Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Issue</strong> autumn 01/<strong>2021</strong><br />

A publication from the RUTHMANN Holdings GmbH | www.ruthmann.de<br />

120 years RUTHMANN<br />

#YourRuthmannStory<br />

28<br />

Xtra short Xtra performance<br />

- the new<br />

STEIGER® T 300 XS!<br />

38<br />

Restructuring of the<br />

company group<br />

39<br />

New assembly centre in<br />

Gescher-Hochmoor<br />

from 51<br />

ECOLINE AND BLUE-<br />

LIFT in operation

RUTHMANN RENTAL & USED<br />

CLEVERUSED<br />

CLEVERUSED<br />

YOUR ADVANTAGES TO PURCHASE<br />

We offer a wide range and decade-long competences with<br />

used aerial platforms and special transport vehicles, not<br />

only from the company Ruthmann - but also from other<br />

manufacturers.<br />

All used vehicles with a high quality guarantee (TÜV, UVV<br />

according to BGG) - ensured by our highly qualified service<br />

staff and documented by seamless maintenance histories.<br />

Thanks to our tip-top conditioning (cleaning and painting),<br />

you will get your used vehicle in a unique almost as new<br />

look.<br />

We show you individual financing and insurance models<br />

and offer you service and maintenance for the purchased<br />

equipment.<br />

CLEVERRENT<br />

CLEVERRENT<br />

ALL INCLUSIVE - OUR COMPLETE SERVICE<br />

When purchasing a machine, the service and maintenance costs<br />

as well as the wear costs tear to a variable pool of costs in addition<br />

to depreciation and interest. Renting offers you maximum<br />

availability (also due to our primary vehicle regulation) at a<br />

fixed rental rate.<br />

Our complete service includes all statutory inspections (TÜV/<br />

BGG) and repair works including wear parts both on vehicle but<br />

and on the Ruthmann superstructure in addition comprehensive<br />

insurance and maintenance services. Our factory-owned<br />

service points combined with our mobile service vehicles are<br />

available for you 24-hours a day and ensure that your machine<br />

is always ready for use.<br />

Individual consultation as well as rehearsal/testing possibilities<br />

are a matter of course for us upon appointment.<br />

WE OFFER FIRST CHOICE USED MACHINES WITH THE RUTHMANN<br />

TYPICAL QUALITY PROMISE IF YOU:<br />

• want to gain your first experience in operating your own<br />

aerial platform<br />

• are searching your own special vehicle<br />

• wish to become self-employed with a low budget<br />

• need to increase your own capacities at short term<br />

All offers on the web: www.ruthmann.de/rental-used<br />

We have awakened your interest?<br />

Then please touch in contact with us:<br />

Stefan Linnemann<br />

unter: +49 2863 204-237<br />

via E-mail unter:<br />

stefan.linnemann@ruthmann.de<br />

Stefan Linnemann,<br />

Director Rental & Used,<br />

authorized representative

GREETING<br />

GREETING<br />

Dear Customers, Partners and Readers,<br />

We are celebrating our 120th anniversary and we were very delighted<br />

with the numerous stories about and with the RUTHMANN STEIGER ® you<br />

sent us. You can read some few selected ones in this issue. Other will be<br />

published in the next weeks on our social media.<br />

At the beginning of the year, we informed about the acquisition by the<br />

American TIME Manufacturing Company. After having now acted together<br />

a few months, we feel confirmed in our actions and are pleased<br />

about the great synergy from which our customers will benefit. Actually,<br />

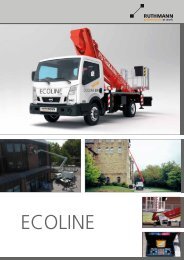

for example the sales network for our BLUELIFT and ECOLINE machines<br />

has already been highly expanded. These are now also available by our<br />

European Versalift subsidiaries.<br />

From left to right: Uwe Strotmann, Rolf Kulawik,<br />

Uwe Stapper und Dr. Nico Krekeler.<br />

Not on the picture: Stefan Linnemann<br />

Our new compact 30 meter STEIGER ® T 300 XS is now also available<br />

which was for the first time presented online at 23rd June <strong>2021</strong>. Please<br />

read from page 28 what makes our new STEIGER ® unique and why the<br />

sector still celebrates it.<br />

In order to satisfy the increased demand for RUTHMANN STEIGER ® , we<br />

have invested in a new modern assembly centre in Gescher-Hochmoor. In<br />

addition to the STEIGER ® of the TB/TBR range, also new workplaces will<br />

be created here by the end of 2022..<br />

We wish you an enjoyable read.<br />

Your RUTHMANN management team<br />

Rolf Kulawik, Managing Director of the<br />

RUTHMANN Holdings GmbH (on the left) and<br />

Curt Howell, CEO TIME Manufacturing Company<br />

(on the right) further rely on innovations and an<br />

expanded sales and service network.<br />

CONTENT 4 ................120 years RUTHMANN<br />

28 .............. Xtra short Xtra performance: The new STEIGER T 300 XS is here<br />

32 .............. STEIGER ® T 700 HF - 70 m on a compact chassis<br />

34 .............. T 295 A - STEIGER T 900 HF becomes an American legend<br />

35 .............. RUTHMANN-solutions for the material handling<br />

36 .............. BLUELIFT ST 31 – 31 meters and 18.2 meters outreach<br />

38 .............. With the TIME Manufacturing Group on a new course<br />

39 .............. New assembly centre in Gescher-Hochmoor<br />

40 .............. CEO Curt Howell‘s visit in Gescher-Hochmoor<br />

41 .............. Expansion of the BLUELIFT and ECOLINE sales network<br />

42 .............. RUTHMANN STEIGER ® in operation<br />

48 .............. VERSALIFT truck-mounted platforms in operation<br />

51 .............. ECOLINE truck-mounted platforms in operation<br />

54 .............. BLUELIFT rubber-tracked platforms in operation<br />

58 .............. SERVICE with the TeamViewer-Pilot<br />

59 .............. RUTHMANN aktiv<br />

60 .............. RUTHMANN in-house<br />

64 .............. Working at RUTHMANN<br />

| 3

#YourRuthmannStory<br />

| 4

120 YEARS RUTHMANN: STORIES FROM OUR CUS-<br />

TOMERS ABOUT AND WITH THE RUTHMANN STEIGER ®<br />

Under the hashtag #YourRuthmannStory, we had asked for your stories about and<br />

with the RUTHMANN STEIGER at the beginning of the year. Many customers, friends<br />

