issue 01/2022

Highlights: Automotive Foam Basics: Biodegradation

Highlights:

Automotive

Foam

Basics: Biodegradation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Bioplastics - CO 2<br />

-based Plastics - Advanced Recycling<br />

Vol. 17<br />

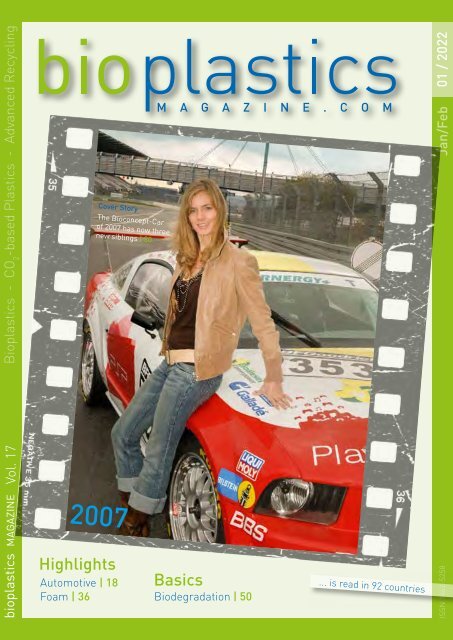

Cover Story<br />

The Bioconcept-Car<br />

of 2007 has now three<br />

new siblings | 30<br />

bioplastics MAGAZINE<br />

Jan/Feb <strong>01</strong> / <strong>2022</strong><br />

2007<br />

Highlights<br />

Automotive | 18<br />

Foam | 36<br />

Basics<br />

Biodegradation | 50<br />

... is read in 92 countries<br />

... is read in 92 countries<br />

ISSN 1862-5258

“GREEN MESSAGE IN A BOTTLE" MADE OF BIOPLASTICS FROM<br />

THE BIOPLASTIC<br />

SPECIALIST<br />

With its new “BIO variant” PUSTEFIX offers a sustainable alternative<br />

to its traditional bubble bottle. PUSTEFIX trusts on closures made of<br />

bio-based I’m green Polyethylene in combination with a bottle made<br />

Bio-Flex ® . The injection-moldable Bio-Flex ® used for the bottle is characterized<br />

by a balanced ratio of stiffness and toughness combined with a good<br />

flow-ability and processability. In terms of strength, stability and weight,<br />

the Pustefix “BIO variant” can easily compete with those made from<br />

fossil plastics. An all-round successful "green message in a bottle" for<br />

dazzling soap bubbles that simply last longer. Let us show you how<br />

FKuR bioplastics and recyclates support you on your way to a<br />

circular economy.

dear<br />

Editorial<br />

readers<br />

Alex Thielen, Michael Thielen<br />

With the current cover, we are taking a small trip down memory lane –<br />

15 years ago we had our first <strong>issue</strong> featuring automotive applications and<br />

have since made it a tradition to kick off the new year with everything new<br />

and innovative in and around bioplastics in cars. Looking back at the first<br />

Bioconcept-Car from 2007 makes me realize how much has changed.<br />

Back then they were just like us, “crazy dreamers” thinking this whole<br />

bio-thing has a shot in our all too often “bottom-line driven” world. Now,<br />

15 years later they have three Bioconcept-Cars proving on the track how<br />

competitive bio-materials really are. However, they are not alone anymore<br />

as more and more big car brands are including biobased materials.<br />

One of them is Mercedes-Benz with their ambitious VISION EQXX an<br />

electrical vehicle that uses bioplastics for both interior design as well as<br />

technically demanding parts. Turns out, the crazy dreamers were right<br />

“going bio” – or better “going renewable” – has become a normal, even<br />

desirable choice for many in and outside the automotive industry.<br />

Bioplastics - CO 2<br />

-based Plastics - Advanced Recycling<br />

Jan/Feb <strong>01</strong> / <strong>2022</strong><br />

Our second focus point is almost as much a tradition as the first,<br />

Foam. Here we have new developments in both the fields of bioplastics<br />

and chemical recycling. But that is not all, we have an interesting<br />

look at Biodegradability in our Basics section as it is (sadly) a topic<br />

often misunderstood or misrepresented. Last but not least we talk<br />

about a topic that is important for everybody doing anything with<br />

bioplastics – LCAs. Those of you that were at the European Bioplastics<br />

Conference last year will know about the current debate about the LCA<br />

methodology the Joint Research Centre (JRC) developed for the European<br />

Commission – and the controversy around it. If you haven’t heard of it and<br />

are wondering what this is all about, the answer is 42.<br />

Vol. 17<br />

bioplastics MAGAZINE<br />

2007<br />

Highlights<br />

Automotive | 18<br />

Foam | 36<br />

Basics<br />

Biodegradation | 50<br />

... is read in 92 countries<br />

... is read in 92 countries<br />

ISSN 1862-5258<br />

Even if our conference season starts with a purely digital bio!PAC on<br />

March 15 + 16, we desperately hope to meet you in person at our<br />

7 th PLA World Congress on May 24 + 25 in Munich, Germany. And for<br />

October we are already getting excited about the upcoming K-show and our<br />

Bioplastics Business Breakfast.<br />

Follow us on twitter!<br />

www.twitter.com/bioplasticsmag<br />

Until then, we hope you all got good into the new year, let’s hope it will be<br />

