National Hardwood Magazine - July 2021

In this issue of National Hardwood Magazine, learn about Mans Lumber and Millwork, Prime Lumber Company and Woods on Wheels. The issue also features highlights from the Appalachian Lumbermen and Southwestern Hardwood Manufacturers Club meetings.

In this issue of National Hardwood Magazine, learn about Mans Lumber and Millwork, Prime Lumber Company and Woods on Wheels. The issue also features highlights from the Appalachian Lumbermen and Southwestern Hardwood Manufacturers Club meetings.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

LAKE STATES Continued from page 6<br />

still a problem, however.<br />

In Indiana, another source reported a strong market<br />

for <strong>Hardwood</strong> sales. “Demand is outpacing production in<br />

pretty much anything we produce,” the lumber supplier<br />

said. This company is experiencing a better market compared<br />

to six months ago, with the contact emphasizing it<br />

as “significantly better.”<br />

His company offers mostly White and Red Oak in all<br />

grades, with everything selling well. The sawmill sells<br />

to both end users and distribution yards, with “a small<br />

amount of export.” The source reported his customers as<br />

all being very busy. “The end users, especially if they’re<br />

making cabinets, they are having a real hard time getting<br />

all the other things to make cabinets,” he said.<br />

When asked if transportation was affecting his business,<br />

the contact replied, “Absolutely.” He observed an<br />

increase in domestic trucking prices as well as shortage<br />

of truck drivers. Exports have become increasingly difficult<br />

to book. He explained that even if he is able to find<br />

a booking, the chances are slim for there to actually be<br />

an available truck with a driver to get lumber to the port.<br />

A lumber supplier in Ohio also reported a strong market<br />

with high demand in his area. He described the market<br />

as “better” than it was in the recent past. His company<br />

offers Ash, Cherry, Hard and Soft Maple, Red and<br />

White Oak and Poplar in thicknesses ranging from 4/4<br />

to 16/4.<br />

The best-sellers for this sawmill are White Oak and<br />

Poplar, which are sold to a mix of end users and distribution<br />

yards. “We sell to a retail store, and we sell to wholesalers,”<br />

the contact stated. Customers ask, “How quickly<br />

can we get it?” according to him. The supplier described<br />

transportation costs as “double” what they are normally,<br />

with a shortage of trucks to take lumber from the yard. n<br />

NORTHEAST Continued from page 6<br />

ter; 4/4 through 8/4. His best seller is White Oak.<br />

He sells his lumber to distribution yards, and he said<br />

his customers’ sales are good.<br />

Transportation isn’t a problem for this lumberman. “We<br />

have three or four carriers we work really closely with,<br />

and we give them business when it’s slow and we give<br />

them business when it’s fast. Also, we pay them fast.<br />

That pay has something to do with it. When they send<br />

us the bill, we send them money. That helps the relationship.”<br />

A sawmiller from Vermont termed his market as “pretty<br />

strong.” He added: “Certainly we’ve made significant<br />

gains since December of last year. Also, pricing is better.”<br />

He sells all northern species, including Hard and<br />

Soft Maple, Red and White Oak, Birch and Cherry in No.<br />

2 Common and Better, 4/4 and 5/4 with some 8/4.<br />

