Issue 04/2023

Highlights 100th issue Rebranding

Highlights

100th issue

Rebranding

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ioplastics MAGAZINE [<strong>04</strong>/23] Vol. 18<br />

3<br />

dear<br />

readers<br />

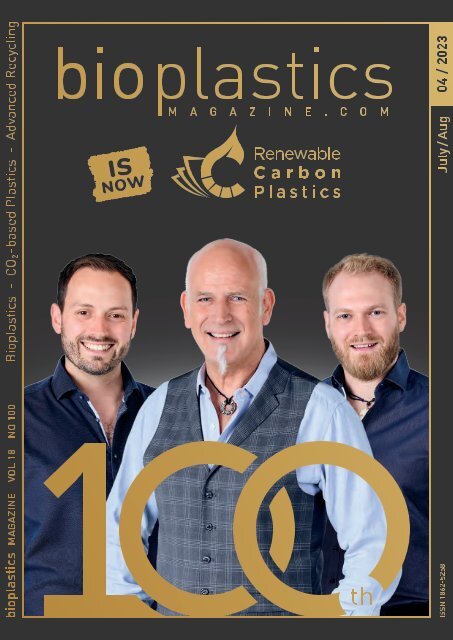

Assuming this isn’t your first-time reading bioplastics MAGAZINE, you will have<br />

noticed that this issue looks a little different (if it is your first – odd choice, but<br />

welcome!). If the big golden “100” isn’t enough of a hint, I will gladly (but briefly)<br />

explain it as it represents a milestone that fills me with pride and gratitude in<br />

equal parts. bioplastics MAGAZINE has reached 100 issues! To celebrate this<br />

achievement, we decided to make this issue exceptional. Next to a “Best<br />

of bioplastics”, starting at the centre of the issue where we look back over<br />

almost 18 years of content, we also have a bioplastics MAGAZINE first on<br />

pp. 20 where our Head of Design (the handsome gentleman on the left side<br />

of the cover), who tends to stay in the background, grabs the spotlight in a<br />

somewhat different cover story.<br />

On the next page, you will also find a brief explanation about our<br />

rebranding and new title “Renewable Carbon Plastics”, which is a different<br />

milestone in its own right.<br />

As you can see, a lot is happening behind the scenes of Renewable Carbon<br />

Plastics aka bioplastics MAGAZINE. We also have a brand new online archive<br />

that is more intuitive and user-friendly – more details will follow soon.<br />

Last but certainly not least – 100 issues do not just happen, and while I<br />

am “only” officially working for the magazine for three years now as this<br />

is a family business, my involvement goes back much further and some of<br />

you have known me for many years. So I would like to take this opportunity<br />

to thank all our supporters and friends that helped us over the years, be it<br />

loyal advertisers that help us pay the bills, collaborators that contributed<br />

content for the magazine and conferences, and of course, you – dear<br />

reader, wherever and however you are reading this – Thank you<br />

I am proud too, but I’ll spare you a list. There are many bits and pieces of<br />

memories in this issue about challenges, milestones, changes and so on. But I<br />

am also proud of the two young men next to me on the cover who are supporting<br />

me in doing the magazine and our conferences. Or am I supporting them?<br />

The achievements so far and the rebranding of the magazine were reason enough<br />

to name Alex the Editor-in-Chief of Renewable Carbon Plastics. Congratulations.<br />

But don’t worry. I’ll stick around, and I’m looking forward to meeting many of<br />

you at the upcoming events. Be it our very own 3 rd PHA World Congress that is<br />

leaving Europe for the first time to be held in Atlanta on 10 and 11 of October. Or<br />

be it the European Bioplastics Conference later this year in Berlin.<br />

Until then, I hope you enjoy reading this new, yet well-established publication.<br />

