Jewellery World Magazine - December 2021

This issue looks at white diamonds and a new Australian watch brand.

This issue looks at white diamonds and a new Australian watch brand.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

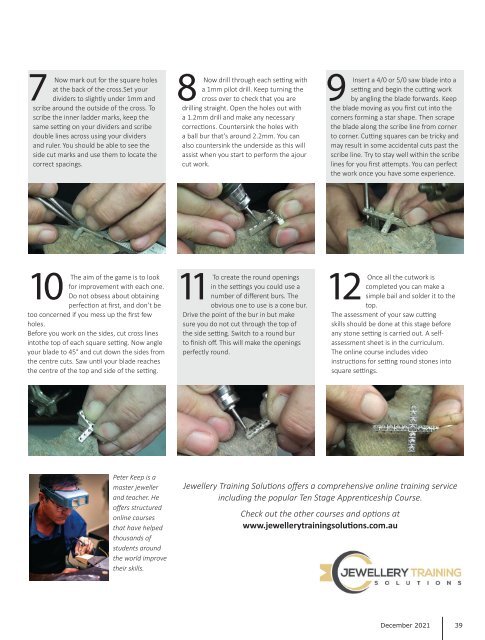

7<br />

Now mark out for the square holes<br />

at the back of the cross.Set your<br />

dividers to slightly under 1mm and<br />

scribe around the outside of the cross. To<br />

scribe the inner ladder marks, keep the<br />

same setting on your dividers and scribe<br />

double lines across using your dividers<br />

and ruler. You should be able to see the<br />

side cut marks and use them to locate the<br />

correct spacings.<br />

8<br />

Now drill through each setting with<br />

a 1mm pilot drill. Keep turning the<br />

cross over to check that you are<br />

drilling straight. Open the holes out with<br />

a 1.2mm drill and make any necessary<br />

corrections. Countersink the holes with<br />

a ball bur that’s around 2.2mm. You can<br />

also countersink the underside as this will<br />

assist when you start to perform the ajour<br />

cut work.<br />

9<br />

Insert a 4/0 or 5/0 saw blade into a<br />

setting and begin the cutting work<br />

by angling the blade forwards. Keep<br />

the blade moving as you first cut into the<br />

corners forming a star shape. Then scrape<br />

the blade along the scribe line from corner<br />

to corner. Cutting squares can be tricky and<br />

may result in some accidental cuts past the<br />

scribe line. Try to stay well within the scribe<br />

lines for you first attempts. You can perfect<br />

the work once you have some experience.<br />

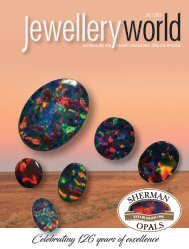

10<br />

The aim of the game is to look<br />

for improvement with each one.<br />

Do not obsess about obtaining<br />

perfection at first, and don’t be<br />

too concerned if you mess up the first few<br />

holes.<br />

Before you work on the sides, cut cross lines<br />

intothe top of each square setting. Now angle<br />

your blade to 45° and cut down the sides from<br />

the centre cuts. Saw until your blade reaches<br />

the centre of the top and side of the setting.<br />

11number of different burs. The<br />

To create the round openings<br />

in the settings you could use a<br />

obvious one to use is a cone bur.<br />

Drive the point of the bur in but make<br />

sure you do not cut through the top of<br />

the side setting. Switch to a round bur<br />

to finish off. This will make the openings<br />

perfectly round.<br />

12<br />

Once all the cutwork is<br />

completed you can make a<br />

simple bail and solder it to the<br />

top.<br />

The assessment of your saw cutting<br />

skills should be done at this stage before<br />

any stone setting is carried out. A selfassessment<br />

sheet is in the curriculum.<br />

The online course includes video<br />

instructions for setting round stones into<br />

square settings.<br />

Peter Keep is a<br />

master jeweller<br />

and teacher. He<br />

offers structured<br />

online courses<br />

that have helped<br />

thousands of<br />

students around<br />

the world improve<br />

their skills.<br />

<strong>Jewellery</strong> Training Solutions offers a comprehensive online training service<br />

including the popular Ten Stage Apprenticeship Course.<br />

Check out the other courses and options at<br />

www.jewellerytrainingsolutions.com.au<br />

<strong>December</strong> <strong>2021</strong> 39