National Hardwood Magazine - January 2022

In the new issue of the National Hardwood Magazine, get a look ahead at the new year, the furniture sales boom and much more.

In the new issue of the National Hardwood Magazine, get a look ahead at the new year, the furniture sales boom and much more.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

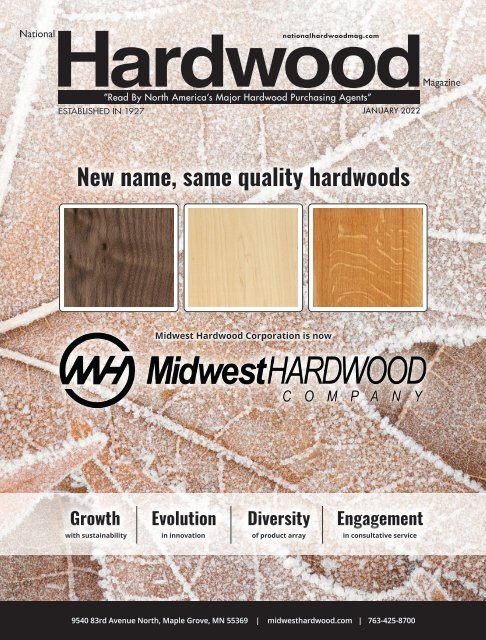

New name, same quality hardwoods<br />

Midwest <strong>Hardwood</strong> Corporation is now<br />

Growth Evolution Diversity Engagement<br />

with sustainability in innovation of product array in consultative service<br />

JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE 1<br />

9540 83rd Avenue North, Maple Grove, MN 55369 | midwesthardwood.com | 763-425-8700

More Efficient,<br />

By Design<br />

Manage orders and inventory in real-time with Agility ERP. Turn<br />

complicated tasks into simple steps. That’s how you supercharge<br />

your team and get things done.<br />

Learn more at DMSi.com<br />

2 JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE

Midwest <strong>Hardwood</strong> Corporation is now<br />

with sustainability in innovation of product array in consultative service<br />

9540 83rd Avenue North, Maple Grove, MN 55369 | midwesthardwood.com | 763-425-8700<br />

New name, same quality hardwoods<br />

About The Cover<br />

MIDWEST HARDWOOD<br />

COMPANY<br />

Contents<br />

<strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong> JANUARY <strong>2022</strong> Volume 95 No. 13<br />

Features & Industry Events<br />

Midwest <strong>Hardwood</strong> Corporation is<br />

now Midwest <strong>Hardwood</strong> Company,<br />

a new name, but not a new purpose.<br />

Growth Evolution Diversity Engagement<br />

Our mission remains as does our<br />

commitment to our customers. Our<br />

next step into the future is solidly in<br />

place now with the recent acquisition of Midwest <strong>Hardwood</strong>.<br />

We will boldly go forward with these concepts in mind;<br />

Sustainable growth, responsibly and reliably. Evolution driven<br />

by innovation to service the everchanging marketplace for<br />

quality hardwoods. We will continue to build our diverse<br />

product array in forms that service our customers so they<br />

too are better equipped to thrive. And lastly, we will strongly<br />

engage, consultatively, with our customers and supplier<br />

partners. We appreciate your continued loyalty as we<br />

celebrate our 40th anniversary, and now set out to build a<br />

new history as Midwest <strong>Hardwood</strong> Company.<br />

www.midwesthardwood.com<br />

email: info@midwesthardwood.com<br />

18<br />

20<br />

22<br />

24<br />

Cabinet Door Shop - Best Quality<br />

And Pricing Makes A Family Proud<br />

Purchasing Approximately 5 Million<br />

Board Feet Of Lumber, DIXIEPLY<br />

Delivers Throughout U.S.A.<br />

Laser-Focused Service At Paw Taw<br />

John Services Inc.<br />

U.S. Furniture Makers Report Sales<br />

Boom<br />

26<br />

Equipment And Services Providers<br />

To The <strong>Hardwood</strong> Lumber Industry<br />

See Challenges – And Opportunity<br />

– Abounding In <strong>2022</strong><br />

Departments<br />

4 <strong>Hardwood</strong> Calendar<br />

6 U.S.A. Trends<br />

8 Canadian Trends<br />

10 News Developments<br />

12 HMA Update<br />

34<br />

36<br />

44<br />

14 AHEC Report<br />

15 <strong>Hardwood</strong> Federation<br />

Info<br />

16 WCMA Insights<br />

17 NHLA News<br />

Federal Reserve: Taper Begins<br />

Appalachian Lumbermen Learn<br />

About Advocacy And Promotion<br />

Eleven Students Graduate From<br />

196th Class Of The NHLA Inspector<br />

Training School<br />

54 Who’s Who<br />

56 Trade Talk<br />

18<br />

62 Classified Profit<br />

Opportunities<br />

64 Advertisers Index<br />

Founded in 1927 by: O.L. Miller – 1894-1963<br />

Publisher: Paul J. Miller – 1963-2010<br />

• Forest Products Export Directory • Imported Wood Purchasing Guide<br />

• Import/Export Wood Purchasing News • <strong>Hardwood</strong> Purchasing Handbook<br />

• Green Books’s <strong>Hardwood</strong> Marketing Directory<br />

• Green Books’s Softwood Marketing Directory<br />

• The Softwood Forest Products Buyer<br />

Paul J. Miller Jr. – President<br />

Terry Miller – Vice President<br />

Zach Miller – Sales<br />

Sue Putnam – Editor<br />

Matthew Fite – Staff Writer<br />

Lydian Kennin – Who’s Who Coordinator<br />

Rachael Stokes – Graphic Artist<br />

Pamela McFarland – Graphic Artist<br />

Tammy Daugherty – Production Manager<br />

Jennifer Trentman – Green Book Market Sales<br />

Lisa Carpenter – Circulation Manager<br />

Lexi Hardin – Subscription & List Services<br />

ADVERTISING OFFICES:<br />

5175 Elmore Rd., Suite 23, Memphis, TN 38134<br />

901-372-8280 FAX: 901-373-6180<br />

Reach us via the Internet at: www.nationalhardwoodmag.com<br />

E-mail addresses:<br />

ADVERTISING: tammy@millerwoodtradepub.com<br />

EDITORIAL: editor@millerwoodtradepub.com<br />

SUBSCRIPTIONS: circ@millerwoodtradepub.com<br />

EDITORIAL CORRESPONDENTS:<br />

Chicago, Los Angeles, High Point, Grand Rapids, Portland, Toronto<br />

Controlled circulation postage paid at Memphis, TN<br />

(USPS #917-760)<br />

The NATIONAL HARDWOOD MAGAZINE (ISSN 0194-0910) is published<br />

monthly, except for two issues in December, for $55.00 per year and<br />

$65.00 (U.S. dollars) per year for Canada by <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>, Inc.,<br />

5175 Elmore Rd., Suite 23, Memphis, TN 38134. Periodicals Postage paid at<br />

Memphis, TN, and at additional mailing offices.<br />

POSTMASTER: Send address changes to <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>,<br />