Yours sincerely<br />

@BIOPLASTICSMAG<br />

@RENEWABLECARBONPLASTICS

Imprint<br />

Content<br />

July / Aug <strong>04</strong>|<strong>2023</strong><br />

3 Editorial<br />

5 News<br />

13 10 years ago<br />

50 Application News<br />

56 Basics<br />

58 Glossary<br />

62 Suppliers Guide<br />

65 Event calendar<br />

66 Companies in this issue<br />

Publisher / Editorial<br />

Alex Thielen, Editor-in-Chief (AT)<br />

Dr Michael Thielen,<br />

Senior Consulting Editor, Publisher (MT)<br />

Samuel Brangenberg, Reporter (SB)<br />

Head Office<br />

Polymedia Publisher GmbH<br />

Hackesstr. 99<br />

41066 Mönchengladbach, Germany<br />

phone: +49 (0)2161 664864<br />

fax: +49 (0)2161 631<strong>04</strong>5<br />

info@bioplasticsmagazine.com<br />

www.bioplasticsmagazine.com<br />

Media Adviser<br />

Samsales (German language)<br />

phone: +49(0)2161-6884467<br />

fax: +49(0)2161 6884468<br />

sb@bioplasticsmagazine.com<br />

Michael Thielen (English Language)<br />

(see head office)<br />

Layout/Production<br />

Philipp Thielen<br />

Photography<br />

Philipp Thielen<br />

Print<br />

Poligrāfijas grupa Mūkusala Ltd.<br />

10<strong>04</strong> Riga, Latvia<br />

bioplastics MAGAZINE is printed on<br />

chlorine-free FSC certified paper.<br />

Renewable Carbon Initiative<br />

12 Food and feed crops for biobased materials<br />

– Really?<br />

14 No Sustainable Future without CCU<br />

Materials<br />

24 From Lord of the Rings armour to biobased<br />

facades<br />

26 Enzymatic Biomaterials Technology Platform<br />

Best Of<br />

34 Cover<br />

35 New Series<br />

36 Milestones<br />

38 Important stories<br />

40 The evolution to Renewable Carbon Plastics<br />

41 Michael’s slice of life<br />

From Science & Research<br />

46 Biodegradable water-soluble support structures<br />

for additive manufacturing<br />

Blow Moulding<br />

48 Biobased, recyclable bottles made from<br />

bioplastics<br />

TOP TALK<br />

Events<br />

16 3 rd PHA World Congress<br />

25 8 th PLA World Congress<br />

Cover Story<br />

20 A centenary of sustainable innovations<br />

Top Talk<br />

28 Chemical recycling as a reset button<br />

Advanced Recycling<br />

28 Chemical recycling as a reset button<br />

30 Microwave assisted depolymerisation<br />

of PET<br />

Biocomposites<br />

32 PLA food packaging project<br />

Sustainability<br />

42 Sustainability with strategy<br />

Report<br />

44 Awareness and preferences for<br />

bioplastics in Japan<br />

bioplastics MAGAZINE<br />

Volume 18 – <strong>2023</strong><br />

ISSN 1862-5258<br />

bM is published 6 times a year.<br />

This publication is sent to qualified<br />

subscribers (179 Euro for 6 issues).<br />

bioplastics MAGAZINE is read in<br />

100 countries.<br />

Every effort is made to verify all information<br />

published, but Polymedia Publisher<br />

cannot accept responsibility for any errors<br />

or omissions or for any losses that may<br />

arise as a result.<br />

All articles appearing in<br />

bioplastics MAGAZINE, or on the website<br />

www.bioplasticsmagazine.com are strictly<br />

covered by copyright. No part of this<br />

publication may be reproduced, copied,<br />

scanned, photographed and/or stored<br />

in any form, including electronic format,<br />

without the prior consent of the publisher.<br />

Opinions expressed in articles do not<br />

necessarily reflect those of Polymedia<br />

Publisher.<br />

bioplastics MAGAZINE welcomes contributions<br />

for publication. Submissions are<br />

accepted on the basis of full assignment<br />

of copyright to Polymedia Publisher GmbH<br />

unless otherwise agreed in advance and in<br />

writing. We reserve the right to edit items<br />

for reasons of space, clarity, or legality.<br />

Please contact the editorial office via<br />

mt@bioplasticsmagazine.com.<br />

The fact that product names may not be<br />

identified in our editorial as trademarks is<br />

not an indication that such names are not<br />

registered trademarks.<br />

bioplastics MAGAZINE uses British spelling.<br />

Envelopes<br />

A part of this print run is mailed to the<br />

readers wrapped bioplastic envelopes<br />

sponsored by Minima Technology Co.,<br />

Ltd./Bioplastics products/Taiwan (R.O.C).<br />

Cover<br />

From left: Philipp, Michael and Alex<br />

Thielen) (Photo: Dirk Schumacher)<br />

@BIOPLASTICSMAG @BIOPLASTICSMAGAZINE @RENEWABLECARBONPLASTICS

ioplastics MAGAZINE [<strong>04</strong>/23] Vol. 18<br />

5<br />

From 100 to 1 – the start of a new era<br />

Bioplastics MAGAZINE has been an established source of<br />

information about and for the bioplastics industry for over 15<br />

years. The global trade journal was for a long time focused<br />

exclusively on bioplastics (i.e. biobased and/or biodegradable<br />

and compostable plastics). Now, with its 100 th edition, the<br />

magazine will rebrand to “Renewable Carbon Plastics”<br />

starting with the current issue.<br />

Plastic materials are indispensable for our current modern<br />

society. While some applications could be replaced with other<br />

materials, e.g. steel, wood, or glass, it is not possible in many<br />

areas – and often, even if possible, not advisable. Plastics are<br />

great materials due to their light weight, their mouldability<br />

into almost any shape imaginable, and their low cost.<br />

However, the last point of low cost has come at a price.<br />

Plastic pollution and the contribution to global warming are<br />

the result of decades of callous mismanagement on a global<br />

scale. We all know the pathetically low recycling rates by now,<br />

showing a huge end-of-life problem. The beginning of life of<br />

most plastic materials isn’t much better as they are made<br />

from fossil-based resources, be it oil, gas, or coal, and their<br />

negative environmental impact.<br />

Plastics made from biogenic sources (crops or waste<br />

streams) can be a great alternative. There has been a<br />

plethora of inventions and developments that the editorial<br />

team of bioplastics MAGAZINE never worried about having<br />

enough content. However, we also recognized that these raw<br />

materials are not the only possible alternative.<br />

The main objective is to avoid the new excavation of fossil<br />

resources from the ground. So, in addition to using biogenic<br />

resources, plastics made from direct carbon capture<br />

(CCU = Carbon Capture & Utilisation) is another viable way to<br />

avoid new fossil resources being used. Here carbon dioxide<br />

(CO 2<br />

) from the atmosphere or exhaust processes or methane<br />

(C 2<br />

H 4<br />

) e.g. from biogasification, can be used to make plastic<br />

raw materials. Another alternative is certainly recycling,<br />

which has seen a revival of sorts in recent years.<br />

That is why the editorial team of bioplastics MAGAZINE<br />

started about two years ago to broaden their scope of topics<br />

into plastics made from CCU and from Advanced Recycling.<br />

The latter comprises technologies such as chemical recycling,<br />

enzyme-based recycling, solvent-based recycling and the<br />

like. Together with the well-established topic of bioplastics,<br />

it completed the concept of renewable carbon in plastics.<br />

So, it comes as no surprise that the team behind<br />

bioplastics MAGAZINE has decided to change the title of the<br />

publication, as with this expanding range of topics, the<br />

name "bioplastics MAGAZINE" didn’t ring true any longer.<br />

This lead to the new name of the publication – "Renewable<br />

Carbon Plastics – RCP". The milestone of the 100 th edition<br />

of bioplastics MAGAZINE seemed like a natural starting point<br />

for this transformation. From 100 to 1, this issue is both the<br />

100 th issue of bioplastics MAGAZINE as well as the first issue of<br />

“Renewable Carbon Plastics”. Content-wise, not much will<br />

change, as we have already been reporting about all renewable<br />

carbon sources for plastics for a couple of years now.<br />

“We all know that bioplastics won’t be able to solve the<br />

problems we are facing by themselves”, says Alex Thielen,<br />

new Editor-in-Chief of RCP and son of founder Michael<br />

Thielen, “but cooperation and a combination of technologies<br />

will lead to the change we all hope to see – the name change<br />

is supposed to represent that philosophy”.<br />

www.renewable-carbon-plastics.com<br />

daily updated News at

6 bioplastics MAGAZINE [<strong>04</strong>/23] Vol. 18<br />

News<br />

Picks & clicks<br />

Most frequently clicked news<br />

Here’s a look at our most popular online content of the past two months.<br />

The story that got the most clicks from the visitors to bioplasticsmagazine.com was:<br />

tinyurl.com/news-<strong>2023</strong>0612<br />

daily updated News at<br />

www.bioplasticsmagazine.com<br />

Grandpuits PLA project update<br />

(12 June <strong>2023</strong>)<br />

TotalEnergies Corbion (Gorinchem, the Netherlands) announced that it will<br />

not pursue a new PLA bioplastics plant in Grandpuits, France.<br />

This announcement followed a review of the investment case of the project<br />

and is in line with the announcements of the company shareholders.<br />

Monument Chemical plans to produce<br />

CO 2<br />

-based polyurethanes in USA<br />

Monument Chemical (Indianapolis, IN, USA) is the first US<br />

company to license Econic’s (Macclesfield, UK) process for<br />

manufacturing polycarbonate ether (PCE) polyols made from<br />

CO 2<br />

as a sustainable source of renewable carbon.<br />

With Econic’s technology, Monument will upcycle waste<br />

carbon dioxide into polyols for high-performance foams,<br />

laminates, coatings, and elastomers for use in automotive,<br />

furniture, mattress, construction, and industrial applications.<br />

Monument will begin production based on the Econic<br />

process in late <strong>2023</strong>.<br />

Econic’s pioneering technology is based on its proprietary<br />

catalyst and process that enables manufacturers to replace<br />

up to 30 % of the fossil-based component in their polyols with<br />

readily available captured CO 2<br />

, in their existing production<br />

plants. The technology allows the level of CO 2<br />

to be controlled<br />

at a molecular level, enabling customers to produce costcompetitive<br />

polyurethane products with equal or higher<br />

performance and a lower carbon footprint.<br />

Don Phillips, Vice President and General Manager, Oxides,<br />

of Monument Chemical, said, “Licensing the Econic process<br />

marks a key milestone in Monument’s commitment to<br />

providing specialty solutions to our customers in the US.<br />

By embracing this groundbreaking technology, we can help<br />

our customers deliver higher-performance products with<br />

enhanced sustainability that will stand out in the marketplace”.<br />

“The world’s drive to net-zero is forcing manufacturers to<br />

move to sustainable carbon sources, without compromising<br />

performance and cost. Monument recognizes that, and we are<br />

delighted to be working with them to make this a reality in the<br />

US polyurethane market. Our aim is to work with Monument<br />

to help sustainably grow their business with Econic’s<br />

groundbreaking technology”, said Econic CEO Keith Wiggins.<br />

The ability of Econic’s technology to make polyurethane<br />

products better and more sustainable by using CO 2<br />

as a<br />

renewable carbon source is being recognized by major<br />

consumer brands and their supply chains. The company<br />

recently announced that it has issued licences to polyol<br />

manufacturers in India and China. AT<br />

www.econic-technologies.com | www.monumentchemical.com<br />

Our frame colours<br />

Topics related to the<br />

Renewable Carbon Initiative...<br />

Bioplastics related topics, i.e.<br />

all topics around biobased<br />

and biodegradable plastics,<br />

come in the familiar<br />

green frame.<br />

All topics related to<br />

Advanced Recycling, such<br />

as chemical recycling<br />

or enzymatic degradation<br />

of mixed waste into<br />

building blocks for<br />

new plastics have this<br />

turquoise coloured frame.<br />

When it comes to plastics<br />

made of any kind of carbon<br />

source associated with<br />

Carbon Capture & Utilisation<br />

we use this frame colour.<br />

The familiar blue<br />

frame stands for rather<br />

administrative sections,<br />

such as the table of<br />

contents or the<br />

“Dear readers” on page 3.<br />

If a topic belongs to more<br />

than one group, we use<br />

crosshatched frames.<br />

Ochre/green stands for<br />

Carbon Capture &<br />

Bioplastics, e. g.<br />

PHA made from methane.<br />

Articles covering<br />

Recycling and Bioplastics ...<br />

Recycling & Carbon Capture<br />

We’re sure, you got it!

ioplastics MAGAZINE [<strong>04</strong>/23] Vol. 18<br />

7<br />

Bluepha and TotalEnergies Corbion collaborate<br />

Bluepha, the leading synthetic biology company in China (Beijing), and TotalEnergies<br />

