Total Contractor

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

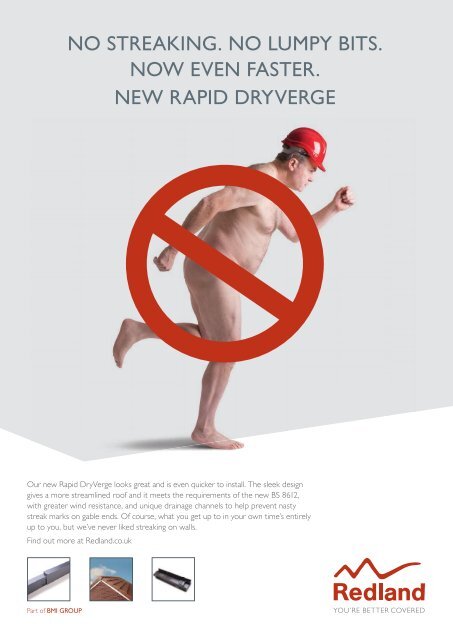

NO STREAKING. NO LUMPY BITS.<br />

NOW EVEN FASTER.<br />

NEW RAPID DRYVERGE<br />

Our new Rapid DryVerge looks great and is even quicker to install. The sleek design<br />

gives a more streamlined roof and it meets the requirements of the new BS 8612,<br />

with greater wind resistance, and unique drainage channels to help prevent nasty<br />

streak marks on gable ends. Of course, what you get up to in your own time’s entirely<br />

up to you, but we’ve never liked streaking on walls.<br />

Find out more at Redland.co.uk<br />

Part of BMI GROUP