better than the last. Stay healthy, stay crazy, keep dreaming.<br />

Yours sincerely<br />

Like us on Facebook!<br />

www.facebook.com/bioplasticsmagazine<br />

bioplastics MAGAZINE [<strong>01</strong>/22] Vol. 17 3

Imprint<br />

Content<br />

34 Porsche launches cars with biocomposites<br />

32 Bacteriostatic PLA compound for 3D printingz<br />

Jan/Feb <strong>01</strong>|<strong>2022</strong><br />

3 Editorial<br />

5 News<br />

45 Application News<br />

30 Cover Story<br />

50 Basics<br />

53 10 years ago<br />

54 Suppliers Guide<br />

58 Companies in this <strong>issue</strong><br />

Publisher / Editorial<br />

Dr. Michael Thielen (MT)<br />

Alex Thielen (AT)<br />

Samuel Brangenberg (SB)<br />

Head Office<br />

Polymedia Publisher GmbH<br />

Dammer Str. 112<br />

41066 Mönchengladbach, Germany<br />

phone: +49 (0)2161 6884469<br />

fax: +49 (0)2161 6884468<br />

info@bioplasticsmagazine.com<br />

www.bioplasticsmagazine.com<br />

Media Adviser<br />

Samsales (German language)<br />

phone: +49(0)2161-6884467<br />

fax: +49(0)2161 6884468<br />

sb@bioplasticsmagazine.com<br />

Michael Thielen (English Language)<br />

(see head office)<br />

Layout/Production<br />

Kerstin Neumeister<br />

Print<br />

Poligrāfijas grupa Mūkusala Ltd.<br />

1004 Riga, Latvia<br />

bioplastics MAGAZINE is printed on<br />

chlorine-free FSC certified paper.<br />

bioplastics magazine<br />

Volume 17 - <strong>2022</strong><br />

Events<br />

9 European Bioplastics Conferene 2021<br />

14 bio!PAC <strong>2022</strong><br />

16 Chinaplas <strong>2022</strong><br />

17 7 th PLA World Congress<br />

Automotive<br />

18 Bio-PA composites<br />

20 Lightweight biobased cellulose<br />

reinforcement for automotive applications<br />

22 Tyre News<br />

23 BIOMOTIVE<br />

24 Automotive Bioplastics Market<br />

26 Why cycle when you could travel in style?<br />

28 Sustainable materials in high-end luxury car<br />

34 Car headliner from plastic waste and old tyres<br />

Cover Story<br />

30 The Bioconcept Car has 3 new siblings<br />

Award<br />

12 And the winner is ...<br />

Foam<br />

36 Mattress recycling now a reality<br />

38 PHBH foam products<br />

Materials<br />

39 New 3D printing powder for<br />

the food industry<br />

Processing<br />

40 Extrusion lines for natural<br />

fibre waste<br />

41 PLA crystallisation and drying<br />

Opinion<br />

42 The new JRC’s “Plastics LCA<br />

method” already needs an update<br />

Basics<br />

50 Biodegradation<br />

One concept - many nuances<br />

ISSN 1862-5258<br />

bM is published 6 times a year.<br />

This publication is sent to qualified subscribers<br />

(169 Euro for 6 <strong>issue</strong>s).<br />

bioplastics MAGAZINE is read in<br />

92 countries.<br />

Every effort is made to verify all Information<br />

published, but Polymedia Publisher<br />

cannot accept responsibility for any errors<br />

or omissions or for any losses that may<br />

arise as a result.<br />

All articles appearing in<br />

bioplastics MAGAZINE, or on the website<br />

www.bioplasticsmagazine.com are strictly<br />

covered by copyright. No part of this<br />

publication may be reproduced, copied,<br />

scanned, photographed and/or stored<br />

in any form, including electronic format,<br />

without the prior consent of the publisher.<br />

Opinions expressed in articles do not necessarily<br />

reflect those of Polymedia Publisher.<br />

bioplastics MAGAZINE welcomes contributions<br />

for publication. Submissions are<br />

accepted on the basis of full assignment<br />

of copyright to Polymedia Publisher GmbH<br />

unless otherwise agreed in advance and in<br />

writing. We reserve the right to edit items<br />

for reasons of space, clarity or legality.<br />

Please contact the editorial office via<br />

mt@bioplasticsmagazine.com.<br />

The fact that product names may not be<br />

identified in our editorial as trade marks<br />

is not an indication that such names are<br />

not registered trade marks.<br />

bioplastics MAGAZINE tries to use British<br />

spelling. However, in articles based on<br />

information from the USA, American<br />

spelling may also be used.<br />

Envelopes<br />

A part of this print run is mailed to the<br />

readers wrapped bioplastic envelopes<br />

sponsored by Sidaplax/Plastic Suppliers<br />

(Belgium/USA)<br />

Cover<br />

Michael Thielen, from cover shooting for<br />

<strong>issue</strong> <strong>01</strong>/2007<br />

Follow us on twitter:<br />

http://twitter.com/bioplasticsmag<br />

Like us on Facebook:<br />

https://www.facebook.com/bioplasticsmagazine

Bio-based acrylonitrile<br />

for carbon fibers<br />

Solvay (Brussels, Belgium) and Trillium<br />

Renewable Chemicals (Knoxville, Tennesse, USA)<br />

have signed a letter of intent to develop the supply<br />

chain for biobased acrylonitrile (bio-ACN). Trillium<br />

will supply Solvay with bio-ACN from Trillium’s<br />

planned commercial asset, and Solvay will evaluate<br />

bio-ACN for carbon fibre manufacturing as part of its<br />

long-term commitment to developing sustainable<br />

solutions from biobased or recycled sources. The<br />

aim of this partnership is to produce carbon fibre<br />

for use in various applications such as aerospace,<br />

automotive, energy, and consumer goods.<br />

Acrylonitrile is a chemical intermediate typically<br />

made from petroleum-based feedstocks like<br />

propylene and is the primary raw material used<br />

in the production of carbon fibre. Trillium’s Bio-<br />

ACN process delivers acrylonitrile from plantbased<br />

feedstocks like glycerol with a lower carbon<br />

footprint.<br />

“We are thrilled to be partnering with Trillium<br />

which aligns well with our Solvay One Planet<br />

commitment to more than double our revenue<br />

based on renewable or recycled materials by 2030,”<br />

comments Stephen Heinz, head of composite<br />

research & innovation, Solvay. “Innovation<br />

partnerships such as this are driven by a desire to<br />

make a real-world sustainability impact. Biobased<br />

feedstocks are a key part of Solvay’s sustainability<br />

strategy, and we look forward to being a consumer of<br />

bio-ACN from Trillium’s first biobased acrylonitrile<br />

plant.”<br />

“Trillium’s bio-ACN process technology enables<br />

bio-carbon fibre,” explains Corey Tyree, CEO of<br />

Trillium. “We are excited to continue our partnership<br />

with Solvay, who have supported the bio-ACN<br />

process technology development since 2<strong>01</strong>4. Solvay<br />

is a leader in the most rapidly-growing acrylonitrile<br />

segment (carbon fibre) and is market leader in biocarbon<br />

fibre and sustainable development.”MT<br />

www.trilliumchemicals.com | www.solvay.com<br />

NatureWorks: New headquarter<br />

and R&D facilities<br />

In response to rapid growth in the market for sustainable<br />

biomaterials, NatureWorks (Minnetonka, Minnesota, USA)<br />

recently announced their intent to open a new headquarters and<br />

advanced biopolymer research facility in Plymouth, Minnesota.<br />

Expanded laboratory capabilities will support research into the<br />

full circular lifecycle of Ingeo PLA biopolymers from nextgeneration<br />

fermentation technology to new applications, to<br />

increased functionality.<br />

The expanded R&D capabilities will also support the<br />

construction and operation of NatureWorks’ new fully integrated<br />

Ingeo PLA manufacturing complex located in Thailand. With<br />

an expected opening in 2024, the facility will have an annual<br />

capacity of 75,000 tonnes of Ingeo biopolymer and produce the<br />

full portfolio of Ingeo grades.<br />

“In the face of these challenging times, we’ve designed a<br />

space that will enable research, invention, and collaboration<br />

between us, our partners, and the market, no matter where<br />

we are located in the world,” said Rich Altice, President & CEO<br />

of NatureWorks. “These new facilities will help accelerate the<br />

pace of research and innovation as the urgent need for real,<br />

safe solutions that help address climate and environmental<br />

challenges from plastics and chemicals continues to grow.”<br />

The new space is designed to embody NatureWorks’s<br />

mission to create sustainable, high-performance materials by<br />

incorporating low environmental impact materials including<br />

lighting, flooring, and art made with Ingeo as well as systems for<br />

reducing water and energy usage. A robust organics recycling<br />

collection system will divert food waste away from landfills to<br />

compost with compostable food serviceware, coffee pods, and<br />

tea bags all available to visitors and employees.<br />

Whether participating in trials in NatureWorks’ applications<br />

lab or meeting with employees, visitors will find a redesigned<br />

experience that facilitates collaboration and showcases<br />

examples of Ingeo in applications from appliances to 3D printing,<br />

to compostable and recyclable paper coatings.<br />

The move to the new headquarters and R&D facility will begin<br />

in February <strong>2022</strong>. MT<br />

www.natureworksllc.com<br />

News<br />

daily updated News at<br />

www.bioplasticsmagazine.com<br />

Picks & clicks<br />

Most frequently clicked news<br />

Here’s a look at our most popular online content of the past two months.<br />

The story that got the most clicks from the visitors to bioplasticsmagazine.com was:<br />

tinyurl.com/news-202112<strong>01</strong><br />

Global bioplastics production will more than triple<br />

within the next five years<br />

(<strong>01</strong> December 2021)<br />

At the 16 th EUBP Conference, taking place on 30 November and 1 December<br />

in Berlin, European Bioplastics presented a very positive outlook for the<br />

global bioplastics industry. Production is set to more than triple over the next<br />

five years according to market data which was compiled in cooperation with<br />

the nova-Institute (Hürth, Germany); (see also p. 11).<br />

bioplastics MAGAZINE [<strong>01</strong>/22] Vol. 17 5

News<br />

daily updated News at<br />

www.bioplasticsmagazine.com<br />

Helian's PHA alliances<br />

Bluepha (Beijing, China) and Dutch company<br />

Helian Polymers (Belfeld) recently announced their<br />

cooperation. The aim of the cooperation is to bring a<br />

new PHA based building block to the market, targeting<br />

various applications as a replacement for existing<br />

petrochemically based plastics. This addition will enable<br />

Helian Polymers to create and offer an even broader<br />

range of PHA based material formulations.<br />

Helian Polymers has been active in bioplastics ever<br />

since 2007, as well as trading in colour concentrates<br />

and additives on an international scale. With increased<br />

regulatory pressure and social concerns regarding<br />

petrochemically based plastics, Helian is stepping up<br />

its efforts to supply both biobased and biodegradable<br />

materials and develop bespoke applications with its<br />

customers.<br />

Founded by scientists with interdisciplinary<br />

backgrounds in 2<strong>01</strong>6, Bluepha has strong research and<br />

engineering expertise in the area of cellular agriculture<br />

for molecule and material innovations. On Jan 1 st , <strong>2022</strong>,<br />