P.O. Box 34908, Memphis, TN 38184.<br />

Publications mail agreement No. 40739074.<br />

Return undeliverable Canadian addresses to:<br />

P.O. Box 503, RPO W. Beaver Cre., Rich-Hill, ON L4B 4R6.<br />

The publisher reserves the right to accept or reject editorial<br />

content and Ads at the staff’s discretion.<br />

2 JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE 3

HARDWOOD CALENDAR<br />

INDUSTRIES<br />

CONTROLS<br />

CLEEREMAN LUMBER COMPANY 1930’s CLEEREMAN INDUSTRIES 1955 CLEEREMAN CONTROLS 2019<br />

<strong>January</strong><br />

Appalachian Lumbermen’s Club, Meeting, The<br />

Grove Park Inn, Asheville, NC.<br />

www.lumberclub.org. Jan. 11.<br />

Lake States Lumber Association, Annual<br />

Winter Meeting, Tundra Lodge Resort, Green<br />

Bay, WI. www.lsla.com. Jan. 19-21.<br />

February<br />

Indiana <strong>Hardwood</strong> Lumbermen’s Association,<br />

Convention, Marriott Indianapolis Downtown,<br />

Indianapolis, IN. www.ihla.org. Feb. 7-9.<br />

<strong>National</strong> Association of Home Builders,<br />

International Builders’ Show (IBS), Orange<br />

County Convention Center, Orlando, FL.<br />

Feb. 8-10. n<br />

CLEEREMAN<br />

TODAY<br />

For optimal efficiency. . .<br />

knows what a sawmill needs:<br />

Now, TWO ENTITIES TO SERVE YOU BETTER!<br />

CLEEREMAN the newest name in sawmill controls and optimization<br />

CLEEREMAN The most trusted name in carriages<br />

n Over 1200 Carriages sold<br />

n Lowest cost of ownership<br />

n All parts in stock and reasonably priced<br />

n In-house engineering department<br />

n Everything from single piece equipment to<br />

turn-key mills<br />

n Simple easy to use touch<br />

screen with additional<br />

tactile buttons<br />

n Remote access for<br />

troubleshooting<br />

n No custom electrical<br />

hardware, all parts are<br />

off-the-shelf components<br />

n Industry Standard<br />

JoeScan X6 heads<br />

n 3D data used for<br />

opening the log and<br />

estimating the back of<br />

log profile<br />

n Realistic views of the log<br />

n Sure Grip Joystick<br />

handles<br />

n Operational statistics and<br />

reports<br />

n Over 65 systems sold<br />

4 JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE<br />

STEFAN DRACOBLY<br />

President Of<br />

Controls<br />

PAUL CLEEREMAN<br />

VP Cleereman<br />

Industries & Controls<br />

Sales<br />

DAN TOOKE<br />

Senior Optimization<br />

& Controls Engineer<br />

Cleereman Industries<br />

and Cleereman Controls<br />

715-674-2700<br />

www.cleereman.com<br />

info@cleereman.com

U.S.A. TRENDS<br />

Supplier news about<br />

sales, labor, prices, trends,<br />

expansions and inventories<br />

LAKE STATES<br />

NORTHEAST<br />

SOUTHEAST<br />

WEST COAST<br />

Lumber movement in the Lake States region was described<br />

recently as favorable.<br />

The co-owner of a Wisconsin sawmill characterized<br />

the market as fine. “I would say the market overall is<br />

good,” he reported. “Everything for the most part is selling<br />

and at pretty decent prices.”<br />

The market was better six months ago, he commented.<br />

“Some of the cavities got filled up,” he quipped. “A<br />

lot has to do with exporting. Right now, I can export anything<br />

I want, probably, but the customers aren’t willing to<br />

pay the prices of what I want now, so I’m holding out.”<br />

The Badger State operation manufactures Red and<br />

White Oak, Hard and Soft Maple, Basswood, as well<br />

as Ash and Cherry. Hard and Soft Maple sell best with<br />

Basswood also coming in well, he said. “Everything is<br />

moving really fast,” he described. “My Red Oak, the upper<br />

grades, is probably the slowest in sales. White Oak<br />

is much stronger.” The mill sells mostly 4/4 but also does<br />

some 5/4.<br />

The operation’s distribution yard and end user customers<br />

tell him their sales are strong. “I could probably have<br />

more sales if they could find more labor,” he remarked.<br />

“Since the market’s been strong after COVID, once we<br />

got through that and the market got strong, labor has<br />

been a real issue for my customers. I know a lot of people<br />

in different businesses. I do not know where there is<br />

not a shortage of labor.”<br />

Movement remained steady at an Indiana sawmill.<br />

“The market is probably a little slower than six months<br />

ago,” said the lumber source. The market was moving<br />

“pretty hot” at that point. The first couple months of this<br />

year were busy, and in November, the mill was still doing<br />

well with its orders,” he said.<br />

“Log inventories seem to be lower than I would like<br />

them to be but K/D (kiln dried lumber)-wise, everything<br />

is moving steady as long as you can get trucks under it,”<br />

the contact commented.<br />

Because it’s slow moving, Cherry has been “the dog,”<br />

while Walnut seems to be doing “pretty well” as well as<br />

White Oak. Poplar has had some pushback on price, but<br />

it’s still moving and going out the door strong, he said.<br />

“Hickory is strong, Red Oak is steady. Everything seems<br />

to be moving well.”<br />

Most of the lumber we sell is to distributors and end<br />

user customers in 4/4 through 8/4.<br />

In general, trucking remains tight. “Outside trucks are<br />

The <strong>Hardwood</strong> lumber markets in the Northeast remain<br />

strong, according to sources contacted.<br />

In recent weeks, the lumber market was trending well,<br />

said the president and sales manager of a Pennsylvania<br />

firm. “The market has been moving fairly quickly,” he<br />

said. “Just when you think things may be slowing down<br />

a tad bit, they creep back up again and people focus on<br />

the items they need very quickly.”<br />

Production numbers are still not where they have<br />

been and may never return to historical numbers, he<br />

commented. “For the year that started September 2020<br />

for the cycle now, what we’ve been going through is not<br />

normal. Prices just shot up. <strong>Hardwood</strong> prices have been<br />

on or near recessionary pricing. Prices have gotten to<br />

where they should be in order for operations to remain<br />

profitable. Many companies would not be in business today<br />

if we didn’t see where prices are at now.”<br />

He said he foresees a lot of good business to carry on<br />

at least through the third or fourth quarter of <strong>2022</strong>. Hard<br />

and Soft Maple and Poplar are selling well with Hickory<br />

decent. “Red Oak and Cherry are definitely undervalued<br />

now,” he said. “Those items have the most potential to<br />

rise in price once buyers take a look and think they might<br />

be a nice option to use.”<br />

The company also sells White Oak and Ash to distributors<br />

and millwork, furniture and cabinet makers.<br />

Because of a wet fall and a low area log supply, raw<br />

material availability has been very tight, he said. The<br />

cost of import containers remains expensive. To fill justin-time<br />

inventories, he believes buyers who were using<br />

some imported woods may consider turning more to domestic<br />

species because of availability and high freight<br />

costs.<br />

Business has returned to normal for the owner of a<br />

New York sawmill. “It’s not hotter than a pistol, but not<br />

slower than slow,” he remarked. “I would describe the<br />

market as medium. It’s not hot and not cold. It has slowed<br />

a tad from where it was a month ago.”<br />

The market is worse than six months ago, he reported.<br />

Production has started to catch up with demand, only<br />

because he believes demand isn’t as robust as before,<br />

he added.<br />

The company mills Red and White Oak and Hard Maple<br />

for end users and distributors with Maple selling best.<br />

The company sells 4/4-8/4.<br />

Overall, transportation isn’t causing problems, except<br />

Southeastern lumber representatives reported strong<br />

market activity in recent weeks.<br />

For a Georgia sawmill that processes wood in two<br />

states, the market is doing well. “Business is good,” said<br />

the sales manager. After a bit of a fallback on prices,<br />

the prices over the last 90 days seem, in most cases, to<br />

have bottomed and rebounded. “Maybe not to the point<br />

to where they were before they softened, but cryin’ out<br />

loud, lumber was at such record prices we knew at some<br />

point in time they had to come down,” he commented.<br />

The Common Red Oak market is good while all the<br />

White Oak markets remain favorable.<br />

The executive said he expected his FAS Red Oak markets<br />

to return to where they need to be. All his No. 2<br />

Common Poplar was spoken for through the first of <strong>January</strong>,<br />

