CMOS Production Compatible SiGe Heteroepitaxy for High ... - Imec

CMOS Production Compatible SiGe Heteroepitaxy for High ... - Imec

CMOS Production Compatible SiGe Heteroepitaxy for High ... - Imec

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Ge Content (%)<br />

2. Experimental<br />

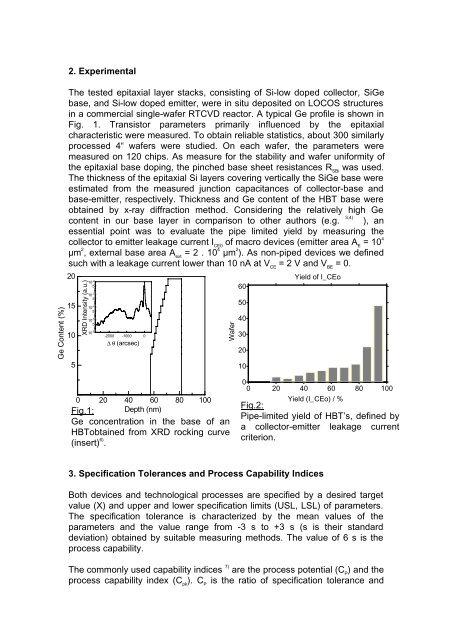

The tested epitaxial layer stacks, consisting of Si-low doped collector, <strong>SiGe</strong><br />

base, and Si-low doped emitter, were in situ deposited on LOCOS structures<br />

in a commercial single-wafer RTCVD reactor. A typical Ge profile is shown in<br />

Fig. 1. Transistor parameters primarily influenced by the epitaxial<br />

characteristic were measured. To obtain reliable statistics, about 300 similarly<br />

processed 4“ wafers were studied. On each wafer, the parameters were<br />

measured on 120 chips. As measure <strong>for</strong> the stability and wafer uni<strong>for</strong>mity of<br />

the epitaxial base doping, the pinched base sheet resistances R SBi was used.<br />

The thickness of the epitaxial Si layers covering vertically the <strong>SiGe</strong> base were<br />

estimated from the measured junction capacitances of collector-base and<br />

base-emitter, respectively. Thickness and Ge content of the HBT base were<br />

obtained by x-ray diffraction method. Considering the relatively high Ge<br />

content in our base layer in comparison to other authors (e.g. 3,4) ), an<br />

essential point was to evaluate the pipe limited yield by measuring the<br />

collector to emitter leakage current I CE0 of macro devices (emitter area A E = 10 4<br />

µm 2 , external base area A ext = 2 . 10 4 µm 2 ). As non-piped devices we defined<br />

such with a leakage current lower than 10 nA at V CE = 2 V and V BE = 0.<br />

20<br />

15<br />

10<br />

5<br />

XRD Intensity (a.u.)<br />

10<br />

5<br />

-2<br />

10 -2<br />

10<br />

5<br />

-3<br />

10 -3<br />

10<br />

5<br />

-4<br />

10 -4<br />

10<br />

5<br />

-5<br />

10 -5<br />

10 -6<br />

10 -6<br />

-2000 -1000 0<br />

Δ θ (arcsec)<br />

Fig.1:<br />

Ge concentration in the base of an<br />

HBTobtained from XRD rocking curve<br />

(insert) 6) 0 20 40 60 80 100<br />

Depth (nm)<br />

.<br />

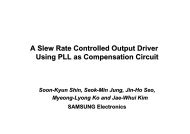

Fig.2:<br />

Pipe-limited yield of HBT’s, defined by<br />

a collector-emitter leakage current<br />

criterion.<br />

3. Specification Tolerances and Process Capability Indices<br />

Wafer<br />

0<br />

0 20 40 60 80 100<br />

Both devices and technological processes are specified by a desired target<br />

value (X) and upper and lower specification limits (USL, LSL) of parameters.<br />

The specification tolerance is characterized by the mean values of the<br />

parameters and the value range from -3 s to +3 s (s is their standard<br />

deviation) obtained by suitable measuring methods. The value of 6 s is the<br />

process capability.<br />

The commonly used capability indices 7) are the process potential (C P ) and the<br />

process capability index (C pk ). C P is the ratio of specification tolerance and<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

Yield of I_CEo<br />

Yield (I_CEo) / %