Bluepha's first industrial PHA project with 25,000 tonnes<br />

capacity per annum broke ground.<br />

Helian Polymers, who culminated in their own brand<br />

PHAradox last year, will start importing and using<br />

Bluepha's unique PHBH based building blocks for<br />

developing specific PHA based compounds. Under the<br />

PHAradox umbrella, multiple PHA based materials have<br />

been developed with the aim of offering more sustainable<br />

alternatives compared to existing materials.<br />

By using various PHA grades like P3HB, PHBV, and<br />

P3HB4HB, Helian Polymers is uniquely suited in the<br />

world to combine these grades with Bluepha's PHBH<br />

material to compound custom-made materials for<br />

various applications. By utilizing these natural building<br />

blocks Helian Polymers is able to mimic properties of<br />

more traditional plastics like PP and ABS. By copying,<br />

or at least approaching, the properties and thus the<br />

functionality of these materials the transition is easier<br />

to make and to communicate with converters and<br />

customers alike.<br />

Earlier in January, Helian already announced a<br />

cooperation with Genecis Bioindustries. (headquartered<br />

in Toronto, Canada). Together both companies will<br />

develop various resin formulations that include Genecis’<br />

PHAs for high-value applications, such as 3D printing<br />

filaments and biomedical applications. By combining<br />

both companies’ strengths, converting food waste into<br />

biodegradable plastics for Genecis and creating unique<br />

PHA based materials from various building blocks for<br />

Helian Polymers, the possibilities of unique materials<br />

arise.<br />

Genecis is a high growth biotechnology company that<br />

upcycles organic waste into compostable plastics. Their<br />

rapid scaling model makes high throughput production<br />

capacities possible by adding adding their technology<br />

onto biogas plants. MT<br />

www.pharadox.com |<br />

www.bluepha.com | www.genecis.co<br />

Green light for<br />

Avantium's FDCA<br />

flagship plant<br />

Avantium (Amsterdam, The Netherlands), a leading<br />

technology company in renewable chemistry, announced<br />

that on January 25 the shareholders have granted the<br />

requested approvals for all items on the agenda of the<br />

Extraordinary General Meeting (EGM).<br />

This includes the green light for Avantium's FDCA<br />

Flagship Plant. The company can begin the execution of<br />

all relevant documentation to complete the transaction<br />

(“Financial Close”), which is expected in the first quarter<br />

of <strong>2022</strong>. Construction of the FDCA Flagship Plant is<br />

planned to start after Financial Close and to be completed<br />

by the end of 2023. Avantium expects that the FDCA<br />

Flagship Plant will be operational in 2024, enabling the<br />

commercial launch of PEF from 2024 onwards. MT<br />

www.avantium.com<br />

Total Corbion PLA<br />

transitions to<br />

TotalEnergies Corbion<br />

Total Corbion PLA will transition to TotalEnergies<br />

Corbion, launching a new company name and logo over<br />

the coming months. TotalEnergies Corbion is a 50/50<br />

joint venture between TotalEnergies and Corbion.<br />

The name change follows the recent rebranding of<br />

TotalEnergies earlier last year, anchoring its strategic<br />

transformation into a broad energy company.<br />

TotalEnergies Corbion expects to launch its updated<br />

brand identity in a phased approach from this January.<br />

Earlier last summer TotalEnergies Corbion celebrated<br />

the cumulative production volume milestone of 100kT<br />

of Luminy ® PLA at its production plant in Thailand. The<br />

company has also entered the engineering stage for a<br />

second facility in Grandpuits (France) in order to respond<br />

to the growing PLA market demand.<br />

Luminy PLA resins from TotalEnergies Corbion are<br />

biobased and made from annually renewable resources,<br />

offering a reduced carbon footprint versus many<br />

traditional plastics. At the end of their useful life, PLA<br />

products can be mechanically or chemically recycled.<br />

The biodegradable and compostable functionalities of<br />

PLA make it the material of choice for a wide range<br />

of markets and applications including fresh fruit<br />

packaging, food service ware, durable consumer goods,<br />

toys, and 3D printing. TotalEnergies Corbion recently<br />

announced the launch of Luminy rPLA: the world’s first<br />

commercially available chemically recycled bioplastics<br />

product. MT<br />

www.totalenergies-corbion.com<br />

6 bioplastics MAGAZINE [<strong>01</strong>/22] Vol. 17

WWF released new position:<br />

Chemical Recycling Implementation Principles<br />

On January 26, as part of the No Plastic in Nature vision, World Wildlife Fund (WWF), Gland, Switzerland, released "Chemical<br />

Recycling Implementation Principles" (see link below). These principles aim to help decision-makers determine if and how<br />

chemical recycling – an emerging technology with unknown environmental and social outcomes – should be pursued as a<br />

plastic waste mitigation tactic. Alix Grabowski, director of plastic and material science at WWF said:<br />

“Even as technologies advance, we can’t recycle our way out of the growing plastic waste crisis. Instead of just focusing on<br />

recycling, we should prioritize strategies like reducing our overall single-use plastic consumption and scaling up reuse, which<br />

offer the best opportunity to achieve the widescale change we need.<br />

“For a technology like chemical recycling to be part of a sustainable material management system, we must carefully look at<br />

how it is designed and implemented and whether or not it offers environmental benefits over the status quo, adheres to strong<br />

social safeguards, and truly contributes to advancing our circular economy. These principles are designed to do exactly that.”<br />

News<br />

daily updated News at<br />

www.bioplasticsmagazine.com<br />

The paper lays out considerations for plastic-to-plastic recycling, not plastic-to-fuel applications. Plastic-to-fuel activities<br />

should not be considered recycling, nor a part of the circular economy.<br />

The paper also states that "Based on currently available evidence, there are significant concerns that these technologies<br />

are energy-intensive, pose risks to human health, and/or will not be able to practically recycle plastic beyond what mechanical<br />