and employees sent us their stories - thank you very much!<br />

On the next pages, you will<br />

find a selection of “stories”,<br />

other ones will be published<br />

in the next weeks and months<br />

on our social media channels.<br />

The stories are partly based on<br />

bullet point forms but also on<br />

fully submitted texts.<br />

The best stories will be prized.<br />

Likewise we sent all supporters<br />

a little thank you in the form of<br />

our anniversary chocolate.<br />

We wish you an entertaining<br />

reading of our small<br />

RUTHMANN stories and hope<br />

that, in addition to a few “aha”<br />

moments, you will find something<br />

here and there for you to<br />

smile about.<br />

One of the first motorised working platforms was delivered to the “lamps<br />

cleaners” of the Stadtwerke Duisburg which was followed by other ones<br />

after the number of accident in this dangerous job could significantly be<br />

reduced. In 1955 the machine was exhibited at the car show in Brussels<br />

what leaded to full order books.<br />

| 5

And our “Tönne” (Anton) is responsible<br />

for the technical department.<br />

He invented the lift truck and<br />

STEIGER ® ”<br />

“Yes but what do you do?<br />

- “Me?” he answered with a grin,<br />

“I am the eldest…”*<br />

The family RUTHMANN was not<br />

originally from Gescher and spoke<br />

High German, not Low German.<br />

GESCHER STORIES „ABOUT THE ÖLLSTEN“<br />

An 82-year-old man from<br />

Gescher still remember the<br />

stories about Ruthmann which<br />

have been told over the last 120<br />

years in Gescher - the following<br />

is one of them.<br />

In an inn in Gescher, „Jupp“ (Josef)<br />

RUTHMANN was once asked what<br />

he was doing in his company:<br />

“Well, my brother Hubert is responsible<br />

for sales.<br />

This story “about the öllsten” was<br />

probably retold in Low German by<br />

the inhabitants from Gescher.<br />

* For the younger ones, here is the explanation:<br />

On Münsterland farms, the firstborn<br />

i.e. the eldest, traditionally inherits the farm.<br />

The younger brothers usually leave the parental<br />

farm. In case single younger brother<br />

still stay on the farm (as “Öhme”), then they<br />

work physically. The heir to the farm - i.e.<br />

the eldest - has more pleasant tasks such as<br />

purchase, negotiating etc.<br />

is the “sustainability advertised on<br />

your website”, reports the proud<br />

owner of the RUTHMANN oldtimer.<br />

The restauration of the STEIGER<br />

should be started in the near future<br />

so that the machine can be used<br />

in style on the old farm for many<br />

years to come. We look forward to<br />

continue to support you. Perhaps<br />

we will be able to present the K<br />

90 in new splendour for the 125th<br />

anniversary.<br />

120 YEARS RUTHMANN<br />

SUSTAINABILITY IN ACTION<br />

“Sustainability in action” - With<br />

this motto, we have received<br />

the pictures of the RUTHMANN<br />

STEIGER ® K 90 from Sven Schroers.<br />

“At the beginning of 2014, you<br />

kindly helped me with documents<br />

about the K 90. Until today, the<br />

“Hubsteiger” is regularly in use at<br />

our farm. Only a few hydraulic lines<br />

have been exchanged for safety.<br />

Otherwise, the “Hubsteiger” built<br />

in 1959 seems indestructible. This<br />

| 6

#YourRuthmannStory<br />

THE LAST OF ITS KIND?!<br />

In 2008, Carsten Schiedrum discovered the “treasure”<br />

by chance on Internet. After days of correspondence,<br />

some pictures and many sleepless<br />

nights, he bought the STEIGER ®® without having<br />

really seen it. “By picking-up the machine in<br />

Cham near to the Czech border, after a 400 kilometre<br />

drive, it became apparent that everything<br />

was true - and I was so relieved” says C. Schiedrum.<br />

At home near to Kassel, the V 80 did not fit in the<br />

intended garage and another place to stay had to<br />

be found. “Fortunately at this time, I was delivering<br />

Christmas stalls for our village and they became so<br />

enthusiastic that I could park the V 80 in the hall”, tells<br />

C. Schiedrum. “But the condition was to present the<br />

“HubSTEIGER ® ” at the next car show in Eschwege”.<br />

Apart from a few parts,<br />

the RUTHMANN<br />

STEIGER ® V 80 is until<br />

today unrestored in<br />

its original state and<br />

still in operation. Who<br />

would like to admire the<br />

Code to the SWR<br />

report on You-<br />

Tube<br />

V 80 in reality: Volkswagen is actually exhibiting the<br />

RUTHMANN V 80 in its utility vehicle customer centre<br />

in Hanover.<br />

This is how the STEIGER ® V 80 on the VW T1 became<br />

known beyond the state’s borders and even became<br />

part of the SWR report “VW-bus a transporter for the<br />

world” in which another vehicle of C. Schiedrum also<br />

played a “role”. At the end, VW Nutzfahrzeuge took<br />

special note from this special T1 exemplar thanks to<br />

the SWR report.<br />

| 7

#YourRuthmannStory<br />

Photo: Frédéric Boyadjian

STEIGER ® T 900 HF<br />

SUPPORT FOR<br />

NOTRE-DAME<br />

In the devastating fire disaster on the evening<br />

of the 15th April 2019 in the about 700-yearold<br />

Notre-Dame de Paris Cathedral, the<br />

complete wooden roof truss of the nave and<br />

the crossing tower were destructed.<br />

Due the extreme heat of the fire, the gigantic<br />

steel scaffolding partially melted into each<br />

and threatened to collapse in the nave as<br />

well.<br />

For dismounting the scaffolding consisting of<br />

around 40,000 parts, working platforms with<br />

a high lateral outreach were needed.<br />

After several French rental companies had to<br />

pass, the solution was found at the company<br />

Joly in a small village in Burgundy. At that<br />

time, Joly was the one rental company in the<br />

world with two RUTHMANN SKY PERFOR-<br />

MANCE STEIGER ® T 900 HF in its fleet and<br />

was able to bring them at short term to<br />

Paris. The RUTHMANN STEIGER ® T 900 HF<br />

is predestined for the task at the Notre-Dame<br />

Cathedral, because with 42 meters lateral<br />

outreach and the High-Flex technology, the<br />

working basket can dive deeply into the<br />

scaffolding structure in order to examine the<br />

state of the scaffolding and to mount sensors<br />

recording the movements of the scaffolding.<br />

Both STEIGER ® T 900 HF have received reinforcement<br />

by a STEIGER ® T 750 HF as well as<br />

through a further another T 900 HF rented<br />

from another supplier.<br />

All three RUTHMANN STEIGER ® are<br />

equipped with the new DRS system (Dynamic<br />

Reach system) and can fully exploit their performance<br />

data when used for Notre-Dame<br />

as the outreach is permanently calculated<br />

depending on the basket load. Thus, no outreach<br />

meter remains unused.<br />

The STEIGER ® were in operation 16 hours a<br />

day, 7 days a week. After about 1.5 year, the<br />

steel scaffolding was dismounted by means<br />

of the three RUTHMANN STEIGER ® and with<br />

the help of a 25 t revolving tower crane as<br />

well as a lot of rope climbers. Afterwards a<br />

rain roof was placed over the former site of<br />

the crossing tower in order to protect the<br />

cathedral from further rain.

JUBILEE READY OPERATION OF THE HF RANGE<br />

As if we had ordered the picture ourselves to promote our HighFlex range, this picture arrived at us on<br />