Corbion (Gorinchem, the Netherlands), a global leader in PLA technology, have signed a<br />

memorandum of understanding (MOU) to accelerate the market adoption of PLA/PHAbased<br />

solutions in China.<br />

The collaboration aims to bring together the expertise and resources of both companies<br />

to further advance the development of high-performance biopolymer solutions, combining<br />

Bluepha ® polyhydroxyalkanoates (PHA) with Luminy ® polylactic acid (PLA) technology.<br />

"We are very excited about this collaboration with TotalEnergies Corbion", said Teng Li,<br />

President & Co-founder of Bluepha. He continued: "TotalEnergies Corbion is a trustworthy<br />

partner and Bluepha PHA mixed with Luminy PLA would be as a Chinese saying Adding<br />

wings to the tiger. Together, the two companies can give more opportunities to our<br />

downstream partners and contribute to a more sustainable future".<br />

"By combining the complementary properties of these materials, we will significantly<br />

expand the application possibilities for brand owners seeking fully biobased material<br />

solutions", said Thomas Philipon, CEO of TotalEnergies Corbion.<br />

Under the terms of the MOU, Bluepha and TotalEnergies Corbion will jointly promote<br />

PLA and PHA market applications in China. Before the MOU signing ceremony, Thomas<br />

Philipon took a tour of the Bluepha PHA Biorefinery, which completed construction in<br />

October 2022 in Yancheng and recently began production of the Bluepha PHA product. AT<br />

