food Marketing & Technology 3/2021

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

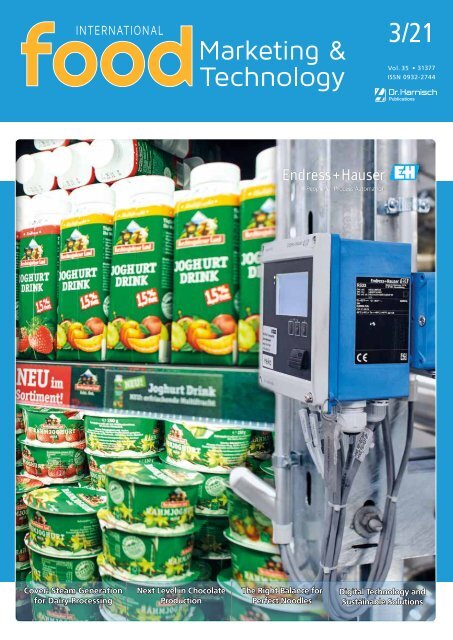

3/21<br />

Vol. 35 • 31377<br />

ISSN 0932-2744<br />

Cover: Steam Generation<br />

for Dairy Processing<br />

Next Level in Chocolate<br />

Production<br />

The Right Balance for<br />

Perfect Noodles<br />

Digital <strong>Technology</strong> and<br />

Sustainable Solutions

FIRST sight. FIRST impression. FIRST spark.<br />

IFT’s Annual Meeting and Food Expo has been transformed into FIRST.<br />

FIRST—where you will gain the insights to move your work,<br />

your business, and our global <strong>food</strong> system forward.<br />

July 19-21, <strong>2021</strong><br />

Register today!<br />

Special IFT member and Solution Exchange<br />

participant discounts available.<br />

Easily source product<br />

solutions and speak<br />

with experts<br />

Get your business done<br />

efficiently and<br />

effectively<br />

Get cutting edge research,<br />

science, and trends<br />

Visiting iftevent.org to learn more<br />

and join our FIRST updates email list.<br />

Key No. 100167

Editorial<br />

The Challenge to Plant-Based Products<br />

The trend to plant-based products is still<br />

relatively small, but is certainly growing.<br />

Products are sprouting up everywhere<br />

as consumers rethink and outthink their<br />

own motivations. Supermarkets are<br />

making space to try and keep up with<br />

their customers. Sustainable reasons<br />

are very honourable. Reasons of animal<br />

welfare are also plausible. So how far<br />

will the journey go and what are the<br />

obstacles on the way?<br />

For most people eating meat is still the<br />

normal state and they are not prepared<br />

to let others dictate to them. The other<br />

extreme is a complete rejection of all<br />

things beef, pork, chicken and co. And<br />

others still are in between, liking the<br />

taste and texure of meat, but plagued<br />

with a guilty conscience.<br />

A reduction in meat consumption may<br />

be one solution. If it is a question of<br />

taste, some people would rather pay<br />

a little more and source local better<br />

quality products so if they eat meat,<br />

then it should be good meat and not<br />

highly processed cheap product or a<br />

substitute that may taste similar, but<br />

often does not. The majority, however,<br />

are still influenced by the price over<br />

other aspects. Nevertheless there is<br />

a growth in vegetarian and vegan<br />

options.<br />

The Vegetarian Butcher is a Dutch<br />

company founded in Den Haag ten<br />

years ago by Jaap Korteweg. He uses<br />

a soya base to recreate the taste and<br />

sensory experience of meat, but with<br />

benefits for the planet and animals.<br />

The motto here is not to replace meat<br />

as such, but to move forwards and see<br />

plant-based products as the new meat.<br />

The traditional craftsman started with<br />

the aim of creating delicious <strong>food</strong>. The<br />

move to plant-based nutrition is seen as<br />

a natural progression.<br />

Part of the problem and maybe the<br />

biggest challenge is that plant-based<br />

products do taste differently to meatbased<br />

ones. For those used to a certain<br />

texture and flavour, a vegetarian or<br />

vegan version of a meat product is not the<br />

same. Perhaps it really is better to design<br />

and produce original products made<br />

completely of meat-free ingredients<br />

Does it have to be one or the other?<br />

An option which has also been talked<br />

about, possibly referring to exhibition<br />

parlance, is a hybrid product. This means<br />

that some meat is replaced by plant<br />

Ian Healey<br />

Editor-in-Chief<br />

protein in a product. The idea is that<br />

the texture and mouthfeel benefits are<br />

improved, but the environmental gains<br />

are also retained. However experts are<br />

not convinced that this is more than<br />

the worst case, since all consumers are<br />

equally unhappy.<br />

When our children were small, we gave<br />

them the best <strong>food</strong> we could, as any<br />

parent would do. Sometimes there was<br />

more meat, sometimes more vegetables<br />

or a combination. Even today, we try<br />

to have a balance. That’s our choice.<br />

We respect that others may choose<br />

differently and they too should find the<br />

best they can. One thing is for sure: the<br />

novelty of plant-based “meat” is giving<br />

way to the reality of it and that’s not at<br />

all bad.<br />

Sincerely,<br />

If you like it – subscribe!<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • June <strong>2021</strong><br />

3<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • June <strong>2021</strong>

International Magazine June 2020 ISSN 2628-5851<br />

<strong>Technology</strong> & <strong>Marketing</strong><br />

your easy way to stay updated<br />

2/20<br />

International Magazine October 2019 ISSN 2628-5851<br />

<strong>Technology</strong> & <strong>Marketing</strong><br />

2/19<br />

xxx<br />

Contents<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> June <strong>2021</strong><br />

1 Editorial<br />

50 Impressum<br />

Ingredients<br />

Ingredients: Hydrocolloids in Pet Food, Acacia Gum's Versatility, Antioxidants<br />

Processing: Optical Sorting, Gentle Cooling, Removing Risks in Food Safety<br />

Ingredients Blueberries, Fiber, Sea<strong>food</strong>, Microencapsulation<br />

Processing Extrusion, Pumping and Dosing, Pellet Production<br />

Packaging Flexible Wet Packaging and Sleeving, Pouches for Treats<br />

<strong>Marketing</strong> Showcase India, Interzoo 2020 Preview<br />

FREE trial issue at <strong>food</strong>@harnisch.com<br />

Packaging: Pouches and Printing, Sustainability, Choosing the Right Bags<br />

<strong>Marketing</strong>: Ask the Vet, Company News, Updates From the Fairs<br />

9 Straddling the Equator for Reliable Raw Material<br />

Sourcing and Production<br />

12 “Next-Level” PGPR for Chocolate Launched<br />

13 Flavors Designed by Nature: Kombucha Nutrition Trend<br />

14 New Mood Support Patent for Saffron Extract<br />

15 Fat and Oils: Targeting the Positive Nutrition Trend<br />

16 No to Food Waste: Avoiding Economic and Ecological<br />

Damage by Saving Food<br />

PetFood PRO magazine<br />

wants to emphasize the<br />

high level of quality and<br />

care in the production<br />

of pet <strong>food</strong> through the<br />

choice of ingredients, the<br />

choice of technology and<br />

the choice of packaging<br />

materials.<br />

International Magazine April 2020 ISSN 2628-5851<br />

1/20<br />

International Magazine April 2019 ISSN 2628-5851<br />

<strong>Technology</strong> & <strong>Marketing</strong><br />

1/19<br />

Recycling is<br />

teamwork<br />

Processing<br />

6 Decentralized Generation of Electricity and Steam –<br />

Berchtesgadener Land Dairy takes Matters into its own Hands<br />

18 Fast service from Gear Specialist Ensures Continued Roll<br />

Production at Fine Lady Bakeries<br />

20 “Cherry Time!” for Smoking and Barbecue<br />

22 Quality is a Nice Feeling Unilever Chooses Checkweighers<br />

24 Bulk Bag Discharger Ups Efficiency of Cocoa Powder line<br />

26 Continuously Operating Ploughshare Mixer<br />

27 The Right Dough Temperature Every Time<br />

30 Firm, Chewy, and Bouncy: GEA Strikes the Right Balance for<br />

Perfect Noodles<br />

32 Chicory Root Cutter CRC200<br />

Packaging<br />

33 Packaging Equipment<br />

34 Case Study – P.E. Labellers & Sani Trasporti<br />

36 Digital <strong>Technology</strong> and Sustainable Solutions: That’s How<br />

You Reach Generation YZ<br />

38 A State of Readiness<br />

40 325 years of paper “Made in Flensburg”<br />

42 How to Make Three out of Two – More Sustainable<br />

Packaging of Deli Products<br />

44 From Nice-to-Have to Must-Have: Tenyears of PROVALIN<br />

Ingredients Indispensable Fatty Acids, Dietary Fiber for Pets, Yeast<br />

Processing HPP <strong>Technology</strong>, Extruding Fish Feed, Encapsulation<br />