the occasion of the 120th anniversary:<br />

The Schickling Company during operation with its T<br />

570 HF at the local court in Cloppenburg. Thanks to<br />

the HighFlex technology, it was possible to work on<br />

the back side over the building on the lower edge of<br />

the balcony though there is no positioning place on<br />

this side.<br />

DID YOU KNOW THE ORIGIN OF THE RUTHMANN LOGO?<br />

Such as Pablo Picasso abstracted his world-famous bull<br />

except a few lines, the “bone” of our RUTHMANN<br />

logo was also created.<br />

Based on a picture taken from another RUTHMANN<br />

STEIGER ® , the picture was reduced to its minimum:<br />

Chassis and working basket.<br />

The result was the RUTHMANN “bone” which was<br />

further optimized and made more symmetrical in the<br />

following years, e.g. for the occasion of the company’s<br />

100th anniversary.<br />

In <strong>2021</strong>, the word and figurative mark were again<br />

adapted and the lettering conveyed. After the motto<br />

“professionals at work” introduced in 2010, the<br />

RUTHMANN logo in its complete representation now<br />

adorns the sub-line “a TIME Manufacturing Company”<br />

to which we have belonged since the beginning of the<br />

year. Please read more about this from page 38.<br />

| 10

#YourRuthmannStory<br />

SCHEURER-ARBEITSBÜHNEN:<br />

“I BELIEVE I CAN FLY”<br />

When we come into our<br />

RUTHMANN halls in the morning,<br />

many a courageous RUTHMANN<br />

STEIGER ® has claimed that they<br />

could fly! Of course, none of us<br />

ever believed that. We thought:<br />

“These “Ruthmen”, they are<br />

crazy…”<br />

But then one of them disappeared<br />

suddenly without a trace for four<br />

weeks and we looked after it<br />

everywhere. Thank God, we have<br />

found him back in the meantime.<br />

Where was he? On the roof of the<br />

new clinic building in Göppingen<br />

by building the new heliport.<br />

We of course confronted him and<br />

asked what that was. He then<br />

answered that he had disappeared<br />

because the boss always required<br />

special and difficult operations<br />

from him. It was the reason why he<br />

had flown round a bit to clear his<br />

head and discovered the helpless<br />

steel construction works on the<br />

clinic roof.<br />

Suddenly he understood why the<br />

boss required so much of him and<br />

thought to himself: “a genuine<br />

RUTHMANN can do anything and<br />

helps in any situation, whenever he<br />

can!”<br />

Thanks to his large outreach and<br />

the mobile lightness, our “I believe<br />

I can fly” runaway safely brought<br />

the construction workers up to the<br />

edge of the heliport - and it was<br />

never even difficult for him.<br />

We are happy that he has reappeared<br />

and is with his RUTHMANN<br />

fleet. As we like to help everywhere<br />

with our 20 “Ruthmen”, you can<br />

never have enough. You never<br />

know if one of them might be<br />

flying through the air - according<br />

to our slogan from the year 1991:<br />

“Scheurer working platforms … as<br />

if you could fly”.<br />

K130: STILL IN USE<br />

EVERY DAY TODAY<br />

The K 130 with the serial number<br />

629 was built in 1972 and is still<br />

in daily service in Serbia.<br />

| 11

FROM THE SEWING MACHINE TO THE LARGEST<br />

WORKING PLATFORM IN THE WORLD<br />

1901 On 01.10.1901 Anton<br />

Ruthmann founds a shop for bicycles<br />

and sewing machines at the<br />

former railway station in Münster.<br />

1920 Construction of a<br />

production hall and warehouse<br />

where Anton Ruthmann produces<br />

and sells his own agricultural<br />

machines.<br />

1909 Due to differences of<br />

opinion within the family about the<br />

management, Anton Ruthmann<br />

moved to Gescher and became<br />

independent once again with a<br />

bicycle business. His wife Clara<br />

manages the “Gabelpunkt” inn<br />

which they have rented.<br />

The company building at the railway station in Gescher<br />

approximately in 1928<br />

1911 He expands the<br />

business by a workshop where<br />

he repairs and sells agricultural<br />

machines.<br />

1926 Purchase of the<br />

country inn “Gabelpunkt” and<br />

rebuilding in a modern hotel<br />

managed by his wife.<br />

1930 Expansion of the pro-<br />

duction by transport machines for<br />

internal purposes such as e.g. sack<br />

trucks or hand carts.<br />

1934 Registration of the<br />

workshop at the Chamber of<br />

Trade Münster in order to carry<br />

out contract work e.g. for the<br />

production of spare-parts for the<br />

mining industry. Also the first<br />

orders from the “Reichsbahn”<br />

for the RUTHMANN containers<br />

bring additional work.<br />

1940 During the Second<br />

World War, the family moves<br />

closer and works in the company<br />

in Gescher. Orders from DEMAG<br />

and the “Reichsbahn” ensure the<br />

continuity of the company.<br />

RUTHMANN presented the lift truck in 1950.<br />

1947 RUTHMANN gets a<br />

provisional production permit from<br />

the English military authorities.<br />

Work can be resumed in the partially<br />

destroyed factory.<br />

1950 The Ruthmann brothers<br />

recognize the great potential<br />

of a self-propelled lift trucks and<br />

present them for the first time at<br />

the “Road and Rail” exhibition in<br />

Essen. The lift truck causes a big<br />

sensation and brings RUTHMANN<br />

full order books.<br />

RUTHMANN produced in 1934 among other things transport containers<br />

for the “Reichsbahn”.<br />

| 12<br />

In 1952, the first lifting equipment for mounting works.

Ruthmann was still smiled for the<br />

purchase of the “Hoher Veen”<br />

moorland. In 1962 the construction<br />

of the current company headquarters<br />

begins.<br />

The first RUTHMANN STEIGER ® in 1954 in operation by the lamp cleaners of the<br />

Stadtwerke Duisburg.<br />

1952 The first lifting equipment<br />

for mounting works is<br />

produced for the industry. The<br />

construction reaches a working<br />

height of 4.5 meters and is primarily<br />

intended to be used for shelving<br />

and maintenance works.<br />

1959 With the new K range,<br />

the STEIGER ® now also disposes a<br />

jib arm which can be used to work<br />

behind small projecting edges.<br />

RUTHMANN registers the terms<br />

“ STEIGER ® ” and “HUBSTEIGER ® ”<br />

with the patent office.<br />

1963 The first STEIGER ® is<br />

produced in the 2,500 m 2 production<br />

hall in Gescher-Hochmoor.<br />

At this time, a production hall as<br />

well an office and a social wing are<br />

situated there.<br />

1966 Further innovative<br />

STEIGER ® such as the US 210 to be<br />

also used for inspecting bridges’<br />

undersides are developed up until<br />

market maturity.<br />

1954 The first RUTHMANN<br />

STEIGER ® is produced for the<br />

Stadtwerke Duisburg based on a<br />

Matador chassis.<br />

The type 60 reaches a working<br />

height of up to 8 meters and makes<br />

the cleaning of the gas lamps in<br />

Duisburg safer.<br />

1956 Only two years later,<br />

RUTHMANN presents the first telescopic<br />

working platform of the type<br />

110. It reaches a working<br />

height of 13 meters and<br />

for the first time, it is also<br />

possible to work laterally<br />

over obstacles.<br />

1957 In addition to<br />

the highly increasing demand<br />

for the new working<br />

platforms, RUTHMANN<br />

develops self-propelled<br />

passenger bridges which<br />

are in use at the Düsseldorf<br />

and Frankfort airports.<br />

1961 After 60 years<br />

of self-employment, Anton<br />

Ruthmann decides to hand<br />

over the company to his children.<br />

From now on, the sons<br />

Josef, Anton-Gerhard and<br />

Hubert manage the business<br />

as an oHG.<br />

At the same time, the<br />

planning for the construction<br />

of a new production<br />

site in Gescher-Hochmoor<br />

is completed. In 1948, Anton<br />

The Ruthmann company premises around 1979 before the<br />

construction of the new office building.<br />

1968 After the rapid rise of<br />

the company and the worldwide<br />

success of his products, the founder<br />

of the company Anton Ruthmann<br />

dies on 26.10.1968 at the age of<br />

88 years.<br />

1970 Presentation of the telescopic<br />

articulated STEIGER ® with<br />

28 meters working height which<br />

finds great sales abroad especially<br />

due to the optional fire brigade<br />

equipment.<br />

| 13

The invited guests marvelled at the worldwide<br />

highest working platform and were able to test<br />

themselves smaller STEIGER ® .<br />

A lovely highlight of the event was the<br />

TTS 1000 pie.<br />

1972 The company previously<br />

run by the family as an oHG<br />

is transformed into a GmbH & Co.<br />

KG. Josef and Hubert Ruthmann as<br />

well as Manfred Holters are appointed<br />

Managing Directors.<br />

1975 Anton-Gerhard<br />

Ruthmann interrupts his retirement<br />

which started one year before. He<br />

builds the first company-owned service<br />

point in Mörfelden, the foundation<br />

stone of the comprehensive<br />

RUTHMANN service network.<br />

1980 The sales department<br />

situated until then in Gescher<br />

moves to the newly built office<br />

building in Hochmoor. The service<br />

follows. The property and the hotel<br />

at the railway station are sold in the<br />

following years.<br />

1985 As worldwide novelty,<br />

the RUTHMANN STEIGER ® TTS 590<br />

with a working height of 60 meters<br />

is presented in 1985. Due to company-owned<br />

development relating<br />

to the telescopic construction, the<br />

machines are becoming even lighter<br />

and more stable. Higher working<br />

heights can be reached in this way.<br />

2001 On the occasion of the<br />

100 th company anniversary, the<br />

RUTHMANN engineers excel themselves<br />

and create with the STEIGER ®<br />

TTS 1000 the worldwide highest<br />

working platform. With 100.4<br />

meters working height and 40<br />

meters lateral outreach, it is so far<br />

ahead of the branch. It took years<br />

before the record was overtaken. A<br />

big celebration with lots of guests<br />

and a varied stage show makes this<br />

glamourous anniversary an extraordinary<br />

event.<br />

2002 After the big anniversary,<br />

several difficult years followed.<br />

Two thirds of the employees had to<br />

be terminated before the trend was<br />

upwards through massive restructuring<br />

in 2003.<br />

2003 The new shareholders<br />

Heinrich Winkelmann and<br />

Heinz-Jürgen Buss restructure the<br />

company and set the company on a<br />

successful course.<br />

2004 With the foundation<br />

of the RUTHMANN Austria GmbH,<br />

RUTHMANN is now also present in<br />

Austria.<br />

2007 RUTHMANN continues<br />

to work on optimising the telescope<br />

profiles and achieves more outreach<br />

and working height with ever<br />

lighter but still stable constructions.<br />

Anton-Gerhard Ruthmann was also congratulated<br />

on his engineering masterpiece and his<br />

professional success.<br />

Heinrich Winkelmann and Heinz-Jürgen Buss restructured RUTHMANN and set the<br />