recycling already achieves."<br />

bioplastics MAGAZINE strongly encourages its readers,<br />

especially those involved in chemical recycling, to read and<br />

comment on the WWF paper. MT<br />

Info:<br />

1: The Chemical Recycling Implementation Principles can be<br />

downloaded form https://tinyurl.com/WWF-Principles<br />

tinyurl.com/WWF-Principles<br />

Arkema increases Pebax elastomer production<br />

Arkema (headquartered in Colombes, France) announced<br />

a 25 % increase in its global Pebax ® elastomer production<br />

capacity by investing in Serquigny in France. This investment<br />

will notably enable increased production of the bio-circular<br />

Pebax Rnew ® and traditional Pebax ranges.<br />

This new capacity will produce a variety of highly<br />

specialized grades to meet growing demand in numerous<br />

demanding applications thanks to the lightweight,<br />

flexibility, and excellent energy return of these materials.<br />

These properties are particularly appreciated in sports<br />

equipment, such as soles for running shoes, ski boots, or<br />

technical textile, in consumer goods such as smartphones<br />

and flexible screens, as well as in other markets such as<br />

medical equipment.<br />

delighted to add this new capacity to support our customers’<br />

growing demand for high-performance sustainable<br />

materials," said Erwoan Pezron, Senior Vice-President of<br />

Arkema’s High Performance Polymers Business Line. "We<br />

will also continue to produce many of these materials at our<br />

Birdsboro plant in Pennsylvania”. MT<br />

www.arkema.com<br />

Derived from renewable castor seeds, Pebax Rnew<br />

advanced bio-circular materials offer sustainables solution<br />

that have a carbon footprint that is up to 50 % lower, compared<br />

to other elastomers on the market, and can be fully recycled.<br />

In addition, this investment, which is scheduled to come on<br />

stream mid-2023, will lower the water consumption of the<br />

site by 25 % thanks to process optimization.<br />

“The Serquigny plant has a long proven legacy in the<br />

production of these advanced materials, and we are<br />

bioplastics MAGAZINE [<strong>01</strong>/22] Vol. 17 7

News<br />

daily updated News at<br />

www.bioplasticsmagazine.com<br />

United Nations recommends bioplastics as a<br />

sustainable alternative to conventional plastics<br />

In mid-December, the Food and Agriculture Organisation<br />

of the United Nations (FAO) published a report assessing the<br />

sustainability of agricultural plastic products recommending<br />

the replacement of non-biodegradable, conventional<br />

polymers with biodegradable, biobased polymers (see link<br />

below) . “We welcome this recognition of the environmental<br />

benefits of these bioplastic products,” commented François<br />

de Bie, Chairman of European Bioplastics (EUBP). “Biobased<br />

and soil-biodegradable mulch films help both in reducing<br />

dependence on fossil carbon sources, by using renewable<br />

carbon instead, and by playing a valuable role in reducing<br />

residual plastic pollution in soil, which can significantly<br />

impact agricultural productivity.”<br />

The FAO study focuses on agricultural plastic products<br />

used in a range of different value chains. A qualitative risk<br />

assessment, which accompanies the study, analyses 13<br />

specific agricultural products. “Significantly, for six out of<br />

13 assessed products, biodegradable, biobased plastics are<br />

recommended as preferable substitutes for conventional<br />

plastic material,” said de Bie. The list of recommended<br />

products included mulch films, fishing gear, polymer-coated<br />

fertilizers, tree guards and shelters, plant support twines, and<br />

pesticide impregnated fruit protection bags.<br />

Mulch films represent the second largest share of plastic<br />

films used in agriculture. “These films, made from soilbiodegradable<br />

plastics, provide significant benefits where<br />

retrieval, recycling, and reuse of conventional plastics pose<br />

significant problems. They are specifically designed to<br />

biodegrade effectively in situ and can therefore be incorporated<br />

into the soil post-harvest," explained François de Bie. In<br />

contrast, especially thin, non- biodegradable mulching films<br />

display an insufficient collection, management, and retrieval,<br />

which can lead to a significant level of plastic pollution in<br />

the fields in which they are used. Even where conventional<br />

mulch films are removed from the field, they are often heavily<br />

contaminated with soils and plant residues, which inhibits the<br />

recycling process.<br />

The FAO report also emphasises the need to develop<br />

polymers that are biodegradable in the marine environment.<br />

“Although any kind of littering, should be avoided, a certain<br />

level of unavoidable loss of fishing gear will always take place.<br />

Therefore, it is important to foster the adoption of marinebiodegradable<br />

solutions,” stated the Chairman of EUBP. In<br />

the case of used products contaminated with fish residues,<br />

such as fish collection boxes, biopolymers, according to FAO,<br />

may ease the organic recycling process.<br />

Commenting on the study, Hasso von Pogrell, Managing<br />

Director of EUBP said: “EUBP welcomes all studies, such as<br />

this one, that contribute towards improving knowledge of the<br />

current data situation. This can’t be done by the bioplastics<br />

industry alone, and in order to establish a proper data pool,<br />

we also need stronger political support. For the European<br />

market, the European Commission should lead efforts to<br />

facilitate and coordinate data pooling in order to develop a<br />

more accurate picture of where the use of bioplastics brings<br />

real benefits in reducing conventional plastic pollution.” The<br />

report also highlights the role of research and innovation<br />

grants as means of pump-priming new ideas which lead to<br />

the development of new products. “However, the funding of<br />

research alone is not enough. An appropriate policy framework<br />

for biobased, biodegradable, and compostable plastics is also<br />

needed, to capture potential for innovation and the economic,<br />

environmental, and societal sustainable benefits of these<br />

products for the European Union,” concluded von Pogrell. MT<br />

https://tinyurl.com/FAO-recommendation<br />

www.european-bioplastics.org<br />

Danimer Scientific and TotalEnergies Corbion cooperate<br />

Danimer Scientific (Bainbridge, Georgia, USA) and TotalEnergies Corbion (Gorinchem, The Netherlands) have entered a<br />

long-term collaborative arrangement for the supply of Luminy ® PLA, a biobased polymer used to manufacture compostable<br />

products. The strategic collaboration is meant to support long-term growth of biopolymer production requiring a blend of<br />

polyhydroxyalkanoate (PHA) and polylactic pcid (PLA) inputs.<br />

As Danimer continues to scale up the commercial production of Nodax ® , its signature PHA, this agreement enhances<br />

Danimer’s ability to fulfil customer needs for resins that require a blend of PLA- and PHA-based inputs.<br />

Stephen E. Croskrey, Chairman and Chief Executive Officer of Danimer, said, “While growing commercial production of<br />

PHA remains the focus of our business, PLA is a part of some compounds that we formulate to meet specific customers’<br />

functionality needs for different applications. Teaming with TotalEnergies Corbion provides an ideal solution to support our<br />

long-term growth strategy while ensuring our short-term customer needs remain fulfilled.”<br />

Thomas Philipon, Chief Executive Officer of TotalEnergies Corbion, said, "The biopolymers market is experiencing strong<br />

growth and customers are requesting innovative solutions tailor-made to their market needs. In today’s dynamic market,<br />

strategic arrangements throughout the value chain are key to ensuring security of supply in both product and technology that<br />

will allow brand owners and ultimately consumers to be comfortable with selecting bioplastics as a sustainable alternative to<br />

traditional plastics." MT<br />

www.danimerscientific.com | www.totalenergies-corbion.com<br />

8 bioplastics MAGAZINE [<strong>01</strong>/22] Vol. 17

Engineering tomorrow’s materials<br />

Your benefits<br />

International Congress<br />

March 30-31, <strong>2022</strong>, Mannheim, Germany<br />

News<br />

daily updated News at<br />

www.bioplasticsmagazine.com<br />

• International industry meeting-point with over 60 exhibitors<br />

• 42 hand-picked keynotes & lectures<br />

• Auto show<br />

• PIAE Afterparty<br />

Focus:<br />

Sustainable use<br />

of plastics!<br />

Sign up!<br />

www.piae-europe.com<br />

bioplastics MAGAZINE [<strong>01</strong>/22] Vol. 17 9

Events<br />

European Bioplastics Conference<br />

At the 16 th annual European Bioplastics (EUBP) Conference, which<br />

took place from 30 November to 1 December in Berlin, industry<br />

experts discussed the role of bioplastics within the European<br />

Green Deal. The conference discussions confirmed that bioplastics<br />

make significant contributions to help with achieving the European<br />

Union’s ambitious climate goals described in the EU strategy.<br />

In his opening remarks, François de Bie, Chairman of European<br />

Bioplastics (EUBP), began by giving a clear answer to the overarching<br />

conference question about the role of bioplastics within the European<br />

Green Deal. “There are many fields of interaction between the European<br />

Commission’s Green Deal and bioplastics where our industry can<br />

make significant contributions towards helping achieve the European<br />

Union’s ambitious climate goals,” said de Bie. “Bioplastics are part of<br />

the solution needed to fix the <strong>issue</strong> that we have with plastics today,” he<br />

continued, referring to the challenges caused by plastic waste. The varied<br />

two-day conference programme, which examined key <strong>issue</strong>s along the<br />

bioplastics value chain, strongly reinforced his statement. In ten different<br />

sessions, which included an exciting keynote and presentations as well<br />

as lively panel discussions, over 40 speakers and moderators focused on<br />

the contribution that biobased, biodegradable, and compostable plastics<br />

can make to achieve a circular economy.<br />

In a pre-recorded address, Kestutis Sadauskas, Director for Circular<br />

Economy and Green Growth at the European Commission’s DG<br />

Environment, said “While biobased and biodegradable and compostable<br />

plastics can be part of the solution, they also present certain challenges.<br />

The feedback received tells us a policy framework is needed.” The<br />

subsequent policy session went on to discuss bioplastics’ role in<br />

achieving Europe’s Green Deal objectives by focussing on key processes,<br />

such as the framework for bioplastics and the Packaging and Packaging<br />

Waste Directive.<br />

Further conference sessions highlighted new opportunities for<br />

compostable plastics and discussed their performance in different<br />

open environments. New European Bioplastics market data, based<br />

on research from the nova-institute, gave a very positive outlook for<br />

bioplastics production, which is expected to more than triple within the<br />

next five years with a growth rate of over 200 % (see next page). The<br />

results correspond to the industry leaders’ perspectives on bioplastics<br />

shared during the conference as well as to the latest insights that were<br />

provided from emerging markets, such as textiles, packaging, and<br />

automotive.<br />

During the session on communicating sustainability of biobased<br />

plastics, participants followed a lively discussion on sustainability,<br />

including the results of a study developed by the Joint Research Centre<br />

(JRC) assessing the Life Cycle Analysis (LCA) of alternative feedstock for<br />

plastics. This coincided with the publication of a position by the European<br />

Bioeconomy Alliance criticising the methodology for favouring fossilbased<br />

over biobased plastics (see p. 42).<br />

This year, bioplastics’ leading business and networking platform was<br />

held in a hybrid format attracting over 320 participants. Around 140<br />

participants attended in person, while the other attendees were able to<br />

follow and actively engage online. At the conference exhibition, around<br />

20 companies and institutions showcased the high diversity of new<br />

products, materials, and applications. Innovation also requires research<br />

– thus the conference also included a poster exhibition with fifteen<br />

different universities and research institutes presenting bioplasticsrelated<br />

projects. MT<br />

www.european-bioplastics.org<br />

10 bioplastics MAGAZINE [<strong>01</strong>/22] Vol. 17

and market development update<br />

Market<br />

Bioplastics currently represent still less than 1 % of<br />

the more than 367 million tonnes of plastic produced<br />

annually1. However, contrary to a slight decrease in the<br />

overall global plastic production, the market for bioplastics<br />

has continuously grown. This development is driven by a rising<br />

demand combined with the emergence of more sophisticated<br />

applications and products. Global bioplastics production<br />

capacity is set to increase significantly from around 2.41 million<br />

tonnes in 2021 to approximately 7.59 million tonnes in 2026.<br />

Hence, the share of bioplastics in global plastic production will<br />

pass the two % mark for the first time.<br />

Applications and market segments<br />

Bioplastics are used for an increasing variety of applications,<br />

ranging from packaging and consumer products to<br />

electronics, automotive, and textiles. Packaging remains the<br />

largest market segment for bioplastics with 48 % (1.15 million<br />

tonnes) of the total bioplastics market in 2021.<br />

Global production capacities of bioplastics by market segment (2021)<br />

Global production capacities of bioplastics<br />

Material development and diversification<br />

Bioplastic alternatives exist for almost every conventional<br />

plastic material and corresponding application. Due to a<br />

strong development of polymers, such as PBAT (polybutylene<br />

adipate terephthalate) but also PBS (polybutylene succinate)<br />

and PAs (polyamides) as well as a steady growth of polylactic<br />

acids (PLAs), the production capacities will continue to<br />

increase significantly and diversify within the next 5 years.<br />

Global production capacities of bioplastics by material type<br />

top: 2021, bottom: 2026<br />

Land use share for bioplastics estimated to be at<br />

0.<strong>01</strong> % of the global agricultural area<br />

The land used to grow the renewable feedstock needed to<br />

produce bioplastics is estimated to remain at approximately<br />

0.70 million hectares in 2021. This accounts for just only<br />

over 0.<strong>01</strong> % of the global agricultural area of 5.0 billion<br />