daily updated News at<br />

www.bluepha.bio | www.totalenergies-corbion.com<br />

Luminy PLA sustainable under<br />

EU Taxonomy Regulation<br />

TotalEnergies Corbion (Gorinchem, the Netherlands) has<br />

announced that its Luminy ® polylactic acid (PLA) bioplastics<br />

successfully meet the stringent criteria of the European<br />

Union (EU) Taxonomy Regulation on climate change<br />

mitigation and adaptation.<br />

The assessment can be found in the newly re-launched<br />

whitepaper titled "Planting the Future with PLA", which<br />

details the regulation and delves into more sustainability<br />

aspects of biobased materials. The achievement underscores<br />

the company's pivotal role in the global sustainable economy.<br />

The EU Taxonomy Regulation is critical for sustainable<br />

innovation because it sets a standard for what can be<br />

labelled as 'sustainable' in business in the European Union.<br />

The framework uses six environmental objectives: climate<br />

change mitigation, climate change adaptation, sustainable<br />

use and protection of water and marine resources, transition<br />

to a circular economy, pollution prevention and control, and<br />

protection and restoration of biodiversity and ecosystems.<br />

The intent of the regulation is to help increase sustainable<br />

investment and further drive the implementation of the<br />

European Green Deal.<br />

"TotalEnergies Corbion continues to work closely with<br />

lawmakers, regulators, and non-governmental organizations<br />

as we push to create more sustainable plastic alternatives",<br />

said Maelenn Ravard, the company's Sustainability and<br />

Regulatory Manager. "In addition to compliance with the<br />

EU Taxonomy Regulation, our entire line of Luminy PLA is<br />

certified 100 % biobased according to EN16785 and the<br />

USDA biopreferred program. What’s more, our production<br />

plant is ISO certified for environmental management, quality,<br />

and safety and we follow the regulations set by the World<br />

Wildlife Fund's sugarcane industry organization Bonsucro.<br />

We are proud to set this standard for the bioplastics<br />

industry moving forward".<br />

Luminy PLA bioplastics are derived from sugarcane, an<br />

annually renewable resource, and are among the few types<br />

of bioplastics that are both biobased and biodegradable.<br />

As outlined in the "Planting the Future with PLA", whitepaper,<br />

creating a kilogram of PLA requires 1.75 m² of sugarcane<br />

farmland which captures 1.8 kg of CO 2<br />

from the atmosphere<br />

as it grows. TotalEnergies Corbion's entire production<br />

capacity requires just 0.08 % of arable land in Thailand, where<br />

the company produces PLA locally. Simply put, the efficiency<br />

of land use combined with the benefits of carbon capture<br />

make PLA bioplastics a great option for reducing our global<br />

reliance on fossil-based plastics.<br />

TotalEnergies Corbion's Luminy PLA bioplastics enable<br />

businesses all over the world to transition to more sustainable<br />

materials without compromising on quality or performance.<br />

They provide a viable alternative to conventional plastics,<br />

aligning with the EU Taxonomy Regulation's objectives and<br />

supporting the global shift towards a more sustainable future.<br />

The white paper titled Planting the Future with PLA can be<br />

downloaded on their website. AT<br />

www.totalenergies-corbion.com

8 bioplastics MAGAZINE [<strong>04</strong>/23] Vol. 18<br />

News<br />

daily updated News at<br />

www.bioplasticsmagazine.com<br />

Braskem expands Its<br />

biopolymer production<br />

by 30 %<br />

In June, Braskem (São Paulo, Brazil) concluded a<br />

30 % increase in the production capacity of its biobased<br />

ethylene plant, located in the Petrochemical Complex of<br />

Triunfo, Rio Grande do Sul, Brazil. The USD 87 million<br />

investment aims to meet the growing global demand for<br />

sustainable products<br />

The plant now operates at an increased capacity, from<br />

200,000 to 260,000 tonnes/year. Braskem’s biobased<br />

ethylene is made from sustainably sourced, sugarcanebased<br />

ethanol which removes CO 2<br />

from the atmosphere<br />

and stores it in products for daily use.<br />

The initiative is an important advance in the company's<br />

ambition to increase the production of biopolymers<br />

to one million tonnes by 2030, and to become<br />

carbon neutral by 2050.<br />

"The expansion of biobased ethylene capacity reinforces<br />

Braskem’s commitment to sustainable development<br />

and innovation and proves the success of the strategy<br />

we engaged in thirteen years ago, when we launched<br />

the world’s first biobased polyethylene production at<br />

industrial scale, with proprietary technology. We want to<br />

meet society's and customers' demand for products with<br />

less impact on the environment”, explains Walmir Soller,<br />

VP Olefins/Polyolefins for Europe and Asia and responsible<br />

for the I’m green TM biobased business globally.<br />

Each tonne of plastic resin made from renewable<br />

feedstock represents the removal of three tonnes of CO 2<br />

from the atmosphere. Since the plant's beginning in<br />

2010, more than 1.2 million tonnes of I’m green biobased<br />

polyethylene have been produced. The recent increase in<br />

production capacity will remove approximately 185,000<br />

tonnes of CO 2<br />

equivalent per year.<br />

Braskem is the world leader in the production of<br />

biopolymers. Today, the portfolio of biobased resins is<br />

exported to more than 30 countries and is used in products<br />

from more than 250 major brands, such as Allbirds, DUO<br />

UK, Grupo Boticário, Johnson & Johnson, Natura & Co,<br />

Nissin, and Tetra Pak. These biobased resins are used to<br />

manufacture packaging, bags, toys, housewares, industrial<br />

cables and wires, packaging films, hockey fields, and<br />

reusable water bottles, among many other products.<br />

The development and production of ethylene and<br />

resins from biobased sources is the result of Braskem's<br />

continued investment in disruptive innovation and<br />

technology. Research, digital transformation, and bold<br />

partnerships are the foundations upon which Braskem<br />

searches for, and scales, sustainable solutions for society<br />

and the environment. Braskem’s current sustainability<br />

commitments include improving the circularity of plastics,<br />

promoting human-centric development, and leading the<br />

revolution in biobased materials. MT<br />

www.braskem.com<br />

New process for<br />

biobased nylon<br />

A research team from the Helmholtz Centre for<br />

Environmental Research (UFZ) and Leipzig University (both<br />

Leipzig, Germany) has now developed a process that can<br />

produce adipic acid, one of two building blocks of nylon,<br />

from phenol through electrochemical synthesis and the<br />

use of microorganisms. The team also showed that phenol<br />

can be replaced by waste materials from the wood industry.<br />

This could then be used to produce biobased nylon.<br />

The research work was published in Green Chemistry.<br />

In T-shirts, stockings, shirts, and ropes – or as a<br />

component of parachutes and car tyres – polyamides are<br />

used everywhere as synthetic fibres. At the end of the 1930s,<br />

the name Nylon was coined for such synthetic polyamides.<br />

Nylon-6 and Nylon-6.6 are two polyamides that account for<br />

around 95 % of the global nylon market. Until now, they have<br />

been produced from fossil-based raw materials. However,<br />

this petrochemical process is harmful to the environment<br />

because it emits around 10 % of the climate-damaging<br />

nitrous oxide (laughing gas) worldwide and requires a<br />

great deal of energy. "Our goal is to make the entire nylon<br />

production chain environmentally friendly. This is possible<br />

if we access biobased waste as feedstock and make the<br />

synthesis process sustainable", says Falk Harnisch,<br />

head of the Electrobiotechnology working group at the<br />

Helmholtz Centre for Environmental Research (UFZ). MT<br />

www.ufz.de<br />

Certification scheme<br />

for home Compostable<br />

carrier bags<br />

Since July <strong>2023</strong>, DIN CERTCO<br />

(Berlin, Germany) offers a<br />

new certification scheme<br />

according to the new standard<br />

EN 17427:2022 "Packaging –<br />

Requirements and test scheme for<br />

carrier bags suitable for treatment in<br />

well-managed home composting installations". With this<br />

certification scheme, carrier bags, fruit and vegetable<br />

bags, and (organic) waste bags can be labelled with the<br />

trusted certification mark "DINplus Home Compostable<br />

Carrier Bags". The modular certification scheme can<br />

also be used to certify the corresponding materials<br />

and semi-finished items<br />

With this unique certification system according to a<br />

European standard, trust is created along the entire<br />

value chain of manufacturers, retailers, consumers, and<br />

regulatory authorities. MT<br />

www.dincertco.de

ioplastics MAGAZINE [<strong>04</strong>/23] Vol. 18<br />

9<br />

Paques and Senbis collaborate on PHA<br />

Paques Biomaterials (Balk, the Netherlands) and Senbis<br />

Polymer Innovations (Emmen, the Netherlands) have partnered<br />

strategically to develop new applications for a breakthrough<br />

biopolymer with all the advantages of conventional plastics<br />

but without its disadvantages.<br />

Paques Biomaterials has been working on a new value<br />

chain in which bacteria in organic waste streams produce the<br />

biopolymer PHA for more than ten years. “Our background<br />

is in biotechnology”, says Joost Paques, founder of Paques<br />

Biomaterials, “and with this collaboration, biotechnology<br />

and chemistry join forces which is a formula for success<br />

for a biopolymer. We are convinced we will soon produce a<br />

high-quality alternative to fossil plastics, which can be widely<br />

applied and prevent microplastics”.<br />

Senbis Polymer Innovations is a chemical R&D company<br />

specialising in biopolymers. “We will help Paques Biomaterials<br />

develop different PHA grades suitable for a wide range of<br />

applications”, explains Gerard Nijhoving, managing director<br />

of Senbis. “Paques Biomaterials develops the PHA, but we<br />

give direction on which way it must be developed and then<br />

evaluate it. Paques Biomaterials has a promising biopolymer<br />

in hand with Caleyda. It is biobased and highly biodegradable<br />

in all kinds of environments. Their product is unique because<br />

it is made from waste streams and doesn’t use genetically<br />

modified bacteria. That makes it sustainable and natural on<br />

all sides. This involves a major challenge to deliver consistent<br />

quality, as for plastic processing purity is the key.<br />

Senbis has all commercially available biopolymers inhouse<br />

and has researched them. We know what works for<br />

which application. Many PHAs we see now need to catch up<br />

in mechanical and thermal properties compared to other<br />

bioplastics. If we can improve these topics with Paques<br />

Biomaterials, their PHA Caleyda will soon be a serious<br />

player in the market”.<br />

“We also see much potential for this material for socalled<br />

compounds. That means mixing the PHA with other<br />

biopolymers. For some applications, you need a mix of<br />

bioplastics to get the required mechanical properties and<br />

velocity of biodegradability”, says Gerard Nijhoving. “Like<br />

applications such as injection moulding, yarns, 3D printing<br />

or films. With this knowledge, Paques Biomaterials can<br />

optimise Caleyda where necessary, and we work together<br />

towards a high-quality PHA. Furthermore, you can use<br />

these compounds to serve new applications. We also see<br />

opportunities for this in our customer portfolio and even within<br />

our product development”.<br />

The beginning of this new circular value chain is already at<br />

an advanced stage. Paques Biomaterials has already signed a<br />

memorandum of understanding (MOU) with Kolon Industries<br />

and Kolon Global in South Korea, launching large-scale<br />

production of PHA from food waste. In Europe, the first full-scale<br />

plants in which bacteria make PHA in industrial wastewater,<br />

sewage sludge, and organic waste streams (vegetable/fruit<br />

waste) are also under development. In cooperation with five<br />

Dutch Water Boards and waste and energy company HVC,<br />

Paques Biomaterials has been optimising this process with a<br />

demo plant in the last few years. The PHA biomass is a reality,<br />

and in the next phase of the value chain, this biomass will be<br />

extracted and purified into a clean biopolymer PHA called<br />

Caleyda. For this phase, the cooperation with Senbis is crucial.<br />

With their knowledge and expertise, Paques Biomaterials will<br />

make Caleyda, a natural and high-quality bioplastic without<br />

the disadvantages of fossil plastics. AT<br />

www.paquesbiomaterials.nl | www.senbis.com<br />

daily updated News at<br />

Avantium and SCGC partner on CO 2<br />

– based polymers<br />

Avantium (Amsterdam, the Netherlands), a leading technology provider in renewable chemistry, announces that it has<br />

agreed to partner with SCGC (Bangkok, Thailand), a leading integrated chemical player in Asia and an innovator of chemical<br />

innovations and solutions.<br />

Under this partnership, Avantium and SCGC agreed to further develop CO 2<br />

-based polymers and to scale up to a pilot plant with<br />

an indicative capacity of 10 tonnes per annum.<br />

Avantium is a frontrunner in developing and commercialising innovative technologies for the production of chemicals and<br />

materials based on sustainable carbon feedstocks, i.e. carbon from plants or carbon from the air (CO 2<br />

). One of Avantium’s<br />

innovative technology platforms, called Volta Technology, uses electrochemistry to convert CO 2<br />

to high-value products and<br />

chemical building blocks including glycolic acid. By combining glycolic acid with lactic acid, Avantium can produce polylacticco-glycolic<br />

acid (PLGA), a carbon-negative polymer with valuable characteristics: it has an excellent barrier against oxygen and<br />

moisture, has good mechanical properties, is recyclable and is both home compostable and marine degradable. This makes PLGA<br />

a more sustainable and cost-effective alternative to, for example, non-degradable, fossil-based polymers.<br />

Since early <strong>2023</strong>, Avantium and SCGC have been working together to further evaluate PLGA. To this end, Avantium has produced<br />

samples of different PLGAs, which have been evaluated at SCGC’s Norner AS facility. The two parties have now agreed to take the<br />

next step in their cooperation and establish a Joint Development Agreement. Under this agreement, Avantium and SCGC intend<br />

to further evaluate PLGA in order to subsequently scale up production of glycolic acid monomer and PLGA polyester in the next<br />

two years to a pilot plant.<br />

“We are delighted that we have entered into this partnership with SCGC, a partner that understands that innovation and bold<br />

action is the key to lasting positive impact for a sustainable future. Under this partnership, we can further develop the very promising<br />

carbon-negative plastic PLGA and bring this material to the next commercialization phase. Both Avantium and SCGC would also<br />

welcome other strategic and complementary partners to participate in this collaboration”, says Tom van Aken, CEO at Avantium. AT<br />

www.avantium.com | www.scgchemicals.com

10 bioplastics MAGAZINE [<strong>04</strong>/23] Vol. 18<br />

News<br />

daily updated News at<br />

www.bioplasticsmagazine.com<br />

Neste will invest in liquefied waste plastic<br />

upgrading unit at its Porvoo refinery<br />

Neste (Espoo, Finland) has made the final investment decision to commence construction of upgrading facilities for liquefied<br />

plastic waste at its Porvoo refinery in Finland.<br />

With the investment of 111 million euros, Neste will build the capacity to upgrade 150,000 tonnes of liquefied waste plastic per<br />

year. Upgrading is one of the three processing steps turning liquefied waste plastic into high-quality feedstock for new plastics:<br />

pretreatment, upgrading and refining. The investment is part of a broader project (PULSE*), which has received an EU Innovation<br />

Fund grant of EUR 135 million if fully implemented and is targeting a total capacity of 400,000 tonnes per year.<br />

