bioplasticsMAGAZINE_0903

bioplasticsMAGAZINE_0903

bioplasticsMAGAZINE_0903

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Rigid Packaging<br />

Study Confirms<br />

Lifecycle Advantages<br />

of PLA over rPET<br />

A<br />

first-of-its-kind lifecycle analysis finds that clamshell<br />

packaging made from NatureWorks‘ Ingeo<br />

(PLA), emits fewer greenhouse gases and uses less<br />

energy when compared to clamshells manufactured with<br />

petroleum-based rPET (recycled polyethylene terephthalate).<br />

The Institute for Energy and Environmental Research<br />

(IFEU), Heidelberg, Germany, conducted the head-tohead<br />

lifecycle comparison on more than 40 different<br />

combinations of clamshell packaging made from Ingeo<br />

PLA, PET, and rPET. Both PLA and rPET clamshells<br />

outperformed PET packaging in terms of lower overall<br />

greenhouse gas emissions and lower overall energy<br />

consumed. PLA clamshells clearly offered further<br />

advantages over the petroleum-based rPET in numerous<br />

comparisons.<br />

“Brand owners and converters will lower the carbon<br />

and energy footprint of clamshell packaging by moving<br />

away from PET and rPET to Ingeo polymer,” said Marc<br />

Verbruggen, president and CEO of NatureWorks, the<br />

manufacturer of Ingeo. “This is true with today’s virgin Ingeo<br />

and, in the longer term, recycled Ingeo will decrease that<br />

footprint even more. Furthermore, the high performance<br />

of Ingeo biopolymer in clamshell applications means that<br />

less material may be required to manufacture them — on<br />

average 2 percent less.”<br />

Representative results of the lifecycle analysis<br />

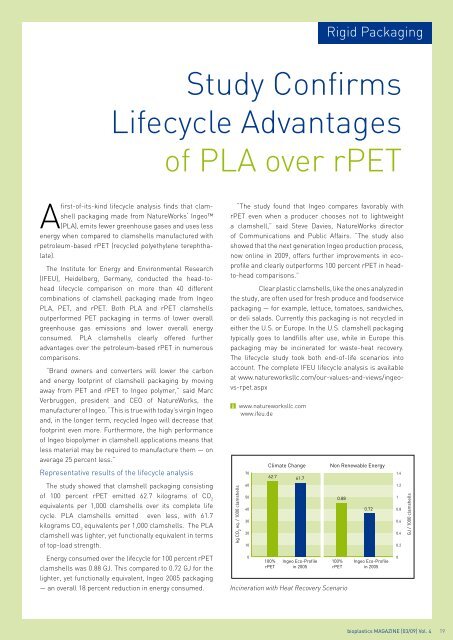

The study showed that clamshell packaging consisting<br />

of 100 percent rPET emitted 2. kilograms of CO 2<br />

equivalents per 1,000 clamshells over its complete life<br />

cycle. PLA clamshells emitted even less, with 1.<br />

kilograms CO 2<br />

equivalents per 1,000 clamshells. The PLA<br />

clamshell was lighter, yet functionally equivalent in terms<br />

of top-load strength.<br />

“The study found that Ingeo compares favorably with<br />

rPET even when a producer chooses not to lightweight<br />

a clamshell,” said Steve Davies, NatureWorks director<br />

of Communications and Public Affairs. “The study also<br />

showed that the next generation Ingeo production process,<br />

now online in 2009, offers further improvements in ecoprofile<br />

and clearly outperforms 100 percent rPET in headto-head<br />

comparisons.”<br />

Clear plastic clamshells, like the ones analyzed in<br />

the study, are often used for fresh produce and foodservice<br />

packaging — for example, lettuce, tomatoes, sandwiches,<br />

or deli salads. Currently this packaging is not recycled in<br />

either the U.S. or Europe. In the U.S. clamshell packaging<br />

typically goes to landfills after use, while in Europe this<br />

packaging may be incinerated for waste-heat recovery.<br />

The lifecycle study took both end-of-life scenarios into<br />

account. The complete IFEU lifecycle analysis is available<br />

at www.natureworksllc.com/our-values-and-views/ingeovs-rpet.aspx<br />

kg CO 2<br />

eq. / 1000 clamshells<br />

www.natureworksllc.com<br />

www.ifeu.de<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

Climate Change<br />

62.7 61.7<br />

Non Renewable Energy<br />

0.88<br />

0.72<br />

1.4<br />

1.2<br />

1<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

GJ / 1000 clamshells<br />

Energy consumed over the lifecycle for 100 percent rPET<br />

clamshells was 0.88 GJ. This compared to 0.2 GJ for the<br />

lighter, yet functionally equivalent, Ingeo 200 packaging<br />

— an overall 18 percent reduction in energy consumed.<br />

0<br />

100%<br />

rPET<br />

Ingeo Eco-Profile<br />

in 2005<br />

100%<br />

rPET<br />

Incineration with Heat Recovery Scenario<br />

Ingeo Eco-Profile<br />

in 2005<br />

0<br />

bioplastics MAGAZINE [03/09] Vol. 4 19