Style: May 20, 2020

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

14 STYLE | report<br />

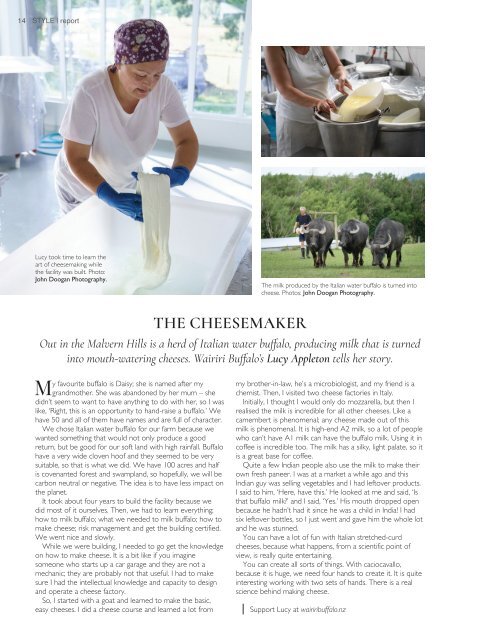

Lucy took time to learn the<br />

art of cheesemaking while<br />

the facility was built. Photo:<br />

John Doogan Photography.<br />

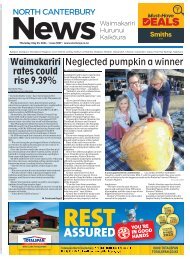

The milk produced by the Italian water buffalo is turned into<br />

cheese. Photos: John Doogan Photography.<br />

THE CHEESEMAKER<br />

Out in the Malvern Hills is a herd of Italian water buffalo, producing milk that is turned<br />

into mouth-watering cheeses. Wairiri Buffalo’s Lucy Appleton tells her story.<br />

My favourite buffalo is Daisy; she is named after my<br />

grandmother. She was abandoned by her mum – she<br />

didn’t seem to want to have anything to do with her, so I was<br />

like, ‘Right, this is an opportunity to hand-raise a buffalo.’ We<br />

have 50 and all of them have names and are full of character.<br />

We chose Italian water buffalo for our farm because we<br />

wanted something that would not only produce a good<br />

return, but be good for our soft land with high rainfall. Buffalo<br />

have a very wide cloven hoof and they seemed to be very<br />

suitable, so that is what we did. We have 100 acres and half<br />

is covenanted forest and swampland, so hopefully, we will be<br />

carbon neutral or negative. The idea is to have less impact on<br />

the planet.<br />

It took about four years to build the facility because we<br />

did most of it ourselves. Then, we had to learn everything;<br />

how to milk buffalo; what we needed to milk buffalo; how to<br />

make cheese; risk management and get the building certified.<br />

We went nice and slowly.<br />

While we were building, I needed to go get the knowledge<br />

on how to make cheese. It is a bit like if you imagine<br />

someone who starts up a car garage and they are not a<br />

mechanic; they are probably not that useful. I had to make<br />

sure I had the intellectual knowledge and capacity to design<br />

and operate a cheese factory.<br />

So, I started with a goat and learned to make the basic,<br />

easy cheeses. I did a cheese course and learned a lot from<br />

my brother-in-law, he’s a microbiologist, and my friend is a<br />

chemist. Then, I visited two cheese factories in Italy.<br />

Initially, I thought I would only do mozzarella, but then I<br />

realised the milk is incredible for all other cheeses. Like a<br />

camembert is phenomenal; any cheese made out of this<br />

milk is phenomenal. It is high-end A2 milk, so a lot of people<br />

who can’t have A1 milk can have the buffalo milk. Using it in<br />

coffee is incredible too. The milk has a silky, light palate, so it<br />

is a great base for coffee.<br />

Quite a few Indian people also use the milk to make their<br />

own fresh paneer. I was at a market a while ago and this<br />

Indian guy was selling vegetables and I had leftover products.<br />

I said to him, ‘Here, have this.’ He looked at me and said, ‘Is<br />

that buffalo milk?’ and I said, ‘Yes.’ His mouth dropped open<br />

because he hadn’t had it since he was a child in India! I had<br />

six leftover bottles, so I just went and gave him the whole lot<br />

and he was stunned.<br />

You can have a lot of fun with Italian stretched-curd<br />

cheeses, because what happens, from a scientific point of<br />

view, is really quite entertaining.<br />

You can create all sorts of things. With caciocavallo,<br />

because it is huge, we need four hands to create it. It is quite<br />

interesting working with two sets of hands. There is a real<br />

science behind making cheese.<br />

Support Lucy at wairiribuffalo.nz