Pretreatment and upgrading of liquefied waste plastic play an important role in Neste’s approach to chemical recycling.<br />

They allow the company to increase flexibility for processing lower-quality plastic waste and scale up processing the liquefied<br />

waste plastic into high-quality petrochemical feedstock in its existing refinery in Porvoo.<br />

“We have developed our capability to process circular raw material at the Porvoo refinery over the recent years and are now set<br />

to build a respective facility. The new facility processing 150,000 tonnes of liquefied waste plastic, is planned to be finalized in the<br />

first half of 2025”, states Markku Korvenranta, Executive Vice President of Neste’s Oil Products.<br />

The project will see Neste building new assets at the Porvoo refinery, but also leveraging existing assets through retrofitting, to<br />

scale-up chemical recycling fast and efficiently. The upgraded liquefied waste plastic will then be processed in the conventional<br />

refinery, in which it will replace a portion of the fossil resources processed at the Porvoo refinery.<br />

Required preparation works at the Porvoo refinery were successfully completed during the first half of <strong>2023</strong>, enabling the<br />

construction work to commence without any delay. AT<br />

*) PULSE = Pretreatment and Upgrading of Liquefied waste plastic to Scale up circular Economy. Project PULSE is funded by the European Union. Views and opinions<br />

expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or European Climate Infrastructure and Environment<br />

Executive Agency (CINEA). Neither the European Union nor the granting authority can be held responsible for them. Neste is the sole beneficiary of Project PULSE’s<br />

funding by the European Union.<br />

www.neste.com<br />

Cooperation on<br />

biobased BOPLA films<br />

Xiamen Changsu Industrial (Xiamen, China) and<br />

TotalEnergies Corbion(Gorinchem, the Netherlands)<br />

have announced a strategic cooperation<br />

agreement that will further advance the polylactic<br />

acid (PLA) industry.<br />

They will work together in the market promotion,<br />

product development, and research and development<br />

of new technologies and applications of biaxially<br />

oriented polylactic acid (BOPLA).<br />

Changsu Industrial is a leading global player<br />

in high-performance specialty plastic films.<br />

Changsu Industrial focus on three major product<br />

segments: new energy, biodegradable, and<br />

functional film materials. The development of<br />

BOPLA is a good example of strong collaboration<br />

between different players in the value chain.<br />

BOPLA is made with biobased PLA using biaxial<br />

stretching technology, making Changsu Industrial's<br />

BOPLA product BiONLY ® biodegradable and capable<br />

of significantly reducing the carbon footprint of<br />

packaging materials. AT/MT<br />

www.changsufilm.com | www.totalenergies-corbion.com<br />

Avantium awarded<br />

EUR 1.5 million EU grant<br />

Avantium (Amsterdam, the Netherlands), a leading<br />

technology provider in renewable chemistry, announces that it<br />

has been awarded a EUR 1.5 million grant by the EU Horizon<br />

Europe programme for its participation in the research and<br />

development programme HICCUPS.<br />

This programme aims to demonstrate the utilisation of CO 2<br />

as a feedstock for the production of polyesters. The grant will<br />

be paid out in tranches to Avantium over a period of four years,<br />

starting in September <strong>2023</strong>.<br />

Under the HICCUPS programme, Avantium will convert CO 2<br />

from biogas produced at wastewater treatment plants into the<br />

sustainable plastic material PLGA (polylactic-co-glycolic acid).<br />

PLGA with 80 % glycolic acid or more has an excellent barrier<br />

against oxygen and moisture and good mechanical properties.<br />

It is furthermore recyclable and both home compostable<br />

and marine degradable. PLGA can be used, for example, as a<br />

coating material and in moulded plastic materials. This makes<br />

PLGA an excellent alternative to fossil-based polyethylene.<br />

The HICCUPS programme, which has received a EUR 5 million<br />

EU Horizon Europe grant in total, will demonstrate the full value<br />

chain from biogenic CO 2<br />

to polyester end-use and is expected to<br />

be executed over four years. AT/MT<br />

www.avantium.com

ioplastics MAGAZINE [<strong>04</strong>/23] Vol. 18<br />

11<br />

Compostable bioplastics biodegrade in real<br />

conditions, study confirms<br />

Chaire CoPack, in partnership with AgroParisTech (Nancy,<br />

France) and the University of Montpellier (France), has<br />

conducted a scientific study that validates the biodegradation<br />

of certified compostable food contact packaging in industrial<br />

composting facilities.<br />

The preliminary report of this study provides conclusive<br />

evidence that certified compostable packaging is a<br />

viable sustainable solution to waste management in the<br />

food packaging industry.<br />

The composting test used 20 tonnes of food – and bio-waste<br />

collected from households, along with 323 kg of assorted<br />

certified compostable packaging. In parallel, a control<br />

compost test was conducted with no packaging added.<br />

“We are thrilled to see the findings of this study”, said<br />

Paolo La Scola, the Public Affairs Manager at TotalEnergies<br />

Corbion (Gorinchem, The Netherlands). “The results send a<br />

strong signal to governments across Europe to grant certified<br />

compostable plastics access to biowaste collection and<br />

composting infrastructure. It’s necessary to reduce plastic<br />

waste mismanagement”.<br />

The research, carried out over a four-month period<br />

from October 2022 to February <strong>2023</strong>, took place in real<br />

industrial composting conditions without forced aeration.<br />

Researchers from the University of Montpellier and<br />

AgroParisTech monitored the study in collaboration with the<br />

industrial composting platform of the Syndicat de Centre<br />

Héraut in Aspiran (France).<br />

The study examined commercially available food packaging<br />

representative of the European market such as compostable<br />

bags, film, food trays, and coffee pods composed of different<br />

resins certified for industrial composting (EN 13432) or home<br />

composting (NF T51-800). These products were made from<br />

biodegradable and compostable resins like PLA, PBAT, and<br />

complexed starch sourced from members of the French<br />

Association of Biobased Compostables, including Novamont<br />

and TotalEnergies Corbion.<br />

The report is currently under review. The preliminary report<br />

is available online. MT<br />

https://tinyurl.com/biodegradabilitystudy<strong>2023</strong><br />

https://tinyurl.com/fate-of-compostable-plastic<br />

daily updated News at<br />

From corn stover to biobased ethylene<br />

Dow's (Midland, MI, USA) agreement with New Energy Blue (Lancaster, PA, USA), staffed by experts with deep experience<br />

in bio-conversion ventures, is the first agreement in North America to generate plastic source materials from corn stover<br />

(stalks and leaves).<br />

This is also Dow's first agreement in North America to utilize agricultural residues for plastic production.<br />

“We are unlocking the value of agriculture residues in this new partnership with New Energy Blue”, said Karen S. Carter, Dow<br />

President of Packaging & Specialty Products. “By committing to purchase their biobased ethylene, we are helping to enable<br />

innovations in waste recycling, meeting demands for biobased plastics from customers, and strengthening an ecosystem for<br />

diverse and renewable solutions”.<br />

Under the terms of the agreement, Dow is supporting the design of New Energy Freedom, a new facility in Mason City, Iowa, that<br />

is expected to process 275,000 tonnes of corn stover per year and produce commercial quantities of second-generation ethanol<br />

and clean lignin. Nearly half of the ethanol will be turned into biobased ethylene feedstock for Dow products. This agreement also<br />

gives Dow similar commercial supply options for the next four future New Energy Blue projects, supporting New Energy Blue's<br />

ability to scale its production and support farmers by providing a reliable market for agricultural residues. The five projects are<br />

expected to displace over one million tonnes of greenhouse gas (GHG) emissions every year. Dow's share of these five projects<br />

will also lead to a reduction in its sourcing of fossil fuels and subsequent GHG emissions.<br />

This agreement would play a pivotal role in Dow's approach to building material ecosystems that value, source, and transform<br />

waste into circular products. By collaborating with the best partners and technologies for collection, reuse, and recycling of<br />

waste – in this case, using a renewable resource – Dow enables global material ecosystems to scale.<br />

Through this agreement, Dow would increase its use of renewable yet still recyclable resources, transforming them into products<br />

that consumers use every day. Since corn stover releases carbon dioxide into the atmosphere as it decomposes, Dow's agreement<br />

with New Energy Blue would also help reduce carbon emissions from agriculture by reusing this otherwise wasted carbon.<br />