hectares. Along with the projected increase of bioplastics<br />

production in 2026, the land use share is expected to be still<br />

below 0.06 %. In relation to the available agricultural area,<br />

this share is minimal. Thus, there is no competition between<br />

the renewable feedstock for food and feed and the production<br />

of bioplastics.<br />

Land use estimation for bioplastics 2021 to 2026<br />

About this market data update<br />

The market data update 2021 has been compiled in<br />

cooperation with the market experts of the nova-Institute<br />

(Hürth, Germany). The market data graphs are available for<br />

download (see link below). MT<br />

tinyurl.com/EUPB-market<br />

www.european-bioplastics.org<br />

bioplastics MAGAZINE [<strong>01</strong>/22] Vol. 17 11

Award<br />

And the winner is ...<br />

The 15 th Global Bioplastics Award 2021<br />

was given to Gruppo Fabbri Vignola<br />

for their Home Compostable Cling Film<br />

This year the prestigious annual Global Bioplastics<br />

Award, presented by bioplastics MAGAZINE, was given to<br />

Gruppo Fabbri Vignola (Vignola, Italy) for their Home<br />

Compostable Cling Film.<br />

Other than in previous years, the winner was not chosen<br />

by a jury. This year for the first time, the attendees of the<br />

16 th European Bioplastics Conference, which was held in<br />

a hybrid format in Berlin, Germany on November 30 th and<br />

December 1 st , voted for the winner, both on-site in Berlin<br />

and online.<br />

Nature Fresh is the first cling film worldwide suitable for<br />

both manual and automatic food packaging and certified<br />

as Home Compostable and Industrial Compostable (EN<br />

13432).<br />

The formulation of Nature Fresh is based on the BASF<br />

certified compostable polymers ecoflex ® and ecovio ® .<br />

It is also the first of its range to combine optimal<br />

breathability for an extended shelf life of fresh food with<br />

high transparency and excellent mechanical properties<br />

for automatic packaging: its tensile strength, elongation<br />

at break, breathability, transparency, gloss, extensibility,<br />

and anti-fogging are comparable to those of traditional<br />

films. Furthermore, Nature Fresh shows a better water<br />

vapour transmission rate, which is essential for optimal<br />

packaging. It preserves the freshness, and the nutritional<br />

and organoleptic properties of food, avoiding food waste.<br />

The shelf-life of mushrooms, for instance, can be extended<br />

to 5-fold, for lettuce even up to 7-fold.<br />

Nature Fresh can be used in minimal thickness and is<br />

also printable with compostable inks.<br />

It is food-contact approved according to the US and<br />

European standards and since no plasticisers are used,<br />

it can pack any kind of fresh foods, even those with high<br />

fat content.<br />

“It took us five years to develop this product,” said Stefano<br />

Mele, CEO of Gruppo Fabbri Vignola in his short statement,<br />

“and I am grateful for the support of our partners.” He<br />

also added that “Nature Fresh has already been produced<br />

in hundreds of tonnes and tens of thousands of reels with<br />

millions of packages already released onto the market.”<br />

Michael Thielen presenting the Award to Stefano Mele<br />

12 bioplastics MAGAZINE [<strong>01</strong>/22] Vol. 17

COMPEO<br />

Leading compounding technology<br />

for heat- and shear-sensitive plastics<br />

The runner up was Refork from the Czech Republic.<br />

The company has developed a new material based on<br />

sawdust, waste from wood processing combined with<br />

natural polymers PHB(V). Their first iconic product is a<br />

fork, but the company is already developing a toothbrush<br />

for the dental market to launch early next year.<br />

Last but not least, third place went to the bio!TOY<br />

conference (which was anonymously nominated).<br />

The 3D-printed award itself is of course also made from<br />

bioplastics. The two different PHA/PLA blends are filled<br />

with wood or stone flour, respectively. The trophy was<br />

provided by colorFabb from Belfeld, The Netherlands. MT<br />

www.gruppofabbri.com<br />

Uniquely efficient. Incredibly versatile. Amazingly flexible.<br />

With its new COMPEO Kneader series, BUSS continues<br />

to offer continuous compounding solutions that set the<br />

standard for heat- and shear-sensitive applications, in all<br />

industries, including for biopolymers.<br />

• Moderate, uniform shear rates<br />

• Extremely low temperature profile<br />

• Efficient injection of liquid components<br />

• Precise temperature control<br />

• High filler loadings<br />

www.busscorp.com<br />

bioplastics MAGAZINE [<strong>01</strong>/22] Vol. 17 13

Events<br />

bioplastics MAGAZINE presents:<br />

The 4 th bio!PAC conference on Biplastics & Packaging, a co-production of bioplastics<br />

MAGAZINE and Green Serendipity, will now be held strictly virtual, due to the latest<br />

developments of the Corona pandemic. The conference fee has been reduced.<br />

Experts from all areas of bioplastics & packaging will present their latest<br />

developments or research. The conference will also cover discussions like endof-life<br />

options, consumer behaviour <strong>issue</strong>s, availability of agricultural land for<br />

material use versus food and feed etc.<br />

bio!PAC uses the WHOVA app and web-platform to offer excellent opportunities for<br />

attendees to connect and network with other professionals in the field.<br />

All presentations will be recorded for a convenient “video-on-demand“ experience<br />

in your time zone. A local meet-up will be organized if covid measures allow!<br />

bio PAC<br />

www.bio-pac.info<br />

International<br />

Bioplastics & Packaging<br />

Conference<br />

15 - 16 March <strong>2022</strong><br />

Online Event<br />

Tuesday, March 15, <strong>2022</strong><br />

08:00 - 08:40 Welcome, solve technical <strong>issue</strong>s, if necessary<br />

08:45 - 09:00 Michael Thielen Welcome remarks<br />

09:00 - 09:20 Gert-Jan Gruter, University of Amsterdam Future of bioplastics & packaging<br />

09:20 - 09:40 Constance Ißbrücker, European Bioplastics European bioplastics pespective for bioplastics (t.b.c.)<br />

09:40 - 10:00 Christopher vom Berg, nova-Institute Packaging from Renewable Carbon Plastics (t.b.c.)<br />

10:00 - 10:15 Q&A<br />

10:15 - 10:40 Coffee– and Networking Break<br />

10:40 - 11:00 Heidi Koljonen, Sulapac Microplastics & Packaging<br />

11:00 - 11:20 Thijs Rodenburg, Rodenburg Biopolymers Starch-based compounds for packaging applications<br />

11:20 - 11:40 Patrick Zimmermann, FKUR From linear to circular - how bioplastics provide solutions for packaging<br />

11:40 - 12:00 Ella Yao, PureGreen PLA coated paper-based packaging<br />

12:00 - 12:15 Q&A<br />

12:15 - 13:15 Lunch- and Networking Break<br />

13:15 - 13:35 Bineke Posthumus, Avantium Plant-based solutions to realize a fossil-free & circular economy<br />

13:35 - 13:55 Martin Bussmann, Neste Renewable carbon solutions for packaging<br />

13:55 - 14:15 Allegra Muscatello, Taghleef Industries New developments in biobased and biodegradable packaging solutions<br />

15:15 - 14:35 Jan Pels, TNO Torwash: a new system for bioplastics recycling<br />

14:35 - 14:50 Q&A<br />

14:50 - 15:15 Coffee– and Networking Break<br />

15:15 - 15:35 Patrick Gerritsen, Bio4pack Bio4Pack moves the earth<br />

15:35 - 15:55 Blake Lindsey, RWDC Moving Past Recycling: Can We Stem the Microplastics Crisis?<br />

15:55 - 16:15 Jane Franch, Numi Organic Tea Practical application of bioplastics in packaging: Brand perspective<br />

