food Marketing & Technology 3/2021

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Packaging<br />

How to Make Three out of Two – More<br />

Sustainable Packaging of Deli Products<br />

Achieving better climate protection through more sustainable use of resources is a global challenge, but <strong>food</strong><br />

manufacturers have a special responsibility here. Packaging made of plastic protects the product against<br />

spoilage throughout its entire shelf life, as well as against damage during storage and transport, thus<br />

ensuring safer and longer- lasting <strong>food</strong>. The downside: according to the European Commission, citizens in<br />

Europe produce 25 million tonnes of plastic waste each year. The European Strategy for Plastics in a Circular<br />

Economy by the European Commission intends to lay the foundation for a new and sustainable plastics<br />

industry. One of the aims of this strategy is to change the way plastic packaging is handled within the<br />

European Union. However, there are a number of <strong>food</strong> applications for which there currently is no suitable<br />

alternative to plastic. Especially in the segment of delicacies, for example when packaging products such<br />

as salads, antipasti, sea<strong>food</strong>, cheese or meat, often only plastic packaging can provide the required product<br />

safety. The challenge for manufacturers lies in finding functional, yet at the same time more sustainable<br />

packaging systems that combine ecological and economic aspects.<br />

In case of deli products, trays with<br />

reclosable lids are a common sight. This<br />

packaging system allows for convenient<br />

handling, safe storage of opened packs<br />

and excellent protection of the product<br />

against premature deterioration. Such<br />

trays are often supplied with a snapon<br />

lid, in addition to the top film that<br />

provides the hermetic seal. “This third<br />

component, however, clearly contradicts<br />

with the general pursuit for plastic<br />

reduction”, as Marcel Veenstra, <strong>Marketing</strong><br />

& Communications Manager at Sealpac<br />

International, explains. SEALPAC, a<br />

leading global supplier of traysealers<br />

and thermoformers, as well as innovator<br />

in packaging technologies, sees itself<br />

as a pioneer. “For some time now, our<br />

research and development activities have<br />

been focused on the optimization of<br />

conventional packaging systems towards<br />

more sustainable alternatives, leading to<br />

innovative solutions such as FlatSkin ® and<br />

eTray ® . Our developments always follow<br />

the same premise: they must be technically<br />

feasible, but also economically viable.”<br />

EasyLid ® – savings across the<br />

entire chain<br />

SEALPAC successfully introduced a whole<br />

new packaging system several years<br />

ago, which is now receiving increased<br />

attention due to the discussion about<br />

plastic waste: EasyLid ® . The concept,<br />

developed together with Naber Plastics,<br />

a well-known injection-moulding<br />

company in the Netherlands, is suitable<br />

for modified atmosphere packaging,<br />

making it ideal for delicacies. In short,<br />

EasyLid ® is a tray-sealing technology<br />

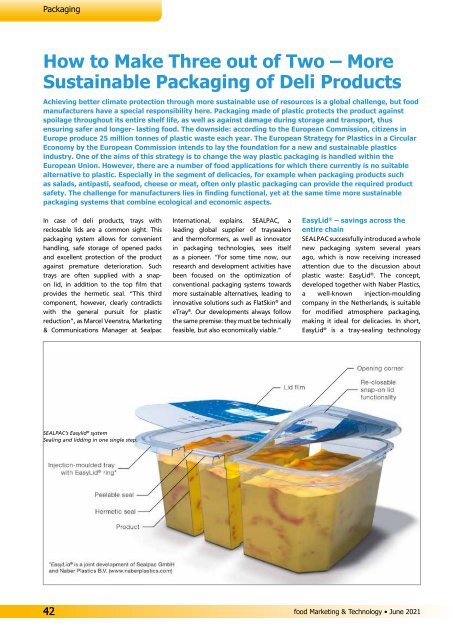

SEALPAC’s Easylid ® system<br />

Sealing and lidding in one single step.<br />

42<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • June <strong>2021</strong>