Packaging Canning, Recyclable Bags, Cartons<br />

<strong>Marketing</strong> The Vet's Corner, News from Fairs and Firms<br />

Ingredients Joint Health & Mobility, Yeast Extracts, Fiber<br />

Processing Batch & Continuous Mixing, Optical Sorting, Extrusion<br />

www.harnisch.com<br />

Packaging Pouches, Bags & Sacks, Tubs, Coding<br />

Departments<br />

46 Kerry Releases Webinar on Food Safety Challenges with<br />

Plant-based Meats<br />

48 FACHPACK <strong>2021</strong>: Ready to go!<br />

49 Calendar of Events

Vol. 35 • 31377<br />

ISSN 0932-2744<br />

Cover: Steam Generation<br />

for Dairy Processing<br />

Next Level in Chocolate<br />

Production<br />

The Right Balance for<br />

Perfect Noodles<br />

3/21<br />

Digital <strong>Technology</strong> and<br />

Sustainable Solutions<br />

Cover: Endress+Hauser<br />

In order to process the raw milk that it<br />

receives, Berchtesgadener Land Dairy<br />

requires considerable amounts of<br />

electricity and steam, such as for the heat<br />

treatment system, for pasteurization<br />

or for the CIP system. The company has<br />

been generating vast quantities of the<br />

energy it needs with its own in-house<br />

system since 2016. For the measurement<br />

instrumentation, Berchtesgadener Land<br />

relies for over 25 years on the partnership<br />

with Endress+Hauser.<br />

Our Cover Story starts on page 6.<br />

GROW<br />

YOUR<br />

BUSINESS<br />

Ingredients: Chocolate Production<br />

PGPR (polyglycerol polyricinoleate) is used in chocolate production<br />

for mould optimization, flow control and viscosity reduction.<br />

Palsgaard’s existing product, Palsgaard(r) PGPR 4150, is already<br />

the market leader, but the company’s latest offering takes PGPR<br />

performance to new levels. See the full story on page 12<br />

fairtrade<br />

agro<strong>food</strong><br />

<strong>food</strong> + bev tec<br />

process & packaging<br />

ingredients<br />

bakery & confectionery<br />

Trade show dates<br />

Processing: Perfect Noodles<br />

Companies today are increasingly focused on healthier types of<br />

noodle, launching gluten-free, MSG-free, lowsalt and low-fat<br />

products, or noodles made using wheat, oats as well as healthier<br />

and fresher ingredients, with the inclusion of more vegetables<br />

or ground meat. GEA designs and installs turnkey process lines<br />

tailored to customers’ specific needs. They take care of every<br />

detail and aspect of noodle production. See page 30<br />

Iran 22 - 25<br />

Sept. <strong>2021</strong><br />

Ethiopia 14 – 16<br />

Oct. <strong>2021</strong><br />

Nigeria 26 - 28<br />

Oct. <strong>2021</strong><br />

Iraq 24 – 27<br />

Nov. <strong>2021</strong><br />

Tehran<br />

www.iran-<strong>food</strong>bevtec.com<br />

www.iran-<strong>food</strong>ingredients.com<br />

Addis Ababa<br />

www.agro<strong>food</strong>-ethiopia.com<br />

Lagos<br />

www.agro<strong>food</strong>-nigeria.com<br />

Erbil<br />

www.iraq-agro<strong>food</strong>.com<br />

Packaging: Digital <strong>Technology</strong><br />

Generation Z and millennials are distinguished by their<br />

comprehensive understanding of technology and media. They<br />

seek information about products and companies primarily<br />

online and are inspired to make purchases on social media.<br />

New forms of advertising therefore need to be used to attract<br />

the attention of representatives of generation YZ. Find out<br />

more on page 36<br />

Show contacts at fairtrade Messe GmbH & Co. KG<br />

Iran / Iraq shows: Mr Paul März<br />

Tel.: +49 62 21 45 65 13 • p.maerz@fairtrade-messe.de<br />

Ethiopia show: Ms Dariah Pfaff<br />

Tel.: +49 62 21 45 65 21 • d.pfaff@fairtrade-messe.de<br />

Nigeria show: Ms Freyja Detjen<br />

Tel.: +49 62 21 45 65 19 • f.detjen@fairtrade-messe.de<br />

www.fairtrade-messe.de<br />

Key No. 97065<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • February 2016

Cover Story<br />

Decentralized Generation of Electricity<br />

and Steam – Berchtesgadener Land Dairy<br />

takes Matters into its own Hands<br />

In order to process the raw milk that it receives, Berchtesgadener Land Dairy requires considerable amounts<br />

of electricity and steam, such as for the heat treatment system, for pasteurization or for the CIP (cleaning<br />

in place) system. Because it maintains a consistent focus on sustainability across all areas, the company<br />

has been generating vast quantities of the energy it needs with its own in-house system since 2016. A gas<br />

turbine engine, which operates at more than 90 efficiency, supplies steam, covers in excess of 50 percent<br />

of the dairy’s electricity needs and as a result helps the company reduce its CO 2<br />

footprint and conserve<br />

resources. For the measurement instrumentation, Berchtesgadener Land meanwhile relies on the more than<br />

25 year partnership with Endress+Hauser.<br />

by Florian Kraftschik<br />

“To sterilize the 148 storage,<br />

sterilization and butter ageing tanks,<br />

steam is injected over a longer period<br />

of time,” says Florian Lexhaller, head<br />

engineer at the dairy. Large quantities<br />

of steam are also used for the process<br />

control technology. On average the<br />

dairy utilizes 7 to 8 tons of steam per<br />

hour, with up to 10 tons during peak<br />

periods.<br />

Because the production of steam<br />

consumes large amounts of energy,<br />

and given that the steam boilers were<br />

getting on in years, management saw<br />

significant savings potential in the<br />

area of energy consumption and CO 2<br />

emissions.<br />

Gas turbine for energy and steam<br />

production<br />

Instead of drawing energy from the<br />

public grid for the plant technology<br />

and the production of steam, the idea<br />

was for the dairy to generate its own<br />

electricity and produce steam from<br />

residual heat. The advantage of this<br />

solution is that energy production can<br />

be designed more efficiently. Since the<br />

plant uses both electricity and steam,<br />

this solution leads to a more reliable<br />

energy supply system while significantly<br />

reducing the risk of downtime.<br />

Berchtesgadener Land worked<br />

together with a plant engineering<br />

partner to carry-out the retrofit while<br />

the plant was still in operation. The 1.6<br />

MW gas turbine from Kawasaki, which<br />

was connected to the dairy’s network<br />

in 2016, produces around half of the<br />

plant’s electricity needs. The residual<br />

heat from the turbine is then diverted<br />

to a recovery boiler that generates<br />

5 tons of steam per hour. The steam<br />

production is supplemented by two<br />

peak-load boilers from Bosch, each of<br />

which can generate 10 tons of steam<br />

per hour at a pressure of 10 bar.<br />

Low-temperature heating for<br />

further efficiency improvements<br />

As if that were not enough, the residual<br />

heat is then used for a warm water<br />

system containing a 200,000-liter buffer<br />

The steam is transported throughout the entire<br />

dairy operation with a piping system.<br />

Vortex flowmeters and steam computers: the steam measurement instruments differ from those used<br />

for the milk production process.<br />

6<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • June <strong>2021</strong>