company on a successful course.<br />

| 14

With the STEIGER ® T 900 HF, RUTHMANN presented for the first time in<br />

2018 a machine equipped with the pioneering Dynamic Reach System (DRS).<br />

2008 RUTHMANN FINANCE<br />

GmbH & Co. KG is founded.<br />

2010 Rolf Kulawik becomes<br />

Managing Director. The previous<br />

managing shareholders Heinrich<br />

Winkelmann and Heinz-Jürgen<br />

Buss remain with RUTHMANN as<br />

shareholders.<br />

2013 With the T 175 A, the<br />

first STEIGER ® is exported to the<br />

USA, opening up another large<br />

market.<br />

2016 Foundation of the<br />

RUTHMANN Italia S.r.l..<br />

2017 The company Hubitec<br />

becomes RUTHMANN Schweiz<br />

AG.<br />

2018 With the development<br />

of the Dynamic Reach System<br />

(DRS), RUTHMANN achieves a<br />

quantum leap in terms of outreach<br />

optimization and a significant performance<br />

increase of the machines<br />

equipped or retrofitted with it.<br />

With the Sky Performance<br />

STEIGER ® T 900 HF equipped for<br />

the first time with DRS (Dynamic<br />

Reach System), RUTHMANN<br />

once again breaks records: 42<br />

meters outreach and an upper<br />

boom length of 33 meters.<br />

RUTHMANN founds the<br />

RUTHMANN North America LP<br />

and expands the sales network in<br />

North America.<br />

With the ECOLINE 180 hybrid,<br />

RUTHMANN for the first time<br />

launches a truck-mounted working<br />

platform on the market both<br />

powered with diesel or electric<br />

engine.<br />

At bauma 2019 RUTHMANN presents<br />

the new TB/TBR range on 3.5<br />

t chassis. The 30 m mark is reached<br />

for the first time with the TB 300.<br />

The TBR 260 disposes of a RÜSSEL ®<br />

and now reaches 26 meters working<br />

height on a 3.5 t chassis.<br />

2020 With the STEIGER ®<br />

T 700 HF, RUTHMANN marks<br />

a new trend for more compact<br />

machines. The STEIGER ® T 700 HF<br />

reaches 70 meters working height<br />

for the first time on a 4-axle chassis<br />

which is shorter than 12 meters.<br />

In the same year, RUTHMANN<br />

acquires the American company<br />

Reachmaster and acts from now on<br />

as RUTHMANN Reachmaster NA<br />

L.P. on the American market.<br />

From now on also 100% electric. In 2019 RUTHMANN<br />

presents the STEIGER ® Ampero TBR 250 E.<br />

2019 With the RUTHMANN<br />

Ampero TBR 250 E, RUTHMANN<br />

goes the step to the first worldwide<br />

fully electric truck-mounted<br />

working platform with 25 meters<br />

working height. Working platform<br />

und chassis use the same battery<br />

and can be easily charged such as<br />

a car.<br />

In the hybrid machine range,<br />

RUTHMANN piles the fire up with<br />

the TB 270 and offers also in this<br />

segment a truck-mounted working<br />

platform relying on both drives.<br />

<strong>2021</strong> The sale of the<br />

RUTHMANN GmbH & Co. KG to<br />

the TIME Manufacturing Group<br />

in February will pave international<br />

channels and significantly expand<br />

the service network.<br />

With the new compact 30 m<br />

STEIGER ® T 300 XS, RUTHMANN<br />

presents a short machine for urban<br />

use with increased performance<br />

data.<br />

On the occasion of the bauma 2019,<br />

RUTHMANN presented the complete TB/TBR<br />

range and with the TB 300 the worldwide highest<br />

working platform on a 3.5 t chassis.<br />

| 15

BEGEMANN’S MIETLIFT SAYS “THANKS YOU FOR THE<br />

BUSINESS RELATIONSHIP EXISTING FOR DECADES”<br />

The e-mail arrived in our anniversary<br />

mailbox with these words from<br />

the company Begemann’s Mielift.<br />

The business relationship between<br />

RUTHMANN and Begemann’s<br />

Mietlift began almost 40 years<br />

ago with the delivery of the first<br />

RUTHMANN GELENKSTEIGER ®<br />

GS 150. The 17 m high articulated<br />

STEIGER ® was popular in Leopoldshöhe<br />

and could be rented for 65<br />

German mark per hour.<br />

“And today it is still there”, says<br />

Klaus Tasche, Managing Director<br />

of Begemann’s Mietservice, “even<br />

though no longer in operation but<br />

in the Begemann’s Mietlift museum.<br />

Further STEIGER ® followed such<br />

as e.g. the first TU 680 which was<br />

added to the fleet in 1996.<br />

Today, the rental fleet of Begemann’s<br />

Mietlift comprises more<br />

than 600 machines including 16<br />

RUTHMANN STEIGER ® .<br />

We would also like to thank you<br />

for the continuing business relationship<br />

and look forward to many<br />

other successful operations of the<br />

RUTHMANN STEIGER ® .<br />

FROM CARPENTER TO THE LARGEST “EMPLOYER” IN GESCHER<br />

Now 87, Klaus Kreylkamp<br />

has worked at Ruthmann for<br />

around 40 years and has now<br />

been retired for 27 years. He<br />

started working in the carpentry<br />

workshop in 1952.<br />

At that time, RUTHMANN acquired<br />

a part of the actual property<br />

in Hochmoor in exchange for a<br />

Deutz tractor. In return, the animals<br />

of the previous owner were allowed<br />

to graze a part of this land.<br />

At that time, Klaus Kreylkamp built<br />

together with five other colleagues<br />

the fence for the animals. As a<br />

thank you, the men were given<br />

a bottle of schnapps - without<br />

glasses :)<br />

Klaus Kreylkamp<br />

is with his bee<br />

colonies one of<br />

the of the largest<br />

employers of<br />

Gescher<br />

Later Klaus Kreylkamp helped to<br />

build hall 1 on the property in<br />

Hochmoor which still stands today.<br />

So he is probably the only who is<br />

still alive today and has worked on<br />

it.<br />

Even then, bees were Klaus<br />

Kreylkamp’s great hobby. On the<br />

RUTHMANN grasslands, where<br />

he took them, they did not yield<br />

much but later all the more when<br />

travelling with the bee colonies all<br />

over Germany.<br />

Today, he still offers<br />

thousands of<br />

bees a safe workplace<br />

in Gescher<br />

and manages the<br />

bee museum on<br />

the Lindenstraße.<br />

#YourRuthmannStory<br />

| 16

Mobilift shareholders<br />

before departure to Gescher to<br />

RUTHMANN<br />

#YourRuthmannStory<br />

SURPRISE VISIT FROM MOBILIFT<br />

In July 1983, the Mobilift shareholders<br />

accepted an invitation from<br />

the HubSTEIGER ® manufacturer<br />

RUTHMANN to Gescher, for a<br />

factory visit and dinner, followed<br />

by an overnight stay. The invitation<br />

from RUTHMANN was negotiated<br />

as two HubSTEIGER ® were<br />

ordered and Hubert Ruthmann did<br />

not want to talk about a higher<br />

discount than 5%. Therefore we<br />

made the suggestion to visit the<br />

factory. But he had no idea that<br />

26 of us were taking part in this<br />

factory tour.<br />

As we arrived at RUTHMANn,<br />

Hubert Ruthmann welcomed us<br />

directly. He was a little bit surprised<br />

by the number of persons and<br />

instructed his employees to organize<br />

more rooms and more places<br />

for dinner. After the factory tour,<br />

we went to different hotels in the<br />

surrounding area. For dinner, the<br />

bus we chartered picked us up<br />

again and brought us to the Lembeck<br />

Castle. Here we were stately<br />

hosted. We had plenty to eat and<br />

the alcohol flowed in streams.<br />

Afterwards we went to the castle<br />

disco.<br />

After dancing the<br />

night away, the tour<br />

group made their<br />

way home on foot<br />

in the early morning,<br />

when it was already<br />

light again.<br />

Here it continued with dancing and<br />

alcohol. Around four o’clock, we<br />

had to leave the disco. As the bus<br />

was no longer available, we tried<br />

to take a taxi or other means of<br />

transport. But this was not possible<br />

at that time and we walked in<br />

different groups and well drunk<br />

along the country road back to our<br />

sleeping accommodations.<br />

Our group had to walk approximately<br />

5 kilometres. The woman<br />

with her high heels took off their<br />

shoes and walked barefoot along<br />

the country road. After an interminably<br />

time, the group reached the<br />

hotel. It was closed and we had to<br />

throw some stones at the windows,<br />

but nobody opened a window.<br />

Next to the hotel, there was a single-track<br />

railway line and here they<br />

were working on the tracks. Since<br />

