Experience issue 2023

Dear customers, partners and readers, After the successful bauma 2022 in Munich, we are now also appearing in our Experience for the first time with all the new brands of the TIME Group. You will find 92 pages of news and information about the products of RUTHMANN, VERSALIFT, France Elévateur and MOVEX. With this issue, which we will launch at APEX 2023, we would also like to announce an outstanding new product: We are very pleased to present the new T 1000 HF on pages 4 - 5 as the goal of our “Tour de TIME” for 2024, with which RUTHMANN will again crack the 100-meter mark and offer the most innovative and flexible equipment in this class. You will certainly read a lot of outstanding things about this in the coming years. Not quite as high, but still just as great, are the other machines in this issue. Benefit from our Experience and read about the many positive experiences our customers have had with the new innovative electric drives and how well they work in practice. We would also like to take this opportunity to thank our colleagues who, with their innovative thinking, enjoyment of their work and outstanding personal commitment, continue to optimize our products and make them the best on the global market. We hope you enjoy reading this issue. Your TIME Management Team: Kim Bach Jensen (TIME Europe), Uwe Strotmann (RUTHMANN), Charles Goffin (France Elévateur)

Dear customers, partners and readers,

After the successful bauma 2022 in Munich, we are now also appearing in our Experience for the first time with all the new brands of the TIME Group. You will find 92 pages of news and information about the products of RUTHMANN, VERSALIFT, France Elévateur and MOVEX. With this issue, which we will launch at APEX 2023, we would also like to announce an outstanding new product: We are very pleased to present the new T 1000 HF on pages 4 - 5 as the goal of our “Tour de TIME” for 2024, with which RUTHMANN will again crack the 100-meter mark and offer the most innovative and flexible equipment in this class. You will certainly read a lot of outstanding things about this in the coming years. Not quite as high, but still just as great, are the other machines in this issue. Benefit from our Experience and read about the many positive experiences our customers have had with the new innovative electric drives and how well they work in practice. We would also like to take this opportunity to thank our colleagues who, with their innovative thinking, enjoyment of their work and outstanding personal commitment, continue to optimize our products and make them the best on the global market. We hope you enjoy reading this issue.

Your TIME Management Team:

Kim Bach Jensen (TIME Europe), Uwe Strotmann (RUTHMANN), Charles Goffin (France Elévateur)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Experience</strong><br />

NOVELTY<br />

RUTHMANN STEIGER ® -<br />

STEP DEPLOYMENT PLANNER -<br />

PRECISE PLANNING WITHOUT<br />

SITE VISIT<br />

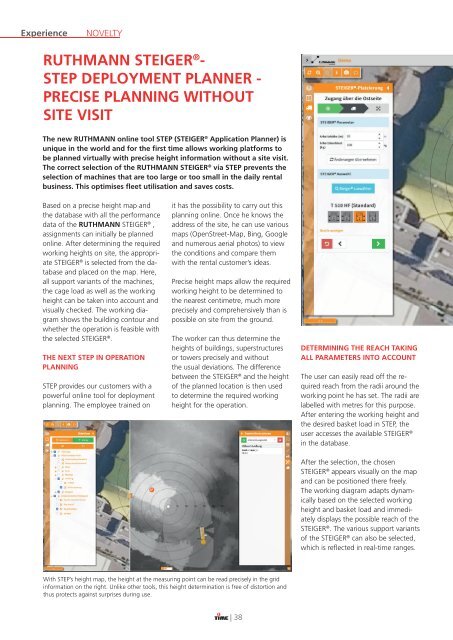

The new RUTHMANN online tool STEP (STEIGER ® Application Planner) is<br />

unique in the world and for the first time allows working platforms to<br />

be planned virtually with precise height information without a site visit.<br />

The correct selection of the RUTHMANN STEIGER ® via STEP prevents the<br />

selection of machines that are too large or too small in the daily rental<br />

business. This optimises fleet utilisation and saves costs.<br />

Based on a precise height map and<br />

the database with all the performance<br />

data of the RUTHMANN STEIGER ® ,<br />

assignments can initially be planned<br />

online. After determining the required<br />

working heights on site, the appropriate<br />

STEIGER ® is selected from the database<br />

and placed on the map. Here,<br />

all support variants of the machines,<br />

the cage load as well as the working<br />

height can be taken into account and<br />

visually checked. The working diagram<br />

shows the building contour and<br />

whether the operation is feasible with<br />

the selected STEIGER ® .<br />

THE NEXT STEP IN OPERATION<br />

PLANNING<br />

STEP provides our customers with a<br />

powerful online tool for deployment<br />

planning. The employee trained on<br />

it has the possibility to carry out this<br />

planning online. Once he knows the<br />

address of the site, he can use various<br />

maps (OpenStreet-Map, Bing, Google<br />

and numerous aerial photos) to view<br />

the conditions and compare them<br />

with the rental customer’s ideas.<br />

Precise height maps allow the required<br />

working height to be determined to<br />

the nearest centimetre, much more<br />

precisely and comprehensively than is<br />

possible on site from the ground.<br />

The worker can thus determine the<br />

heights of buildings, superstructures<br />

or towers precisely and without<br />

the usual deviations. The difference<br />

between the STEIGER ® and the height<br />

of the planned location is then used<br />

to determine the required working<br />

height for the operation.<br />

DETERMINING THE REACH TAKING<br />

ALL PARAMETERS INTO ACCOUNT<br />

The user can easily read off the required<br />

reach from the radii around the<br />

working point he has set. The radii are<br />

labelled with metres for this purpose.<br />

After entering the working height and<br />

the desired basket load in STEP, the<br />

user accesses the available STEIGER ®<br />

in the database.<br />

After the selection, the chosen<br />

STEIGER ® appears visually on the map<br />

and can be positioned there freely.<br />

The working diagram adapts dynamically<br />

based on the selected working<br />

height and basket load and immediately<br />

displays the possible reach of the<br />

STEIGER ® . The various support variants<br />

of the STEIGER ® can also be selected,<br />

which is reflected in real-time ranges.<br />

With STEP’s height map, the height at the measuring point can be read precisely in the grid<br />

information on the right. Unlike other tools, this height determination is free of distortion and<br />

thus protects against surprises during use.<br />

| 38