Cover Story<br />

tank. This so-called low-temperature<br />

heating system will eventually be used<br />

for all of the buildings so that building<br />

heating systems can be deinstalled.<br />

The CIP systems and the milk heating<br />

system for curd cheese will also be<br />

fed by the low-temperature heating<br />

system. A heating network for the<br />

entire company has already been<br />

installed. Using this cascade of heat<br />

exchangers, the 530 °C turbine exhaust<br />

will be cooled down to 50 °C before it<br />

leaves the exhaust pipe.<br />

More reliable supply of energy<br />

and steam<br />

With a peak capacity of 25 tons of<br />

steam per hour, the dairy is positioned<br />

to produce twice the amount of steam<br />

than it currently needs. The aim was<br />

to be prepared for increased capacity<br />

in the future while ensuring there is<br />

a constant supply. If a steam boiler or<br />

even the gas turbine goes down, the<br />

plant continues to be supplied with<br />

steam. Electricity can then be drawn<br />

from the public grid on short notice to<br />

keep the plant operational. Because the<br />

dairy runs completely on steam heat, a<br />

continuous supply is essential. Without<br />

steam, production comes to a halt.<br />

Even if bottlenecks in the public grid<br />

occur, the gas turbine still generates<br />

enough electricity to keep important<br />

systems for cooling the milk and the<br />

products up and running, thus providing<br />

another way to significantly reduce the<br />

risk of production downtime.<br />

The peak-load tank is a vital part of the redundant design of the energy center.<br />

expand the gas power plant. The<br />

installation of a second turbine is also<br />

conceivable, which would help the<br />

company take a further step toward<br />

energy self-sufficiency, although there<br />

are currently no concrete plans for an<br />

expansion.<br />

Measurement technology<br />

provides additional downtime<br />

protection<br />

Florian Lexhaller understands the<br />

importance of selecting the right<br />

measurement technology when it<br />

comes to ensuring that the process<br />

control system for the milk production,<br />

the cleaning systems, the energy center<br />

and the dairy’s energy distribution<br />

network all operate smoothly. To do<br />

this he delved deep into the matter,<br />

becoming intimately familiar with the<br />

measurement instruments used in the<br />

plant. New measurement instruments<br />

are regularly inspected with test<br />

applications. In addition, the equipment<br />

specifications list standard types, which<br />

means the spare instrument inventory<br />

can be kept lean. “When we install a<br />

new system, we provide our partners<br />

exact specifications that outline what<br />

the instrumentation should look like,”<br />

reports Lexhaller. “We are satisfied<br />

with the quality and reliability of the<br />

instruments from Endress+Hauser,”<br />

says the chief engineer who adds that<br />

“the instruments have proven their<br />

worth, especially when it comes to<br />

reliability.”<br />

Favorable conditions<br />

The location in Piding offered highly<br />

favorable conditions for the realization<br />

of the energy center with a gas<br />

turbine. A high-pressure gas line that<br />

transports natural gas at a pressure of<br />

70 bar is located just a short distance<br />

from Berchtesgadener Land Dairy. A<br />

reduction station then reduces the<br />

pressure to 16 bar for the gas turbine.<br />

The natural gas is supplied in gas form<br />

by Erdgas Südbayern.<br />

The location offered the ideal<br />

conditions for the construction of the<br />

energy center from a space standpoint<br />

as well. Since the company was able to<br />

sufficiently dimension the production<br />

halls, there is still enough space to<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • June <strong>2021</strong><br />

7

Cover Story<br />

When the energy center was built,<br />

instruments were installed that had<br />

never been used in the plant before,<br />

such as vortex-based flowmeters and<br />

steam computers. Here Lexhaller once<br />

again placed his complete trust in the<br />

advice and instrumentation layout<br />

provided by the Endress+Hauser field<br />

engineer who has been responsible<br />

for Berchtesgadener Land Dairy for<br />

more than 10 years. After four years<br />

of operating the energy center, he<br />

summed up his experience with a wink<br />

of the eye and said: “The stuff simply<br />

works.”<br />

High degree of automation in the<br />

energy center<br />

To optimize the resource efficiency of<br />

the energy center, the automation<br />

technology in the plant plays an<br />

important role. The system can react<br />

quickly to changes in the operating<br />

conditions and automatically adapts its<br />

performance. Through connection of<br />

the systems, measurement values and<br />

key energy indicators are continuously<br />

analyzed and applied by the energy<br />

management system. One of the key<br />

components here is the heat computer<br />

from Endress+Hauser, which features<br />

a Modbus TCP/IP interface. Lexhaller<br />

emphasizes that “Endress+Hauser is<br />

one of the few providers that offer this<br />

type of transmission link, which allows<br />

us to send the energy values direct to a<br />

central SPS and analyze them without<br />

extensive cabling work.<br />

Summary: well-aligned system<br />

with a high degree of efficiency<br />

The energy center is an important<br />

building block in Berchtesgadener<br />

Land’s sustainability strategy. To<br />

ensure that the system runs stably and<br />

smoothly, and to be able to achieve<br />

an efficiency of more than 90 percent,<br />

the individual components must be<br />

intertwined and well-aligned to one<br />

another. The instrumentation from<br />

Endress+Hauser plays an important<br />

role in ensuring the quality of the<br />

dairy products and the reliability of the<br />

systems.<br />

With the installation of the gas<br />

turbine, the dairy is also taking on<br />

the role of trailblazer when it comes<br />

The EngyCal RS33 steam computer records the<br />

amount of steam and the energy flow.<br />

to decentralized energy provisioning.<br />

Given that the system can be operated<br />

efficiently and the availability ensured<br />

through a redundant design, these<br />

arguments will certainly lead many<br />

other companies to one day follow the<br />

example of the Berchtesgadener Land<br />

Dairies.<br />

fmt<br />

The Author<br />

Florian Kraftschik is MarCom Manager<br />

Media Relations, Endress+Hauser Germany<br />

8<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • June <strong>2021</strong>

Ingredients<br />

Straddling the Equator for Reliable Raw<br />

Material Sourcing and Production<br />

With sustainability in mind, BENEO’s broad-based approach to raw material sourcing ensures a secure supply<br />

