Laboratoire National des Champs Magnétiques Pulsés CNRS – INSA

Laboratoire National des Champs Magnétiques Pulsés CNRS – INSA

Laboratoire National des Champs Magnétiques Pulsés CNRS – INSA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

High magnetic field development<br />

Magnet development outcome: 2005/2009<br />

From 2005 to 2009, the magnetic field available to researchers at the LNCMI has been increased<br />

from 28 teslas in a 50 mm bore to 35 teslas in a 34 mm diameter bore. This result was obtained by<br />

developing the polyhelix technology. The helix technology developed in Grenoble has proved to be able to<br />

produce the highest continuous resistive field in the world. Undergoing project is the preparation of a magnet<br />

with B > 30 teslas in a 50 mm bore and the standardization of the three sites 20 MW sites of the LNCMI<br />

(M8, M9, M10) so that they could accept any high field insert. Critical points of construction have been<br />

patented end 2007 by the laboratory to protect this efficient technology 1 . It consists of the optimization and<br />

realization of patterns in the helix cut itself. This construction procedure is suitable to form windings well<br />

adapted for electromagnet <strong>des</strong>ign (using metal alloys or massive superconductors) as the cut’s pattern can be<br />

optimized to hold mechanical constraints that originated from electromagnetic and/or thermal constraints.<br />

Such a <strong>des</strong>ign has been tested first in the 32 T magnet and is now fully operational in the 35 T magnet.<br />

Table 1: The “high field” status of the LNCMI facility<br />

Magnet site Magnetic field Remarks<br />

M9 35 T in 34 mm World record for resistive magnet (March 2009)<br />

M10 28 T in 50 mm B > 30 T planned for 2010<br />

M8 19 T in 160 mm<br />

From 2010, the configuration will be available on M9 and M10, M8 site<br />

will then be free for the 42 T hybrid project<br />

M1/M6 23 T in 50 mm Field available on two sites, 25 T version for 2010<br />

M7 20 T in 50 mm Dedicated to applied superconductivity<br />

M5 13 T in 130 mm Mainly applied superconductivity and magneto-sciences<br />

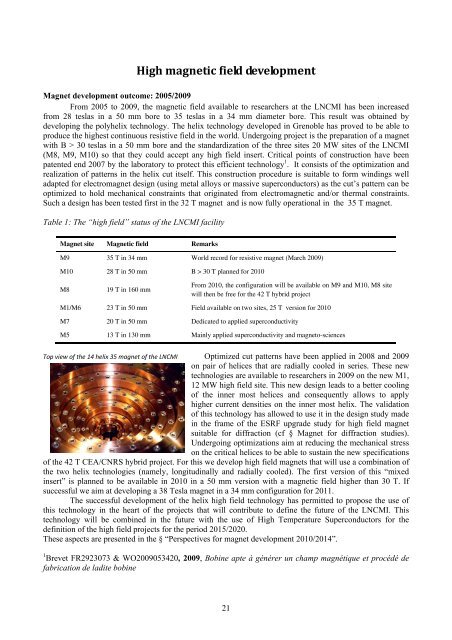

Top view of the 14 helix 35 magnet of the LNCMI Optimized cut patterns have been applied in 2008 and 2009<br />

on pair of helices that are radially cooled in series. These new<br />

technologies are available to researchers in 2009 on the new M1,<br />

12 MW high field site. This new <strong>des</strong>ign leads to a better cooling<br />

of the inner most helices and consequently allows to apply<br />

higher current densities on the inner most helix. The validation<br />

of this technology has allowed to use it in the <strong>des</strong>ign study made<br />

in the frame of the ESRF upgrade study for high field magnet<br />

suitable for diffraction (cf § Magnet for diffraction studies).<br />

Undergoing optimizations aim at reducing the mechanical stress<br />

on the critical helices to be able to sustain the new specifications<br />

of the 42 T CEA/<strong>CNRS</strong> hybrid project. For this we develop high field magnets that will use a combination of<br />

the two helix technologies (namely, longitudinally and radially cooled). The first version of this “mixed<br />

insert” is planned to be available in 2010 in a 50 mm version with a magnetic field higher than 30 T. If<br />

successful we aim at developing a 38 Tesla magnet in a 34 mm configuration for 2011.<br />

The successful development of the helix high field technology has permitted to propose the use of<br />

this technology in the heart of the projects that will contribute to define the future of the LNCMI. This<br />

technology will be combined in the future with the use of High Temperature Superconductors for the<br />

definition of the high field projects for the period 2015/2020.<br />

These aspects are presented in the § “Perspectives for magnet development 2010/2014”.<br />

1Brevet<br />

FR2923073 & WO2009053420, 2009, Bobine apte à générer un champ magnétique et procédé de<br />

fabrication de ladite bobine<br />

21