Dow's use of biobased feedstocks from New Energy Blue is expected to be certified by ISCC Plus, an international sustainability<br />

certification program with a focus on traceability of raw materials within the supply chain. While Dow intends to mix agriculturebased<br />

ethylene into its existing manufacturing process, ISCC Plus's chain of custody certification would allow Dow's customers<br />

to account for biobased materials in their supply chains. AT<br />

www.dow.com | www.newenergyblue.com

12 bioplastics MAGAZINE [<strong>04</strong>/23] Vol. 18<br />

INITIATIVE<br />

RENEWABLE<br />

CARBON<br />

Food and feed crops for<br />

biobased materials – Really?<br />

RCI publishes new insights into a hotly debated topic and urges for<br />

careful and evidence-based debates<br />

In <strong>2023</strong>, the world faces a global hunger crisis. According to<br />

the World Food Programme, “a record 349 million people<br />

across 79 countries are facing acute food insecurity – up<br />

from 287 million in 2021. This constitutes a staggering rise<br />

of 200 million people compared to pre-COVID-19 pandemic<br />

levels. More than 900,000 people worldwide are fighting to<br />

survive in famine-like conditions. This is ten times more than<br />

five years ago, an alarmingly rapid increase”.<br />

Against this backdrop, it may seem misanthropic to publish<br />

a paper challenging the widely held view that the use of food<br />

and feed crops for anything other than food and feed uses –<br />

namely, for biobased chemicals and materials – is detrimental<br />

to food security. However, RCI’s new publication aims to show<br />

that the well-known biomass debate is flawed, subjective,<br />

and not fully based on evidence – and as a result, distracts<br />

from much more powerful causes of hunger in the world.<br />

These are to a large extent climate change, conflict, extreme<br />

inequalities in wealth distribution, heavy dependence on food<br />

imports from industrial countries, overconsumption of meat,<br />

losses along the value chain and the impact of the COVID<br />

pandemic, according to the World Food Programme in <strong>2023</strong>.<br />

Competition between biomass uses is not mentioned among<br />

the relevant causes.<br />

Food Security<br />

Feed Security<br />

Market Stability<br />

Climate<br />

Multiple<br />

Potential<br />

Benefits<br />

Farmers<br />

The use of food and feed crops for biobased materials<br />

(Source: nova-Institiute)<br />

Land Productivity<br />

Enviroment<br />

The use of biomass for industrial applications, on the<br />

other hand, has the potential to replace fossil feedstocks<br />

and thus contribute to the urgently needed reduction of fossil<br />

carbon emissions into our atmosphere to mitigate climate<br />

change. While not denying the dire need to combat world<br />

hunger, the authors of the paper argue that using food and<br />

feed crops for chemicals and materials will not necessarily<br />

exacerbate food insecurity, and in fact has the potential to<br />

cause multiple benefits for local and global food security,<br />

climate mitigation and other factors:<br />

1. The climate wins. There is a need to shift away from<br />

fossil feedstocks to achieve climate change mitigation.<br />

Biobased materials are part of the solution and can<br />

thus help to mitigate one of the leading causes of<br />

hunger in the world.<br />

2. Land productivity wins. The competition between<br />

applications is not for the type of crop grown but for the<br />

land. The overall availability of arable land, and therefore<br />

food and feed on the planet determines what is possible and<br />

what is not. Food and feed crops offer high yields through<br />

long-term optimisation and a variety of co-products used<br />

simultaneously in a variety of applications, making the<br />

most out of the available land.<br />

3. The environment wins due to increased resource efficiency<br />

and productivity of food and feed crops and the reduced<br />

land area, especially if agricultural practices are improved<br />

to better respect soil health and ecosystems.<br />

4. Farmers win because they have more options for selling<br />

stock to different markets (food, feed, biofuels, material<br />

industry) and therefore more economic security. This can<br />

increase investment and ultimately the availability of<br />

arable land and ensure sustainable rural development to<br />

maintain EU agriculture.<br />

5. Market stability wins due to increased global availability<br />

of food and feed crops, reducing the risk of shortages and<br />

speculation peaks. The influence of biofuels and biobased<br />

materials on food prices is negligible.<br />

6. Feed security wins due to the high value of the protein-rich<br />

co-products of food and feed crops (which can also be used<br />

to supply protein for human nutrition).<br />

7. Food security wins due to the increased overall availability<br />

of edible crops that can be stored and flexibly distributed<br />

in times of crisis (emergency reserve), actually mitigating<br />

risks of supply-cycle-triggered regional hunger events.