chain<br />

BENEO’s dietary fibers are in greater<br />

demand than ever before. As<br />

intestinal health becomes a key issue<br />

for consumers around the world, the<br />

industry is responding to the growing<br />

level of interest with new product<br />

developments. But when it comes to<br />

raw materials from Mother Nature,<br />

the company is playing it safe and<br />

ensuring, no matter what obstacles<br />

and weather conditions they face, that<br />

they can reliably deliver consistently<br />

high-quality dietary fibers. The<br />

solution? BENEO is cultivating its<br />

chicory root on both sides of the<br />

globe to guarantee a reliable supply<br />

chain … even in times of crisis. Food<br />

<strong>Marketing</strong> & <strong>Technology</strong> now takes a<br />

closer look at one of these state-ofthe-art<br />

facilities at Pemuco in Chile.<br />

Well positioned for a global<br />

market<br />

To address the ongoing requirements<br />

for the prebiotic dietary fibers inulin<br />

and oligofructose from chicory root,<br />

and to ensure raw material security<br />

for its customers, BENEO opened<br />

a production site in Chile some 15<br />

years ago to complement its plant<br />

in Belgium. Although chicory was<br />

previously hardly grown in the region,<br />

the company has since become<br />

an integral part of the Chilean<br />

agricultural sector and is setting new<br />

standards in terms of sustainability.<br />

For BENEO, the plant in Pemuco, Chile,<br />

offers a decisive strategic advantage.<br />

With two locations on different sides<br />

of the equator, security of supply<br />

for international customers has<br />

significantly increased. Just like sugar<br />

beet, chicory is a seasonal crop that is<br />

harvested in the fall. The move to the<br />

southern hemisphere was therefore<br />

crucial to ensure the availability of<br />

raw materials — even during extreme<br />

climatic conditions. As the harvest<br />

season in Chile usually runs from<br />

March until the end of June, BENEO<br />

can process chicory roots twice a year,<br />

allowing much greater flexibility<br />

to respond to changing customer<br />

requirements in a fast-moving market.<br />

But, production in Chile offers even<br />

more advantages; owing to the high<br />

intensity of sunlight, the on-site<br />

photosynthetic capacity is extremely<br />

high, which benefits both quality and<br />

yield. In addition, frosts are very rare<br />

and, even during the day, it does not<br />

get too hot. In fact, the cultivation<br />

conditions are very similar to Central<br />

Europe in terms of temperature<br />

extremes.<br />

In addition, as BENEO serves a global<br />

market with its natural dietary fibers,<br />

the distances from Central Europe to<br />

some customers — such as those in<br />

Southeast Asia or the West Coast of<br />

the U. S. — are correspondingly long.<br />

The Pemuco location facilitates more<br />

efficient transportation, thus reducing<br />

costs, distances and CO 2<br />

emissions.<br />

Last but not least, Chile is the country<br />

with the highest number of free<br />

trade agreements (FTAs) worldwide.<br />

There are 26 agreements in place<br />

with a total of 62 economies, which<br />

generate almost 90% of the world’s<br />

gross domestic product. Accordingly,<br />

the South American country offers<br />

highly interesting access to a variety<br />

of markets.<br />

Challenging soil<br />

Around 250 employees now work for<br />

BENEO in Pemuco, 200 in production<br />

and administration and about 50<br />

in agriculture. Depending on the<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • June <strong>2021</strong><br />

9

Ingredients<br />

year, the company co-operates with<br />

120–180 farmers and positions itself<br />

as a local service provider for them.<br />

For example, 100% of the seeds are<br />

supplied by BENEO and the company<br />

machines around 60% of the total<br />

cultivated area before and after<br />

sowing on behalf of the farmers.<br />

This also applies to mechanical<br />

weed control. In fact, harvesting<br />

and transport are done entirely and<br />

exclusively by the organisation.<br />

One of the major challenges in Chile<br />

is the soil and its composition. On the<br />

one hand, it can be very stony, which<br />

requires a good separation processing<br />

— both in the field and the factory —<br />

and, on the other hand, heavy rainfall<br />

regularly puts the drainage capacity of<br />

the soils to the test. For the harvesting<br />

machines to be able to access the<br />

fields, even during extreme rainfall,<br />

the harvesting sequence needs to be<br />

well planned and organized. All the<br />

fields are therefore classified by BENEO<br />

according to their drainage capacity.<br />

For example, particularly sandy soils<br />

are only harvested at the end of the<br />

campaign. And, when awarding<br />

contracts for the coming year to the<br />

farmers, care is taken to ensure that<br />

the necessary area is available on soil<br />

that drains well. As a rule, BENEO<br />

relies on a four-year rotation cycle<br />

using crops such as corn, quinoa, chia<br />

and buckwheat to maintain soil health<br />

in the long-term. Existing fallow land<br />

is also used as flowering areas to<br />

promote biodiversity.<br />

Tablets in the field<br />

Owing to the generally good climatic<br />

conditions, however, Chile also suffers<br />

from prolific weed growth. To win the<br />

race between cultivated crops and<br />

wildflowers, sowing, gap closure and<br />

weed control must be timed accurately.<br />

Whether by satellite, airplane or drone,<br />

BENEO makes great efforts in Chile to<br />

obtain the most precise information<br />

possible about the condition of its<br />

fields. With crop care and protection<br />

top of mind, the primary aim is to<br />

be able to work as accurately as<br />

possible. With the aid of soil sensors,<br />

water use and nutrient requirements<br />

of the plants are recorded and can<br />

be analysed over time. Using an app,<br />

farmers can also be directed to those<br />

parts of a field where growth is below<br />

10 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • June <strong>2021</strong>

Ingredients<br />

average. In the future, it should also<br />

be possible to digitally identify weeds,<br />

so that even more targeted control<br />

measures can be taken.<br />

Further investment into<br />

sustainability<br />

At its plant in Pemuco, BENEO<br />

not only produces inulin and<br />

oligofructose, it also processes certain<br />

solid and liquid co-products that are<br />

used as mineral fertilizers or as feed<br />

products. The energy required for all<br />

these processes comes from a biomass<br />

boiler, which was commissioned in<br />

2015. Because there is a lot of wood<br />

and pulp industry in the region, the<br />

use of biomass is particularly fitting;<br />

BENEO actually uses the residual<br />

wood from local sawmills as a source<br />

of energy for its own combined heatpower<br />

plant.<br />

“We have switched the site’s energy<br />

supply to non-fossil fuels as far as<br />

possible. Around 80% of our total<br />

annual energy need comes from<br />

renewable sources and we plan to<br />

expand this in the future to further<br />

reduce our carbon footprint,”<br />

comments Christoph Boettger,<br />

Member of the Executive Board of<br />

BENEO. “In order to ensure continously<br />

a reliable supply chain in future we are<br />

investing more than € 50 million in the<br />

expansion of our Chilean site. This will<br />

enable us to increase our production<br />

capacity by 20% worldwide by 2022,<br />

he went on to say.”<br />

Projekt2_Layout 1 05.03.<strong>2021</strong> 13:23 Seite 1<br />

COLOUR<br />

For extra boost!<br />

The state-of-the-art plant in Pemuco<br />

is an equally important location for<br />

BENEO. In recent years, the company<br />

has established itself as a good<br />

employer and social partner in the<br />

region. For example, BENEO has been<br />

holding a competition for business<br />

start-ups for some time. Every year,<br />

this competition supports several<br />

micro-enterprises with knowledge<br />

and financial contributions. BENEO<br />

also takes care of the next generation<br />

of farmers. A dual training program<br />

has been initiated with local schools,<br />

and the first class has recently<br />

graduated. As such, BENEO is making<br />

an important contribution to leading<br />

the agricultural sector in Chile into a<br />

successful future with bright minds. fmt<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong><br />

Key No. 99993

Ingredients<br />

“Next-Level” PGPR for<br />

Chocolate Launched<br />

Palsgaard has launched a new PGPR product which offers chocolate manufacturers the best ever levels of<br />

functionality and efficiency.<br />

PGPR (polyglycerol polyricinoleate) is<br />

used in chocolate production for mould<br />

optimization, flow control and viscosity<br />

reduction. Palsgaard’s existing product,<br />

Palsgaard ® PGPR 4150, is already the<br />

market leader, but the company’s latest<br />

offering takes PGPR performance to<br />

new levels.<br />

Developed exclusively for chocolate,<br />

Palsgaard ® PGPR 4190 is 15% more<br />

efficient at controlling viscosity than<br />

Palsgaard ® PGPR 4150, and can be used<br />

at a dose 30-40% lower than other<br />

PGPRs, making it highly cost-effective.<br />

Other benefits include easier flow, better<br />

coating of inclusions, and taste- and<br />

odour-neutrality. Palsgaard ® PGPR 4190<br />

will be subject to Palsgaard’s unique<br />

quality standards, with batch-to-batch<br />

checks guaranteeing uniform stability.<br />

Morten Hoffmann Kyed, Director of<br />

Product Management at Palsgaard, said:<br />

“We’ve led the market for many years,<br />

but this really is the next level for PGPR.<br />

Palsgaard ® PGPR 4190 is the result of<br />

years of research and innovation, and<br />

it will offer chocolate manufacturers<br />

unique, best-in-class functionality.<br />

Furthermore, because a tiny drop<br />

delivers a huge effect, its benefits also<br />

include very high cost-in-use savings.”<br />

12 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • June <strong>2021</strong>