we had seen an opened window in<br />

the meantime, the scaffolders got<br />

a ladder from the railway workers<br />

and a person climbed in through<br />

the opened window and opened<br />

the door. So we got a short night’s<br />

rest after all. Around 9:00 we went<br />

back home.<br />

| 17

#YourRuthmannStory<br />

RUTHMANN<br />

STEIGER ® TTS 1000<br />

The milestone for the 100 th<br />

company anniversary<br />

On 23rd March 2001, we<br />

presented on the occasion of<br />

the 100th company anniversary<br />

the first 100 meter working<br />

platform in the world.<br />

The two STEIGER ® of type TTS 1000 were in operation with<br />

the rental companies Gardemann and Gerken during years.<br />

The RUTHMANN STEIGER ® TTS 1000 of the Gerken Company<br />

was sold in 2010 to the company Abilene High Lift Aerial in<br />

Texas. It is still in operation with a MACK tractor unit.<br />

The RUTHMANN STEIGER ® TTS<br />

1000 set completely new standards<br />

for truck-mounted working<br />

platforms and was the highest<br />

working platform in the world<br />

for several years.<br />

In addition to excellent performance<br />

data with 100.4 meters<br />

working height and 40 meters<br />

outreach, the STEIGER ® TTS<br />

1000 also stands out due to its<br />

chassis. Based on a semitrailer,<br />

the tractor unit floats sensationally<br />

in the air after stabilization<br />

and serves as counterweight.<br />

The TTS 1000 was built twice as<br />

an anniversary model.<br />

| 18

HF TECHNOLOGY<br />

CREATES NEW<br />

POSSIBILITIES<br />

With the introduction of the<br />

HighFlex technology in 2016,<br />

RUTHMANN engineers set the bar<br />

a little higher again and presented<br />

for the first time a STEIGER ® with<br />

which works behind projecting<br />

edges could be carried out.<br />

This was made possible, as here<br />

on the STEIGER ® T 750 HF, thanks<br />

to the 220° basket rotation. This<br />

allows getting close to the object<br />

without having the RÜSSEL in the<br />

way.<br />

#YourRuthmannStory<br />

RUTHMANN DRS SYSTEM EXPANDS THE APPLICATION SPECTRUM<br />

The introduction of the Dynamic<br />

Reach System in 2018 marked<br />

a quantum leap in the control<br />

technology of our RUTHMANN<br />

STEIGER ® .<br />

From now on, the optional system<br />

was able to calculate the outreach<br />

and basket load of the HF STEIGER ®<br />

in real time and thus get the maximum<br />

possible performance data.<br />

This is also the case with our campaign<br />

motif, where basket load and<br />

outreach were optimised with the<br />

help of DRS and the imminent picking<br />

up of an additional load into<br />

the cage was taken into account.<br />

#YourRuthmannStory<br />

| 19

JONJO FOLEY ESTIMATES<br />

THE FLEXIBILY<br />

I started my job at Hubitec AG<br />

on 1st November 2016 which<br />

was acquired by RUTHMANN in<br />

2017.<br />

Principally, I work in the internal<br />

sales department. My core task<br />

consists in the commercial and<br />

technical processing and coordination<br />

of projects - from the preparation<br />

of the offer to the order<br />

and the delivery of the complete<br />

machine to the end customer.<br />

In Switzerland, we are a small team<br />

of ten colleagues in the office and<br />

in the workshop. Flexibility is very<br />

important to us. We not only work<br />

together on an equal footing, we<br />

also complement each other. That<br />

is what I like about my job. In addition<br />

to my actual field of activity<br />

in the internal sales department,<br />

new challenges arise that need to<br />

be solved.<br />

RUTHMANN offers me freedom<br />

and flexibility in terms of working<br />

times, so it is a fair give and take.<br />

Our team is very collegial and “almost<br />

familiar”.<br />

This is also supported by events<br />

such as service partner meetings or<br />

the legendary RUTHMANN “Oktoberfest”.<br />

It is almost like “coming<br />

home” when, after a longer period<br />

of time, you meet colleagues again<br />

at an event with whom you otherwise<br />

only phone with. By the way,<br />

there is always enough time for<br />

funny anecdotes and private conversations.<br />

Of course, there is also<br />

a lot of shop talk; for example, I am<br />

impressed e.g. by the technological<br />

progress in the TB range in the 5<br />

years of my period of employment.<br />

When I think of the TB 290 and TB<br />

300: it is really impressive what the<br />

colleagues in Gescher have developed<br />

here on the 3.5 t basis.<br />

SOFIE TELÖKEN TAKES OFF<br />

AFTER THE APPRENTICESHIP<br />

In 2017 I started my apprenticeship<br />

at RUTHMANN in Gescher<br />

as mechatronics technician<br />

and now work in the electrical<br />

assembly.<br />

Sofie Telöken was happy to pose in front<br />

of the camera for our trainee photo shoot.<br />

Many thanks for that!<br />

During my apprenticeship, I got<br />

to know many company departments<br />

and spent much time in our<br />

modern training workshop with my<br />

colleagues.<br />

What I like about RUTHMANN is<br />

the friendly, collegial ambiance and<br />

that you are taken seriously as a<br />

woman in a technical profession.<br />

As it came to my exam, we got all<br />

kinds of help from our trainers and<br />

colleagues in order to be able to<br />

prepare us theoretically but also<br />

practically on our exam. After having<br />

passed my exam, RUTHMANN<br />

wanted to take me over.<br />

I did not think twice and a workplace<br />

was offered in my favourite<br />

department, the electrical assembly.<br />

Even in terms of working times, my<br />

wishes were taken into consideration<br />

and I could flexibly adjust my<br />

numbers of hours, as I still have<br />

plans.<br />

It gave me the necessary free time<br />

I actually need for my electric<br />

engineering correspondence course<br />

which takes about three and a half<br />

years.<br />

I hope to develop myself at<br />

RUTHMANN when I will be<br />

graduated. I would be pleased as I<br />

have come to appreciate the kind<br />

colleagues and the friendly atmosphere.<br />

Also the goodies such as<br />

free drinks and fresh fruit at workplace<br />

are not found in the company<br />

where my acquaintance work.<br />

| 20

DAVID WILMERS KNOWN THROUGH THE JOB OFFERS<br />

Including my apprenticeship<br />

at RUTHMANN, I have worked<br />

here for ten years in November<br />

<strong>2021</strong>. I learnt mechatronics<br />

and actually I principally carry<br />

out electrical installation of the<br />

large-scale machines.<br />

My work here at RUTHMANN consists<br />

by and large in connecting the<br />

STEIGER ® electrically and in taking<br />

them into operation afterwards .<br />

The best moments are when the<br />

control system is activated and you<br />

know that you have wired and adjusted<br />

everything correctly and also<br />

the test drives from the working<br />

basket. One breathes life into a real<br />

high-tech machine - and it is what I<br />

love in my job.<br />

For me, the biggest innovation<br />

in my present career is clearly<br />

the STEIGER ® T 900 HF with DRS<br />

system. A very exciting project that<br />

faced us with lots of challenges we<br />

had to solve.<br />

The “Oktoberfest” at RUTHMANN<br />

are also a great experience where<br />

the whole company and customers<br />

celebrate together. It has also<br />

happened that the party continued<br />

with a mix of customers and employees<br />

in the local disco at the end<br />

of the event.<br />

I can recommend RUTHMANN<br />

as employer because I still like my<br />

job, the colleagues are friendly and<br />

because it is an interesting product<br />

range - RUTHMANN offers me a<br />

secure workplace with diversified<br />

work.<br />

People now know me from pictures<br />

on petrol pumps, hay carts<br />

or from the newspaper and I am<br />

often asked about it but I stand by<br />

it and am proud to be a company<br />

employee.<br />

| 21

TO SUCCESSFUL EXAMINATION<br />

WE SINCERELY CONGRATULATE …<br />

… our colleagues of the RUTHMANN GmbH, Austria. The partly 5 years long learning time with attendance<br />

of evening classes has paid off: Our colleagues can be pleased about the titles awarded by<br />