C<br />

M<br />

Y<br />

CM<br />

MY<br />

CY<br />

CMY<br />

K<br />

for Plastics.<br />

and Services.<br />

Crop<br />

Feed<br />

bioplastics MAGAZINE [<strong>04</strong>/23] Vol. 18<br />

13<br />

The authors argue that “the bigger picture is not the<br />

specific issue of whether food or non-food crops are being<br />

used to produce biomaterials, but rather the integration of<br />

any feedstock for biomaterials production into a landscape<br />

and its social, environmental, and pricing effects there” (BFA<br />

2022). The choice of feedstock in any given case depends<br />

on many factors and is site-specific. There is no “onesize-fits-all”<br />

solution.<br />

Info:<br />

Download the paper here for free:<br />

Short version: https://tinyurl.com/rci-foodfeed-short<br />

Long version: https://tinyurl.com/rci-foodfeed-long<br />

RENEWABLE<br />

All in all, this complex topic requires in-depth and detailed<br />

analyses, and simplified claims will not do it justice. In the<br />

worst case, simple claims will only distract from the real<br />

causes of hunger in the world and at the same time prevent<br />

a young and innovative industry from fulfilling its potential of<br />

contributing to climate change mitigation and offering more<br />

sustainable materials. The Renewable Carbon Initiative<br />

encourages comprehensive discussions that balance the<br />

need for food security with the potential benefits of biobased<br />

materials derived from food and feed crops.<br />

SHORT<br />

LONG<br />

Disclaimer: RCI members are a diverse<br />

group of companies addressing the<br />

challenges of the transition to renewable<br />

carbon with different approaches. The<br />

opinions expressed in this article may not<br />

reflect the exact individual policies and<br />

views of all RCI members.<br />

www.renewable-carbon-initiative.com<br />

10<br />

Years ago<br />

Published in<br />

bioplastics MAGAZINE<br />

Basics<br />

Food or<br />

non-food<br />

Which agricultural feedstocks<br />

are best for industrial uses?<br />

T<br />

he new paper by nova-Institute, Germany, is a<br />

contribution to the recent controversial debate<br />

about whether food crops should be used for<br />

other applications than food and feed. It is based on<br />

scientific evidence and aims to provide a more realistic<br />

and appropriate view of the use of food-crops in biobased<br />

industries, including the production of biobased<br />

plastic materials, taking a step back from the often<br />

very emotional discussion.<br />

The authors, Michael Carus and Lara Dammer, take<br />

the position that all kinds of biomass should be accepted<br />

for industrial uses; the choice should be dependent on<br />

how sustainably and efficiently these biomass resources<br />

can be produced.<br />

Of course, with a growing world population, the first<br />

priority of biomass allocation is food security. At the end of<br />

2011, there were about 7 billion people on our planet. The<br />

global population is expected to reach more than 9 billion<br />

people by 2050. This alone will lead to a 30% increase<br />

in biomass demand. Increasing meat consumption and<br />

higher living standards will generate additional demand<br />

for biomass. According to EU Commission estimations, a<br />

70% increase in food demand is expected, which includes<br />

a projected twofold increase in world meat consumption.<br />

Food and feed clearly are the supply priorities for<br />

biomass use, followed by bio-based products, biofuels<br />

and bioenergy. Fig. 1 shows the use of the 10 billion<br />

Use of harvested agricultural biomass worldwide (2008)<br />

tonnes of biomass harvested worldwide in 2008. Animal<br />

feed predominates with a share of 60%, which will<br />

increase even further.<br />

4 % 4 %<br />

Public debate mostly focuses on the obvious direct<br />

competition for food crops between different uses: food,<br />

32 %<br />

feed, industrial materials and energy. However, the<br />

authors argue that the crucial issue is land availability,<br />

since the cultivation of non-food crops on arable land<br />

would reduce the potential supply of food just as much<br />

or even more. Therefore, they suggest a differentiated<br />

approach to finding the most suitable biomass for<br />

industrial uses.<br />

In a first step, the issue has to be addressed of whether<br />

60 %<br />

the use of biomass for purposes other than food can be<br />

justified at all. This means taking the availability of arable<br />

land into account. Several studies show that some areas<br />

Total biomass ca. 10 billion tonnes<br />

will remain free even after worldwide food demand has<br />

been satisfied. These studies also show potential for<br />

further growth in yields and arable land areas worldwide<br />

– even in the EU, there are between 2.5 and 8 million<br />

Food Animal feed Material use Energy use<br />

hectares arable land that are not currently in use. Despite<br />

these potentials, arable land and biomass are limited<br />

resources and should be used efficiently and sustainably.<br />

As the numbers above show, the industrial material<br />

use of biomass makes up for only a very small share of<br />

biomass competition. Other factors have a much greater<br />

by<br />

Michael Carus, Managing Director<br />

and Lara Dammer, Policy and Strategy<br />

nova-Institute, Huerth, Germany<br />

Notes: Shares of food an feed based on FAOSTAT; gap of animal<br />

feed demand from grazing not included (see Krausmann et al. 2008)<br />

Fig. 1: Worldwide allocation of harvested biomass by production<br />

target (main product) in 2008. Respective amounts include raw<br />

materials and their by-products, even if their uses fall into<br />

different categories.<br />

impact on food availability. Due to a growing demand<br />

from a l sectors, the crucial question is how to increase<br />

the biomass production in a sustainable way.<br />

1. Increasing yields: Tremendous potential in developing<br />

countries is hampered by a lack of investment in we l-<br />

known technologies and infrastructure, unfavourable<br />

agricultural policies such as no access to credits,<br />

insufficient transmission of price incentives, and poorly<br />

enforced land rights.<br />

2. Expansion of arable land: Some 100 mi lion hectares<br />

could be added to the current 1.4 bi lion hectares without<br />

touching rainforest or protected areas. Most estimates<br />

calculate up to 500 mi lion hectares. These areas wi l<br />

require a lot of infrastructure investment before they can<br />

be utilized [1, 2].<br />

Both aspects mean that political reforms and huge<br />

investment in agro-technologies and infrastructure<br />

are necessary. There is also huge potential for saving<br />

biomass and arable land:<br />

• Reduced meat consumption would free up a huge<br />

amount of arable land for other uses. Deriving protein<br />

from cattle requires 40 to 50 times the biomass input<br />

than protein directly obtained from wheat or soy;<br />

• Reducing food losses wi l also free up huge areas<br />

of arable land. Roughly one-third of food produced<br />

for human consumption is lost or wasted globa ly,<br />

amounting to about 1.3 bi lion tonnes per year [3];<br />

• Increasing the efficiency of biomass processing<br />

for a l applications by the use of modern industrial<br />

biotechnology;<br />

• Using a l agricultural by-products that are not inserted<br />

in any value chain today. Lignoce lulosic residues in<br />

particular can be used in second generation biofuels<br />

and biochemicals;<br />

• Fina ly, the use of solar energy, which also takes up<br />

land, for fue ling electric cars is about 100 times<br />

more land-efficient than using the land for biofuels<br />

for conventional cars. In addition, solar energy can be<br />

produced on non-arable land, too. Increased use of this<br />

means of transportation would release huge areas of<br />

arable land that are currently used for biofuels [4]<br />

After the overa l availability of land has been verified,<br />

the second step is to find out how bes to use these areas.<br />

The use of the so-ca led first generation of biomass, such<br />

as sugar, starch, plant oil and natural rubber, to obtain<br />

different chemicals and materials, is virtua ly as old as<br />

mankind (e.g. birch bark pitch use dates back to the late<br />

Paleolithic era). It has been conducted on an industrial<br />

scale for over 100 years. For example, starch is used on<br />

a large scale in the paper industry. Today, a wide range<br />

of chemicals, plastics, detergents, lubricants and fuels<br />

are produced from these resources. Because of their<br />

Opinion<br />

potential direct competition with food and animal feed, the<br />

idea of using lignoce lulosic feedstock as a raw material for<br />

fermentable sugars and also for gasification was introduced<br />

in the last ten years. Lignoce lulose means wood, shortrotation<br />

coppice such as poplar, wi low or Miscanthus, or else<br />

lignoce lulosic agricultural by-products like straw. These are<br />

the so-ca led second-generation feedstocks. Very recently,<br />

more and more research is being carried out into using algae<br />

as a feedstock; this is known as a third-generation feedstock.<br />

Whether the use of second-generation feedstocks wi l<br />

have less impact on food security is questionable and is being<br />

discussed in detail in the complete paper.<br />

Several aspects give reasons to doubt this oftenpostulated<br />

axiom. Recent studies have shown that many<br />

food crops are more land-efficient than non-food crops.<br />

This means that less land is required for the production of a<br />

certain amount o fermentable sugar for example – which is<br />

especially crucial for biotechnology processes, such as the<br />

production of monomers or building blocks for bioplastics –<br />

than would be needed to produce the same amount of sugar<br />

with the supposedly “unproblematic”, second generation<br />

lignoce lulosic non-food crops. <br />

44 bioplastics MAGAZINE [<strong>04</strong>/13] Vol. 8<br />

Basics<br />

Valorization of components of industrially used food crops<br />

Food/feed Industrial use<br />

100%<br />

90%<br />

80%<br />

70%<br />

60%<br />

50%<br />

40%<br />

30%<br />

20%<br />

10%<br />

0%<br />

Sugar Sugar Wheat Corn Soy Rapeseed/<br />

beet cane<br />

canola<br />

magnetic_148,5x105.ai 175.00 lpi 15.00° 75.00° 0.00° 45.00° 14.03.2009 10:13:31<br />