Ingredients<br />

Palsgaard ® PGPR 4190 is designed<br />

for chocolate spreads and enrobed<br />

and moulded products. Although it<br />

works well with traditional chocolate<br />

emulsifier lecithin, it is an ideal partner<br />

for Palsgaard ® AMP 4455, an alternative<br />

to lecithin with better organoleptic<br />

properties. Both products were<br />

showcased at the World Confectionery<br />

Conference on 1st June.<br />

The result of intensive research at<br />

Palsgaard’s main R&D center in<br />

Denmark, Palsgaard ® PGPR 4190<br />

is manufactured in the company’s<br />

specialist facilities in the Netherlands,<br />

where all production is CO 2<br />

-neutral,<br />

and which have recently undergone<br />

extensive equipment upgrades. fmt<br />

Flavors Designed by Nature:<br />

Kombucha Nutrition Trend<br />

A family company, Aromatech was<br />

created in 1987 in France, in Grasse,<br />

the world capital of aromas and<br />

fragrances. At the origin of this<br />

creation, Jacques MARTEL, whose<br />

son Benoit MARTEL now heads<br />

the Group with Yvan GRATTAROLA<br />

and their teams. Its international<br />

expansion then took it from Africa to<br />

the Middle East, then to Asia, from<br />

Thailand to China, via the United<br />

States.<br />

It is this entrepreneurial spirit and the<br />

clever mix of all these flavors from<br />

elsewhere that have built the world<br />

of Aromatech: Flavors designed by<br />

nature.<br />

terpene and iced tea notes. It will<br />

bring a touch of delicacy to sweet<br />

applications such as syrups, yoghurts<br />

and drinks. Relish this flavor full of<br />

sweetness in an alcohol-free cocktail<br />

recipe made with 0.18% liquid<br />

Kombucha flavor.<br />

Aromatech develops aromas specially<br />

formulated for alcoholic or nonalcoholic<br />

drinks, available in liquids,<br />

emulsions, solvents, powders (for<br />

instant drinks) atomized or granulated<br />

depending on the applications and<br />

manufacturing constraints.<br />

fmt<br />

Kombucha is a slightly acidic fermented<br />

drink made from a culture<br />

of bacteria and yeast inserted into<br />

a sweet infusion made from black<br />

tea. The Kombucha flavor, created<br />

by Aromatech Thailand, responds<br />

to the growing trend of consuming<br />

probiotic-based products.<br />

Its organoleptic profile is mainly<br />

characterized by sweet, flowery, fruity,<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • June <strong>2021</strong><br />

13

Ingredients<br />

New Mood Support Patent<br />

for Saffron Extract<br />

Affron earns the exclusive right in the United States to the formulation and use of its saffron extract in<br />

connection with low mood support<br />

Affron ® , Pharmactive Biotech Products,<br />

SL’s flagship saffron extract, has been<br />

awarded a US patent for its proven<br />

positive role in low mood support. This<br />

patent serves as an official recognition<br />

of the company’s unique process in the<br />

formulation of affron and its ability<br />

to assist individuals with low mood<br />

related issues.<br />

The new patent essentially protects the<br />

proprietary composition and dosages of<br />

affron that renders it uniquely effective<br />

as a natural mood-support agent. “This<br />

new accreditation marks a momentous<br />

milestone for affron as it positions it<br />

as a leading-edge formulation at the<br />

forefront of the US cognitive health<br />

category,” enthuses Marguerite<br />

Gerritsen, Managing Director for<br />

Pharmactive.<br />

Pharmactive’s saffron ingredient is<br />

based on an all-natural and lowenergy<br />

consumption extraction<br />

process of saffron (Crocus sativus L.).<br />

Affron is manufactured using a unique<br />

proprietary AFF ® ON Cool-Tech activessaver<br />

extraction procedure, which<br />

is specifically designed to optimize<br />

the preservation and concentration<br />

of the key active ingredients with<br />

minimal industrial processing, without<br />

chemicals, and minimal energy<br />

use. Pharmactive has scientifically<br />

demonstrated its formulation’s<br />

fast-acting capabilities and high<br />

bioavailability in a pharmacokinetics<br />

study. It has a proven the lowest dose<br />

threshold on the market at just 28mg<br />

per day.<br />

Affron is standardized to a high<br />

concentration of crocins and safranals<br />

— the carotenoid pigments responsible<br />

for saffron’s bioactivity, crimson color,<br />

and prized organoleptic qualities. This<br />

is verified by means of HPLC (highperformance<br />

liquid chromatography).<br />

While saffron has a centuries-old<br />

reputation for health benefits in<br />

traditional medicine, the high efficacy<br />

of Pharmactive’s extract is supported<br />

by half a dozen clinical studies<br />

demonstrating a positive effect on<br />

multiple aspects of mental well-being,<br />

earning it a solid reputation as an<br />

all-encompassing cognitive ingredient.<br />

The research has highlighted affron’s<br />

manifold potentials for, relieving stress,<br />

improving mood, inducing positive<br />

feelings, and enhancing sleep quality. It<br />

is also the first commercial extract that<br />

has clinically demonstrated capacity to<br />

raise teens’ spirits.<br />

“Affron’s mood-enhancement capabilities<br />

are owed largely to its role<br />

in the inhibition of the reuptake<br />

of mood-related neurotransmitters,<br />

according to the broader spectrum of<br />

scientific literature,” informs Alberto<br />

Espinel, Head of Strategic R&D in Active<br />

and Functional Natural Ingredients for<br />

Pharmactive. “Affron possesses a potent<br />

antioxidant and anti-inflammatory<br />

impact. This capacity not only balances<br />

levels of key neurotransmitters, such<br />

as serotonin and dopamine, but also<br />

fights the oxidative stress that stress<br />

produces in the brain.”<br />

Pharmactive’s patent request specifically<br />

delineated the effective dose<br />

and appropriate concentrations of<br />

safranal and crocin compounds in the<br />

final extract as a critical condition for<br />

exerting a positive effect on disorders<br />

related to mood.<br />

To overcome the common hurdles<br />

experienced by saffron formulators<br />

in extracting the best of the active<br />

substances from the stigmas of<br />

this highly revered and priceless<br />

botanical, Pharmactive introduced an<br />

improved step in separating the active<br />

substances. Their extraction technique<br />

is based solely on water resulting in an<br />

ingredient that is clean of any solvents<br />

or alcohols.<br />

The patent is paralleled with a new<br />

“Informed Ingredient” certification<br />

mark, and in recognition of the safety<br />

profile and high-quality credentials<br />

of affron. This is in addition to<br />

affron’s previously earned strongbox<br />

of quality and safety seals awarded<br />

by internationally accredited<br />

bodies, including EU Organic, DNA<br />

certification (True-ID) confirming<br />

the authenticity of its botanicals,<br />

Doping-free, Kosher, Halal, etc.<br />

Affron is manufactured in a GMPcertified<br />

installation, complying also<br />

with ISO22000 (for its <strong>food</strong> safety<br />

management), ISO9001 (for its quality<br />

management) and ISO 14001 (for its<br />

commitment to environmental values).<br />

Pharmactive is also the official adopter<br />

of saffron by the American Botanical<br />

Council’s Adopt-an-Herb botanical<br />

research and education program, as<br />

industry leaders in saffron extracts.<br />

“Pharmactive is able to provide<br />

nutraceutical and pharma industry<br />

players with a truly effective, wholly<br />

trustworthy botanical alternative for<br />

use in connection with low mood<br />

related issues,” concludes Gerritsen. “It<br />

also ensures our position as the ideal<br />

partner for the US market for natural,<br />

botanical mood help.”<br />

fmt<br />

14 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • June <strong>2021</strong>

Ingredients<br />

Fat and Oils: Targeting the Positive<br />

Nutrition Trend<br />

Consumers are taking a proactive approach to health maintenance and are actively looking to improve their<br />

diets. Whilst doing this, they are taking a broader approach to what constitutes healthy eating and drinking.<br />

