Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

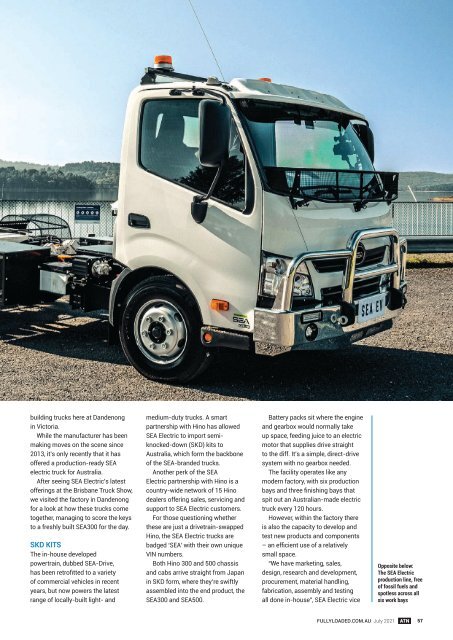

uilding trucks here at Dandenong<br />

in Victoria.<br />

While the manufacturer has been<br />

making moves on the scene since<br />

2013, it’s only recently that it has<br />

offered a production-ready SEA<br />

electric truck for Australia.<br />

After seeing SEA Electric’s latest<br />

offerings at the Brisbane Truck Show,<br />

we visited the factory in Dandenong<br />

for a look at how these trucks come<br />

together, managing to score the keys<br />

to a freshly built SEA300 for the day.<br />

SKD KITS<br />

The in-house developed<br />

powertrain, dubbed SEA-Drive,<br />

has been retrofitted to a variety<br />

of commercial vehicles in recent<br />

years, but now powers the latest<br />

range of locally-built light- and<br />

medium-duty trucks. A smart<br />

partnership with Hino has allowed<br />

SEA Electric to import semiknocked-down<br />

(SKD) kits to<br />

Australia, which form the backbone<br />

of the SEA-branded trucks.<br />

Another perk of the SEA<br />

Electric partnership with Hino is a<br />

country-wide network of 15 Hino<br />

dealers offering sales, servicing and<br />

support to SEA Electric customers.<br />

For those questioning whether<br />

these are just a drivetrain-swapped<br />

Hino, the SEA Electric trucks are<br />

badged ‘SEA’ with their own unique<br />

VIN numbers.<br />

Both Hino 300 and 500 chassis<br />

and cabs arrive straight from Japan<br />

in SKD form, where they’re swiftly<br />

assembled into the end product, the<br />

SEA300 and SEA500.<br />

Battery packs sit where the engine<br />

and gearbox would normally take<br />

up space, feeding juice to an electric<br />

motor that supplies drive straight<br />

to the diff. It’s a simple, direct-drive<br />

system with no gearbox needed.<br />

The facility operates like any<br />

modern factory, with six production<br />

bays and three finishing bays that<br />

spit out an Australian-made electric<br />

truck every 120 hours.<br />

However, within the factory there<br />

is also the capacity to develop and<br />

test new products and components<br />

– an efficient use of a relatively<br />

small space.<br />

“We have marketing, sales,<br />

design, research and development,<br />

procurement, material handling,<br />

fabrication, assembly and testing<br />

all done in-house”, SEA Electric vice<br />

Opposite below:<br />

The SEA Electric<br />

production line, free<br />

of fossil fuels and<br />

spotless across all<br />

six work bays<br />

FULLYLOADED.COM.AU July 2021 <strong>ATN</strong> 57