the Austrian Chamber of Commerce and bear them from now on.<br />

Franz Knopper passes the master<br />

examination for the metal technology<br />

craft in the field of agricultural<br />

and construction machinery. 320<br />

hours lessons are behind him.<br />

Lukas Gomboltz may use the title<br />

“engineer” since February <strong>2021</strong>.<br />

He completed five years of study<br />

which he finished with the Matura.<br />

Szilard Herman has also successfully<br />

completed the examination to<br />

become engineer. Also five years<br />

of study are behind him which he<br />

finished with the Matura.<br />

Franz Knopper Lukas Gombotz Szilard Herman<br />

IBRAHIM ABDALLA IS<br />

IMPRESSED WITH THE<br />

STEIGER ® TTS 1000<br />

For 4 years now, I work as service<br />

technician at RUTHMANN<br />

in the service point Seevetal<br />

near to Hamburg. In this time, I<br />

completed my apprenticeship at<br />

RUTHMANN as agricultural and<br />

construction machinery mechatronics<br />

technician and have<br />

been taken over .<br />

Here we are a very good team with<br />

a friendly boss and colleagues.<br />

I like coming to work and enjoy<br />

that I have a secure workplace<br />

offering again and again interesting<br />

and diversified tasks.<br />

I am always impressed with the<br />

technology. But what most fascinates<br />

me is the STEIGER ® TTS 1000<br />

with 100.4 meters working height.<br />

I would have liked to contribute to<br />

this project but during its development<br />

I was unfortunately not by<br />

RUTHMANN.<br />

I always enjoy meeting again a lot<br />

of colleagues on the occasion of<br />

the “Oktoberfest” in Gescher with<br />

whom you otherwise only have<br />

contact by phone during the year.<br />

We also meet during trainings and<br />

exchange our opinions.<br />

I would recommend RUTHMANN<br />

as employer and training enterprise.<br />

I like my job and we are a<br />

great team.<br />

| 22

SVEN VIETH IS RUTHMANN FAN<br />

In comparison to my previous jobs<br />

as painter, here you can continuously<br />

work throughout the year<br />

and also when it rains, there are<br />

not rest days which have to be<br />

reworked. RUTHMANN also pays<br />

on time and does a lot of for its<br />

employees.<br />

15 years ago, I joined the<br />

company as qualified painter<br />

and varnisher via a temporary<br />

employment agency.<br />

I work in the end equipment<br />

department and I am responsible<br />

for the 100% perfect corrosion<br />

protection of the STEIGER ® . At<br />

RUTHMANN, I really appreciate<br />

being able to work precisely and<br />

conscientiously. Not the quantity<br />

but the quality of our products<br />

is in foreground. We produce a<br />

high-quality machine which is in<br />

use for many years and therefore<br />

very sustainable.<br />

Our team consists of kind colleagues<br />

and I like coming to work<br />

everyone is helpful and there is a<br />

good, relaxed atmosphere.<br />

Through my job, I came privately to<br />

model making and my enthusiasm<br />

for the STEIGER ® became a hobby.<br />

I collect STEIGER ® models which<br />

I buy on EBay. Unfortunately, the<br />

models are sought-after and often<br />

The team with whom the passion began 15<br />

years ago: top from left to right. Andreas<br />

Osterkamp (today team leader of the final<br />

outfitting) and Sven Vieth, below: Andreas,<br />

Josef Schlüter (retired production manager),<br />

Rainhard Wolters (retired), Hartmut Ribbers,<br />

Martin Osterkamp (retired), Manfred Richter<br />

(retired, now porter).<br />

Narrowly missed victory: At the end, Sven<br />

Vieth had to let a customer “go ahead”.<br />

hard to get. Also in “Hamburger<br />

Miniaturwunderland”, I discovered<br />

a few STEIGER ® models during a<br />

visit - that makes the heart beat a<br />

little bit faster.<br />

As a balance to my quiet hobby, I<br />

am still active in the volunteer fire<br />

brigade - experiences with height<br />

access technology are abundantly<br />

available.<br />

But also in job, there is often<br />

variety and we have fun often. The<br />

highlight is always the “Oktoberfest”.<br />

We look forward to this far<br />

in advance. Last time, I almost won<br />

at holding beer mug - if it had not<br />

been for this RUTHMANN customer…<br />

Well, next time!<br />

The comprehensive model making collection<br />

includes around 40 RUTHMANN STEIGER ® ,<br />

some of them real rarities.<br />

| 23

ANGELO CALIGIURI<br />

ENJOYS TO HAVE LEARNT<br />

BY RUTHMANN<br />

In our plant in Satan Maria Del<br />

Piano in Italia, I am responsible<br />

for the mounting of the telescopic<br />

system.<br />

I started to work at RUTHMANN<br />

seven years ago. I had the opportunity<br />

to complete my apprenticeship<br />

there under the guidance of<br />

Paolo Marti from whom I learnt a<br />

lot of. During my apprenticeship,<br />

I was able to expand my knowledge.<br />

I am very happy to work<br />

for RUTHMANN and to assemble<br />

these great machines.<br />

The history of RUTHMANN, which<br />

stands for quality and reliability,<br />

is unique. The incredible growth<br />

of the company in the last years<br />

impressed me and I am proud of<br />

being involved in this success.<br />

I am responsible for the assembly<br />

of the boom system what is very<br />

important for the proper and safe<br />

functioning of the machine. Highest<br />

precision and care have highest<br />

priority in my work.<br />

It motivates me again every day to<br />

search for new improvements in<br />

order to make our products even<br />

better. My superiors always have an<br />

eye open for this and some of the<br />

proposals are already integrated in<br />

new products.<br />

I really enjoy working at<br />

RUTHMANN Italia s.r.l. and I look<br />

forward to my job every morning.<br />

RUTHMANN is one of the best<br />

employers here and I can only recommend<br />

it.<br />

DAVID VANNUCCI LEARNED MUCH BY RUTHMANN<br />

When I started my apprenticeship<br />

at RUTHMANN Italia 6<br />

years ago, I did not quite know<br />

how to hold a drill :) Fortunately,<br />

I had Roberto Marti as<br />

instructor and he taught me a<br />

lot.<br />

After the successful apprenticeship,<br />

I was taken on by RUTHMANN<br />

and now I am responsible for the<br />

assembly and pre-testing of the hydraulic<br />

system in our plant in Santa<br />

Maria del Piano.<br />

As employee at RUTHMANN, I<br />

feel that I am taken seriously. The<br />

management is very interested in<br />

innovations and takes our suggestions<br />

into account. We then<br />

consider together what can be<br />

integrated into the product in the<br />

future in order to further improve<br />

the products. I feel as important<br />

part of a sworn team.<br />

In my sector, the pre-testing of the<br />

hydraulic system, there are new<br />

challenges daily and it is a dynamic<br />

process that never bores me. Every<br />

day presents challenges and that’s<br />

what drives me. I enjoy going to<br />

work.<br />

In the last years, RUTHMANN has<br />

expended very much and continues<br />

to do so. It’s fun being part of this<br />

company and it feels great being<br />

involved in these machines.<br />

There is always a lot of fun with<br />

our team, also during work and the<br />

atmosphere is very good. I particularly<br />

remember a visit of a trade fair<br />

together which was very funny -<br />

but I better not reveal any details :)<br />

| 24

STOREKEEPER GEORG EVERS<br />

We received some pictures by mail from a photo<br />

album as part of the estate of RUTHMANN’s<br />

employee Georg Evers which we do not want to<br />

withhold from you.<br />

Georg Evers worked as storekeeper until the 100 th<br />

company anniversary and experienced the move from<br />

the Bahnhofstraße in Gescher to the new premises in<br />

Gescher-Hochmoor.<br />

#YourRuthmannStory<br />

The RUTHMANN team at the end of the 1970s - the move from the site on<br />

the Bahnhofstraße in Gescher to the new large premises in Hochmoor was<br />

imminent.<br />

RUTHMANN Cargoloader as car transporter with a lowerable<br />

lifting bed. A Mercedes-Benz Unimog served as engine basis here.<br />

At that time, RUTHMANN in Gescher produced in<br />

addition to the STEIGER ® also the RUTHMANN Cargo-Loader<br />

with a lowerable lifting bed. The vehicles<br />

were available in a wide variety of versions.<br />

STEIGER ® T 265: MY LOYAL COMPANION<br />

My name is Helmut Hauck. In 1999,<br />

I have started my own business<br />

as arborist and at the beginning I<br />

also worked as subcontractor for<br />

a building cleaning company in<br />

Nuremberg. The company had purchased<br />

a STEIGER ® T 265 and also<br />

the company put the STEIGER ® at my<br />

disposal so that I could trim trees in<br />

Nuremberg as newly self-employed<br />

person.<br />

A few years later, in 2004, I carried<br />

out arboricultural works for a<br />

landscaping company in Bamberg in<br />

the former US barracks in Schweinfurt<br />

und Bamberg exactly with this<br />

HUBSTEIGER ® . In the meantime,<br />

this company had purchased the<br />

STEIGER ® T 265 from the building<br />

cleaning company in Nuremberg.<br />

After a few years in which I<br />

worked again and again with this<br />

RUTHMANN STEIGER ® and it never<br />

let me down, I decided to buy it. So<br />

it is in my possession since 2010 and<br />

together we carry out my orders for<br />

arboricultural works every day my<br />

orders for arboricultural works every<br />

day.<br />

My T 265 is a loyal companion and I<br />

especially appreciate the robustness<br />

and reliability of the machine. Even at<br />

very low or high temperatures, the T<br />

265 has always worked perfectly and<br />

never let me down.<br />

In 2024 we hopefully will celebrate<br />

its 25th anniversary together :-)<br />

Helmut Hauck and his STEIGER ® T 265 are an<br />

inseparable team for more than 20 years.<br />

#YourRuthmannStory<br />

| 25

SUCCESSFUL<br />

OPERATION<br />

FOR BULACCES<br />

IN SOFIA<br />

In the around 100-year-old<br />

university in Sofia, repair works<br />

were needed on the colourful<br />

windows set in lead. The works<br />

on the 10 m high windows and<br />

on the ceiling should be carried<br />

out from a stair landing.<br />

#YourRuthmannStory<br />

Done: The BLUELIFT SA 18 HB stands at the planned place and can begin with the works - the<br />

