Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

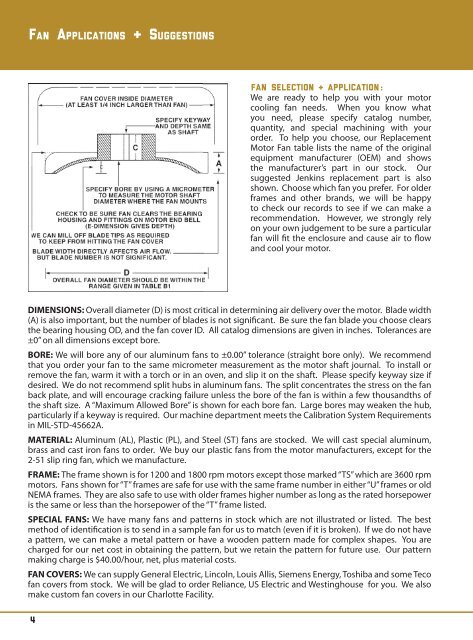

fan appliCaTionS & SUggeSTionS<br />

FAN SELECTION & APPLICATION:<br />

We are ready to help you with your motor<br />

cooling fan needs. When you know what<br />

you need, please specify catalog number,<br />

quantity, and special machining with your<br />

order. To help you choose, our Replacement<br />

Motor <strong>Fan</strong> table lists the name of the original<br />

equipment manufacturer (OEM) and shows<br />

the manufacturer’s part in our stock. Our<br />

suggested <strong>Jenkins</strong> replacement part is also<br />

shown. Choose which fan you prefer. For older<br />

frames and other brands, we will be happy<br />

to check our records to see if we can make a<br />

recommendation. However, we strongly rely<br />

on your own judgement to be sure a particular<br />

fan will fit the enclosure and cause air to flow<br />

and cool your motor.<br />

DIMENSIONS: Overall diameter (D) is most critical in determining air delivery over the motor. Blade width<br />

(A) is also important, but the number of blades is not significant. Be sure the fan blade you choose clears<br />

the bearing housing OD, and the fan cover ID. All catalog dimensions are given in inches. Tolerances are<br />

±0” on all dimensions except bore.<br />

BORE: We will bore any of our aluminum fans to ±0.00” tolerance (straight bore only). We recommend<br />

that you order your fan to the same micrometer measurement as the motor shaft journal. To install or<br />

remove the fan, warm it with a torch or in an oven, and slip it on the shaft. Please specify keyway size if<br />

desired. We do not recommend split hubs in aluminum fans. The split concentrates the stress on the fan<br />

back plate, and will encourage cracking failure unless the bore of the fan is within a few thousandths of<br />

the shaft size. A “Maximum Allowed Bore” is shown for each bore fan. Large bores may weaken the hub,<br />

particularly if a keyway is required. Our machine department meets the Calibration System Requirements<br />

in MIL-STD-45662A.<br />

MATERIAL: Aluminum (AL), Plastic (PL), and Steel (ST) fans are stocked. We will cast special aluminum,<br />

brass and cast iron fans to order. We buy our plastic fans from the motor manufacturers, except for the<br />

2-51 slip ring fan, which we manufacture.<br />

FRAME: The frame shown is for 1200 and 1800 rpm motors except those marked “TS” which are 3600 rpm<br />

motors. <strong>Fan</strong>s shown for “T” frames are safe for use with the same frame number in either “U” frames or old<br />

NEMA frames. They are also safe to use with older frames higher number as long as the rated horsepower<br />

is the same or less than the horsepower of the “T” frame listed.<br />

SPECIAL FANS: We have many fans and patterns in stock which are not illustrated or listed. The best<br />

method of identification is to send in a sample fan for us to match (even if it is broken). If we do not have<br />

a pattern, we can make a metal pattern or have a wooden pattern made for complex shapes. You are<br />

charged for our net cost in obtaining the pattern, but we retain the pattern for future use. Our pattern<br />

making charge is $40.00/hour, net, plus material costs.<br />

FAN COVERS: We can supply General Electric, Lincoln, Louis Allis, Siemens Energy, Toshiba and some Teco<br />

fan covers from stock. We will be glad to order Reliance, US Electric and Westinghouse for you. We also<br />

make custom fan covers in our Charlotte Facility.<br />

4