Experience issue 2023

Dear customers, partners and readers, After the successful bauma 2022 in Munich, we are now also appearing in our Experience for the first time with all the new brands of the TIME Group. You will find 92 pages of news and information about the products of RUTHMANN, VERSALIFT, France Elévateur and MOVEX. With this issue, which we will launch at APEX 2023, we would also like to announce an outstanding new product: We are very pleased to present the new T 1000 HF on pages 4 - 5 as the goal of our “Tour de TIME” for 2024, with which RUTHMANN will again crack the 100-meter mark and offer the most innovative and flexible equipment in this class. You will certainly read a lot of outstanding things about this in the coming years. Not quite as high, but still just as great, are the other machines in this issue. Benefit from our Experience and read about the many positive experiences our customers have had with the new innovative electric drives and how well they work in practice. We would also like to take this opportunity to thank our colleagues who, with their innovative thinking, enjoyment of their work and outstanding personal commitment, continue to optimize our products and make them the best on the global market. We hope you enjoy reading this issue. Your TIME Management Team: Kim Bach Jensen (TIME Europe), Uwe Strotmann (RUTHMANN), Charles Goffin (France Elévateur)

Dear customers, partners and readers,

After the successful bauma 2022 in Munich, we are now also appearing in our Experience for the first time with all the new brands of the TIME Group. You will find 92 pages of news and information about the products of RUTHMANN, VERSALIFT, France Elévateur and MOVEX. With this issue, which we will launch at APEX 2023, we would also like to announce an outstanding new product: We are very pleased to present the new T 1000 HF on pages 4 - 5 as the goal of our “Tour de TIME” for 2024, with which RUTHMANN will again crack the 100-meter mark and offer the most innovative and flexible equipment in this class. You will certainly read a lot of outstanding things about this in the coming years. Not quite as high, but still just as great, are the other machines in this issue. Benefit from our Experience and read about the many positive experiences our customers have had with the new innovative electric drives and how well they work in practice. We would also like to take this opportunity to thank our colleagues who, with their innovative thinking, enjoyment of their work and outstanding personal commitment, continue to optimize our products and make them the best on the global market. We hope you enjoy reading this issue.

Your TIME Management Team:

Kim Bach Jensen (TIME Europe), Uwe Strotmann (RUTHMANN), Charles Goffin (France Elévateur)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Experience</strong><br />

IN USE<br />

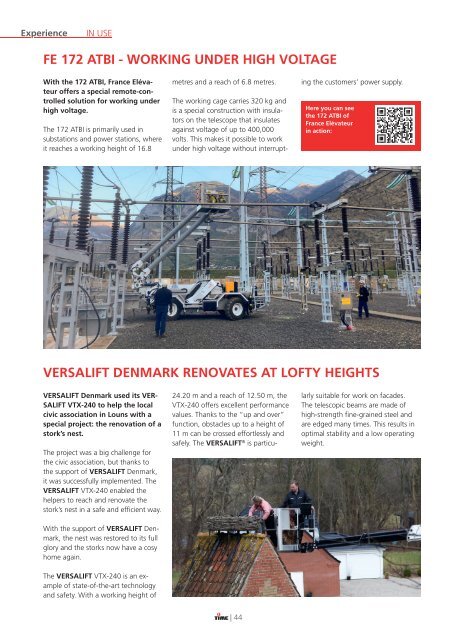

FE 172 ATBI - WORKING UNDER HIGH VOLTAGE<br />

With the 172 ATBI, France Elévateur<br />

offers a special remote-controlled<br />

solution for working under<br />

high voltage.<br />

The 172 ATBI is primarily used in<br />

substations and power stations, where<br />

it reaches a working height of 16.8<br />

metres and a reach of 6.8 metres.<br />

The working cage carries 320 kg and<br />

is a special construction with insulators<br />

on the telescope that insulates<br />

against voltage of up to 400,000<br />

volts. This makes it possible to work<br />

under high voltage without interrupting<br />

the customers’ power supply.<br />

Here you can see<br />

the 172 ATBI of<br />

France Elévateur<br />

in action:<br />

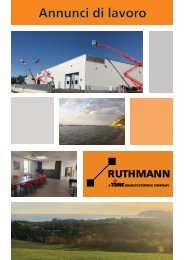

VERSALIFT DENMARK RENOVATES AT LOFTY HEIGHTS<br />

VERSALIFT Denmark used its VER-<br />

SALIFT VTX-240 to help the local<br />

civic association in Louns with a<br />

special project: the renovation of a<br />

stork’s nest.<br />

The project was a big challenge for<br />

the civic association, but thanks to<br />

the support of VERSALIFT Denmark,<br />

it was successfully implemented. The<br />

VERSALIFT VTX-240 enabled the<br />

helpers to reach and renovate the<br />

stork’s nest in a safe and efficient way.<br />

With the support of VERSALIFT Denmark,<br />

the nest was restored to its full<br />

glory and the storks now have a cosy<br />

home again.<br />

24.20 m and a reach of 12.50 m, the<br />

VTX-240 offers excellent performance<br />

values. Thanks to the “up and over”<br />

function, obstacles up to a height of<br />

11 m can be crossed effortlessly and<br />

safely. The VERSALIFT ® is particularly<br />

suitable for work on facades.<br />

The telescopic beams are made of<br />

high-strength fine-grained steel and<br />

are edged many times. This results in<br />

optimal stability and a low operating<br />

weight.<br />

The VERSALIFT VTX-240 is an example<br />

of state-of-the-art technology<br />

and safety. With a working height of<br />

| 44