16:15 - 16:30 Q&A<br />

Wednesday, March 16, <strong>2022</strong><br />

08:45 - 09:00 Michael Thielen Welcome remarks<br />

09:00 - 09:20 Lise Magnier, TU Delft Insights in consumer behaviour in relation to sustainable packaging<br />

09:20 - 09:40 Bruno de Wilde, OWS Environmental Benefits of biodegradable packaging?<br />

09:40 - 10:00 Johann Zimmermann, NaKu PLA packaging: returnable, recyclable, re...<br />

10:00 - 10:20 Erwin Vink, NatureWorks The Compostables Project<br />

10:20 - 10:35 Q&A<br />

10:35 - 11:00 Coffee- and Networking Break<br />

11:00 - 11:20 Jenifer Mitjà, Total Corbion Expanding end-of-life options for PLA bioplastics<br />

11:20 - 11:40 Remy Jongboom, Biotec The added value of compostable materials in packaging applications<br />

11:40 - 12:00 Julia Schifter, TIPA Creating a circular bio-economy through compostable packaging<br />

12:00 - 12:20 Philippe Wolff, Ricoh Europe (t.b.c.) PLAIR – a new material made from plants and air<br />

12:20 - 12:35 Q&A<br />

12:35 - 13:35 Lunch- and Networking Break<br />

13:35 - 13:55 Tom Bowden, Sidaplax Evolutions of Biopolymer Film Performance and Environmental Degradability<br />

13:55 - 14:15 Jojanneke Leistra, Superfoodguru PLA bottles from a brand owners perspective<br />

14:15 - 14:35 Alberto Castellanza, Novamont Mater-Bi ® : Novel Developments in Food Packaging Applications<br />

14:35 - 14:55 Caroli Buitenhuis, Green Serendipity Bioplastics in Packaging - Review and outlook<br />

14:55 - 15:10 Q&A<br />

15:10 - 15:30 Caroli Buitenhuis, Michael Thielen Closing remarks<br />

Subject to changes<br />

14 bioplastics MAGAZINE [<strong>01</strong>/22] Vol. 17

io PAC<br />

bioplastics MAGAZINE presents:<br />

ONLINE<br />

#biopac<br />

www.bio-pac.info<br />

International Conference on Bioplastics & Packaging<br />

15 - 16 March <strong>2022</strong> - ONLINE<br />

Bioplastics packaging<br />

• can be recyclable, biodegradable and/or compostable<br />

• can be made from renewable resources or waste streams<br />

• can offer innovative features and beneficial barrier properties<br />

• can offer multiple environmental benefits in the end-of-life phase<br />

• helps to reduce the depletion of finite fossil resources and CO 2<br />

emissions<br />

At the bio!PAC the focus will be on packaging based on biobased feedstock that leads to genuine environmental benefits in the<br />

future. Specific and considerable attention will also be paid to the criteria for these applications.<br />

Silver Sponsors<br />

Bronze Sponsors<br />

Coorganized by<br />

supported by<br />

Media Partner

Events<br />

Green, the theme Colour<br />

of Chinaplas <strong>2022</strong><br />

The advent of the dual-carbon era has triggered further<br />

efforts in reducing carbon emissions. Many countries,<br />

regions and chemical enterprises have set the goal of<br />

net-zero emissions and carbon neutrality. Green and low<br />

carbon have become hot topics in the plastics and rubber<br />

industries. Chinaplas <strong>2022</strong>, to be held from April 25 to 28,<br />

will bring together more than 4,000 prominent exhibitors<br />

from all over the world to launch innovative green solutions.<br />

A lot of can’t-miss concurrent events will be organized<br />

during Chinaplas <strong>2022</strong>, focusing on green topics such as<br />

carbon neutrality and sustainable development.<br />

Plastics Recycling & Circular Economy<br />

Conference: Inspiring green ideas<br />

What are the macro trends in the global circular economy?<br />

What are the hot topics and technologies? By attending<br />

the 3 rd Chinaplas x CPRJ Plastics Recycling and Circular<br />

Economy Conference and Showcase, to be held one day<br />

prior to Chinaplas <strong>2022</strong> in Shanghai, attendees can get the<br />

answers from renowned speakers, who are to share their<br />

insights on relevant policies and industry trends, as well as<br />

the showcase of innovative solutions.<br />

Government officials, representatives from industry<br />

organizations, brands, machinery and material suppliers<br />

from different countries and regions are invited. They<br />

will deliver more than 50 speeches online and offline to<br />

400+ industry elites, of which over 60 % are end-product<br />

/ targeted manufacturers. The conference will outline the<br />

landscape and prospect of the plastics recycling industry<br />

in Asia and worldwide at large, by focusing on topics such<br />

as international trends and latest policies for plastics<br />

recycling, successful cases and achievements in recycling<br />

experiences, and innovative ideas.<br />

Thematic seminars will be held at the conference to<br />

facilitate the discussions on carbon neutrality, PCR/<br />

PIR, renewable plastics, recycled ocean plastics, monomaterials,<br />

eco-design/design for recycling, chemical<br />

recycling, innovative solutions for plastics recycling, and<br />

new technologies for recycled materials. At the same time,<br />

world-leading enterprises in the scope of plastics recycling<br />

will showcase their latest solutions for new materials,<br />

technologies, and automation. Experts will also introduce<br />

their latest technological achievements and interact with<br />

the participants.<br />

Tech Talk: a showcase for green technologies<br />

Green will be seen as a focus of Chinaplas <strong>2022</strong> from the<br />

topics of Tech Talk. This concurrent event is a series of open<br />

forums under 8 themes, including antibacterial solutions,<br />

surface treatment solutions, in-mould electronic solutions,<br />

5G applications, eco-friendly solutions, lightweight<br />

solutions, innovative materials, of which the last three are<br />

more relevant to the green technologies and development.<br />

Leading enterprises from the plastics and rubber<br />

industries will participate in the event. Among others, Cathay<br />

Biotech will show its thermoplastic high-temperatureresistant<br />

biobased polyamide engineering plastic products<br />

and green lightweight materials (see also p. 18).<br />

Chinaplas has become a product debut platform for the<br />

plastics and rubber industries, where exhibitors launch a<br />

wide range of new products. Tech Talk is the annual stage<br />

for the plastics and rubber industries, to bring the spotlight<br />

to the new and edge-cutting products, helping new<br />

technological products to gain more exposure while visitors<br />

can get quick access to the resources of quality suppliers.<br />

Under the theme of “New Era · New Potential · Innovation<br />

for Sustainability”, Chinaplas <strong>2022</strong> will proudly return to the<br />