100-year-old marble staircase survives the contribution undamaged.<br />

More than 50 steps must be overcome in<br />

the university in Sofia before the machine<br />

weighing only 2,200 kg reaches its place of<br />

operation.<br />

A big challenge but one for which<br />

our BLUELIFT SA 18 HB seemed<br />

to be made. With a weight of<br />

just over 2 tons, the load on the<br />

100-year-old marble staircase and<br />

the risk of breaking it were very<br />

low.<br />

After a thorough inspection of<br />

the site, the operation could start<br />

a few days later. By using lots of<br />

underlay material, the team around<br />

Sava Dimitrov wanted to tackle this<br />

challenge.<br />

The BLUELIFT SA 18 HB with its<br />

powerful battery rides very slowly<br />

up the numerous steps over the<br />

wooden planks always strictly<br />

observed by the team so that there<br />

are no surprises.<br />

After about one hour, it’s done:<br />

The BLUELIFT SA 18 HB stands on<br />

the planned stair landing and the<br />

works on the windows can begin.<br />

120 YEARS RUTHMANN - THE BEGIN OF A FRIENDSHIP<br />

A large painting company - neighbour<br />

of our scaffolding company in<br />

Cologne-Braunsfeld - “suddenly”<br />

had a truck-mounted working platform<br />

(Maltech = a Swiss painting<br />

company) on its premises for its<br />

own use and for rent. As a scaffolding<br />

contractor, this made me<br />

aware of the possibility of renting<br />

lifts.<br />

So we, as scaffolders from Cologne<br />

(scaffolding regular table), visited<br />

the working platforms exhibited at<br />

bauma and thus we got in touchwith<br />

the company Ruthmann.<br />

The common interest in an alternative<br />

to scaffoldings ultimately led to<br />

an association of concurrent companies<br />

founding a conjoint working<br />

platform rental company in Mai<br />

1981 which is still successful today.<br />

During the foundation phase, the<br />

name “Mobilift” working platform<br />

rental has been created.<br />

In the course of the years, a good<br />

and friendly business relationship<br />

developed with Ruthmann which<br />

ended in a visit to Ruthmann where<br />

the mutual “Du” (you) was agreed.<br />

It turned out that we Cologne<br />

people and the Ruthmann people<br />

indulge a common hobby, namely<br />

celebrating carnival. This, on the<br />

other hand, led to mutual visits<br />

to carnival events in Coesfeld or<br />

Cologne.<br />

This friendship still continues today,<br />

with business and private matters<br />

being kept strictly separate without<br />

any problems.<br />

Remembered and written down on<br />

20 th July <strong>2021</strong><br />

Udo Feldbusch<br />

| 26

From left to right: Our Spanish<br />

sales and service partner Bert<br />

Wiegel (Managing Director<br />

AMCO Machinery & Consulting),<br />

Marco Rodriguez (Board Member<br />

Roxu Grupo), our Managing<br />

Director Rolf Kulawik, Garcia<br />

Rodriguez (Board Member Roxu<br />

Grupo) and our General Sales<br />

Manager Uwe Strotmann at the<br />

bauma in Munich in 2016.<br />

#YourRuthmannStory<br />

DELIVERY OF THE 200 TH<br />

HEIGHT PERFORMANCE STEIGER ® TO ROXU<br />

In 2012 we launched our first<br />

HEIGHT performance STEIGER ®<br />

T 460 In the meantime, a complete<br />

range of HEIGHT performance<br />

machines with 9 models has been<br />

created, covering working heights<br />

between 38 and 90 meters.<br />

And with almost 600 unit sold, it is<br />

also the worldwide most successful<br />

range in the field of truck-mounted<br />

large scale machines.<br />

At bauma 2016 in Munich, we<br />

honoured our 200th Height performance<br />

purchaser - the Spanish<br />

rental company Roxu Grupo.<br />

Congratulations to the Roxu<br />

Grupo!<br />

The Roxu Grupo, with headquarters<br />

situated in Oviedo (region of<br />

Asturias in Spain), is one of the<br />

worldwide best known and largest<br />

crane and working platform rental<br />

company in Europe. With the<br />

acquisition of three new Height<br />

performance-STEIGER ® - 2 x 720<br />

and 1 x T 540 - the Roxu Grupo has<br />

effectively reinforced its working<br />

platform fleet, the “Plaas”.<br />

#YourRuthmannStory<br />

WHEN THE<br />

BRANDENBURG<br />

GATE CAME TO<br />

ÖHRINGEN IN 2003<br />

This picture was taken on the occasion<br />

of the 750th anniversary of the<br />

town Öhringen near Stuttgart.<br />

The “small” Brandenburg Gate was<br />

positioned at the town entrance of<br />

Öhringen by means of large canvases<br />

over scaffold construction.<br />

Two RUTHMANN STEIGER ® from<br />

Rolf Herbold GmbH were used for<br />

positioning this work of art.<br />

| 27

STEIGER ® T 300 XS<br />

SHORTER VEHICLE LENGTH,<br />

HIGHER OUTREACH - THE NEW 30 M<br />

STEIGER ® T 300 XS FROM RUTHMANN<br />

On 23 June <strong>2021</strong>, RUTHMANN<br />

presented the compact<br />

STEIGER ® T 300 XS with 30<br />

meters working height to its<br />

customers and interested participants<br />

in an online presentation<br />

announcing herewith its market<br />

launch. With a length of 7.59<br />

m, the new working platform<br />

is more than 60 centimetres<br />

shorter than the actual T 300<br />

and therefore the most compact<br />

30 meter machine on a 7.49 t<br />

chassis on the market. The new<br />

STEIGER ® T 300 XS achieves 23<br />

meters outreach - a full 2 meters<br />

more as its predecessor.<br />

Thanks to the shorter overall length<br />

and reduced rear overhang, the<br />

STEIGER ® T 300 XS can be used<br />

even more safely in urban spaces.<br />

Thanks to the higher outreach, it<br />

covers a wider application range<br />

without having to move the working<br />

platform.<br />

This makes the new RUTHMANN<br />

STEIGER ® T 300 XS interesting for<br />

several fields of applications from<br />

building cleaning to tree pruning.<br />

Further interesting application possibilities<br />

result from the increased<br />

basket load of now even 350 kg<br />

combined with the particularly high<br />

outreach.<br />

Thanks to the short wheelbase<br />

of 3.60 meters and the short rear<br />

overhang, the rear part of the vehicle<br />

swings out significantly less and<br />

the risk of accidents is reduced.<br />

When things get tight, the STEIGER ®<br />

T 300 XS particularly scores well. With<br />

compact dimensions and a one-sided<br />

stabilisation, it can also be used in<br />

urban environments.<br />

| 28

STEIGER ® T 300 XS<br />

With 7.59 m overall vehicle<br />

length and increased performance<br />

data, the new<br />

RUTHMANN STEIGER ® T 300<br />

XS is a performant machine for<br />

urban use. The short rear overhang<br />

makes the machine easy<br />

to handle.<br />

<strong>Experience</strong> the<br />

RUTHMANN<br />

STEIGER ® T 300 XS<br />

in 360°<br />

COMPACT TELESCOPE FOR A<br />

SHORTER OVERALL LENGTH<br />

Our engineers were able to reduce<br />

the length of the retracted<br />

telescope by 60 centimetres in the<br />

redesign. This was made possible<br />

by an optimised and more stable<br />

boom profile as well as the more<br />

compact boom heads of STEIGER ®<br />

T 300 XS which have already<br />

proven themselves in a similar form<br />

on the RUTHMANN STEIGER ® T<br />

900 HF.<br />

For the first time, two telescopic<br />

cylinders are now used in the<br />

high-strength fine-grained steel<br />

construction to extend the telescope.<br />

Through this, the telescope<br />

profile has further been optimised.<br />

Likewise, the energy chain of the<br />

STEIGER ® T 300 XS runs inside the<br />

telescope on top of the boom extensions<br />

leading to a more compact<br />

structural shape of the telescope<br />

and to a high ease of maintenance.<br />

The new turret construction of the<br />

T 300 XS offers a further particularity.<br />

Due to the new geometrical<br />

shape, the weight could be further<br />

optimised and the stability increased.<br />

STABLE BASE FRAME ENABLES<br />

EXTRAORDINARY PERFOR-<br />

MANCES<br />

Thanks to the shorter, completely<br />

