Laboratoire National des Champs Magnétiques Pulsés CNRS – INSA

Laboratoire National des Champs Magnétiques Pulsés CNRS – INSA

Laboratoire National des Champs Magnétiques Pulsés CNRS – INSA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

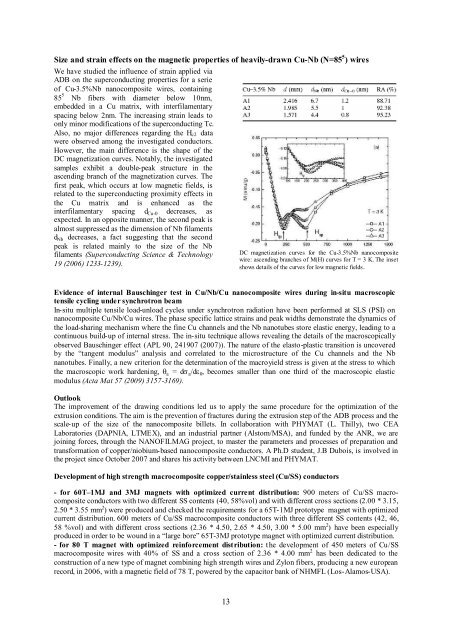

Size and strain effects on the magnetic properties of heavily-drawn Cu-Nb (N=85 5 ) wires<br />

We have studied the influence of strain applied via<br />

ADB on the superconducting properties for a serie<br />

of Cu-3.5%Nb nanocomposite wires, containing<br />

85 5 Nb fibers with diameter below 10nm,<br />

embedded in a Cu matrix, with interfilamentary<br />

spacing below 2nm. The increasing strain leads to<br />

only minor modifications of the superconducting Tc.<br />

Also, no major differences regarding the Hc2 data<br />

were observed among the investigated conductors.<br />

However, the main difference is the shape of the<br />

DC magnetization curves. Notably, the investigated<br />

samples exhibit a double-peak structure in the<br />

ascending branch of the magnetization curves. The<br />

first peak, which occurs at low magnetic fields, is<br />

related to the superconducting proximity effects in<br />

the Cu matrix and is enhanced as the<br />

interfilamentary spacing d Cu-0 decreases, as<br />

expected. In an opposite manner, the second peak is<br />

almost suppressed as the dimension of Nb filaments<br />

d Nb decreases, a fact suggesting that the second<br />

peak is related mainly to the size of the Nb<br />

filaments (Superconducting Science & Technology<br />

19 (2006) 1233-1239).<br />

13<br />

DC magnetization curves for the Cu-3.5%Nb nanocomposite<br />

wire: ascending branches of M(H) curves for T = 3 K. The inset<br />

shows details of the curves for low magnetic fields.<br />

Evidence of internal Bauschinger test in Cu/Nb/Cu nanocomposite wires during in-situ macroscopic<br />

tensile cycling under synchrotron beam<br />

In-situ multiple tensile load-unload cycles under synchrotron radiation have been performed at SLS (PSI) on<br />

nanocomposite Cu/Nb/Cu wires. The phase specific lattice strains and peak widths demonstrate the dynamics of<br />

the load-sharing mechanism where the fine Cu channels and the Nb nanotubes store elastic energy, leading to a<br />

continuous build-up of internal stress. The in-situ technique allows revealing the details of the macroscopically<br />

observed Bauschinger effect (APL 90, 241907 (2007)). The nature of the elasto-plastic transition is uncovered<br />

by the “tangent modulus” analysis and correlated to the microstructure of the Cu channels and the Nb<br />

nanotubes. Finally, a new criterion for the determination of the macroyield stress is given at the stress to which<br />

the macroscopic work hardening, � a = d� a/d� 0, becomes smaller than one third of the macroscopic elastic<br />

modulus (Acta Mat 57 (2009) 3157-3169).<br />

Outlook<br />

The improvement of the drawing conditions led us to apply the same procedure for the optimization of the<br />

extrusion conditions. The aim is the prevention of fractures during the extrusion step of the ADB process and the<br />

scale-up of the size of the nanocomposite billets. In collaboration with PHYMAT (L. Thilly), two CEA<br />

Laboratories (DAPNIA, LTMEX), and an industrial partner (Alstom/MSA), and funded by the ANR, we are<br />

joining forces, through the NANOFILMAG project, to master the parameters and processes of preparation and<br />

transformation of copper/niobium-based nanocomposite conductors. A Ph.D student, J.B Dubois, is involved in<br />

the project since October 2007 and shares his activity between LNCMI and PHYMAT.<br />

Development of high strength macrocomposite copper/stainless steel (Cu/SS) conductors<br />

- for 60T<strong>–</strong>1MJ and 3MJ magnets with optimized current distribution: 900 meters of Cu/SS macrocomposite<br />

conductors with two different SS contents (40, 58%vol) and with different cross sections (2.00 * 3.15,<br />

2.50 * 3.55 mm 2 ) were produced and checked the requirements for a 65T-1MJ prototype magnet with optimized<br />

current distribution. 600 meters of Cu/SS macrocomposite conductors with three different SS contents (42, 46,<br />

58 %vol) and with different cross sections (2.36 * 4.50, 2.65 * 4.50, 3.00 * 5.00 mm 2 ) have been especially<br />

produced in order to be wound in a “large bore” 65T-3MJ prototype magnet with optimized current distribution.<br />

- for 80 T magnet with optimized reinforcement distribution: the development of 450 meters of Cu/SS<br />

macrocomposite wires with 40% of SS and a cross section of 2.36 * 4.00 mm 2 has been dedicated to the<br />

construction of a new type of magnet combining high strength wires and Zylon fibers, producing a new european<br />

record, in 2006, with a magnetic field of 78 T, powered by the capacitor bank of NHMFL (Los-Alamos-USA).