<br />

box body, there is still enough reserve<br />

for tools and materials, making the<br />

STEIGER ® T 230 XS ideal for pruning<br />

work or maintenance and servicing.<br />

The 2.85 metre long trunk, which can<br />

be swivelled by 185°, makes the T 230<br />

XS universally applicable and enables<br />

work in hard-to-reach places. At the<br />

same time, it manages the maximum<br />

basket load of 350 kg at almost all<br />

points of the working diagram and<br />

is thus also ideal for the assembly of<br />

heavy parts with several people.<br />

The convenient new outrigger monitor<br />

offers numerous outrigger variants, so<br />

that the STEIGER ® T 230 XS can also<br />

be used in very confined conditions.<br />

Narrowly supported, it still reaches up<br />

to 17 metres with full basket load.<br />

Of course, different basket variants are<br />

still available for the different applications<br />

of the T 230 XS, in addition to<br />

the pruning basket also a GRP basket<br />

with double insulation.<br />

In the workman basket itself, the new<br />

cockpit provides an information and<br />

diagnostic display that leaves little to<br />

be desired. All relevant operating data,<br />

including the current fuel level, can be<br />

read off.<br />

With the high payload,<br />

box bodies can also be<br />

implemented according to<br />

customer requirements.<br />

Even supported on one side or in the profile,<br />

the STEIGER ® T 230 XS achieves outstanding<br />

performance data.<br />

The compact and extremely stable STEIGER ® T 230 XS shines with a<br />

reach of up to 18 metres at a full 350 kg basket load.<br />

| 18

NOVELTY<br />

<strong>Experience</strong><br />

STEIGER ® T 300 XS HV12:<br />

“HEAVY BOY” WITH<br />

A LOT OF RESERVES<br />

On an 18 t chassis, the STEIGER ® T 300 XS HV12 offers<br />

several advantages over the STEIGER ® T 300 XS on a<br />

7.5 t chassis, making it ideal for roadway clearance<br />

cutting, for example. The T 300 XS HV12 excels here<br />

with a lateral reach of up to 15.3 metres with a narrow<br />

support in the profile, due to the higher vehicle<br />

weight. The 18-t chassis also offers large payload<br />

reserves and has a high load capacity for tools, personnel<br />

and materials.<br />

Even box bodies with drawers, pull-outs and sorting systems<br />

can be realised excellently and without compromise<br />

according to the customer’s wishes - due to the higher<br />

payload reserve of the 18 t chassis.<br />

The generously dimensioned supports offer a higher<br />

support stroke and thus enable the STEIGER ® T 300 XS to<br />

be used with the RUTHMANN inclined support plates on<br />

sloping terrain of up to 9° or on large uneven ground.<br />

Fully outriggered, the STEIGER ® T 300 XS HV12 reaches<br />

its maximum outreach of 21.8 metres. With an outrigger<br />

surface of only 3.58 x 3.89 metres, it requires around 1.5<br />

metres less in width and 1.3 metres less in length than the<br />

T 300 XS on a 7.5 t chassis. This means that the STEIGER ®<br />

T 300 XS HV 12 can be used successfully with its maximum<br />

performance data even in very confined conditions. Thanks<br />

to the short overall length of only 7.72 metres, it is still easy<br />

to manoeuvre even in cramped conditions.<br />

The RUTHMANN STEIGER ® T 300 XS HV12 is also available<br />

on a four-wheel drive chassis, for example, which greatly<br />

expands the range of applications far from paved roads<br />

and in rough terrain.<br />

Comfortable box bodies with drawers and extendable ladders can be<br />

fitted on the 18 t chassis according to the customer’s wishes.<br />

The RUTHMANN STEIGER ® T 300 XS HV12 achieves its maximum performance<br />

data with an outrigger width of just 3.58 metres.<br />

| 19

<strong>Experience</strong><br />

NOVELTY<br />

COMPACT AND POWERFUL:<br />

FRANCE ELÉVATEUR 101 FP<br />

The new France Elévateur 101 FP particularly meets the requirements of<br />

telecommunications companies for use in urban environments. However, it<br />

is also suitable for many other industries that require an extremely compact<br />

working platform.<br />

With an overall length of just 5.87 metres on a Renault-Trafic chassis, the 101 FP<br />

is as manageable as a large passenger car even in very confined conditions. Its low<br />

overall weight of 3,400 kg and low height of 2.60 metres mean it can also be used<br />