Indeed, focus is no longer associated just on avoidance and moderation but instead, ensuring that they have<br />

ingredients in their diets that offer a health boost beyond basic nutrition. This is something that the fats and<br />

oils industry needs to respond to, educating consumers about how “good” fats are something that can help<br />

address issues such as heart health and immunity<br />

Over the last twelve months, consumers<br />

have become more conscious about<br />

their health. For instance, in 2020 a<br />

total of 57% of consumers said that<br />

they deemed themselves vulnerable to<br />

disease and illness – compared to 38%<br />

who said this a year before. At the<br />

same time, satisfaction with immune<br />

health declined from 54% to 49% over<br />

the same period. This is due to the<br />

impact of the pandemic. Originally,<br />

concerns about the virus was about<br />

vulnerability to it, especially when less<br />

was known about how deadly it was.<br />

However over the last twelve months,<br />

consumers have had chance to reevaluate<br />

and have taken a broader<br />

approach to health, recognizing that<br />

even if they were not necessarily<br />

vulnerable to problems arising from<br />

COVID-19, they were at risk of other<br />

long-term health problems. This is<br />

due to consumers recognizing that<br />

their dietary habits are not as healthy<br />

as they could be. As such, they are<br />

wanting to take a proactive approach<br />

to health maintenance – with 76%<br />

saying that they plan to eat and drink<br />

more healthily over the last twelve<br />

months.<br />

As consumers take a proactive<br />

approach to health maintenance, they<br />

are focusing more on the concept of<br />

positive nutrition. This means that<br />

consumers are not associating dieting<br />

with avoidance and moderation in<br />

order to lose weight but instead,<br />

believing that if they adopt a well<br />

balanced diet, they will be able to<br />

improve all aspects of their health. The<br />

focus on this means that ingredientled<br />

claims are becoming more<br />

influential on purchasing behavior,<br />

with consumers wanting to see active<br />

ingredient and claims on products<br />

that offer a health boost beyond basic<br />

nutrition. Although it is important<br />

to not over-estimate consumer<br />

awareness of fats, they do recognize<br />

that some in moderation and part of<br />

a balanced diet can have a positive<br />

impact on health. For instance, 42% of<br />

consumers associate monounsaturated<br />

fats with having a positive impact<br />

on health, whilst 39% say this for<br />

polyunsaturated fat. Meanwhile, 47%<br />

of consumers say that they are prone<br />

to looking for these ingredients on<br />

product packaging. Over the last<br />

couple of decades, sugar has replaced<br />

fat as the number one dietary evil in<br />

the eyes of the consumer, and this<br />

research shows that consumers believe<br />

that fats, in moderation, can have a<br />

positive impact on health.<br />

“Good” fats such as monounsaturated<br />

fats and polyunsaturated fats can have<br />

a variety of benefits, such as helping<br />

aid with weight loss, improving heart<br />

health and boosting overall immunity.<br />

These areas of health are important to<br />

consumers. For instance, FMCG Gurus<br />

research shows that in 2020, a total of<br />

70% of consumers say that they have<br />

looked to make changes to their diets<br />

and lifestyles to improve their immune<br />

health – compared to 53% who said<br />

this a year earlier. Meanwhile, 65% in<br />

the same year said that they wanted<br />

to improve their heart health. Finally,<br />

in <strong>2021</strong>, a total of 34% of consumers<br />

said that they were on a diet to lose<br />

weight (around a ten percent increase<br />

compared to when the survey was<br />

run three years earlier). The focus on<br />

health maintenance reflects the extent<br />

that COVID-19 has had on consumer<br />

attitudes to health, as more focus is<br />

placed on disease maintenance than<br />

ever before.<br />

Given that many consumers believe<br />

that there will be future waves of<br />

the virus and one in five believe that<br />

it is something that will impact on<br />

daily lives for several years, increased<br />

concern about vulnerability to disease<br />

will remain for some time. At the<br />

same, it is important to recognize that<br />

even before the pandemic, consumers<br />

were not conscious about their health,<br />

and were focusing on trying to stay<br />

fit and active until as late in life as<br />

possible. This is something that the<br />

fat and oils industry needs to respond<br />

to, educating consumers about the<br />

benefits of products and highlighting<br />

the benefits these ingredients have<br />

when consumed in moderation and as<br />

part of a balanced diet. At the same<br />

time, it is important that brands are<br />

not seen to be making exaggerated<br />

or misleading claims around these<br />

benefits.<br />

fmt<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • June <strong>2021</strong><br />

15

Ingredients<br />

No to Food Waste: Avoiding Economic<br />

and Ecological Damage by Saving Food<br />

● More than 1.6 billion tons of <strong>food</strong> are wasted annually<br />

● $660 billion in economic losses due to waste of <strong>food</strong> raw materials<br />

● $356 billion global market volume of raw materials for <strong>food</strong> production<br />

The statistics are bleak. Out of them<br />

came an inspiration to change<br />

something. LEROMA’s philosophy is<br />

to act in a sustainable and economical<br />

way, because everyone has to play<br />

their part in this process to make a<br />

positive contribution.<br />

LEROMA GmbH, from Düsseldorf,<br />

Germany have set themselves the goal<br />

of combating the problem of <strong>food</strong><br />

waste and the lack of transparency<br />

in the market. They have developed<br />

a B2B portal for <strong>food</strong> raw materials<br />

because they have recognized that<br />

<strong>food</strong> industry players need efficient<br />

raw material sourcing. LEROMA’s<br />

unique selling point is the specific<br />

filters that can be set differently<br />

for each product. In addition, the<br />

appropriate certificates are available<br />

for each raw material, which provide<br />

information about the quality of the<br />

product.<br />

Raw material suppliers can advertise<br />

their raw materials on LEROMA.<br />

This way, a comprehensive raw<br />

material database is created, which is<br />

constantly expanded with each new<br />

partner. Food manufacturers benefit<br />

from the platform, where they can<br />

easily find the raw materials they<br />

need and their suppliers.<br />

In addition, the Surplus Exchange has<br />

been developed, where companies<br />

simply offer to the market residual<br />

items, surpluses and remaining stocks<br />

of raw materials that have been<br />

incorrectly purchased or can no longer<br />

be processed, instead of disposing of<br />

them. In this way, there is an active<br />

contribution to reducing <strong>food</strong> waste<br />

and a step forward to sustainability.<br />

Examples of projects and cooperation<br />

so far include tomatoes processed<br />

into sauce, since they were no longer<br />

physically attractive, rice being made<br />

into rice protein and extracts being<br />

won from dried plants. Generally<br />

speaking, vegetables and fruits can be<br />

made into powder to add a delicious<br />

aroma in specific meals. It is also<br />

possible to make oil from e.g. apple<br />

cores and omega-3 capsules from fish<br />

skins.<br />

Other options include processing<br />

surplus <strong>food</strong> to cosmetics, cleaning<br />

materials or even use as paint balls.<br />

The only limit is the imagination! fmt<br />

16 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • June <strong>2021</strong>

Ingredients<br />

SIMULATE WHOLE MUSCLE MEATS<br />

IN LOOK, TASTE AND NUTRITION.<br />

For meat analog and extender production,<br />

rely on the pioneer of the process for textured<br />

vegetable proteins by extrusion. Wenger began<br />

the worldwide initiative over 50 years ago, and<br />

continues to lead with ever expanding options<br />

today.<br />

High moisture meat analogs (HMMAs) produced on<br />

Wenger twin screw extruders mimic whole muscle<br />

meat, with similar characteristics for moisture,<br />

protein and fat contents, as well as a densely<br />

layered, somewhat fibrous structure.<br />

After extrusion, HMMAs may be cut, sliced or<br />

shredded – and then further processed or frozen.<br />

In addition to soy proteins or wheat gluten<br />

ingredients, alternative protein sources can be used<br />

for texture, mouthfeel and appearance objectives.<br />

Discover the latest in cutting edge extrusion<br />

processing and product development assistance.<br />

Email info@wenger.com now.<br />

Key No. 99334<br />

PHONE: 785.284.2133 | EMAIL: INFO@WENGER.COM | WENGER.COM<br />

USA | BELGIUM | TAIWAN | BRASIL | CHINA<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • June <strong>2021</strong><br />