to be sold as it comes through the system and gets<br />

dressed and gets put-up and ready for shipments. The<br />

operation also sells small amounts of Ash and Cherry to<br />

its customers, which include flooring and pallet manufacturers<br />

and <strong>Hardwood</strong> distribution yards.<br />

“When you look at the overall book of business, we are<br />

not in a position to where you have to worry about selling<br />

those six loads of FAS Red Oak,” he quipped. “We’re not<br />

out looking to have a fire sale on any of that stuff. We<br />

are just looking for the next good business that comes<br />

our way.”<br />

Because of weather changes, logging until March will<br />

be difficult at best, he cautioned. “It will have some effect<br />

on our business, too,” he predicted.<br />

“The flooring markets are still bullish and still strong,”<br />

he assessed. “They’re helping prop-up the back end of<br />

the sawmill.”<br />

The operation cuts 4/4 lumber for White Oak, 4/4 and<br />

5/4 for Red Oak and 4/4 to 10/4 for Poplar.<br />

In Arkansas, the president of a <strong>Hardwood</strong> flooring<br />

manufacturer who sells to wholesale flooring distributors<br />

throughout the U.S. characterized the flooring market as<br />

robust. “Demand for flooring exceeds supply,” he said.<br />

“It’s better than it was six months ago. It’s at the top.”<br />

The equation remains favorable. “Flooring demand in<br />

relation to supply is about as tight of a market right now<br />

as you could get,” he said. “It will likely become looser<br />

slowly over time and the less differential between supply<br />

and demand.”<br />

The firm buys No. 1, 2, and 3A Red and White Oak.<br />

Labor is still the main factor effecting his business and<br />

The market was strong recently along the West Coast,<br />

said the sales manager of an Oregon-based <strong>Hardwood</strong><br />

distribution yard. “Everything’s still strong nationally,” he<br />

said. “We are incredibly under-supplied. We are seeing<br />

really strong demand for the building construction markets,<br />

cabinetry, furniture and flooring. The industry is in<br />

a good spot, one we haven’t seen for quite a while, but it<br />

has been that way for most of the year.”<br />

The market is about the same as it was six months<br />

ago and much better than 12 to18 months ago, he said.<br />

“Most of 2021 has been pretty good,” he commented. “If<br />

anything, it’s probably starting to level some. There’s not<br />

any downward pressure I can sense.”<br />

The firm sells Ash, Cherry, Birch, Hard and Soft Maple,<br />

Red and White Oak and Poplar to distributors and manufacturers<br />

that service the cabinetry, furniture and pallet<br />

markets. It sells primarily 4/4 and 5/4.<br />

Soft Maple is the top selling species followed closely<br />

by Hard Maple and Birch. “There’s not a dead item<br />

out there,” he remarked. “There’s really not a weak line.<br />

A couple of items like Cherry, Poplar and Red Oak are<br />

starting to level off, coming off of peaks, but they’re still<br />

better than they were 12 to 18 months ago.”<br />

Movement is going well for the operation’s customers.<br />

“Most people have order files that are extended,” he<br />

said. “There’s more concern about getting supply than<br />

what the price is now. That’s a good spot to be in. You<br />

need to make sure you can secure the volume as most<br />

people are backlogged to some degree.”<br />

Lack of labor remains an issue keeping businesses<br />

from being able to catch-up with orders. “I think the supply<br />

situation has been exacerbated by labor and other<br />

things,” he reported. “It’s keeping everything pretty tight.<br />

But, when we’re tight, we do fairly well as an industry.”<br />

Freight is more expensive whether shipping domestically<br />

or internationally. Fuel prices have escalated prices<br />

in general for anything and everything. Delays at ports<br />

are causing some grief on the export side, he added.<br />

“Fortunately, the domestic market has been okay, as<br />

we’re able to move what we want to move and when<br />

we want to move, but costs have definitely gone up,” he<br />

commented.<br />

For a Southern California distribution yard, the market<br />

“is not as fast as it was,” but remains favorable. “Customers<br />

are not in a hurry to get the orders, but still want<br />

the orders,” the company owner said. “They’re taking the<br />

Please turn to page 46 Please turn to page 46<br />

Please turn to page 47 Please turn to page 47<br />

6 JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE 7

ONTARIO<br />

CANADIAN TRENDS<br />

News from suppliers about prices, trends, sales and inventories<br />

As we head into a new year, and reflect on the past<br />

year, there were many positives for the <strong>Hardwood</strong> industry.<br />