in areas that are inaccessible to other truck-mounted working platforms.<br />

France Elévateur 101 FP<br />

Technical specifications<br />

Working height: 10.10 m<br />

Reach without supports: 6.20 m<br />

Basket load: 120 kg/1 person<br />

Tower rotation: 400°<br />

Max. Set-up inclination: 15 %/5 %<br />

1,000 V insulated fibreglass basket<br />

Energy chain inside the telescope<br />

Control light for transport<br />

position in driver’s cab.<br />

| 20

NOVELTY<br />

<strong>Experience</strong><br />

QUICK DEPLOYMENT WITHOUT OUTRIGGERS<br />

The France Elévateur 101 FP does not require any outriggers<br />

and reaches a working height of 10.10 metres and a<br />

lateral outreach of 6.20 metres. The workman basket can<br />

carry a maximum of 120 kg and can be rotated by 2 x 60°.<br />

Due to the high maximum permissible inclinations of 15 %<br />

in longitudinal and 5 % in transverse direction, the working<br />

platform can also be used on slopes or inclined roadways<br />

without any problems.<br />

OPTIONAL EQUIPMENT FOR THE TELECOMMUNICA-<br />

TIONS INDUSTRY<br />

The 101 FP has been specially designed for the telecommunications<br />

industry to meet the need for an extremely<br />

compact machine for urban environments. Special telecom<br />

accessories are also available, such as a 750 kg towing<br />

hook for pulling fibre optic cables through the conduits in<br />

the floor.<br />

LIGHT WEIGHT AND HIGH PAYLOAD<br />

The 101 FP is currently available on a Renault Trafic or<br />

Ford Transit custom chassis. With a gross vehicle weight of<br />

3,400 kg, it is one of the lightest truck-mounted working<br />

platforms on the market. It can therefore reach work sites<br />

for which other vehicles are too heavy. Despite the low<br />

total weight, the 101 FP has a payload of 895 kg.<br />

COMPACT DIMENSIONS ALMOST LIKE A CAR<br />

With an overall length of just 5.87 metres and a height<br />

of 2.6 metres, the 101 FP is particularly suitable for work<br />

in urban environments, in narrow alleys or behind low<br />

gateways.<br />

Since June 2022, France Elévateur has been part of the<br />

TIME Manufacturing Company, as have RUTHMANN,<br />

VERSALIFT and MOVEX. This guarantees a dense<br />

Europe-wide service and sales network and ensures the<br />

successful and problem-free use of our working platforms.<br />

| 21

<strong>Experience</strong><br />

IN USE<br />

MATECO SETS NEW<br />

STANDARDS WITH<br />

THE STEIGER ® T 650 HF<br />

ON HIGHFLEX<br />

TECHNOLOGY FROM<br />

RUTHMANN<br />

With the delivery of the new STEIGER ® s T 650 HF to<br />

mateco in the Netherlands, customers there can now<br />

also benefit from the HighFlex advantages.<br />

The many possibilities offered by the RUTHMANN HF<br />

system are complex and not always easy to explain in<br />

a consultation or on site.<br />

In order to remedy this, mateco decided to produce<br />

a video that impressively shows the advantages and<br />

also offered the opportunity to test the machine<br />

extensively.<br />

REACH WORLD CHAMPION<br />

With a lateral outreach of 43 metres, the STEIGER ® T 650<br />

HF is the STEIGER ® with the highest outreach ever built. In<br />

combination with the HighFlex technology - which allows<br />

the working cage to rotate 180° - fantastic and unprecedented<br />

application possibilities arise. For example, it is<br />

possible to work across a building on the back side of this<br />

building as if the working platform was placed on exactly<br />

this side of the building. In practice, this opens up possibilities<br />

where previously it was either not possible to use<br />

a working platform at all or the ground at the back of a<br />

building had to be elaborately stabilised with steel plates or<br />

excavator mats.<br />

PERFECT FOR INSPECTION AND ASSEMBLY<br />

With this flexibility, buildings and facades can now be<br />

completely driven down in the shortest possible time,<br />

| 22

IN USE<br />

<strong>Experience</strong><br />

ideal, for example, for inspecting the building structure or<br />

assembling components. With a cage load of 600 kg and<br />

a working cage that can be telescoped to a width of 3.82<br />

metres, the T 650 HF is also ideally suited for this purpose.<br />

Although nothing was mounted during the video shoot by<br />

mateco, the reach and the HighFlex functions of the machine<br />

were tested extensively. The compact overall length<br />

of the STEIGER ® was also helpful during the shoot, because<br />

with a vehicle length of just under 12 metres, it was able to<br />

easily pass the relatively narrow road to the site.<br />

A successful video shoot in which the STEIGER ® T<br />

650 HF completely fulfilled the high expectations of<br />

mateco in the Netherlands. The video of the operation<br />