Proze s CyanProze s MagentaProze s GelbProzess Schwarz<br />

Fig. 2: Valorization of components o food crops used in industry.<br />

This considers only the special case of when a l carbohydrates<br />

(sugar beet, sugar cane, wheat and corn) or oils (soy and canola)<br />

are used for industrial material use only, their by-products being<br />

subsequently used for food and feed. 1<br />

Magnetic<br />

www.plasticker.com<br />

for Plastics<br />

This is not very surprising, considering that starch, sugar<br />

and plant oils are used by the crops as energy storage<br />

for solar energy, and easy to utilize again. In contrast,<br />

lignoce lulose gives the crop a functional structure – it is<br />

not built to store energy, but to last and protect the plants<br />

from microorganisms. Only specific enzymes (plus energy)<br />

are able to saccharify the lignocellulosic structure and<br />

transform it into fermentable sugars. Although terrific<br />

improvements have been achieved in this field over the last<br />

two decades, the technology is sti l in its infancy. The price of<br />

the enzymes as well as their efficiency are, alongside capital<br />

requirements, sti l the biggest obstacle to this strategy. As a<br />

result, lignoce lulosic biomass is not an efficient option for<br />

fermentation processes.<br />

This means that the often raised question: “When wi l<br />

your company switch from food crops to second generation<br />

lignoce lulosic feedstock?” is too shortsighted and simplistic.<br />

The authors argue tha the real question is: “What is the most<br />

resource efficient and sustainable use of land and biomass<br />

in your region?” It is not the issue of whether the crop can<br />

be used for food or feed; it is a question of resource and land<br />

efficiency and sustainability. The competition is for land. Land<br />

used for cultivating lignocellulosic feedstock is not available<br />

for food or feed production (see Chapter 6 in the complete<br />

paper). So the dogma of “no food crops for industry” can<br />

lead to a misallocation or underutilization of agricultural<br />

resources, i.e. land and biomass.<br />

• International Trade<br />

in Raw Materials,<br />

Machinery & Products<br />

Free of Charge<br />

• Daily News<br />

from the Industrial Sector<br />

and the Plastics Markets<br />

• Cu rent Market Prices<br />

Also, the utilization o food crops in bio-based industries is<br />

very efficient, since the process chains have been optimized<br />

over a very long time and the by-products are used in food<br />

and feed. Biorefineries for food crops have existed for many<br />

years that convert a l parts of a harvested crop into food,<br />

feed, materials and energy/ fuel, maximizing the total value.<br />

If this maximum output value were not attained, the prices of<br />

the food and feed parts would go up.<br />

For example, using sugar, starch or oil for bio-based<br />

chemicals, plastics or fuel leaves plant-based proteins,<br />

which are an important feedstock for the food and animal feed<br />

industry. At present, the world is mainly short of protein and<br />

not of carbohydrates such as sugar and starch. This means<br />

that there is no real competition with food uses, since the<br />

valuable part of the food crops still flows into food and feed<br />

uses. (More information is available in the complete paper.)<br />

Table 1 and Fig. 2 above give an overview of the valorization<br />

of processed fractions of crops, if the main use is material<br />

use, dry matter only. The percentage is related to grain or<br />

fruit only; additional (lignoce lulosic) fibres from straw,<br />

leaves, etc. are no taken into account.<br />

Another very important aspect that is rarely mentioned is<br />

that food crops for industry can also serve as an emergency<br />

reserve of food and feed supply, whereas second-generation<br />

lignoce lulose cannot be used in the same way. This means<br />

that food security can be assured through the extended use<br />

of food crops. In a food crisis, sugar cane (Brazil) and corn<br />

• Buyer’s Guide<br />

for Plastics Additives,<br />

Machinery & Equipment,<br />

Subcontractors<br />

• Job Market<br />

for Specialists and<br />

Executive Sta f in the<br />

Plastics Industry<br />

Up-to-date • Fast • Professional<br />

bioplastics MAGAZINE [<strong>04</strong>/13] Vol. 8 43<br />

Carbohydrates Oils Proteins Fibres (lignoce lulosic)<br />

% Use % Use % Use % Use<br />

Sugar beet 65–70% Industrial 5–7% Feed 5–7% Feed<br />

Sugar cane 30% Industrial<br />

Wheat 60% Industrial 10% Feed, Food 30% Feed, Food<br />

Corn 75% Industrial 5% Food 15% Feed 5% Feed<br />

Feed, Food<br />

Proteins and<br />

Soy 20% Industrial<br />

Fibres 80%<br />

Rapeseed/<br />

Proteins and<br />

40% Industrial<br />

Canola<br />

Fibres 60%<br />

External origin<br />

attributes of the environment<br />

Internal origin<br />

attributes of the biomass<br />

Helpful<br />

to achieving the objective<br />

• Established logistic and processes (varieties,<br />

cultivation, harvest, storage, quality control)<br />

• Sugar cane and beet: Highest yields of fermentable<br />

sugar per ha (high land effi ciency)<br />

• Positive GHG balance and low non-renewable<br />

resource depletion, high resource efficiency<br />

• Protein rich by-product press cake or DDGS (Dried<br />

Distillers Grains with Solubles) for feed<br />

• Lower production costs than sugars from<br />

lignoce lulose<br />

• Easy to use for biotech processes<br />

STRENGTHS<br />

WEAKNESSES<br />

OPPORTUNITIES<br />

THREATS<br />

(US), for example, can be immediately redirected to the availability, resource- and land efficiency, valorization of byproducts<br />

and emergency food reserves are taken into account.<br />

food and feed market. This is especially possible with<br />

crop varieties certified for food and feed.<br />

This also means that research into first generation<br />

First-generation crops also have the potential to give processes should be continued and receive fresh support e.g.<br />

the farmer more flexibility in terms of his crop’s end from European research agendas and tha the quota system<br />

use. If the market is already saturated with food exports for producing sugar in the European Union should be revised<br />

of a crop, this a lows the crop to be diverted towards in order to enable increased production of these feedstocks<br />

industrial use. The reverse is also true when there is a for industrial uses.<br />

food shortage.<br />

And the authors ask for a level playing field between<br />

Therefore, growing more food crops for industry creates industrial material uses of biomass and biofuels/bioenergy<br />

a quintuple win situation:<br />

in order to reduce market distortions in the allocation of<br />

• The farmer wins, since he has more options for se ling<br />

biomass for uses other than food and feed.<br />

his stock and therefore more economic security;<br />

• The environment wins due to greater resource efficiency<br />

o food crops and the sma ler area of land used;<br />

References:<br />

• Food security wins due to flexible a location of food<br />

crops in times of crisis;<br />

• Feed security also wins due to the high value of the<br />

protein-rich by-products o food crops;<br />

• Market stability wins due to increased global availability<br />

of food crops, which wi l reduce the risk of shortages<br />

and speculation peaks.<br />

For all these reasons, the authors reques that political<br />

measures should not differentiate simply between<br />

food and non-food crops, but that criteria such as land<br />

Table 1: Valorization of components o food crops used in industry.<br />

This considers only the special case of when a l carbohydrates<br />

(sugar beet, sugar cane, wheat and corn) or oils (soy and canola)<br />

are used for industrial material use only, their by-products being<br />

subsequently used for food and feed. 1 Sources: Kamm et al. 2006;<br />

IEA Bioenergy, Task 42 Biorefinery 2012: Country Reports.<br />

1 Table 1 and Figure 2 do not give an overview of actual current use o food crops, but only the special case when carbohydrates or oil are<br />

used exclusively for industrial material use. The reality is somewhat di ferent: (1) Most of Brazil’s mi ls can produce both ethanol and sugar,<br />

bu the amount of each product varies according to market conditions. The regular mix is 55 % ethanol and 45 % sugar. (2) With one raw<br />

material, the European starch industry serves di ferent application sectors – confectionary and drinks, processed foods, feed, paper and<br />

corrugating, pharmaceuticals, chemicals/ polymers and biofuels – in an integrated, continuous and balanced manner.<br />

For this episode of “10 Years ago in bioplastics<br />

MAGAZINE” it wasn’t even necessary to look for an<br />

interesting article and ask the author for his or<br />

her today’s view. This time it came by itself, so<br />

we just need to point our readers<br />

to the publication of nova<br />

Intitute from 2013. MT<br />

(soy milk<br />

and tofu from<br />

extracted proteins)<br />

• Fast implementation and growth of the Biobased<br />

Economy; required technology is state of the art<br />

• Food security only possible with a globa ly growing<br />

volume o food crops: Emergency reserves & market<br />

stabilization; (partial substitution with non-food crops<br />

would lead to artifi cial shortage)<br />

• Economic security for the farmer due to more choices<br />

of se ling his stock<br />

Fig. 3: SWOT Analysis o food crop use for industry (nova 2013)<br />

www.bio-based.eu<br />

[1] Dauber, J. et al. 2012: Bioenergy from “surplus” land:<br />

environmental and socio-economic implications; BioRisk 7: 5 –<br />

50 (2012)<br />

[2] Zeddies, J. et al. 2012: Globale Analyse und Abschätzung des<br />

Biomasse-Flächennutzungspotentials. Hohenheim 2012<br />

[3] FAO – Food and Agriculture Organization of the United Nations<br />

2011: Global food losses and food waste. Rome 2011<br />

[4] Carus, M. 2012: From the field to the wheel: Photovoltaic is 40<br />

times more efficient than the best biofuel; bioplastics MAGAZINE<br />

(1/12), Vol. 7, 2012<br />

nova paper #2 on bio-based economy: Food or non-food: Which<br />

agricultural feedstocks are best for industrial uses? (2013-07)<br />

nova papers on bio-based economy are proposals to stimulate<br />

the discussion on curren topics of the bio-based economy<br />

by inviting relevant stakeholders to participate in decisionmaking<br />

processes and debates.<br />

Download this paper and further documents at:<br />

www.bio-based.eu/policy/en<br />

bioplastics MAGAZINE [<strong>04</strong>/13] Vol. 8 45<br />

Helpful<br />

to achieving the objective<br />

• Direct competition to food and feed market<br />

• Price level directly linked to food and feed<br />

prices; high prices during food crisis<br />

• High volatility of the raw material prices<br />

• Decreasing production would cause shortages<br />

on animal feed markets<br />

• Sensitive to drought and dry winter freeze<br />

• Under high pressure from public, NGOs and<br />

politicians: Claimed impact on food prices and food<br />

shortages<br />

• Simple strong and populistic messages like “No Food<br />

Crops for Industry”<br />

• During food crisis: High prices and no secure supply<br />

for the industry<br />

• Insecure political framework; very complex EU<br />

legislation concerning specifi c food crops (e.g. sugar)<br />

Opinion<br />

tinyurl.com/foodfeed2013<br />

42 bioplastics MAGAZINE [<strong>04</strong>/13] Vol. 8

14 bioplastics MAGAZINE [<strong>04</strong>/23] Vol. 18<br />

INITIATIVE<br />

RENEWABLE<br />

CARBON<br />