The strong housing sector in both Canada and<br />

the U.S. helped keep businesses going, showing its<br />

resilience in spite of COVID-19 lockdowns and all the<br />

challenges it brought, along with labor shortages and<br />

delays in shipping. Also, the very strong renovation market,<br />

which is continuing, is boosting business for those in<br />

the <strong>Hardwood</strong> industry. As the borders start reopening, it<br />

is hoped that delays in shipping will be greatly reduced<br />

as we move forward into <strong>2022</strong>. Output has improved for<br />

most products such as furniture, cabinets, moulding and<br />

millwork, flooring and wood components, which is helping<br />

to meet the strong demand from housing and renovation<br />

sectors. Contacts noted Hard Maple availability<br />

continues to be tight, as for Soft Maple, Aspen and Ash.<br />

As strong housing and renovations markets continue<br />

to be strong, limited Birch production with a higher demand<br />

from these sectors reduced kiln-dried inventories.<br />

Some wholesalers and secondary manufacturers noted<br />

better sales of this species due to lower costs as compared<br />

to Soft and Hard Maple. Strong demand is pushing<br />

up prices of limited supplies of Birch, noted contacts.<br />

Some noted green supplies are also rather tight at this<br />

time.<br />

Some areas reported that the upper grades of Hard<br />

Maple are outperforming the lower grades. However,<br />

sales for most grades are good. Orders are keeping<br />

pace with production, and competition for No. 1 Common<br />

and Better is driving prices higher. Kiln-dried inventories<br />

are thin in some cases as interest remains solid.<br />

The high price of Hard Maple is aiding sales of Soft<br />

Maple, and so production of this species is not keeping<br />

pace with market needs, and kiln-dried inventories are<br />

also low at this time.<br />

Ash production was controlled moving into late fall and<br />

early winter. Markets are thin for kiln-dried inventories,<br />

commented contacts. Demand on the domestic front is<br />

steady, with international markets also holding up well.<br />

Imports from the U.S. were noted to have made strong<br />

gains in Canada in recent months, as well as to the UK.<br />

Aspen sales are based on established buyer-seller relationships.<br />

However, some noted non-traditional business<br />

is opening up as end users are looking for lower<br />

QUEBEC<br />

As we head into <strong>2022</strong>, contacts are cautiously optimistic<br />

for a better year than 2021 in the <strong>Hardwood</strong> industry.<br />

The year was filled with many challenges of the ongoing<br />

COVID-19 pandemic, but with businesses re-opening<br />

and a sense of returning to a more normal life, it is hoped<br />

the economic recovery will continue to strengthen. With<br />

the holiday season behind us, the expected slowdown<br />

of the period should pick up heading through winter and<br />

planning for early spring. It is hoped that the labor shortage<br />

being felt in most areas will improve as the economic<br />

recovery takes hold. Demand for Hard and Soft Maple,<br />

as well as Oak, are the leading species, as has been the<br />

case for some time.<br />

Red Oak sales are doing well due to the demand in the<br />

remodeling sector, flooring and stair components. Oak<br />

flooring is a favored consumer product. Production is<br />

sufficient to meet current demands, although at this time<br />

it is seasonally slower with prices noted as stable.<br />

Interest in upper grade material for White Oak is best,<br />

even though production is not high, which is putting a<br />

strain on some grades and pushing prices higher. The<br />

same is noted for kiln-dried stocks. However, prices are<br />

steady for the Common grades.<br />

Demand for green White Oak is mixed. Interest in upper<br />

grade material is best. At the same time, production<br />

is not very high, which is straining FAS and Select supplies<br />

and pressuring prices higher.<br />

Pallet and lumber cants were in great demand in 2020<br />

and 2021, where it grew for wooden pallets and raw materials<br />

faster than the supply could provide. Production<br />

has since edged up bringing supply and demand to a<br />

more balanced level.<br />

Ash sales saw an increase on domestic markets over<br />

the past year and to the U.S. Shipments are also noted<br />

as good to the Middle East and to Europe. Basswood<br />

sales have been favorable for sawmillers and wholesalers.<br />

Demand increased in 2021 due to new home construction<br />

and the renovation markets both in Canada and<br />

the U.S. Basswood was in tight supply, due to sawmills<br />

producing the higher-priced species.<br />

Exports of Cherry to China were good, which sustained<br />

this species as domestic and U.S. markets were weaker.<br />

Supply is still ahead of demand, with prices reduced<br />

slightly for this species.<br />

Production of the regionally important species Hard<br />

Maple remained high over the past year, with inventories<br />

Please turn to page 48 Please turn to page 49<br />

WE ARE GRAF BROTHERS<br />

The world’s largest manufacturer of<br />

rift & quarter sawn white oak products<br />

From logs to lumber, timber to flooring, and everything in between,<br />

consider us your sole source for all your hardwood needs.<br />

ROUGH LUMBER<br />

FLOORING INVENTORY<br />

QUALITY / LOYALTY / TRADITION<br />

8 JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE 9<br />

www.grafbro.com<br />

LOG SALES<br />

Partner with us!<br />

606-932-3117<br />

sales@grafbro.com

NEWS DEVELOPMENTS<br />

NEWS ABOUT NORTH AMERICAN INDUSTRIAL<br />

HARDWOOD CONSUMERS INCLUDING MERGERS,<br />

PLANT EXPANSIONS & ASSOCIATION ACTIVITIES<br />

WOODGENIX IS EXPANDING AND<br />

CONSOLIDATING ITS FACILITIES<br />

WoodgeniX, located in Random Lake, WI, is currently<br />

undergoing a 25,000 square foot expansion, which is expected<br />

to finish by the end of the second quarter of <strong>2022</strong>.<br />

The expansion will bring the facility to 50,000 square feet.<br />

WoodgeniX (formerly Schu Industries) is a Random Lakebased<br />

manufacturing and design company that creates<br />

high-quality wood case goods and furniture for clients in<br />

hospitality, long-term care, residential, and point of purchase<br />

markets both nationally and<br />

internationally.<br />

WoodgeniX uses solid U.S. <strong>Hardwood</strong>s,<br />

including Hard and Soft Maple,<br />

Oak and others, and manufactures<br />

its furniture only in the United<br />

States.<br />

The current project will consolidate<br />

two of their existing plants, bringing<br />

all their operations under one roof.<br />

Schu Industries launched their new<br />

brand WoodgeniX July 1, 2021. CEO<br />

Paul Golden bought the company,<br />

which has been in operation for over<br />

40 years, at the end of 2018. The new<br />

brand represents the company’s history<br />

in wood products while also alluding<br />

to what is to come for the company<br />

in terms of new technologies,<br />

materials, and markets.<br />

The expansion will create more<br />

space for new technology and equipment,<br />

helping to increase sales.<br />

Golden’s long-term goals for WoodgeniX<br />

include expanding in all of their<br />

markets and continuing to grow as a<br />

company overall.<br />

WoodgeniX serves a wide range of<br />

clients, from Fortune 500 businesses<br />

to start-ups. WoodgeniX has worked<br />

on projects for DoubleTree, Camelback<br />

Resorts, Days Inn, Ho-Chunk<br />

Casino, and other notable businesses.<br />

For more information, go to www.<br />

woodgenixllc.com.<br />

NWFA COMPLETES 58TH<br />

HOME WITH GARY SINISE<br />

FOUNDATION<br />

The <strong>National</strong> Wood Flooring Association<br />

(NWFA), headquartered in<br />

U.S. Army First Sergeant<br />

Jarrid “Jay” Collins<br />

homes for<br />

severely wounded veterans and first<br />

responders. The home dedication<br />

for United States Army First Sergeant<br />

(Ret.) Jarrid “Jay” Collins took place<br />

recently in Odessa, FL. Flooring for<br />

the project was donated by NWFA<br />

member Mannington.<br />

As a Green Beret, Collins deployed<br />

to Afghanistan, Iraq, and twice to<br />

South America. During his 2007 Afghanistan<br />

deployment, Collins was<br />

hit in the arm, continued fighting, and<br />

later helped perform surgery on himself<br />

in the field of battle. He returned<br />

to full combat operations after just 30<br />

days of recovery. A few months later,<br />

he sustained severe injuries to his<br />

leg. Collins overcame these injuries<br />

to be selected for U.S. Army Special<br />

Operations Command, but ultimately<br />

had to have his leg amputated due to<br />

the severity of his condition. Following<br />

his amputation, Collins requalified<br />

as a fully deployable Green Beret and<br />

served five more years on active duty.<br />

“First Sergeant Collins is a highly-decorated<br />

Army Special Forces<br />

combat veteran and Purple Heart recipient<br />

with more than two decades<br />

of service,” said NWFA President and<br />

CEO Michael Martin. “His dedication<br />

to serving our country is admirable,<br />

as is his commitment to not letting his<br />

injuries define his path. We’re honored<br />

to partner with Mannington to<br />

provide beautiful wood floors for his<br />

St. Louis, MO, has provided flooring<br />

for its 58th home in support<br />

of the Gary Sinise Foundation<br />

R.I.S.E. program (Restoring Independence<br />

Supporting Empowerment).<br />

The<br />

R.I.S.E. program<br />

builds<br />

custom, specially<br />

adapted<br />

smart<br />

UPGRADE YOUR<br />

OPTIMIZATION EXPERIENCE<br />

BIG enough to support your operation; small enough to care.<br />

09 Members on<br />

the software team<br />

13 Members on<br />

the controls team<br />

24/7Support<br />

with experts<br />

in 3 time zones<br />

across the globe<br />

40+Optimization<br />

systems<br />

700+ Control<br />

Systems installed<br />

worldwide<br />

new home.”<br />

In addition to the 58 homes already completed, NWFA<br />

currently is working with its members to source wood<br />

flooring for 14 additional R.I.S.E. homes in various stages<br />

704.200.2350<br />

sales@automationelecusa.com<br />

automationelecusa.com<br />

Please turn to page 51<br />

10 JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE 11

HMA UPDATE<br />

SOMETHING FOR EVERYONE AT NATCON <strong>2022</strong><br />

<br />

HMA’s <strong>2022</strong> <strong>National</strong> Conference and<br />

Expo is fast approaching, and I look<br />

forward to meeting with many of you<br />

in Florida, March 23-25. If you are new<br />

to the <strong>Hardwood</strong> industry, you may not<br />

know that this HMA event is open to<br />

all industry stakeholders. And so, I am<br />

extending to you my personal invitation.<br />

Join us at the Sandestin Golf and Beach<br />

Resort. As you will see, the Conference<br />

agenda has something for everyone.<br />

This year’s event has been designed around the theme,<br />

“Investing in the Future.” And our goal is to provide<br />

a host of events, business sessions, and networking<br />

opportunities to assist all Conference participants in<br />

accomplishing today’s goals and tomorrow’s dreams.<br />

For starters …<br />

The Opening Reception and Expo, set for the<br />

evening of Wednesday, March 23, will provide the<br />

perfect opportunity to browse the technology Expo, enjoy<br />

a sumptuous array of refreshments, plus meet, greet,<br />

network, catch-up, make new contacts, and connect with<br />

industry colleagues and old friends.<br />

And regarding business sessions for the multi-day<br />

event, I’m pleased to announce that ITR Economist<br />

and Senior Forecaster, Connor Lokar, will<br />

be joining us, in-person, with a two-fold<br />

offering that will not disappoint.<br />

•His formal presentation titled, “Plan and<br />

Prosper,” will discuss business responses,<br />

tactics and strategies regarding the<br />

challenges, uncertainties and projected<br />

economic changes for <strong>2022</strong> and 2023.<br />

•He will then conduct a 45-minute workshop<br />

geared to <strong>Hardwood</strong> specific issues.<br />

A member of the ITR team since 2014, Mr. Lokar<br />

brings a fresh and entertaining perspective to the world<br />

of economics. And we are very much looking forward to<br />

having him on the dais.<br />

Other presentations on the <strong>2022</strong> Conference agenda<br />

will include:<br />

“Backstage Pass” Joshua Davis, Farm Credit<br />

Mid-America Vice President of Food & Agribusiness,<br />

will discuss what financial institutions consider when<br />

evaluating loan requests and provide a behind-thescenes<br />

look, from the lender’s point of view, regarding<br />

timber and forest product lending.<br />

“Advocacy and Representation” <strong>Hardwood</strong><br />

Please turn to page 52<br />

BY LINDA JOVANOVICH,<br />

EXECUTIVE VICE PRESIDENT,<br />

HARDWOOD MANUFACTURERS ASSOCIATION,<br />

PITTSBURGH, PA<br />

412-244-0440<br />

WWW.HMAMEMBERS.ORG<br />

Efficiency. Quality. Speed.<br />

Check out our YouTube Video Series:<br />

12 JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE<br />

(800) 777-6953 Kilnsales@nyle.com www.nyle.com

AHEC REPORT<br />

HARDWOOD FEDERATION INFO<br />

“SLOW DESIGN FOR FAST CHANGE”<br />

AHEC Works with Young Designers in Germany and a Prestigious Berlin Museum to<br />

Showcase the Environmental Credentials of American <strong>Hardwood</strong>s.<br />