National Exhibition and Convention Center in Hongqiao,<br />

Shanghai, from April 25 - 28, <strong>2022</strong>. MT<br />

www.chinaplasonline.com<br />

National Exhibition and Convention Center in Hongqiao, Shanghai<br />

16 bioplastics MAGAZINE [<strong>01</strong>/22] Vol. 17

7 th PLA World Congress<br />

24 + 25 MAY <strong>2022</strong> > MUNICH› GERMANY<br />

HYBRID EVENT<br />

Automotive<br />

organized by<br />

Call for papers still open<br />

www.pla-world-congress.com<br />

PLA is a versatile bioplastics raw material from renewable<br />

resources. It is being used for films and rigid packaging, for<br />

fibres in woven and non-woven applications. Automotive,<br />

consumer electronics and other industries are thoroughly<br />

investigating and even already applying PLA. New methods<br />

of polymerizing, compounding or blending of PLA have<br />

broadened the range of properties and thus the range of<br />

possible applications. That‘s why bioplastics MAGAZINE is<br />

now organizing the 7 th PLA World Congress on:<br />

24 + 25 May <strong>2022</strong> in Munich / Germany<br />

Hybrid event<br />

Experts from all involved fields will share their knowledge<br />

and contribute to a comprehensive overview of today‘s<br />

opportunities and challenges and discuss the possibilities,<br />

limitations and future prospects of PLA for all kind<br />

of applications. Like the six previous congresses the<br />

7 th PLA World Congress will also offer excellent networking<br />

opportunities for all delegates and speakers as well as<br />

exhibitors of the table-top exhibition. Based on the good<br />

experices with the hybrid format (bio!TOY and PHA World<br />

Congress 2021) we will offer this format also for future<br />

conferences, hoping the pandemic does no longer force us<br />

to. So the participation at the 7 th PLA World Congress will<br />

be possible on-site as well as online.<br />

bioplastics MAGAZINE [<strong>01</strong>/22] Vol. 17 17

Automotive<br />

Bio-PA<br />

composites<br />

Renewable 1,5 pentanediamine<br />

based polyamide composites for<br />

automotive applications<br />

250 —<br />

200 —<br />

150 —<br />

100 —<br />

50 —<br />

Comparison of basic physical properities of different materials<br />

Cathay Biotech, Shanghai, China, is a leader in<br />

synthetic biology specializing in the production of<br />

biobased polyamides that are based on its 100 %<br />

renewable 1,5-pentanediamine (DN5). The option of using<br />

either fossil-based or renewable diacids enables the biocontent<br />

level of PA5X to be as high as 100 %. Cathay has<br />

been engaged in the application and development of<br />

biobased PA5X and marketed these engineering polyamides<br />

under the tradename ECOPENT ® . The melting point of its<br />

Ecopent engineering materials can be varied from 197 ºC<br />

of Ecopent 3300 (E-3300) to 300 ºC of Ecopent 6300, which<br />

fulfils a plethora of different application requirements of<br />

polyamides.<br />

Recently, Cathay focused on the investigation and<br />

production of fibre-reinforced PA5X composite such as<br />

prepreg tape, which is an alternative solution for metal<br />

replacement. The continuous glass/carbon fibre-reinforced<br />

biobased PA5X (CFRT-PA5X) shows excellent mechanical<br />

properties, high specific strength, and specific modulus,<br />

among others. By modifying the manufacturing process,<br />

the fibre content of such CFRT-PA5X could be tuned flexibly<br />

from 50 % to 70 %, by weight, which provides for a high<br />

design flexibility of these products and would contribute to<br />

a significant weight reduction for automobile applications<br />

(among others).<br />

Using Ecopent 2260 (E-2260) as the matrix and glass/<br />

carbon fibre as reinforcement, composites with different<br />

mechanical properties could be easily produced by<br />

employing proper processing technology. The produced<br />

composite exhibits increased tensile strength and tensile<br />

modulus with increasing fibre retention length. For<br />

example, the CFRT of E-2260 70 % GF possesses tensile<br />

strength higher than 1,000 MPa, while its density is onefourth<br />

that of steel. More importantly, its specific strength is<br />

three times that of super-steel.<br />

Moreover, CFRT-PA5X composites with higher mechanical<br />

properties could be produced by using continuous carbon<br />

fibre instead of glass. For instance, the CFRT of E-2260<br />

50 % CF has only one-third the density of super-steel but<br />

exhibits 10 % higher tensile strength than it. In addition, the<br />

specific strength and specific modulus of CFRT of E-2260<br />

50 % CF are six times and two times that of super-steel,<br />

respectively.<br />

Continuous fibre reinforced unidirectional<br />

prepreg tape<br />

Basically, the thickness of CFRT-PA5X unidirectional<br />

prepreg tape is between 0.25 mm and 0.30 mm. Their<br />

tensile strength is usually higher than 1,000 MPa, which is<br />

0 —<br />

1600 —<br />

1400 —<br />

1200 —<br />

1000 —<br />

800 —<br />

600 —<br />

400 —<br />

200 —<br />

Steel Super steel Aluminium E-2260-<br />

70%GF (CFRT)<br />

Tensile modulus (GPa)<br />

E-2260-70GF tape<br />

Tensile modulus (MPa)<br />

E-2260-<br />

50%CF (CFRT)<br />

Specific modulus (GPa-cm3/g)<br />

Properities of different unidirectional prepreg tape<br />

0 —<br />

E-3300-70GF tape<br />

1200 —<br />

1000 —<br />

800 —<br />

600 —<br />

400 —<br />

200 —<br />

700 —<br />

600 —<br />

500 —<br />

400 —<br />

300 —<br />

200 —<br />

100 —<br />

Comparison of different composite board<br />

0°C/90°C Bending strength (Mpa)<br />

E-2260-50CF<br />

0 —<br />

E3300-70%GF board E-2260-70%GF board PP-composite board<br />

0 —<br />

E-2260-50CF tape<br />

0°C Bending strength (Mpa)<br />

0°C Interlaminar shear strength (Mpa) 90°C Bending strength (MPa)<br />

Comparison of bending strength of PA5X-70%GF at 23°C and 70°C for 2h<br />

546,26<br />

E3300<br />

603,20<br />

631,02<br />

23°C<br />

E-2260<br />

666,76<br />

70°C<br />

434,52<br />

PP<br />

382,06<br />

18 bioplastics MAGAZINE [<strong>01</strong>/22] Vol. 17

1800 —<br />

1600 —<br />

1400 —<br />

1200 —<br />

1000 —<br />

800 —<br />

600 —<br />

400 —<br />

200 —<br />

0 —<br />

Comparison of basic physical properities of different materials<br />

Steel Super steel Aluminium E-2260-<br />

70%GF (CFRT)<br />

Tensile strength (MPa)<br />

E-2260-70GF tape<br />

Tensile modulus (MPa)<br />

E-2260-<br />

50%CF (CFRT)<br />

Specific strength (MPa-cm3/g)<br />

Properities of different unidirectional prepreg tape<br />

90 —<br />

80 —<br />

70 —<br />

60 —<br />

50 —<br />

40 —<br />

30 —<br />

20 —<br />

10 —<br />

0 —<br />

E-3300-70GF tape<br />

70 —<br />

60 —<br />

50 —<br />

40 —<br />

30 —<br />

20 —<br />

10 —<br />

0 —<br />

Comparison of different composite board<br />

E3300-<br />

70%GF board<br />

E-2260-<br />

70%GF board<br />

0°C/90°C Bending modulus (Gpa)<br />

90°C Bending modulus (Gpa)<br />

PPcomposite<br />

board<br />

E-2260-50CF<br />

E-2260-<br />

55%CF board<br />

0°C Bending modulus (Gpa)<br />

Comparison of bending modulus of PA5X-70%GF at 23°C and 70°C for 2h<br />

25 —<br />

23,83<br />

21,80<br />

By:<br />

Yuanpin Li, Qilei Song<br />

Engineering Plastics Application Development Engineer<br />

Cathay Biotech Inc.<br />

Shanghai, China<br />

affected by the fibre content and fibre type. Furthermore,<br />

through winding or moulding process technology, these<br />

prepreg tapes could be further applied in automobiles such<br />

as fender, front cover, and battery pack etc.<br />

Biobased PA5X composite board<br />

In terms of 70 % continuous glass fibre reinforced E-2260<br />

composite, its 0° bending strength could be up to 1,033 MPa,<br />

twice as strong as a PP composite with the same glass fibre<br />

content. Its 0° bending modulus also reaches 38 MPa, which<br />

is 30 % higher than that of a 70 % glass fibre reinforced<br />

PP composite. Furthermore, the 90° bending strength<br />

and 0° interlaminar shear strength of such biobased PA5X<br />

composite are 1.5 times that of PP composites with the<br />

same glass fibre content.<br />

When CFRT of E-2260 70 % GF, CFRT of E-3300 70 % GF,<br />

and PP composite are baked at 70 ºC for 2 h, the bending<br />

strength of E-3300 70 % GF and CFRT of E-2260 70 % GF is<br />

increased by 5 %, while PP ones are reduced by 12 %. The<br />

bending modulus of CFRT of E-2260 70 % GF is higher 40 %<br />

than that of PP composite at 70 °C.<br />

Application<br />

CFRT of PA5X, due to their extremely high strength-toweight<br />

and stiffness-to-weight ratios, can be a sustainable<br />

lightweight solution to meet increasingly challenging<br />

requirements from different industries, e.g., automotive,<br />

construction, or shipping. In addition, CFRT of PA5X have<br />

shown excellent chemical resistance, anti-fatigue and antimar<br />

performance depending on the biobased polyamide<br />

selected. The increase in temperature will lead to a decrease<br />

in the rigidity of composites. CFRT of biobased polyamides<br />

(E-3300 and 2260) have proven its advantage of mechanical<br />

performance at 70 °C, when compared with general plastic,<br />

like PP. This can make CFRT of biobased polyamides strong<br />

candidates for new vehicles, compressed gas tanks, or<br />

shipping containers, which needs much lighter, safer, and<br />

more efficient materials.<br />

www.cathaybiotech.com<br />