is available online on YouTube.<br />

You can see the<br />

STEIGER ® T 650<br />

HF in action at:<br />

https://www.<br />

youtube.com/<br />

watch?v=Oo4Bknxv4A<br />

in action.<br />

| 23

<strong>Experience</strong><br />

NOVELTY<br />

VERSALIFT VTX-240 G3<br />

ONE FOR ALL ...<br />

The VERSALIFT VTX-240 G3 articulated telescopic working platform is<br />

equipped with a joint in the telescope, making it ideal for working behind<br />

obstacles that cannot be reached by the direct route. The articulation<br />

point is at a maximum height of 12 metres, from which the VTX-240<br />

G3 can then telescope up to another 12.5 metres to the side. Ideal, for<br />

example, for work on roofs or in urban environments. The maximum<br />

working height is 24.2 metres and is achieved with the maximum basket<br />

load of 220 kg.<br />

Despite its outstanding operating<br />

data, the VTX-240 G3 is no higher<br />

than a standard Mercedes-Benz<br />

Sprinter chassis and, with a height<br />

of only 2.28 metres, can also pass<br />

through many low passageways, e.g.<br />

to courtyards. With a permissible total<br />

weight of less than 3.5 t, the<br />

VTX-240 G3 can be driven with a class<br />

B driving licence.<br />

EVEN ON SLOPES POWERFUL<br />

The VTX-240 G3 can also be used in<br />

garage entrances or on slopes. The<br />

outriggers have a large outrigger<br />

stroke, so that up to 6° inclination to<br />

the longitudinal or transverse axis can<br />

be compensated as standard.<br />

COMFORT FUNCTIONS SAVE TIME<br />

The new user-friendly display system<br />

makes it easy to set up the machine<br />

and can also be switched to different<br />

languages. This makes outriggering<br />

and automatically levelling the VER-<br />

SALIFT VTX-240 G3 very easy, even<br />

for less experienced operators.<br />

After successful operation, the new<br />

comfort home function automatically<br />

returns the machine to the home position<br />

and it can immediately be moved<br />

on to the next job site.<br />

UNDERFLOOR WORK INCLUDED<br />

The VTX-240 G3 not only stands out<br />

with its 12.5-metre lateral reach at<br />

a height of around 12 metres, it can<br />

also be used for underfloor work.<br />

Thanks to the articulated telescopic<br />

design, it is possible to work with the<br />

workman basket up to 3.3 metres<br />

below the level at which the machine<br />

has been placed. This makes it possible,<br />

for example, to inspect smaller<br />

bridges, walls or road pavements that<br />

lie below the vehicle.<br />

OPTIONALLY ALSO 100 % ELECTRIC<br />

Based on the IVECO eDaily chassis,<br />

the VTX-240 G3 is also available as a<br />

100 % electric version. The all-electric<br />

VTX-240 G3 has a unique concept:<br />

The VERSALIFT VTX 240 G3 has an articulated telescope and reaches a lateral reach of 12.5<br />

metres at a height of around 12 metres - ideal for working over obstacles.<br />

The new user-friendly operating concept<br />

offers numerous comfort functions<br />

| 24

NOVELTY<br />

<strong>Experience</strong><br />

Here is the VERSALIFT<br />

VTX-240 G3 in action:<br />

... NOW ALSO<br />

100 % ELECTRIC<br />

the built-in battery of the IVECO<br />

eDaily can be used for the travel drive<br />

and at the same time for the drive of<br />

the working platform, so emission-free<br />

working, e.g. in inner-city areas, is<br />

now also possible with the popular<br />

articulated telescopic work platform.<br />

The operation of the unit is almost<br />

noiseless due to the electric drive,<br />

so that operations at night, during<br />

events and even indoors are possible.<br />

The VTX-240 G3 on the 4.25 t IVECO<br />

eDaily chassis has a range of around<br />

200 km, depending on the frequency<br />

of use of the working platforms.<br />

THE E-MOTOR HAS MANY<br />

ADVANTAGES<br />

The electric motor has a high torque<br />

and shows an efficient engine braking<br />

effect, e.g. when driving downhill<br />

with energy recovery. The vehicle has<br />

fewer moving parts, such as the alternator<br />

and gearbox, which increases<br />

the service life. Running costs are also<br />

significantly lower.<br />

Even work up to 3 metres below floor level is possible with the versatile<br />

VTX-240 G3.<br />

Ideal for fast work on roof surfaces: The VTX-240 G3 reaches up to<br />

12.5 metres lateral reach at a height of 12 metres<br />

| 25

<strong>Experience</strong><br />

NOVELTY<br />

ECOLINE 270:<br />

“THE NEXT LEVEL” IN THE LOW-BUDGET SEGMENT<br />

27 metres working height and 16 metres outreach - ECOLINE 270 extends the ECOLINE range by 3 metres<br />

working height. Add to this a vehicle length of 7.53 metres and a permissible set-up angle of up to 5° - it<br />