redesigned base frame, the chassis<br />

has also been shortened accordingly.<br />

RUTHMANN relies here on<br />

jack boxes and turret tube made<br />

of high-strength fine-grained steel<br />

in order to achieve a high torsion<br />

resistance and maximum performance<br />

data.<br />

With 23 meters outreach,<br />

the STEIGER ® T 300 XS is now<br />

2 meters further as its predecessor<br />

and can also be used for<br />

operations what were previously<br />

only feasible with larger working<br />

platforms<br />

| 29

350 kg<br />

200 kg<br />

100 kg<br />

STEIGER ® T 300 XS<br />

With 30 m working height and<br />

350 kg basket load, the STEIGER ®<br />

T 300 XS also plays its trump<br />

cards in industrial use.<br />

30 m<br />

20 m<br />

10 m<br />

COMFORTABLE JACK<br />

CONTROL STAND WITH<br />

MONITOR AT EYE LEVEL<br />

The STEIGER ® T 300 XS offers great<br />

features also “on the ground”.<br />

30 m<br />

The new jack control stand, which<br />

is still very popular in the TB/TBR<br />

range, is used as standard for the<br />

first time in the T range.<br />

20 m<br />

The new control stand is optimally<br />

integrated on the chassis at eye<br />

10 m<br />

level and offers in addition to the<br />

reliable stabilization types and<br />

comfort functions a practicable<br />

stabilisation of the machine from<br />

the vehicle at all times. Clear and<br />

well recognisable switches that<br />

can change their colours, never<br />

leave the machine operator in the<br />

dark.<br />

MORE BASKET LOAD AND<br />

PROVEN OPERATION<br />

The basket load has been increased<br />

by a further 30 kg to achieve a<br />

maximum of 350 kg thanks to the<br />

stable new telescope design of the<br />

STEIGER ® T 300 XS.<br />

0m<br />

0m<br />

0m 20 m 10 m 0m 10 m 20 m<br />

0m 10 m 20 m<br />

30 m<br />

30 m<br />

10 m<br />

5,00 m<br />

0 m<br />

2,50 m<br />

0m<br />

20 m<br />

20 m<br />

100 kg<br />

200 kg<br />

350 kg<br />

100 kg<br />

200 kg<br />

350 kg<br />

100%<br />

10 m<br />

60°<br />

60°<br />

Slope =

STEIGER ® T 300 XS<br />

Thanks to the boom heads, the retracted telescope has been<br />

reduced by 60 centimetres to achieve the compact vehicle length<br />

of only 7.59 m.<br />

The telescope, the substructure and the turret unit of the T 300<br />

XS have been redesigned by RUTHMANN. Objective: the high<br />

outreach of 23 meters with increased basket load of 350 kg.<br />

The known working basket from<br />

the T range is compatible with<br />

other baskets of the same range.<br />

The modern RUTHMANN Cockpit<br />

is used, with numerous comfortable<br />

functions and real-time readable<br />

operating data. Another new<br />

feature is that vehicle chassis data<br />

are displayed in real time, depending<br />

on the manufacturer. This<br />

means that the operator is never<br />

left in the dark about e.g. how<br />

full the tank is or when the Ad-<br />

Blue system will carry out the next<br />

self-cleaning. The operator gets all<br />

relevant data at any time.<br />

The STEIGER ® T 300 XS can be<br />

equipped with all working baskets<br />

of the range, e.g. tree pruning and<br />

insulated baskets or with the large<br />

2.10 m wide working basket. As<br />

usual by RUTHMANN, this can be<br />

carried by 2 persons in just a few<br />

steps.<br />

The proven and robust basket<br />

rotating device of 2 x 90° is also<br />

standard on the T 300 XS.<br />

MUTLI-CHASSIS CONCEPT<br />

RUTHMANN also relies on the<br />

multi-chassis concept for the<br />

STEIGER ® T 300 XS. The working<br />

platform can be mounted on different<br />

7.49 t up to 8.6 t chassis from<br />

Mercedes-Benz, MAN, or Iveco.<br />

The proven jack control stand<br />

from the TB/TBR range is now also<br />

used on the STEIGER ® T300 XS.<br />

The coverings of the rear lights<br />

are completely accessible what<br />

makes e.g. the loading of the<br />

vehicle easier.<br />

| 31

STEIGER ® T 700 HF<br />

RUTHMANN STEIGER ® T 700 HF WITH 70 M WORKING<br />

HEIGHT AND 24.6 METER LONG TRIPLE UPPER BOOM<br />

With the new STEIGER ® T 700 HF, RUTHMANN present a further highlight of German engineering. For the first<br />

time at RUTHMANN, the compact machine achieves a working height of 70 m and an outstanding outreach of<br />

41 m on a carrier chassis less than 12 m long.<br />

The HighFlex RÜSSEL can be rotated by 220° and enables a<br />

working radius of 6 meters directly at the object.<br />

The compact chassis of the RUTHMANN STEIGER ® T 700 HF is only 11.99 meters<br />

long and can be operated without special permit according to § 70 StVO (German<br />

road traffic regulations) or without a driving licence according to § 29 StVO (German<br />

road traffic regulations). The T 700 HF is therefore ready for use at any time.<br />

| 32

STEIGER ® T 700 HF<br />

This development fulfils the market<br />

requirement for a compact machine<br />

of 70 m with a high lateral outreach<br />

for the confined working space.<br />

Through the new long triple upper<br />

boom, the Up&Over outreach is<br />

increased by further 3.5 m in comparison<br />

to the T 650 HF. In transport<br />

position, the machine is again very<br />

compact.<br />

Due to the 1.7 m higher articulation<br />

point and the now 24.6 m long upper<br />

boom, operations can be carried<br />

out in narrow house canyons, e.g.<br />

at the rear of buildings which were<br />

previously very difficult to achieve<br />

in this height class. Together with<br />

the highly stable base frame, the extremely<br />

robust construction made of<br />

high-tech steel in polygonal technology<br />

authorises a position inclination<br />

of up to 2°.<br />

The lower boom enables an angle<br />

of elevation of 83°, so that the machine<br />

can be positioned even closer<br />

to the building and the outreach be<br />

used even more efficiently.<br />

The T 700 HF can be mounted on<br />

different carrier chassis and be registered<br />

with a GVWR between 32 and<br />

36 tons. Due to its overall length of<br />

only 11.99 m, neither an exemption<br />

according to § 70 StVO (German<br />

road traffic regulations) nor a driving<br />

licence according to § 29 StVO<br />

(German road traffic regulations) are<br />

necessary in Germany. This allows<br />

maximum operational flexibility - the<br />

STEIGER ® T 700 HF is always ready<br />

for use.<br />

The proven Highflex functions of the<br />

RUTHMANN’s HF series also make<br />

the T 700 HF an all-rounder for all<br />

imaginable situations. The working<br />

basket can be rotated by 440°.<br />

Working behind obstacles such as<br />

pipelines or roof structures is optimally<br />

feasible (up, over & back). The<br />

2 m long Highflex-RÜSSEL ® can be<br />

rotated by 220° – still more flexibility<br />

for „under and up” works with<br />

upright working basket as well as<br />

for „up, over and back” works with<br />

lowered Highflex-RÜSSEL ® .<br />

Such as the complete HEIGHTperformance<br />

series, the new STEIGER ®<br />

T 700 HF can additionally be used<br />

for underfloor works. Thanks to<br />

the movable Highflex-RÜSSEL ® , it<br />

is ideal for bridge inspections up to<br />

17 meters below zero. It achieves 5<br />

meter more underfloor outreach as<br />

comparable machines.<br />

The powerful Highflex working<br />

basket of the STEIGER ® T 700 HF<br />

carries up to 600 kg and can be<br />

extended up to a maximum size of<br />

3.82 x 0.97 m – remaining it to be<br />

the largest working basket of the<br />

market. All Highflex positions of the<br />

STEIGER ® T 700 HF are also possible<br />

with the extended working basket<br />

and offer thus optimum space for<br />

an assembly team, for example.<br />

The approved HighFlex functions of the HF series are also on<br />

board of the RUTHMANN-STEIGER ® T 700 HF.<br />

The working basket can be rotated by 440° and in combination with the<br />

movable Highflex-RÜSSEL ® , works behind and under pipelines are possible.<br />

| 33

STEIGER ® T 295 A<br />

T 295 A - T 900 HF ON THE WAY TO TEXAS<br />