Automotive<br />

20 —<br />

15 —<br />

16,74 17,07<br />

16,84<br />

15,80<br />

10 —<br />

5 —<br />

0 —<br />

E3300<br />

E-2260<br />

PP<br />

23°C<br />

70°C<br />

bioplastics MAGAZINE [<strong>01</strong>/22] Vol. 17 19

Automotive<br />

Lightweight<br />

biobased<br />

cellulose<br />

reinforcement<br />

for automotive<br />

applications<br />

The automotive industry continuously strives to<br />

improve the driving range of cars. Whether being per<br />

litre of petrol for a combustion engine or in kilowatthour<br />

(kWh) for electrically powered vehicles. Car owners<br />

thereby receive a better mileage at lower cost, while CO 2<br />

emissions per kilometre driven are reduced as well. One<br />

way of achieving this is by reducing the overall weight of<br />

the car, which is becoming increasingly important for the<br />

comparatively heavier battery-powered electric vehicles.<br />

Cellulose fibre is one of the answers to address this<br />

need for weight reduction. Sappi Symbio is a lightweight<br />

cellulose solution to reinforce conventional thermoplastic<br />

and biobased plastics. Symbio provides a double advantage,<br />

it’s not only a lightweight material filler, but it also answers<br />

the increasingly important demand for more renewable and<br />

non-fossil based carbon materials.<br />

Symbio is a bio-renewable wood-based cellulose fibre<br />

that is an alternative to incumbent mineral materials like<br />

talc and (short) glass fibre. Due to its relatively low density<br />

of about 1.5 g/cm 3 , it decreases the overall material weight<br />

when added to a thermoplastic, in comparison to talc or<br />

glass. These are commonly used fillers to give a material<br />

more stiffness and strength. Figure 1 shows an example<br />

for a 20 % loaded polypropylene and its influence on the<br />

resulting material property in terms of weight. This weight<br />

saving opportunity, which can go up to 15 % (at 40 % cellulose<br />

load) has drawn the attention of several automotive OEMs<br />

who are already manufacturing car components with<br />

Symbio today.<br />

Symbio cellulose fibre reinforced compounds easily meet<br />

industry requirements of mechanical performance and can<br />

be a renewable alternative to typical mineral fillers. Table 1<br />

shows how the stiffness, in terms of flexural modulus, of<br />

polypropylene can be enhanced by Symbio in comparison<br />

to talc and short glass fibre (SGF). It also shows the heat<br />

deflection temperature for the various solutions which is<br />

increased compared to unfilled polypropylene but also to a<br />

talc-filled compound.<br />

As mentioned already, Symbio consists of wood-based<br />

cellulose. Cellulose is the most abundant organic polymer<br />

on earth and can be found in any plant-like material.<br />

There are many different sources today for cellulose fibre,<br />

like grass or bamboo, and likewise as many variations in<br />

quality and performance. Symbio is a premium quality<br />

cellulose fibre that is also used within Sappi for producing<br />

high-quality speciality paper or high-end paperboard. The<br />

fibre consistency, as well as the very high purity, is why<br />

car manufacturers and brand owners select Symbio as a<br />

material to use for interior car components. Where other<br />

natural fibres can have <strong>issue</strong>s with odour or emission of<br />

volatile components, Symbio passes the most stringent<br />

requirements measured by internationally accepted<br />

standards. In the VDA 270 odour test, Sappi Symbio,<br />

measured on a plaque produced with Symbio PP40<br />

(containing 40 % cellulose) by a German OEM, receives a<br />

rating 2 classified as “perceptible, non-disturbing” (the<br />

scale ranges from 1 “imperceptible” to 6 “unbearable”). This<br />

rating allows the parts to be used in automotive interiors.<br />

Fig. 1<br />

Glass fibre<br />

Talc<br />

Symbio<br />

Cellulpse<br />

Density of 20 % filled polypropylene<br />

0,94 0,96 0,98 1 1,02 1,04 1,06<br />

Specific gravity g/cm 3<br />

Table 1<br />

Property<br />

Test method<br />

Symbio<br />

PP20<br />

Symbio<br />

PP20MI<br />

Symbio<br />

PP20HI<br />

PP + 20% talc PP + 20% SGF Units<br />

Reinforcement<br />

content<br />

- 20 20 20 20 20 Weight %<br />

Density ISO 1183 0.98 0.99 0.98 1.05 1.04 g/cm³<br />

Tensile strength ISO 527-2/1A 49 34 23 28 85 MPa<br />

Flexural modulus ISO 178, 23°C 3,080 2,545 1,678 2,400 4,200 MPa<br />

Impact, Charpy<br />

notched (23°C)<br />

ISO 179-1 4.2 4.3 10 6 11 KJ/m²<br />

HDT-B at 0.45 MPa ISO 75 141 136 123 100 155 °C<br />

20 bioplastics MAGAZINE [<strong>01</strong>/22] Vol. 17

Symbio has also been selected for other fields of<br />

application besides interior car components. Manufacturers<br />

of home appliances and lifestyle & furniture are interested<br />

in Symbio due to its haptic response and the warmer<br />

touch which provides a part with a natural touch and feel.<br />

The examples given above were based on polypropylene<br />

By:<br />

Juul Cuijpers, Product Manager Symbio<br />

Sappi Europe | Sappi Netherlands Services BV<br />

Maastricht, The Netherlands<br />

but of course, Symbio is not limited to this thermoplastic.<br />

Applications made from biobased and/or biodegradable<br />

filled polymers like PLA and PHA are also possible and<br />

are receiving increased interest. The aim is to expand the<br />

current portfolio of Symbio products in the coming period.<br />

www.sappi.com<br />

Automotive<br />

Instrument panel<br />

Interior trims<br />

Air ducts<br />

Luggage board<br />

Centre console and armrest<br />

Cable tray<br />

23 – 24 March • Hybrid Event<br />

Leading Event on Carbon Capture & Utilisation<br />

• Strategy & Policy<br />

• Green Hydrogen Production<br />

• Carbon Capture Technologies<br />

• Carbon Utilisation (Power-to-X): Fuels for Transport and Aviation, Building Blocks,<br />

Bulk and Fine Chemicals, Advanced Technologies, Artificial Photosynthesis<br />

• Innovation Award “Best CO2 Utilisation <strong>2022</strong>”<br />

Call for Innovation<br />

Vote for the Innovation<br />

Award “Best CO2<br />

Innovation Award<br />

Sponsor<br />

Innovation Award<br />

Co-Organiser<br />

Sponsors<br />

Utilisation <strong>2022</strong>”<br />

Organiser<br />

nova-institute.eu<br />

Contact<br />

Dominik Vogt<br />

dominik.vogt@nova-institut.de<br />

Tel.: +49 2233 / 481449<br />

co2-chemistry.eu<br />

bioplastics MAGAZINE [<strong>01</strong>/22] Vol. 17 21

Tyre News<br />

How plastic bottles end up in tyres<br />

Tyres can’t last forever. However, the life cycle of the<br />

materials used in one tyre can be much longer than that<br />

of the tyre itself. Continental just got one<br />

step closer to the goal of tyres made<br />

from 100 % recycled or sustainable<br />

materials. “We are at the vanguard<br />

of a more eco-friendly automotive<br />

industry and are already committed<br />

to using new technologies that utilize<br />

recycled materials. From <strong>2022</strong>, we will<br />

be able to use reprocessed polyethylene<br />

terephthalate (PET) in the construction<br />

of Continental tyre carcasses, completely<br />

replacing the use of conventional<br />

virgin PET,“ as a press release stated<br />

To re-use recycled PET bottles in tyres,<br />

Continental teamed up with OTIZ, a fibre<br />

specialist and textile manufacturer, to develop a specialized<br />

technology that produces high-quality polyester yarn from<br />

recycled PET without the chemical steps<br />

previously required in the recycling<br />

process. Polyester may not be the first<br />

material you think of when you see a car<br />

tyre, PET yarn is actually an essential<br />

ingredient that makes up the tyre carcass<br />

in the form of textile cords that run from<br />

bead to bead (the inner circle of the<br />

tyre). The horseshoe-shaped layer sits<br />

just above the inner liner, affecting tyre<br />

durability, load carriage, and comfort.<br />

It’s the backbone of the tyre, sustains<br />

loads, and absorbs shock. It maintains its<br />

Picture: Continental<br />

shape even at very high temperatures, so<br />

thermal stability is crucial. MT<br />

www.continental-tires.com<br />

Biobased itaconate butadiene rubber<br />

Last year the the Beijing University of Chemical Technology introduced biobased itaconate butadiene rubber. This project, led<br />

by professor Liqun Zhang started the research in 2008. After 13 years a new generation of high performance and biobased<br />

itaconate butadiene rubber has been successfully developed by professor Zhang’s team. The first class of macromolecular<br />

chain structures based on an itaconic acid resource is epoxy group functionalized poly(dibutyl itaconate-co-butadieneglycidyl<br />

methacrylate) (PDBIBG). It can realize the high value-added utilization of biomass resources and promote green and<br />

sustainable development within the rubber industry.<br />

Itaconic acid is a promising organic acid that has been categorized as one of the top 12 building block molecules in advanced<br />

biorefineries. The specific steps for constructing high molecular weight, crosslinkable biobased rubber with itaconic acid as<br />

the main raw material are as follows (see graph):<br />

• Step 1: Fermentation of biomass resources such as corn and sugar cane to obtain itaconic acid.<br />

• Step 2: In order to obtain high molecular weight polymers, itaconate monomer is obtained by<br />

esterification of biobased alcohol.<br />