doesn’t get more compact than this.<br />

The stable fine-grained steel construction incorporates a<br />

great deal of RUTHMANN know-how and components<br />

from proven series, a guarantee of durability and reliability.<br />

ECOLINE 270 - THE LEAP UPWARDS<br />

Until now, ECOLINE telescopic working platforms up to 23<br />

metres and articulated telescopic working platforms up to<br />

24 metres working height were available. With the new<br />

ECOLINE 270, RUTHMANN presented this powerful truckmounted<br />

working platform with 4 metres more working<br />

height and compact dimensions on a 3.5 t chassis at<br />

bauma 2022. The working platform is particularly tolerant<br />

when setting up, even on slopes, with a 5° permissible<br />

set-up inclination and a large outrigger stroke. With a<br />

length of just 7.53 metres, it is more compact than comparable<br />

offers and scores with increased manoeuvrability and<br />

less risk of damage. As with the RUTHMANN TB series, the<br />

end crossbar is foldable.<br />

ECOLINE 270 - THE PERFECT MATCH<br />

The ECOLINE 270 is characterised by the combination of<br />

proven and optimised components. It is based on proven<br />

components from the ECOLINE and RUTHMANN STEIGER ®<br />

TB series. The carrier system with the telescope comes from<br />

the successful STEIGER ® TB 270+, the optimised base frame<br />

from the ECOLINE 230 and the foldable light carriers from<br />

With a reach of up to 16 metres and a working height of 27 metres, the<br />

new ECOLINE 270 is ideal for building cleaners, for example. Large glass<br />

surfaces can be worked on without having to move the machine.<br />

the TB 270 pro. The control panel and workman basket<br />

with 230 kg basket load also come from the ECOLINE 230.<br />

For our customers, this means: extreme performance at an<br />

attractive price.<br />

The fast availability of spare parts is guaranteed by compatible<br />

spare and wear parts. RUTHMANN customers benefit<br />

from a close-knit service network with highly qualified staff,<br />

short distances and modern workshop equipment.<br />

The ECOLINE 270 has a permissible set-up inclination of 5° and is excellent for<br />

working on slopes due to the 50 mm increased support stroke. The wedge-shaped<br />

RUTHMANN shims ensure a safe stand.<br />

The ECOLINE 270 offers a wide range of support variants and can also<br />

be used in cramped conditions.<br />

| 26

NOVELTY<br />

<strong>Experience</strong><br />

FLEXIBLE APPLICATION POSSIBILITIES THROUGH<br />

PROVEN SUPPORT VARIANTS<br />

Despite the favourable overall price, the ECOLINE 270<br />

offers a wide range of applications and is therefore interesting<br />

for many industries and the rental business. The<br />

modern horizontal and vertical outriggers allow the ECO-<br />

LINE 270 to be set up close to the building and to make<br />

optimum use of the available outreach. Supports are possible<br />

on both sides, on one side and in profile and allow,<br />

among other things, use in confined spaces. If desired, the<br />

automatic function helps to bring the ECOLINE 270 quickly<br />

into the operating position.<br />

The stable design of the ECOLINE 270 also allows it to be<br />

used with a maximum working platform tilt of 5°, which is<br />

4° more than the direct competition provides.<br />

Another new feature of the ECOLINE 270 - compared to<br />

the ECOLINE 230 - is the 50 mm longer support stroke.<br />

This makes working on slopes much easier. Together with<br />

the wedge-shaped RUTHMANN shims, it can be used<br />

safely here.<br />

The ECOLINE 270 is attractive for a wide range of<br />

target groups. Maximum performance on a compact<br />

chassis makes it universally applicable for many industries<br />

and in the rental business.<br />

The popular ECOLINE control panel is also used in the ECOLINE 270<br />

with the familiar operating concept. The machine can be used immediately<br />

without having to get used to it.<br />

The ECOLINE 270 offers a wide range of applications for almost all industries<br />