Designers today have an enormous influence<br />

on how products are made and where,<br />

with what and how they are manufactured.<br />

The future of this shift lies within the next<br />

generation of designers – the students and<br />

recent graduates who are likely to shape<br />

the industry for decades to come. Thus far,<br />

the global pandemic has largely robbed this<br />

generation of opportunities to showcase<br />

their ideas and products to international audiences.<br />

Working with AHEC, they now have<br />

both a platform to demonstrate their talents<br />

and an incentive to rise to the challenge and<br />

come up with innovative products, objects<br />

and ideas that reflect and accelerate the<br />

transition towards slow design.<br />

The concept of ‘slow’ – as understood in terms of slow<br />

fashion or slow food – has come to entail a holistic approach<br />

to creative thinking, production processes, and<br />

products. It does not refer to how long it takes to design<br />

or do something, but rather to an expanded state<br />

of awareness and accountability for our daily actions.<br />

Products that keep materials in circulation for as long<br />

as possible are increasingly appealing. In parallel, the<br />

global COVID-19 pandemic has made people re-evaluate<br />

their lives and reassess how they want to spend their<br />

time, as lockdowns, working from home and social distancing<br />

have transformed the way we live and work. All<br />

over the world, once-hectic routines have been forced to<br />

slow down drastically, making people even more aware<br />

of what and how they consume.<br />

SLOW consists of nine projects from<br />

emerging designers hand-picked by a selection<br />

panel comprising their university tutors,<br />

the project’s manufacturing partner (German<br />

workshop Holzfreude), three professional<br />

mentors (Hanne Willmann, Sebastian Herkner<br />

and Garth Roberts), and the AHEC<br />

team. Working with four species that are<br />

abundant in the U.S. <strong>Hardwood</strong> forest but<br />

under-represented in export markets–American<br />

Red Oak, Cherry and Hard and Soft Maple–each<br />

designer has created an object that<br />

reflects their approach towards the theme<br />

‘slow design for fast change’. The result is a<br />

wide range of products, including bowls, chairs, benches,<br />

shelving systems, tables and modular furniture elements.<br />

This variety reflects the diverse voices and ideas<br />

that define the design industry today, united by an emphasis<br />

on sustainability, longevity, and a focus on quality.<br />

The pieces will be exhibited from November 26, 2021<br />

through February 20, <strong>2022</strong> at Berlin’s prestigious Kunstgewerbemuseum<br />

