TLA48_AllPages

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TRACKING THE TRENDS<br />

Learning to follow<br />

Autonomous technology may<br />

be ready before the rules are<br />

By Cliff Abbott<br />

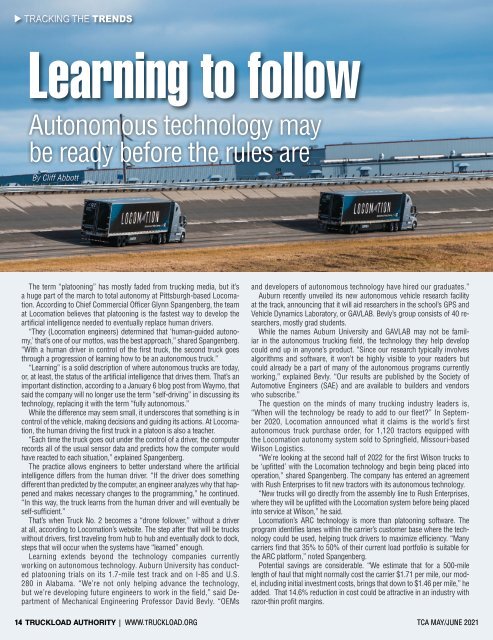

The term “platooning” has mostly faded from trucking media, but it’s<br />

a huge part of the march to total autonomy at Pittsburgh-based Locomation.<br />

According to Chief Commercial Officer Glynn Spangenberg, the team<br />

at Locomation believes that platooning is the fastest way to develop the<br />

artificial intelligence needed to eventually replace human drivers.<br />

“They (Locomation engineers) determined that ‘human-guided autonomy,’<br />

that’s one of our mottos, was the best approach,” shared Spangenberg.<br />

“With a human driver in control of the first truck, the second truck goes<br />

through a progression of learning how to be an autonomous truck.”<br />

“Learning” is a solid description of where autonomous trucks are today,<br />

or, at least, the status of the artificial intelligence that drives them. That’s an<br />

important distinction, according to a January 6 blog post from Waymo, that<br />

said the company will no longer use the term “self-driving” in discussing its<br />

technology, replacing it with the term “fully autonomous.”<br />

While the difference may seem small, it underscores that something is in<br />

control of the vehicle, making decisions and guiding its actions. At Locomation,<br />

the human driving the first truck in a platoon is also a teacher.<br />

“Each time the truck goes out under the control of a driver, the computer<br />

records all of the usual sensor data and predicts how the computer would<br />

have reacted to each situation,” explained Spangenberg.<br />

The practice allows engineers to better understand where the artificial<br />

intelligence differs from the human driver. “If the driver does something<br />

different than predicted by the computer, an engineer analyzes why that happened<br />

and makes necessary changes to the programming,” he continued.<br />

“In this way, the truck learns from the human driver and will eventually be<br />

self-sufficient.”<br />

That’s when Truck No. 2 becomes a “drone follower,” without a driver<br />

at all, according to Locomation’s website. The step after that will be trucks<br />

without drivers, first traveling from hub to hub and eventually dock to dock,<br />

steps that will occur when the systems have “learned” enough.<br />

Learning extends beyond the technology companies currently<br />

working on autonomous technology. Auburn University has conducted<br />

platooning trials on its 1.7-mile test track and on I-85 and U.S.<br />

280 in Alabama. “We’re not only helping advance the technology,<br />

but we’re developing future engineers to work in the field,” said Department<br />

of Mechanical Engineering Professor David Bevly. “OEMs<br />

and developers of autonomous technology have hired our graduates.”<br />

Auburn recently unveiled its new autonomous vehicle research facility<br />

at the track, announcing that it will aid researchers in the school’s GPS and<br />

Vehicle Dynamics Laboratory, or GAVLAB. Bevly’s group consists of 40 researchers,<br />

mostly grad students.<br />

While the names Auburn University and GAVLAB may not be familiar<br />

in the autonomous trucking field, the technology they help develop<br />

could end up in anyone’s product. “Since our research typically involves<br />

algorithms and software, it won’t be highly visible to your readers but<br />

could already be a part of many of the autonomous programs currently<br />

working,” explained Bevly. “Our results are published by the Society of<br />

Automotive Engineers (SAE) and are available to builders and vendors<br />

who subscribe.”<br />

The question on the minds of many trucking industry leaders is,<br />

“When will the technology be ready to add to our fleet?” In September<br />

2020, Locomation announced what it claims is the world’s first<br />

autonomous truck purchase order, for 1,120 tractors equipped with<br />

the Locomation autonomy system sold to Springfield, Missouri-based<br />

Wilson Logistics.<br />

“We’re looking at the second half of 2022 for the first Wilson trucks to<br />

be ‘upfitted’ with the Locomation technology and begin being placed into<br />

operation,” shared Spangenberg. The company has entered an agreement<br />

with Rush Enterprises to fit new tractors with its autonomous technology.<br />

“New trucks will go directly from the assembly line to Rush Enterprises,<br />

where they will be upfitted with the Locomation system before being placed<br />

into service at Wilson,” he said.<br />

Locomation’s ARC technology is more than platooning software. The<br />

program identifies lanes within the carrier’s customer base where the technology<br />

could be used, helping truck drivers to maximize efficiency. “Many<br />

carriers find that 35% to 50% of their current load portfolio is suitable for<br />

the ARC platform,” noted Spangenberg.<br />

Potential savings are considerable. “We estimate that for a 500-mile<br />

length of haul that might normally cost the carrier $1.71 per mile, our model,<br />

including initial investment costs, brings that down to $1.46 per mile,” he<br />

added. That 14.6% reduction in cost could be attractive in an industry with<br />

razor-thin profit margins.<br />

14 TRUCKLOAD AUTHORITY | WWW.TRUCKLOAD.ORG TCA MAY/JUNE 2021