and the rental business. The use of proven components makes<br />

it easy to maintain and reliable in use.<br />

| 27

<strong>Experience</strong><br />

NOVELTY<br />

VERSALIFT PRESENTS<br />

THE NEW V-SERIES AT<br />

THE APEX <strong>2023</strong><br />

VERSALIFT is introducing the groundbreaking V-series<br />

at APEX <strong>2023</strong>: a new range of high-quality telescopic<br />

working platforms on 3.5 t chassis!<br />

The new range will initially comprise three models:<br />

the V170 with 17 metres working height, the V-200<br />

with 19.9 metres working height and the V225 with<br />

22.5 metres working height. The first is the V-200,<br />

which will be launched in May <strong>2023</strong> and will make its<br />

debut at the APEX trade fair in <strong>2023</strong>.<br />

This new range has been developed to complement our<br />

existing product line and fill the gap in our portfolio previously<br />

created by the strong focus on working platforms<br />

based on enclosed panel vans. Over the years, we have<br />

received numerous requests for VERSALIFT telescopic<br />

boom lifts on a 3.5 t chassis, and we decided to respond to<br />

our customers’ requests by offering a complete range with<br />

the new V-series, which meets the different needs of the<br />

diverse market in Europe.<br />

CLOSE COOPERATION IN THE DEVELOPMENT THE V<br />

SERIES<br />

Based on market analyses and suggestions from our customers,<br />

we are constantly reviewing which products should<br />

be added to our portfolio. Since RUTHMANN and, more<br />

recently, France Elévateur have become part of the TIME<br />

Group, we have been working closely together to find out<br />

which products we need to add to strengthen our range of<br />

machines.<br />

With our combined expertise, we have found that adding<br />

a range of straight telescopic platforms with working<br />

heights between 17 and 22.5 metres in the well-known<br />

VERSALIFT quality is the solution. We will soon be launching<br />

a whole range of new telescopic platforms on chassis,<br />

including the V-200, V-170 and V-225-F models.<br />

To tailor our offer to the French market, it has also been decided<br />

that the V170 will be a joint venture between France<br />

Elévateur and VERSALIFT. This will allow us to work<br />

closely together on the development of the unit, with VER-<br />

SALIFT designing and manufacturing the lift, and France<br />

Elévateur providing the undercarriage and assembly at its<br />

state-of-the-art facilities in northern France.<br />

The first model in the V range, the V-200, will be launched<br />

in spring <strong>2023</strong> and presented at APEX <strong>2023</strong>. The V170 will<br />