(Museum of Decorative Arts). Woven<br />

among the museum’s permanent exhibits, these<br />

contemporary pieces represent fresh design voices that<br />

articulate new ways of thinking about sustainability and<br />

accountability in terms of design, material choice and the<br />

production process. Full life cycle environmental impact<br />

analyses have been produced for all pieces and are an<br />

integral part of the project messaging.<br />

Please turn to page 53<br />

BACK TO THE FARM BILL<br />

It seems like Congress drafted<br />

and passed a comprehensive<br />

Farm Bill just yesterday, but the<br />

old saying that time flies is a true<br />

one. The latest Farm Bill iteration<br />

was enacted in 2018 and we are<br />

about to enter another reauthorization<br />

round with Congressional<br />

hearings likely to commence early<br />

this year. Recall two things about the Farm Bill. One,<br />

Congress must enact a new one every five years and<br />

two, while it’s predominantly focused on row crop agriculture<br />

and other farm and nutrition programs, there are<br />

a number of programs of vital importance to forestry and<br />

forest products generally, and the <strong>Hardwood</strong> industry<br />

specifically.<br />

One of the <strong>Hardwood</strong> Federation’s primary areas of<br />

focus in the context of the five-year Farm Bill is the trade<br />

title, which includes provisions authorizing and funding<br />

our two key trade promotion platforms—the Market Access<br />

(MAP) and Foreign Market Development (FMD)<br />

programs. These two highly effective platforms have a<br />

proven track record of opening up and sustaining markets<br />

across the globe for U.S. produced <strong>Hardwood</strong> products.<br />

One positive outcome from the 2018 Farm Bill rewrite<br />

was that MAP and FMD were consolidated for purposes<br />

of funding under a new umbrella program known as the<br />

Agricultural Trade Promotion and Facilitation Program<br />

(ATPFP). This was significant as the consolidation also<br />

provided for mandatory funding of $255 million over the<br />

life of the current Farm Bill to be apportioned among<br />

the programs under ATPFP. Before 2018, the <strong>Hardwood</strong><br />

Federation and our allies<br />

that support these trade promotion<br />

programs were forced to work<br />

the Congressional appropriations<br />

process each year to advocate for<br />

MAP and FMD funding. And each<br />

year there were a select few Members<br />

of Congress looking to defund<br />

these programs or eliminate them<br />

entirely. Now that they are seeded with mandatory money<br />

and consolidated under this larger umbrella program,<br />

these funding concerns are generally not an issue.<br />

Through MAP, the U.S. Department of Agriculture<br />

(USDA) partners with U.S. agricultural trade groups and<br />

state agencies to share costs of overseas marketing<br />

and promotional activities for a range of U.S. agricultural<br />

products, including <strong>Hardwood</strong> forest products. MAP<br />

currently receives minimum annual mandatory funding<br />

of $200 million for fiscal years 2019 through 2023. Under<br />

the FMD Cooperator Program, USDA’s Foreign Agricultural<br />

Service partners with U.S. nonprofit agricultural<br />

trade associations to address long-term opportunities<br />

to reduce foreign import constraints or expand export<br />

growth opportunities for U.S. agricultural commodities<br />

including <strong>Hardwood</strong>s. FMD also receives mandatory annual<br />

funding allocations for FY 2019 through FY 2023 at<br />

$34.5 million. The <strong>Hardwood</strong> Federation will be looking<br />

to preserve these mandatory funding levels at a minimum<br />

in the next Farm Bill round.<br />

Outside of trade, the Farm Bill typically includes a robust<br />

forestry title which seeks to help private landowners<br />

maintain their working forest landscapes and includes<br />

Please turn to page 53<br />

BY MICHAEL SNOW,<br />

EXECUTIVE DIRECTOR,<br />

AMERICAN HARDWOOD EXPORT<br />

COUNCIL,<br />

STERLING, VA<br />

703-435-2900<br />

WWW.AHEC.ORG<br />

BY DANA LEE COLE,<br />

EXECUTIVE DIRECTOR,<br />

HARDWOOD FEDERATION,<br />

WASHINGTON, DC<br />

202-463-5186<br />

WWW.HARDWOODFEDERATION.WILDAPRICOT.ORG<br />

14 JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE 15

WCMA INSIGHTS<br />

NHLA NEWS<br />

WCMA LOOKING FORWARD TO <strong>2022</strong>!<br />

NEW YEAR, NEW OPPORTUNITIES<br />

As we wrap up 2021, I am grateful<br />

that the WCMA was able to add value<br />

to WCMA members by creating opportunities<br />

to network, participate in pertinent<br />

industry informational sessions,<br />

and finally meet in person and tour<br />

manufacturing facilities.<br />

In October of 2021, over 80 WCMA<br />

and WMMA Members participated in<br />

the joint Wood Component Manufacturers<br />

Association and Woodworking<br />

Machinery Manufacturers Association’s Fall Conference<br />

and Plant Tour Event in Louisville, KY. This was the first<br />

joint meeting with the two associations, and attendees<br />

were grateful for the expanded networking opportunities,<br />

the ability to meet one-on-one with suppliers, and the<br />

chance to tour manufacturing plants in the area.<br />

Educational sessions featured a broad variety of industry<br />

hot topics including Workforce Hiring & Retention,<br />

Digital Marketing, and “The Trust Advantage” about the<br />

astonishing benefits of trust, the leadership trait that most<br />

directly contributes to our success. Plant tours included<br />

Anderson Wood Products, the Louisville Slugger Museum<br />

and Factory, and Koetter Woodworking. As this was<br />

the first in-person gathering for WCMA members since<br />

2019, attendees were excited to see advancements in<br />

technology and learn how others are handling the workforce<br />

and supply chain challenges facing the industry.<br />

I am now looking forward to <strong>2022</strong> and am excited<br />

about the variety of benefits WCMA has to offer. Our<br />

board cares about the members and wants to continue<br />

to offer excellent programs and services to help our<br />

members be successful.<br />

Educational Opportunities &<br />

Member Benefits<br />

In 2021, the WCMA added virtual<br />

roundtable events that are FREE to<br />

members. Topics have included Workforce<br />

Development in Manufacturing,<br />

OSHA Requirements and COVID-19,<br />

Machinery Maintenance, US <strong>Hardwood</strong><br />

Supply & Demand Update, Tips & Tricks<br />

for Sanding Operations, and Cyber Security.<br />

We plan on continuing these sessions<br />

in <strong>2022</strong> with current and relevant topics for attendees.<br />

We are also planning our signature Fall Conference &<br />

Plant Tour event in Minnesota for <strong>2022</strong>. There are a large<br />

number of manufacturing facilities that are open for tours,<br />

and we are excited to again partner with WMMA.<br />

The WCMA is also offering members new member<br />

benefits. We’ve partnered with AHMI to add a Multiple<br />

Employee Plan (MEP) with UBS Financial. This plan allows<br />

companies to pool existing retirement accounts or<br />

start new programs for employees. The plan offers economies<br />

of scale pricing that lowers costs for recordkeeping,<br />

third-party administrators, and financial consultants.<br />

As a founding contributor to the Real American <strong>Hardwood</strong><br />

Coalition (RAHC), WCMA is invested in real promotion<br />

for domestic <strong>Hardwood</strong> manufacturers. Because<br />

of the WCMA’s financial support, WCMA members are<br />

able and encouraged to download and use the RAH logo<br />

on all products that qualify, and help consumers start recognizing<br />

the brand and spread the word. This exciting<br />

initiative helps our members products stand out!<br />

Please turn to page 61<br />

Civilizations around the world have been<br />

celebrating the start of each new year for<br />

at least four millennia. In 46 B.C. the emperor<br />

Julius Caesar introduced the Julian<br />

calendar and instituted <strong>January</strong> 1 as the<br />

first day of the year. This was done partly<br />

to honor the month’s namesake: Janus,<br />

the Roman god of beginnings. Today, New<br />

Year’s celebrations begin on the evening of<br />

December 31 and continue into the early<br />

hours of <strong>January</strong> 1. Traditions of New Year celebrations<br />

include fireworks, special food dishes, attending parties<br />

and making resolutions for the year ahead.<br />

As NHLA and its staff prepare for the coming year<br />

of service to the <strong>Hardwood</strong> industry, we reflect on the<br />

year 2021. No doubt the last two years have strained<br />

the industry and the Association; first with tariffs, then<br />

with COVID-19 and now with the lingering effects of a<br />

world-wide pandemic. Despite those obstacles, NHLA<br />

has moved along in stride, and we are optimistic about<br />

the year ahead.<br />

The Inspector Training School continues to offer<br />

much-needed education to the industry and in <strong>2022</strong>, will<br />

be developing new courses to address the rise in automated<br />

sawmill technology. The Inspection Services team<br />

as always stands ready to assist with in-house education<br />

and training, quality control issues, and delivering a portfolio<br />

of services and programs that can make your business<br />

better. The team recently added a new resource to<br />

its portfolio in the form of Mr. Benji Richards – Industry<br />

Services Sales Manager. He will be a great<br />

asset to the team and the industry. Benji<br />

can be reached at b.richards@nhla.com or<br />

by phone at 828-610-3406.<br />

The Membership and Business Development<br />

team has ambitious goals for <strong>2022</strong>!<br />

After 16 months of limited engagement<br />

and interaction with the <strong>Hardwood</strong> industry,<br />

they are getting ready for a busy year of<br />

in-person event attendance with the goal of<br />

significantly increasing membership and member value.<br />

NHLA is looking at new industry partnership opportunities<br />

to reach more sectors of the <strong>Hardwood</strong> industry as<br />

we look to expand our membership services.<br />

And finally, NHLA is looking forward to the developments<br />

of the Real American <strong>Hardwood</strong> Coalition in <strong>2022</strong>.<br />

As initial work for the consumer-facing website is underway<br />

as of the writing of this article, it is my hope that by<br />

the reading of these words, the project has progressed<br />

significantly with a website launch date in-hand. NHLA<br />

has been a proud supporter, worker, and contributor to<br />

the RAHC since its inception and believe in the power<br />

of a collective voice for the <strong>Hardwood</strong> industry. If your<br />

company has not become a supporter of the Coalition<br />

yet, we encourage you to visit realamericanhardwood.<br />

org to learn more and give your donation today.<br />

Happy New Year from NHLA! May you make the most<br />

of the year ahead and the opportunities that are always<br />

present. And in the words of C.S. Lewis – “You are never<br />

too old to set another goal or to dream a new dream.” n<br />

BY AMY K. SNELL, CAE,<br />

EXECUTIVE DIRECTOR,<br />

WOOD COMPONENT MANUFACTURERS ASSOC.,<br />

LINDSTROM, MN<br />

651-332-6332<br />

WWW.WCMA.COM<br />

BY RENEE HORNSBY,<br />

DIRECTOR OF MARKETING & COMMUNICATIONS,<br />

NATIONAL HARDWOOD LUMBER ASSOCIATION,<br />

MEMPHIS, TN<br />

901-399-7560<br />

www.nhla.com<br />

16 JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE 17

CABINET DOOR SHOP<br />

- Best Quality And Pricing Makes A Family Proud<br />

By Deborah Wilbrink<br />

Here is a custom kitchen adorned with woodwork by Cabinet Door Shop, located in Hot Springs, AR.<br />

18 JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE<br />

All doors and drawers are made to order<br />

at CDS. Variations generated by customer<br />

demand keep the product line growing.<br />

Hot Springs, AR – Family-owned and operated Cabinet Door Shop<br />

(CDS), located here, produces custom cabinet doors and dovetail<br />

drawers for cabinet makers across the United States. A one-stopshop,<br />

they also offer drawer slides, hinges, appliance panels, wainscoting<br />

and other cabinet specialties such as moulding, woodcarving and<br />

adornments—everything needed for cabinet installation.<br />

To manufacture their hundreds of designs, CDS purchases 400,000<br />

board feet a year from mills and distributors. About 75 percent of incoming<br />

truckloads is 4/4 Select and Better (S&B) paint-grade Hard Maple<br />

and Nos. 1 & 2 Common White Hard Maple. Co-owner Noel Uzick<br />

explained, “We no longer use Brown Maple because it shows too many<br />

stress fractures after it is painted. We are a high-end door company and<br />

we do our best to cull any imperfections before the product leaves our<br />

hands. We have found a source that provides a ‘white paint grade’ that<br />

is perfect for our needs.”<br />

Additional woods are S&B red leaf Soft Maple, 1&2 White, S&B Red<br />

Oak, color sorted, S&B Hickory and Rustic Hickory, S&B Yellow Birch<br />

(color sorted), S&B Walnut (color sorted), S&B Cherry (color sorted)<br />

and 4/4 premium frame and superior Alder, all in 15/16 with a small<br />

amount of 5/4 in all species.<br />

Please turn to page 40<br />

“We are all handson<br />

and pretty much<br />

involved in the entire<br />

process from start to<br />

finish. My two brothersin-laws<br />

and I are on<br />

the floor every day,<br />

constantly looking at<br />

quality.”<br />

— Noel Uzick<br />

co-owner<br />

Cabinet Door Shop<br />

JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE 19

Pictured are pallets of 4/4 Poplar lumber in stock at a DIXIEPLY Florida location.<br />

Purchasing Approximately 5 Million Board Feet Of<br />

Lumber, DIXIEPLY Delivers Throughout U.S.A.<br />

Savannah, GA–Established in 1944 by the late Waldo<br />

Bradley, Dixie Plywood and Lumber Companies<br />

(aka DIXIEPLY) is headquartered in Georgia’s first<br />

city and is just a couple of blocks from the high-traffic areas,<br />

almost in the center of Savannah. By being a leader<br />

in the industry in quality, innovation and service, the firm,<br />

which buys approximately 5 million board feet of lumber,<br />

is now among the largest independent distributors<br />

of building materials in the nation.<br />

With each of its operations having its own lumberyard,<br />

“It is our policy to remain on the<br />

leading edge as suppliers to our<br />

clients.”<br />

– Tom Heard<br />

director of marketing and business development<br />

DIXIEPLY<br />

By Michelle Keller<br />

By being a leader in the industry in quality, innovation and service,<br />

DIXIEPLY, which buys approximately 5 million board feet<br />

of lumber, is now among the largest independent distributors of<br />

building materials in the nation. Pictured is the Orlando, FL, location.<br />

facilities and fleet of delivery trucks, large and diversified<br />

inventories are what define DIXIEPLY.<br />

In <strong>Hardwood</strong>s the company carries certified lumber in<br />

many species such as Poplar, Ash, Alder, Cherry, Birch,<br />

Maple and Red and White Oak. Also offered are panel<br />

products, <strong>Hardwood</strong> plywood, prefinished <strong>Hardwood</strong> plywood,<br />

particleboard, medium density fiberboard (MDF),<br />

Some of the softwood products offered by the company are: SPF boards, SYP boards, cedar boards, fencing, decking, dimension,<br />