17

Processing<br />

Fast service from Gear Specialist<br />

Ensures Continued Roll Production at<br />

Fine Lady Bakeries<br />

When Fine Lady Bakeries, the Banbury based bakery producer, needed to replace a failed gear unit on an<br />

operationally vital winding drum that needed to put back into production as quickly as possible, they turned<br />

to the nearby located NORD DRIVESYSTEMS GROUP member – NORD GEAR LTD. In ultra-quick time, NORD<br />

was able to replace Fine Lady’s failed gear unit with one from its standard range fitted with a specially<br />

designed and manufactured shaft.<br />

For many years, Fine Lady has produced<br />

a wide range of baked goods at its 10<br />

hectare premises in Oxfordshire, UK.<br />

Together with a factory in Manchester,<br />

the company produces millions of<br />

loaves of bread every week. As well as<br />

this, it produces various types of rolls as<br />

well as biscuits and Good Friday “hot<br />

cross buns”.<br />

UK Sales Manager - Distribution & End<br />

Users, at NORD GEAR LTD. “We’re<br />

located just 30 minutes from the<br />

Fine Lady site at Banbury. One of our<br />

engineers immediately visited the<br />

site to identify the failed gear unit. It<br />

turned out to be a competitor gear<br />

unit that had been discontinued for a<br />

number of years.”<br />

“In selecting the gear unit we took into<br />

consideration the maximum output<br />

torque of the existing unit, which was<br />

25,000 Nm at 1 rpm output speed,” says<br />

Paul Martin. “We also had to consider<br />

that any gear unit we chose could<br />

withstand the thrust load from the<br />

carousel, which rested on the gear unit<br />

as part of the design configuration.”<br />

The Easter period resulted in a<br />

considerable production increase<br />

of “hot cross buns” at Fine Lady. So<br />

the request for an urgent gear unit<br />

replacement on its dough proofer<br />

meant NORD had to act fast.<br />

“Due to the urgency, it was decided that<br />

the gear unit failure would be repaired<br />

so that they could restart production,<br />

although a long-term solution was<br />

clearly required,” explains Paul Martin,<br />

The NORD engineer set about taking<br />

key dimensions, such as shaft size and<br />

length, along with how the gear unit<br />

was mounted to the dough proofer.<br />

In discussions with the engineering<br />

team at Fine Lady, it was made clear<br />

that although there was a degree<br />

of flexibility in the mounting design<br />

(as the mounting frame could be reengineered),<br />

however the shaft size and<br />

length had to be as per the original gear<br />

unit in order to suit the drive coupling.<br />

The MAXXDRIVE industrial gear units from NORD DRIVESYSTEMS offer very high output torques,<br />

quiet running and a long service life. They are available as helical or bevel gear units<br />

Image: NORD DRIVESYSTEMS<br />

Once the thrust load was calculated,<br />

NORD opted for a gear unit from its<br />

MAXXDRIVE industrial gear unit series.<br />

Specifically, a size 8 gear unit was<br />

chosen, which has a rated torque of<br />

31,000 Nm and a thrust load capacity of<br />

140,000 N.<br />

NORD MAXXDRIVE gear units are<br />

specially designed for heavy-duty<br />

applications such as mixers, offering<br />

high output torques from 15,000 to<br />

25,000 Nm, along with quiet running<br />

and long service life. These gear units<br />

are available as helical or bevel gear<br />

units, and are equipped with highquality,<br />

low-friction bearings, and a<br />

torsionally rigid, one-piece housing.<br />

“The problem was that for large<br />

customer specific gear units, delivery<br />

times can range from 4 weeks for a<br />

standard model, up to 16 weeks for a<br />

more complex unit,” states Martin. “In<br />

addition, the Fine Lady Bakeries’ gear<br />

unit required a special shaft, which<br />

had to be specified and designed at<br />

the NORD headquarters in Germany.<br />

However, our team pulled out all the<br />

stops. The design was completed within<br />

24 hours and a quote, along with<br />

drawing, was issued to the customer.<br />

For a unit with a special shaft the usual<br />

lead time is 12 weeks, but due to the<br />

urgent nature of the situation at Fine<br />

18 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • June <strong>2021</strong>

Processing<br />

Robust and powerful The MAXXDRIVE industrial gear units are specially designed for heavy-duty applications such as mixers<br />

Image: iStock – VladimirGerasimov<br />

Lady, we managed to reduce delivery<br />

to under 6 weeks.”<br />

Keith Holloway, Engineering Buyer at<br />

Fine Lady Bakeries Ltd, says: “Through<br />

past experience we knew that rapid<br />

assistance was needed due to the<br />

gear unit failure and its age. We<br />

contacted NORD, who were quick in<br />

reacting to our predicament. The unit<br />

was identified and measured within a<br />

short period, and an order was placed<br />

for two units, which has been fitted<br />

to the machine after some framework<br />

modifications. We’re very happy with<br />

the service provided and would not<br />

think twice about using NORD in the<br />

future.”<br />

Having made the necessary changes to<br />

the existing mounting framework, the<br />

drive is now in operation. The new gear<br />

unit from NORD not only gives Fine<br />

Lady the confidence that it can fully<br />

rely on the local service and support,<br />

but also that it can depend on a high<br />

level of productivity.<br />

fmt<br />

HYGIENIC DESIGN Rotary Valve Easy Clean Twice<br />

Key No. 99937<br />

Hygienic Design<br />

Easy Cleaning<br />

Replaceable<br />

seal cartridge<br />

FDA–certified<br />

elastomers<br />

ATEX Protection System<br />

EHEDG Type EL Class II<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • June <strong>2021</strong><br />

»COMPETENCE FOR LEADERSHIP«<br />

JAUDT Dosiertechnik<br />

Maschinenfabrik GmbH<br />

Raiffeisenstraße 3-5<br />

D-86167 Augsburg<br />

19<br />

e-mail: verkauf@jaudt.de<br />

www.jaudt.de

Processing<br />

“Cherry Time!” for Smoking and Barbecue<br />

With summer fast approaching,<br />

RÄUCHERGOLD ® brings a new variety<br />

to all professional and amateur<br />

smokers alike, introducing “Cherry”<br />

as the latest recommendation from<br />

the “MASTER of SMOKE” portfolio.<br />

Boasting a mild, fruity smoke aroma,<br />

“Cherry” delivers new possibilities,<br />

whilst offering the perfect smoke<br />

accompaniment for different meats,<br />

such as chicken, pork, or lamb, plus<br />

fish and even vegetables.<br />

100% natural smoke of wild cherry<br />

wood At JRS (J. Rettenmaier &<br />

Söhne, Rosenberg) “Traditional<br />

Smoking” means 100% natural<br />

smoke. RÄUCHERGOLD ® cherry is no<br />

exception. Obtained from selected<br />

wild cherry wood, grown in sustainable,<br />

PEFC-certified forests. Already during<br />

smoking, it exudes the unmistakable,<br />

sweet-fresh scent of the noble fruit<br />

tree.<br />

Safety of the known premium product<br />

quality RÄUCHERGOLD ® proven engineering,<br />

guarantees smooth plant<br />

operation and full <strong>food</strong> safety. The<br />

exclusive use of natural raw materials<br />

in our purely mechanical and thermal<br />

production process, meet the strict<br />

RÄUCHERGOLD ® purity requirements<br />

and no chemicals or artificial additives<br />

are ever present at any time in<br />

production.<br />

The fresh, untreated wood is processed<br />

without any loss of aroma and is perfectly<br />

fractionated to enable optimum smoke<br />

production, suitable for just-in-time, stateof-the-art<br />

smoking facilities. The HACCP<br />

certification of RÄUCHERGOLD ® smoking<br />

chips ensures full compliance with all<br />

<strong>food</strong> standards during the entire smoking<br />

process.<br />

RÄUCHERGOLD ® cherry wood products<br />

are the perfect addition to the extensive<br />

RÄUCHERGOLD ® portfolio of beech, alder,<br />

oak and spruce.<br />

fmt<br />

Your newsletter registration at:<br />

www.harnisch.com<br />

Digital as usual.<br />

The newsletter of Dr. Harnisch Publications<br />

Always know the latest news? In addition to our<br />

information and exclusive content from various<br />

print magazines, we will keep you up to date with<br />

industries. You can register for the newsletter at:<br />

20 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • June <strong>2021</strong><br />

our newsletter free of charge. Receive current<br />

www.harnisch.com

Processing<br />

We understand how you strive for constant<br />

product quality and optimized costs.<br />

CONSISTENT<br />

+ CONFIDENT<br />

You are poised to meet your safety and quality requirements<br />

while optimizing resources and securing process repeatability.<br />

Liquitrend QMW43 – Continuous inline measurement of build-up and liquid conductivity<br />

to increase plant availability<br />

• Detailed data about possible buildup and media conductivity without<br />

the need to open up the tank<br />

• Continuous measurement values optimize the use of your cleaning<br />

resources condition-based and reduce the process time to a minimum<br />

• Reliable, repeatable and accurate measurement independent of media<br />

properties for ease of use<br />

Key No. 96342<br />

Do you want to learn more?<br />

www.endress.com/qmw43<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • June <strong>2021</strong><br />