be the next model to follow and the V225 will complete<br />

the range. At VERSALIFT, we strive to meet our customers’<br />

needs and continuously improve our product offering. The<br />

addition of the V-Range will allow us to offer an even more<br />

comprehensive product range, providing customers with a<br />

greater choice of high quality lifts.<br />

“We are pleased to announce the launch of the V-Range,<br />

which is the result of our strong partnership with RUTH-<br />

MANN and France Elévateur,” says Martin Sloth, Product<br />

Manager at VERSALIFT Europe. “We have listened to our<br />

customers and the V-Range is the perfect addition to our<br />

product range, giving our customers more options and<br />

solutions for their working platform needs.”<br />

INTRODUCTION OF VERSALIFT’S V-200.<br />

The V-200 is a powerful telescopic platform that rides on<br />

a 3.5 tonne Iveco Daily with a wheelbase of 3750 millimetres.<br />

The short wheelbase reduces the turning radius and<br />

ensures optimal manoeuvrability. Both the telescope and<br />

the subframe of the V-200 are made of high-strength steel.<br />

They are lightweight yet robust and provide ample free<br />

payload for the installation of a VERSALIFT hybrid system,<br />

such as the E-Tech lithium battery pack.<br />

| 28

NOVELTY<br />

<strong>Experience</strong><br />

19.9 METRES WORKING HEIGHT AND<br />

300 KG BASKET LOAD<br />

With a maximum working height of 19.9 metres and a horizontal<br />

reach of 14 metres, the V-200 covers a large working<br />

area and is extremely powerful. It has a high maximum<br />

basket load of 300 kg and offers space for two people in<br />

the work basket. The operator can thus easily transport<br />

tools and material in the workman basket. In the transport<br />

position, the machine is less than 3 metres high.<br />

Equipped with an automatic outrigger, this lift guarantees<br />

safe and reliable operation. The automatic stabilisation<br />

and levelling system facilitates effortless levelling of the<br />

machine and increases safety. The operator can control the<br />

supports from the work cage or from the optional control<br />

panel located at the rear of the vehicle, offering flexibility in<br />

different situations.<br />

The precise and smooth proportional movements of the<br />

VERSALIFT control system give the operator more control,<br />

especially during simultaneous manoeuvres. The V-200 has<br />

an aluminium workman basket that provides access from<br />

both the front and rear for entry and exit. This gives the<br />

operator flexibility for roof work and other tasks. The workman<br />

basket is equipped with a hydraulic swivel as standard,<br />

giving the operator maximum flexibility.<br />

| 29

<strong>Experience</strong><br />

NOVELTY<br />

STEIGER ® T 300 XS HYBRID<br />

THE WORLD’S FIRST<br />

HYBRID STEIGER ® ON A<br />

7.49 T CHASSIS<br />

Based on the current and very successful STEIGER ® T 300 XS, RUTHMANN<br />

now offers the STEIGER ® T 300 XS Hybrid, the first hybrid truck-mounted<br />

working platform on a 7.49 t chassis. The STEIGER ® T 300 XS Hybrid offers<br />

the same outstanding performance data: 30 metres working height,<br />

23 metres outreach and 350 kg basket load on a compact 7.59 metre<br />

chassis. The speed of the individual movements is almost identical to the<br />

STEIGER ® T 300 XS.<br />

POWERFUL HYBRID DRIVE WITH-<br />

OUT COMPROMISE<br />

The RUTHMANN engineers have<br />

succeeded in designing the powerful<br />

hybrid with 12.8 KWh battery in such<br />

a way that the zGG of the STEIGER ® s<br />

T 300 XS Hybrid on MAN or IVECO<br />

chassis is still less than 7.5 tonnes. This<br />

means that the machine can still be<br />

driven with a C1 driving licence (old<br />

class III). This means that the STEIGER ®<br />

T 300 XS Hybrid is still available to<br />

a large target group who need the<br />

robustness and top performance data<br />

of STEIGER ® s on 7.49 t chassis in their<br />

daily work.<br />

CONVENIENT CHARGING -<br />

EVEN DURING STEIGER ® USE<br />

With its 12.8 KW battery, the STEI-<br />

GER ® T 300 XS Hybrid achieves 13 full<br />

working cycles before it needs to be<br />

charged. The STEIGER ® T 300 XS Hybrid<br />

can be charged either while driving<br />

or by connecting it to the mains<br />

via the easily accessible charging<br />

socket with standard CEE plug. Based<br />

on the good experience with the TB/<br />

TBR Hybrid STEIGER ® s, the T 300 XS<br />

Hybrid can also be charged during<br />

STEIGER ® operation. This opens up<br />

completely new application possibilities<br />

for the STEIGER ® T 300 XS Hybrid,<br />

e.g. it can continue to be operated<br />

silently via mains power during long<br />

building cleaning operations in inner<br />

courtyards. This feature should also be<br />

a very interesting aspect for TV and<br />

film productions.<br />

The operator has the option of changing<br />

the type of drive at any time. If the<br />

battery is empty and no mains power<br />

is available, work can continue with<br />

the combustion engine. The standard<br />

The batteries with a<br />

total of 12.8 KWh<br />

allow the STEIGER ® T<br />

300 XS 13 full working<br />

cycles before it<br />

needs to be charged.<br />

This is done while<br />

driving or without<br />

interrupting work via<br />

the mains connection<br />

with standard<br />

CEE plug.<br />

charging time in idle state is approx.<br />

6 hours at a standard 230 V connection<br />

until the battery has reached full<br />

capacity again.<br />

Alternatively, the STEIGER ® T 300 XS<br />

is also available with a 400 V electric<br />

drive, specially designed for use near<br />

a mains connection. Even with this<br />

option, the permissible total weight of<br />

the STEIGER ® s T 300 XS Hybrid is still<br />

less than 7.5 tonnes.<br />

CONVENIENT JACK CONTROL<br />

PANEL WITH SCREEN AT EYE LEVEL<br />

The STEIGER ® T 300 XS Hybrid also<br />

offers many proven innovations “on<br />

the ground”. For example, the new<br />

outrigger operation, which is very<br />

popular in the TB/TBR series, is used as<br />

standard. The STEIGER ® s T 300 XS Hybrid<br />

can be propped using the electric<br />

drive or also with the combustion engine.<br />

The new control unit is optimally<br />

| 30

NOVELTY<br />

<strong>Experience</strong><br />

With a vehicle length of only 7.59 metres, the STEIGER ® T 300 XS Hybrid<br />

is the most compact truck-mounted working platform in its class<br />

and boasts outstanding performance data.<br />

The work basket can carry up to 350 kg and can be rotated 90° at a<br />

time. There is a choice of numerous work baskets that can be easily<br />

changed.<br />

integrated at eye level on the chassis<br />

and, in addition to the reliable support<br />

variants and comfort functions, offers<br />

practical stabilization of the machine<br />

on the vehicle at all times. Clear, easily<br />

recognisable switches that can change<br />

colour never leave the machine operator<br />

in the dark.<br />

MORE BASKET LOAD AND PROVEN<br />

OPERATION<br />

The stable new telescopic design of<br />

the STEIGER ® T 300 XS Hybrid has also<br />

increased the basket load by a further<br />

30 kg to a maximum of 350 kg.<br />

Die Stützensteuerung<br />

des STEIGER ® s T 300<br />

XS Hybrid ist bequem<br />

auf Augenhöhe angeordnet<br />

und erlaubt<br />

es, die Maschine über<br />

den Elektro- oder<br />

Verbrennungsmotorantrieb<br />

abzustützen.<br />

The familiar workman basket from<br />

the T series is compatible with other<br />

baskets from the same series. The<br />

modern RUTHMANN Cockpit is used,<br />

with numerous comfort functions and<br />

real-time readable operating data. It<br />

provides the platform operator with all<br />

relevant data at all times.<br />

The STEIGER ® T 300 XS Hybrid can<br />

also be equipped with all work cages<br />

of the series, e.g. pruning and insulated<br />

work cages or the large, 2.10<br />

m wide work cage. As usual with<br />

RUTHMANN, this is done with two<br />

people and a few simple steps.<br />

| 31

<strong>Experience</strong><br />

NOVELTY<br />

THE NEW VERSALIFT VTE AND VDTE ARE ALSO<br />

AVAILABLE ALSO 100 % ELECTRICALLY AVAILABLE<br />

VERSALIFT proudly presents the launch of its latest family members, the VTE and the VDTE, specifically designed<br />

to meet the different needs of professionals in various industries.<br />

These two new working platforms can be mounted on various box trucks with different drives and are characterised<br />