cypress patterns and siding, fir clear boards, green Douglas fir dimension, hem-fir dimension and studs, ponderosa pine boards,<br />

engineered wood products, and joists, such as the Boise Cascade products pictured.<br />

moisture resistant particleboard,<br />

moisture resistant MDF, melamine,<br />

vinyl overlay panels, hardboard and<br />

pegboard, rated sheathing and OSB<br />

flooring, and fire-retardant treated<br />

panels.<br />

Specialty items include cabinet<br />

doors, prefinished drawer sides, cutto-size<br />

panels, particleboard and<br />

MDF countertops, shelving and slat<br />

wall, veneers, solid surface countertops,<br />

MDF mouldings, wood mouldings,<br />

interior/exterior doors, composite<br />

decking products, composite<br />

trim products, and laminated veneer<br />

lumber. “Product diversity is a fact of<br />

life around here,” said Tom Heard,<br />

director of marketing and business<br />

development, referring to colleagues<br />

in Savannah as well as distribution<br />

associates nationwide.<br />

DIXIEPLY also offers on-site custom<br />

lamination services for high<br />

pressure laminated panels for its<br />

Florida customers, as well as banding<br />

groove and landscape stakes.<br />

Softwood products offered by the<br />

company include: SPF boards, fascia,<br />

dimension & studs; SYP boards,<br />

patterns, dimension and treated<br />

decking; European spruce dimension<br />

and studs; cedar boards, fencing,<br />

decking, dimension; cypress<br />

patterns and siding; fir clear boards;<br />

Also offered by DIXIEPLY are <strong>Hardwood</strong> plywood, panel products and prefinished <strong>Hardwood</strong><br />

plywood, among a long list of other building material products.<br />

green Douglas fir dimension; hem-fir<br />

dimension and studs; Ipe decking;<br />

ponderosa pine boards; and engineered<br />

wood products.<br />

The company’s first wholesale<br />

distribution center opened in Atlanta<br />

and operated under the name Ponce<br />

de Leon Plywood Co. after the street<br />

on which it was located. When the<br />

second distribution center opened in<br />

Savannah in 1945, the name of the<br />

company was changed to Dixie Plywood<br />

Company.<br />

Please turn to page 42<br />

In <strong>Hardwood</strong>s DIXIEPLY carries certified<br />

lumber in many species such as Poplar,<br />

Ash, Alder, Cherry, Birch, Maple and Red<br />

and White Oak.<br />

20 JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE 21

Paw Taw John (PTJ) Services founder Jerry Johnson tests PVT on hydraulics.<br />

Laser-Focused Service At<br />

Paw Taw John Services Inc.<br />

By Terry Miller<br />

“Our sweet spot is having the<br />

ability to provide the smaller<br />

sized business owner, a<br />

system that is effective, they<br />

can make money with it, and<br />

gives them the ability to compete<br />

in their market. We have<br />

entry level systems, and we<br />

have systems that are more<br />

advanced. As a client grows<br />

in profitability and has growth<br />

potential, our systems will<br />

grow with that idea in mind.”<br />

–Founder Jerry Johnson<br />

Paw Taw John Services<br />

Rathdrum, ID—Paw Taw John Services Inc. (PTJ) is a veteran-owned-and-operated<br />

machine systems integrator, distributor<br />

and repair center. Founded in 1986 by Jerry Johnson, PTJ offers<br />

affordable, reliable control systems designed for precision optimization.<br />

PTJ’s proprietary sawmill system control technology provides primary and<br />

secondary log breakdown systems to meet clients’ individual needs with<br />

industry-specific solutions.<br />

While working as part of the engineering group at Louisiana Pacific,<br />

Johnson saw a need in the marketplace and fulfilled it. “What I discovered<br />

is that a lot of sawmills were using motion control systems and devices I<br />

had not seen before,” he said. “I was fascinated with motion control systems<br />

in the sawmills, and I learned as much as I could about the technology<br />

and Temposonics devices. Today, PTJ is the largest distributor of Temposonics<br />

products in the forest products industry in the United States.”<br />

The devices from Temposonics are put into a hydraulic cylinder to provide<br />

position feedback. The feedback goes into a closed loop controller<br />

that operates a hydraulic valve to target the cylinder, which is typically<br />

attached to a band mill or an edger saw. “Every segment of the log breakdown<br />

system is affected, and value is added continually throughout the<br />

whole process, even as far down as the trimmer,” Johnson explained.<br />

Tyler Stiles, systems installer, designs PLC layout for a system.<br />

After working with both tenured and new sawyers,<br />

Johnson evaluated the craft of operating the machines<br />

and using control systems to improve performance so<br />

that the sawyers could do a more effective job in the<br />

mill. “I spent a lot of time at Louisiana Pacific working<br />

with the designs, building, maintaining and changing the<br />

programs for efficiency,” he explained.<br />

PTJ prioritizes helping customers meet their operating<br />

and business needs. The company delivers exceptional<br />

customer service, quick resolution and turnaround time<br />

for customer orders and sales. Johnson offered, “We<br />

provide our customer base a level of support you won’t<br />

find on a typical phone call. We have online remote access<br />

24/7 support on all PTJ systems. Our systems are<br />

designed and manufactured with the idea of streamlined<br />

efficiency, user-friendly interface and ease of maintainability.<br />

We have engineers available to provide top-level<br />

design, product quality control and business needs consultation,<br />

with onsite installation.<br />

“Factory-trained technicians and assemblers ensure<br />

sensors and products are repaired efficiently and expertly,”<br />

he continued. “With PTJ private online customer<br />

remote systems access, technicians can link (talk) with<br />

a control system in the mill. This allows them to set up<br />

or change any operational parameter on the system,<br />

calibrate scanning systems and provide programming<br />

upgrades and changes.”<br />

PTJ vendor relationships are an important part of how<br />

the company is maintained. “Our relationships allow us<br />

to continuously provide the lowest cost for the highest<br />

quality product on the market to our customers across<br />

multiple industries,” Johnson said. PTJ vendor relationships<br />

include the Temposonics Industrial and Liquid<br />

sensors, cables, Encoder Products, Connexus laser line<br />

and Bosch/Rexroth Valves. Although the Temposonics<br />

sales territory of PTJ is limited to Idaho, Wyoming, Montana,<br />

Washington, Northern CA, and Oregon due to<br />

Please turn to page 43<br />

Othman Ali, chief engineer, works on a scanning program.<br />

Ed Grambusch, manufacturing assembler, tests PVT.<br />

Jerry Johnson is seen with Best Opening Face Sawing Simulation<br />

Analysis Routine user’s guide for log breakdown.<br />

22 JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE 23

This Maple dining set was on display at High Point Market from<br />

Copeland Furniture, headquartered in VT.<br />

Copeland Furniture also presented this solid Walnut desk and<br />

chair at the Market.<br />

This bedroom group from Westwood in Millersburg, OH was built from solid Hard Maple.<br />