21

Processing<br />

Quality is a Nice Feeling<br />

Unilever Chooses Checkweighers<br />

The Unilever company is one of the world’s most important branded goods manufacturers. Each day, 2.5<br />

billion people use Unilever products. With 400 brands in over 14 categories, no other company touches the<br />

everyday lives of so many people in so many different ways. The 25 small symbols – tucked away in the<br />

logo – show the company’s numerous business areas. Production ranges from <strong>food</strong>stuffs and cosmetics to<br />

body care, as well as household and fabric care, products. The company has 161,000 employees in over 100<br />

countries around the world.<br />

Its fundamental principles include<br />

beneficial relationships with suppliers<br />

and business partners. So it’s not<br />

without good reason that the company<br />

relies on multihead weighers from<br />

MULTIPOND for weighing a diverse<br />

range of products. A new type MP-<br />

36-400-400-C multihead weigher has<br />

recently been acquired for the site in<br />

Heilbronn, Germany. Gunter Löffler,<br />

Project Engineer, justified the decision:<br />

“The MULTIPOND brand stands for the<br />

highest level of quality worldwide. Our<br />

past experience has been all good, and<br />

so MULTIPOND was our first choice<br />

from the outset.”<br />

Thanks to its multi-flexible design,<br />

the multihead weigher is able to<br />

gently weigh a highly diverse range<br />

of products, from mushrooms and<br />

vegetables to powdered products such<br />

as instant soup ingredients or ready-touse<br />

products.<br />

The system operates based on the<br />

principle of combining partial<br />

portions. The product is supplied from<br />

the top level of a MULTIPOND cross<br />

head feeder, which in turn feeds the<br />

multihead weigher. Once at the top<br />

on the weigher, the product is first<br />

conveyed to the prefeed hoppers via<br />

the radially positioned feed trays and<br />

then to the weigh hoppers below.<br />

Using the partial portions, a computer<br />

determines the best combination to<br />

achieve or come closest to the targeted<br />

weight. The finished, precisely weighed<br />

portions are then discharged into the<br />

the timing hoppers via the two outlets<br />

and finally to the floor-mounted form<br />

fill seal machine. Maximum accuracy<br />

and availability are ensured by the<br />

calibration systems integrated into<br />

each proprietary load cell. MULTIPOND<br />

is the only manufacturer of multihead<br />

weighers anywhere in the world that<br />

offers this solution. The system works<br />

fully-automatically, continuously and<br />

without production interruption.<br />

The target weight is up to 70 g, the<br />

achieved mean value, the decisive<br />

criterion for the existing giveaway,<br />

actually corresponding to the target<br />

weight to be achieved.<br />

Due to the output potential of the<br />

downstream packaging machine, the<br />

weigher runs with an output of up<br />

to 220 weighings per minute. The<br />

28-head weigher originally offered by<br />

MULTIPOND would have been adequate.<br />

However, Unilever had already<br />

considered future plans in the machine<br />

design, hence the decision for a 36-head<br />

weigher. In the long-term, the packaging<br />

machine is also to be replaced to be able<br />

to utilize the full output potential of 240<br />

packs per minute.<br />

Because the product is changed several<br />

times a day, it is vital that all productcarrying<br />

parts can be removed quickly<br />

and easily without tools for cleaning and<br />

maintenance.<br />

The systems are controlled and operated<br />

using a convenient color touchscreen<br />

monitor. Easy-to-use controls make<br />

working with the systems uncomplicated.<br />

According to the employees, learning<br />

to operate the machines is quick and<br />

unproblematic - an important criterion<br />

for Unilever.<br />

Photos: Multipond<br />

Simple operation, precise weigher<br />

results and faster speeds create an ideal<br />

platform for further optimizing the<br />

company’s processes. The weigher was<br />

designed to allow special dust enclosures<br />

to be retrofitted at anytime. During the<br />

weighing process, products such as soup<br />

ingredients, powder or granulates in<br />

particular whirl up a huge amount of<br />

dust, and this collects on the units.<br />

According to Gunter Löffler, Project<br />

Engineer, the cooperation between<br />

22 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • June <strong>2021</strong>

Packaging<br />

Unilever and MULTIPOND is incredibly<br />

smooth: “Having solutions that are<br />

tailored exactly to the conditions<br />

and requirements of our production<br />

facility is extremely important to<br />

us. That’s how we know we are in<br />

the right hands with MULTIPOND.<br />

Ultimately, the conditions differ<br />

from product to product. In case of<br />

problems, we contact the specialists<br />

at MULTIPOND and get the perfect<br />

solution within the shortest possible<br />

response time.”<br />

MULTIPOND has been an ownermanaged<br />

German company since the<br />

very beginning. Drawing on more<br />

than 70 years’ experience in industrial<br />

weighing technology, we are a pioneer<br />

in this sector. Our success<br />

is based on the high quality and<br />

excellent technical standard of our<br />

weighing systems. We consciously<br />

commit to a high level of vertical<br />

integration, as well as production<br />

focus has become our corporate<br />

maxim. A team of more than 300<br />

employees commits worldwide to<br />

offer our customers from the <strong>food</strong><br />

and non-<strong>food</strong> sectors optimized,<br />

unique solutions tailored exactly<br />

to their requirements at all times.<br />

Sales, project planning and service<br />

are handled by the headquarters in<br />

Germany, by the four subsidiaries in<br />

France, the Netherlands, England and<br />

the USA, and by a worldwide network<br />

of agents.<br />

exclusively in Germany. Customer fmt<br />

STARCH IS LIKE<br />

GOLD<br />

THE IDEAL<br />

RAW MATERIAL<br />

FOR MEAT<br />

SUBSTITUTES<br />

Profit from a real boom market –<br />

with Zeppelin!<br />

DYMOMIX ®<br />

Vegetarian <strong>food</strong>s, such as meat substitutes,<br />

are fully in trend. Profit from this and<br />

increase your success. With maximum<br />

efficiency and quality – through<br />

innovative technology from Zeppelin!<br />

Key No. 99398<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • June <strong>2021</strong> 23<br />

zeppelin-systems.com

Processing<br />

Bulk Bag Discharger Ups Efficiency of<br />

Cocoa Powder line<br />

From locally grown cocoa<br />

beans, Singapore-listed JB Cocoa<br />

manufactures and markets cocoa<br />

butter, cocoa powder and cocoa<br />

mass. Located 30 km from the port<br />

of Surabaya in the province of East<br />

Java, Indonesia, JB Cocoa’s facility can<br />

process 50,000 tonnes of cocoa beans<br />

annually.<br />

The beans are cleaned, roasted and<br />

winnowed to separate the cocoa nibs,<br />

which are treated to enhance flavor<br />

and color. The nibs are then ground<br />

into cocoa liquor, which is squeezed<br />

by a “butter press” to yield cocoa<br />

butter used in making chocolate, and<br />

crumbled cocoa “presscake” that is<br />

pulverized into cocoa powder.<br />

A portion of the presscake is shipped<br />

directly to customers in 1 tonne bulk<br />

bags, but most is processed into cocoa<br />

powder and packaged in handheld<br />

sacks.<br />

Rapid discharging from bulk bags<br />

dust-free<br />

To increase efficiency of the cocoa<br />

powder line, the plant installed a<br />

installed a Flexicon BULK-OUT ® BFC-<br />

C-X bulk bag discharger to handle<br />

loose cocoa presscake being put in<br />

storage before being reduced to<br />

powder and packaged for customers<br />

The discharger is configured with an<br />

electric hoist and trolley that ride on<br />

a cantilevered I-beam, allowing bulk<br />

bags to be loaded into the frame<br />

without the need for a forklift.<br />

To connect a bag, the operator slips<br />

the bag straps into four Z-Clip strap<br />

holders of a bag lifting frame, and<br />

Photos: Flexicon<br />

24 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • June <strong>2021</strong>

Processing<br />

uses a pendant to hoist the bag into<br />

the discharger frame. A Tele-Tube<br />

telescoping tube pneumatically raises<br />