by their high level of quality and user-friendly features.<br />

EXCEPTIONALLY LIGHT CONSTRUCTION<br />

VTE-34-125-F on Renault<br />

During the design phase of the VTE and VDTE, the primary<br />

objective was to achieve an extremely light construction so<br />

that these lifts could also be fitted to 100% electric vans.<br />

Currently available vans with electric drives have a limited<br />

payload, which is a major challenge when it comes to<br />

providing customers with a lift that offers both an optimal<br />

working height and sufficient payload for materials.<br />

Thanks to our extreme weight optimisation, which has<br />

gone into the development of the new models, the two<br />

new models VTE and VDTE can be installed in fully electric<br />

vans. This gives our customers the choice between a<br />

van chassis with an internal combustion engine or a 100<br />

% electric panel van, without having to compromise on<br />

operational data.<br />

USER-FRIENDLY DESIGN<br />

The VTE and VDTE models Length: feature 6692 simple mm Height: and effective 2990 controls<br />

with LCD screens on both the upper and removable<br />

mm Wheelb<br />

lower controls. In addition, these units are designed without<br />

outriggers, allowing for quick and effortless set-up, and<br />

the working platforms can also be used with an inclination<br />

12,3 m 10,3 m 7 m 120 kg 1-man N/A Single Joysti<br />

Diagramme(s)<br />

| 32<br />

Technical data VTE-34-125-F<br />

Working height:<br />

Reach:<br />

Max. basket load:<br />

strength steel booms provide<br />

improved rigidity, stiffness and<br />

performance<br />

12.3 m<br />

7 m<br />

120 kg<br />

Max. inclination: 3°/5°<br />

Max. weight:<br />

Max. payload:<br />

3,500 kg<br />

395 kg<br />

1 kV insulation<br />

Notes

NOVELTY<br />

<strong>Experience</strong><br />

of 3° to the transverse axis and 5° to the longitudinal axis.<br />

Weighing less than 3.5 t, these models are compact and<br />

highly manoeuvrable, offering a working height of around<br />

12 metres. The VDTE in particular is mounted on a cut-van,<br />

which is perfect for working in urban areas where a particularly<br />

short design is required.<br />

VDTE-33-120 on Renault<br />

OPTIMAL UTILISATION OF THE LOADING SPACE<br />

The VTE and VDTE models are equipped with an innovative<br />

plinth and sub-frame design that allows for a flat floor and<br />

thus optimum utilisation of the cargo space within the van.<br />

This feature is particularly useful for professionals who need<br />

to transport a variety of tools and materials. The VTE and<br />

VDTE have a large payload of 395 and 768 kg respectively<br />

and are easy to load and unload. The asymmetric workman<br />

basket allows material to be conveniently loaded from the<br />

interior directly into the workman basket without having to<br />

step onto the carriageway.<br />

The VTE and VDTE are available from dealers now. If you<br />

would like to learn more about these new aerial work platforms,<br />

please visit our website or contact us directly. Our<br />

team is always available to assist you with any questions<br />

you may have.<br />

The VDTE is mounted on a Length: cut van and 5260 is therefore mm extremely Height: compact 2800 mm Whee<br />

with an overall length of only 5.26 metres. In operation, it reaches a working<br />

height of 12 metres and a lateral reach of around 7 metres.<br />

11,9 m 9,9 m 6,7 m 120 kg 1-man N/A Single Jo<br />

Diagramme(s)<br />

Technical data VDTE-33-120<br />

Working height:<br />

11.9 m<br />

Reach:<br />

6.7 m<br />

Max. basket load: 120 kg<br />

Max. inclination: 3°/5°<br />

Max. weight:<br />

3,500 kg<br />

Max. payload:<br />

768 kg<br />

| 33<br />

strength steel booms provide<br />

improved rigidity, stiffness and<br />

performance<br />

Ultra compact transport<br />

dimensions suitable for urb<br />

work environments

<strong>Experience</strong><br />

IN USE<br />

COMPACT IN USE: KARGL GMBH RELIES<br />

ON THE BLUELIFT SA 18 HB IN TREE CARE<br />

For more than 20 years and now in its second generation, the company<br />

Kargl GmbH has been shaping and maintaining trees, gardens and<br />

landscapes in the Regensburg region. In addition to numerous trucks,<br />

tractors and forestry equipment, a BLUELIFT SA 18 HB crawler working<br />

platform has also been part of the fleet since 2022.<br />

The compact crawler working platform perfectly complements the fleet, as it<br />

can reach work sites that are inaccessible to other machines. With a width of<br />

only 0.78 metres and a height of just 1.99 metres, the BLUELIFT SA 18 HB can<br />

be brought into gardens by Kargl’s landscape gardeners, for example, to prune<br />

trees there. With its low tare weight of 2,200 kg and the rubber track chassis,<br />

it overcomes lawns or slopes without damage and does not even stop at steps.<br />