His sales are to distribution yards. His customers’ business<br />

remains strong, he said. “It doesn’t seem as desperate<br />

a situation as it did eight to 10 weeks ago. That<br />

seems to have crested. I don’t know that our availability<br />

of lumber has changed a whole lot,” he stated. “But you<br />

don’t get beat with 15 phone calls every day with people<br />

trying to source lumber. They seem to be a little more<br />

comfortable. However, there is no lack of need for lum-<br />

ber, he stated. Transportation is starting to get better for<br />

his concentration yard, he observed.<br />

In New York, a distribution yard executive – who buys<br />

green lumber, kiln dries it and sells it – says his market is<br />

“good. We seem to be buying the lumber we need to buy<br />

and we’re able to sell the lumber we have for sale.” His<br />

market is better, he said, than it was six months earlier.<br />

He sells Red and White Oak, Hard Maple and Cherry<br />

in No. 1 Common, No. 2 Common, FAS/1 Face and Betber<br />

from customers.”<br />

Transportation is a problem, he noted. “There is a real<br />

lag, certainly from a week to three weeks. It’s slow getting<br />

wood out of here. All of our customers take care of<br />

their own transportation, so we don’t have direct contact<br />

with trucking contractors.” n<br />

SOUTHEAST Continued from page 7<br />

them as best you can.”<br />

This lumberman sells to distribution yards, end use<br />

manufacturers and to exporters. “Everything seems to<br />

be pretty strong,” he said of his customers’ business.<br />

“The market seems to be good in the Middle East. You<br />

can’t argue with how things are going in Asia. However,<br />

Vietnam seems slow, and I’m not sure why that is. Maybe<br />

they haven’t adjusted to the price increases.<br />

“Moving product to the port has been a huge issue,”<br />

he stated. “Finding trucks to move domestic lumber has<br />

been very difficult. Freight rates have doubled.”<br />

In Tennessee, a source commented that his market is<br />

“excellent, no doubt. Remodeling is part of it. In wholesale,<br />

everything is great, too. Prices have skyrocketed.<br />

Everything is doing good.”<br />

Please turn the page<br />

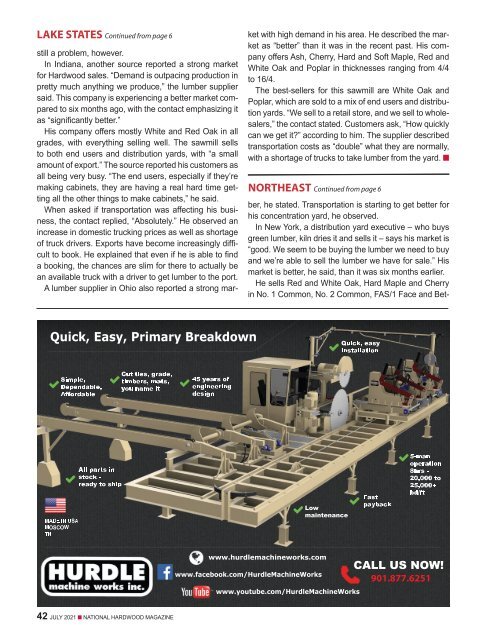

Quick, Easy, Primary Breakdown<br />

Quick, easy<br />

installation<br />

Simple,<br />

Dependable,<br />

Affordable<br />

Cut ties, grade,<br />

timbers, mats,<br />

you name it<br />

45 years of<br />

engineering<br />

design<br />

MADE IN USA<br />

MOSCOW<br />

TN<br />

All parts in<br />

stock -<br />

ready to ship<br />

Low<br />

maintenance<br />

Fast<br />

payback<br />

5-man<br />

operation<br />

8hrs -<br />

20,000 to<br />

25,000+<br />

bd/ft<br />

• Top Quality Kiln Dried <strong>Hardwood</strong> Lumber Rough/S2S<br />

• Specializing in 5/4 thru 8/4 Red Oak & White Oak<br />

Sirianni <strong>Hardwood</strong>s, Inc.<br />

912 Addison Road<br />

Painted Post, New York 14870<br />

Telephone: (607) 962-4688<br />

Fax: (607) 936-6237<br />

www.hurdlemachineworks.com<br />

www.facebook.com/HurdleMachineWorks<br />

www.youtube.com/HurdleMachineWorks<br />

CALL US NOW!<br />

901.877.6251<br />

• Also: Cherry, Hard Maple & Soft Maple<br />

• Shipping Mixed Trucks/Containers Worldwide<br />

www.siriannihardwoods.com<br />

Sales - Tom Armentano<br />

sales@siriannihardwoods.com<br />

Purchasing - Andy Dickinson<br />

andy@siriannihardwoods.com<br />

42 JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 43