U.S. Furniture Makers Report Sales Boom<br />

By Tom Inman<br />

The “sunbleached” look on White Oak attracted<br />

attention at the Market for Vaughan-Bassett<br />

Furniture, of Galax, VA.<br />

High Point, NC–The report from the fall 2021 High Point Market<br />

is great for U.S. manufacturers and frustrating for importers.<br />

The furniture industry returned for the fall market with thousands of<br />

exhibitors and retail buyers and designers eager to see new product.<br />

Most domestic producers reported very strong sales for 2020 and<br />

2021 because they have had furniture to sell.<br />

Many importers are struggling with the supply chain providing<br />

finished goods and components from Asia, Vietnam and other countries.<br />

There were fewer Asian exhibitors and their showrooms had<br />

lower volumes of introductions.<br />

“It was a great market for us and other American manufacturers<br />

because we have product,” said Doug Bassett, president of<br />

Vaughan-Bassett Furniture. “We have reduced our number of lines to<br />

focus on what we can make and deliver that is profitable.”<br />

COVID-19 has kept many U.S. consumers at home as cities and<br />

states enforced quarantines over the past two years of the pandemic.<br />

These consumers quickly tired of the look or comfort or design of their<br />

existing furniture and when retail stores opened, they were ready to buy.<br />

Orders placed in the first quarter of 2021 were up 50 percent over<br />

the same period in the previous year. March 2021 orders recorded a 40<br />

percent increase over those of March 2019, and 1Q21 orders posted a<br />

Maple with a medium stain on this dining set from Country View<br />

Furniture, of Millersburg, OH was on display at High Point.<br />

38 percent increase compared with 1Q19.<br />

Many retailers have sold out of existing inventories and<br />

those that are dependent on imported goods are delayed<br />

because of supply chain issues. Foreign manufacturers<br />

are struggling to get furniture into the U.S. because of<br />

freight backlogs.<br />

Vietnam has become the sixth largest source of U.S.<br />

imports overall and in 2020 was the second-ranked<br />

source for inbound shipments of furniture. Vietnam accounted<br />

for 19 percent by value of this trade in the period<br />

from <strong>January</strong> through April 2021, behind only China with<br />

a 37 percent share. Just five years ago, Vietnam ranked<br />

third with a 7 percent share, while China supplied 50 percent.<br />

Significantly, Vietnam is the top source for U.S. imports<br />

of wood furniture with a 43 percent share of this market,<br />

followed by China with 15 percent.<br />

American companies with plants in Ohio, Indiana, Mississippi<br />

and North Carolina echoed the same success as<br />

Bassett. Their showrooms at High Point had new products<br />

and retailers were purchasing goods to fill ware-<br />

A live edge Maple side table that incorporated metal legs was<br />

admired at the Market.<br />

Character-marked Hard Maple is the focus of this Artisan & Post<br />

design from Vaughan-Bassett Furniture.<br />

houses and showrooms.<br />

Copeland Furniture in Vermont had introductions in<br />

Cherry and Walnut that were well-received by retailers<br />

and designers who cater to high-end consumers. Presi-<br />

Please turn to page 43<br />

24 JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE 25

Equipment And Services<br />

Providers<br />

To The<br />

<strong>Hardwood</strong> Lumber Industry<br />

See Challenges<br />

– And<br />

Opportunity –<br />

Abounding In<br />

<strong>2022</strong><br />

By Matthew Fite<br />

Equipment and services providers to the <strong>Hardwood</strong> lumber industry<br />

had to fight their way through a host of challenges in 2021 – yet they<br />

tended to meet with success. Looking ahead to <strong>2022</strong>, they foresee more<br />

sophisticated high-tech solutions – especially for overcoming labor shortages.<br />

However, one respondent noted: “…with so many material delays<br />

in the supply chain, labor shortages, and overseas shipping issues, it<br />

would be surprising to see capital equipment purchases continue at the<br />

same rate as 2021.” On the other hand, another respondent stated: “Sawmills<br />

have seen better prices on their lumber and <strong>2022</strong> looks to be very<br />

strong for both sawmills and equipment manufacturers.”<br />

Paul Cleereman<br />

Cleereman Industries and Cleereman Controls<br />

Newald, WI<br />

In 2021, we saw an increase<br />

in capital spending in both <strong>Hardwood</strong><br />

and softwood sawmills. A<br />

lot of mills were replacing older<br />

Paul Cleereman equipment and controls that will<br />

help them maximize speed and<br />

yield recovery. Sawmills have seen better prices on their<br />

lumber and <strong>2022</strong> looks to be very strong for both sawmills<br />

and equipment manufacturers. One problem that<br />

both sawmills and equipment manufacturers are experiencing<br />

is a labor shortage. With the government handing<br />

out the stimulus checks and free money we have basically<br />

trained people not to work. We have also seen our<br />

steel prices triple on a lot of steel since 2020. Purchased<br />

items have also skyrocketed and lead times to get items<br />

keep getting longer and longer. It has been very challenging<br />

to get enough purchased parts to keep up with<br />

manufacturing of our equipment. The outlook for <strong>2022</strong> on<br />

purchase parts doesn’t look much better.<br />

Cleereman Industries/Cleereman Controls introduced<br />

our new Cleereman Edger Line for the sawmill industry.<br />

We have installed a couple of our optimized Edgers,<br />

and customers are reporting increased production and<br />

yield. The newly designed Edger fits into existing Edger<br />

locations with minimal modifications to surrounding<br />

equipment. Our Edger was designed to help increase<br />

production and reduce operator fatigue and gain the mill<br />

maximum yield. At the time of writing this article we have<br />

sold 14 Edgers since Richmond Expo and customers<br />

seem to be very pleased with price and quality.<br />

Cleereman Controls builds Carriage Controls, Edger<br />

Controls, both optimized and non-optimized, along with<br />

Debarker, Trimmer, Resaw, Slabber and material handling.<br />

Cleereman Industries has an in-house engineering<br />

department to serve our customers’ needs. We offer everything<br />

from single piece equipment to complete turnkey<br />

sawmill design.<br />

Over the last several years we have seen our industry<br />

go more towards the one stop shop style of purchasing.<br />

Our in-house engineering department has allowed us to<br />

handle not only equipment but also electrical MCC/Starter<br />

design of cabinets and building/foundation layouts.<br />

We are able to assist our customers from start to finish<br />

on their sawmill projects.<br />

Cleereman Industries/Cleereman Controls offer everything<br />

from single piece equipment to turn-key sawmills.<br />

We offer custom sawmill controls and on-site consultation<br />

and installation services. We stock all parts for all<br />

machines in-house for same day shipment or pick-up.<br />

Our in-house engineering department can handle all our<br />

customers’ needs from start to finish. Our product line<br />

includes Stave Mills, Lumber-Pro Thin Kerf Bandmills,<br />

Debarkers, Log Hauls, Metal Detectors, Log Decks, Log<br />

Turners, Track Frames, Rail, Husks, Drop-Belts, Rollcases,<br />

Transfers, Resaws, Edgers, Trimmers, Material<br />

Handling Lines, Carriage Drives, Operators Cabs and<br />

custom purpose built sawmill equipment. J<br />

Please turn the page<br />

26 JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE<br />

JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE 27

EQUIPMENT/SERVICES <strong>2022</strong> FORECASTS<br />

Continued<br />

Eric Degenfelder<br />

Eric Degenfelder, CEO U-C Coatings<br />

Headquarters in Buffalo, NY<br />

Branches in Seattle, WA; Portland, OR; and<br />

Kenosha, WI<br />

In 2021, raw material supply has been difficult with<br />

several shortages, but we have done well to keep our<br />

customers continually supplied. Raw material costs<br />

have escalated and finding production staff was challenging.<br />

Transportation has been difficult, especially for<br />

our imported raw materials and exported products. The<br />

carriers we partner with in North America have done a<br />

good job with deliveries despite the state of the overall<br />

industry.<br />

In <strong>2022</strong>, we are expanding the rollout of our Contechem®<br />

products for sapstain, mold, and iron stain<br />

control.<br />

We are also introducing new grades of Gempaint® for<br />

panel manufacturers, such as ULTRA for plywood, and<br />

investing in capacity expansion for Anchorseal® production.<br />

In <strong>2022</strong>, we will introduce new paints and stains from<br />

our Eco Chemical® division for the prefinished wood<br />

markets such as siding and fencing.<br />

U-C Coatings is a leading manufacturer and supplier<br />

of premium wood protection products. We offer the Contechem®<br />

product line featuring Britewood for mold and<br />

sapstain control in softwood and <strong>Hardwood</strong> applications.<br />

Our Eco Chemical® division provides water-based wood<br />

stains and other coatings for the rapidly expanding prestained<br />

pressure treated lumber market as well as the<br />

pre-stained fencing and decking market. We are wellknown<br />

for Anchorseal® end sealers, and Gempaint®<br />

and Gempaint Plus for lumber and plywood branding.<br />

Seal-Once® is a line of eco-friendly, long lasting, water-based<br />

sealers for wood and concrete that provides<br />

excellent water repellant performance. In October 2021,<br />

U-C Coatings acquired Abatron, a premier manufacturer<br />

of epoxy compounds for wood and concrete repair<br />

based in Kenosha, WI. J<br />

28 JANUARY <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE<br />

Peter McCarty<br />

Peter McCarty<br />

TS Manufacturing<br />

Lindsay, ON, Canada<br />

Getting parts, material, trucking and workers<br />

are all getting more difficult. Items are also getting<br />

more expensive, trucking is getting more expensive,<br />

workers you can hire want higher rates<br />

of pay than you are used to, and, as a result,<br />

selling prices rise as well to offset them all.<br />

We are sold out for <strong>2022</strong> so we will not be developing<br />

any new products. We will concentrate<br />

on building what we have sold.<br />

We recently developed our own board tally<br />

software program called AccuTally and have<br />

near 50 units sold and in operation. We were<br />

not able to satisfy the needs of our customers<br />

with programs we could purchase already on the<br />

market, so we developed our own. It has been<br />