The 1.3 x 0.7 metre working cage carries up<br />

to 230 kg and can reach many locations.<br />

COMPACT YET FLEXIBLE IN USE<br />

The SA 18 HB reaches a working height of up to 17.8 metres when pruning<br />

and is easy to manoeuvre into the treetops thanks to its articulated design and<br />

compact working cage. “The flexible application possibilities of the compact<br />

machine are very much appreciated by the employees,” says Karl-Heinz Kargl,<br />

owner and managing director of Kargl GmbH. “In particular, the fact that the<br />

machine requires just a support area of 3 x 3 metres to achieve its full operating<br />

data is very advantageous in our applications,” Kargl continues.<br />

The BLUELIFT SA 18 HB is powered by a Honda petrol engine, which enables<br />

self-sufficient use in the forest and off-road. Likewise, the almost noise- and<br />

emission-free drive with mains electricity is also possible. “Many of our<br />

customers appreciate this very much when the engine is not always causing<br />

exhaust fumes and noise in the garden during longer tree care operations,” Mr<br />

Kargl reports from daily practice.<br />

“For us, the BLUELIFT SA 18 HB fills a gap left by other, larger machines,” Mr<br />

Kargl continues. “A compact yet powerful solution that supports us in our<br />

daily work and that my employees can easily take to the customer themselves<br />

on the trailer.”<br />

Due to the small support surface, the machine<br />

can also be used on small plateaus, for example.<br />

The SA 18 HB can handle slopes of up to 28%.<br />

The supports prevent it from tipping over if the<br />

ground should give way a little.<br />

With a width of just 0.78 metres, the BLUELIFT<br />

SA 18 HB can reach almost any site, no matter<br />

how remote.<br />

The SA 18 HB reaches a height of 18 metres<br />

and a lateral reach of up to 9.3 metres.<br />

| 34

IN USE<br />

<strong>Experience</strong><br />

IN PRACTICE: THE ALL-ELECTRIC STEIGER ® AMPERO<br />

TBR 250 E AFTER ONE YEAR IN OPERATION<br />

GERKEN was the first access<br />

platform rental company to invest<br />

in the 100% electric RUTHMANN<br />

STEIGER ® Ampero TBR 250 E in<br />

2019.<br />

RUTHMANN developed the E-STEI-<br />

GER ® with a working height of 25<br />

metres and a range of 16 metres<br />

together with the Orten company,<br />

which electrified the Mercedes<br />

Sprinter. Today, there are already<br />

several fully electric RUTHMANN<br />

STEIGER ® in the GERKEN rental<br />

fleet under the name GL 25 N. One<br />

of them is in permanent rental at a<br />

parks department in the Ruhr area.<br />

ROBUST AND VERSATILE<br />

The electric truck mounted platform is ideal for municipal use in urban environments.<br />

The operating time per battery charge is on average two working days.<br />

The Ampero is not spared in its work<br />

and now replaces an older working<br />

platform with a combustion engine<br />

that was previously used. The parks<br />

department uses the working platform<br />

for a wide range of tasks, including<br />

tree pruning and grove maintenance<br />

in residential areas, on the outskirts<br />

of the city and in schoolyards. Tree<br />

pruning is consistently carried out<br />

with battery-powered equipment, so<br />

that the peace and quiet gained is<br />

not disturbed by the noise of a petrol<br />

chainsaw.<br />

ADVANTAGES NO ONE WANTS TO<br />

DO WITHOUT<br />

The all-electric truck-mounted working<br />

platform has not only completely<br />

replaced its predecessor, but also<br />

offers many advantages that no one<br />

would want to do without. Particularly<br />

worth mentioning is the extremely low<br />

noise level during operation, which<br />

allows employees to work even in<br />

the early morning hours or late in the<br />

evening without disturbing the neighbourhood.<br />

In addition, communication<br />

between employees has improved,<br />

leading to fewer mistakes, as everyone<br />

can communicate better in the quiet<br />

environment.<br />

The environment and the health of<br />

the employees also benefit from the<br />

electric STEIGER ® , as it does not emit<br />

any exhaust gases or fine dust that<br />

could be inhaled. Passers-by also react<br />

very positively to the emission-free<br />

machine.<br />

TOP PERFORMANCE DATA<br />

The Ampero rides on a 5-ton Sprinter<br />

chassis. Due to this higher operating<br />

weight, it achieves a significantly<br />

higher reach than the usual truckmounted<br />

working platforms on a 3.5<br />

t chassis, both with narrow and full<br />

jacking.<br />

Thanks to the 5 t chassis and the box body,<br />

the required tools can be taken to the site.<br />

The parks department now relies mainly on<br />

quiet battery-powered equipment.<br />

WELL ON ITS OWN POWER<br />

For the parks department, it is particularly<br />

attractive to operate their working<br />

platforms with electricity from<br />

their own grid or from renewable<br />

sources. With one battery charge, the<br />

Ampero at the Parks Department can<br />

be operated for around two days. The<br />

daily workload is 5 to 8 tree-cutting<br />

operations and about 20 kilometres,<br />

which are also covered electrically.<br />

“The conclusion after one year of<br />

continuous operation is absolutely<br />

positive! Despite initial reservations,<br />

the all-electric machine was convincing<br />

in all respects and in some respects<br />

even exceeded expectations,” says<br />

the head of operations at the office.<br />

head of the office. “The employees no<br />

longer want to be exposed to the exhaust<br />

fumes and noise of conventional<br />