LRyIrue LnuINATEI USS CoruSrIruTION SNIM I ... - Wood Tools

LRyIrue LnuINATEI USS CoruSrIruTION SNIM I ... - Wood Tools

LRyIrue LnuINATEI USS CoruSrIruTION SNIM I ... - Wood Tools

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

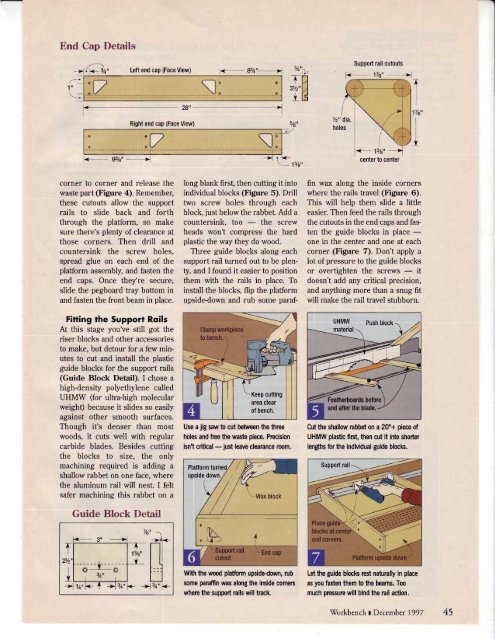

End Cap Details<br />

4{l-< 27o,' Left endcap(FaceView)<br />

.-.<br />

1"<br />

'"<br />

Right end cap (Face View)<br />

ts-<br />

83/q" --1<br />

o av :7 ::::::::::::::::::::::::]::::::::::::::::::::::::::::::::::::::::::::::E::<br />

\: vo<br />

ts- 93/e" 4<br />

{a<br />

Support rail cutouts<br />

"/0,,1,<br />

1lVB"<br />

s/e"<br />

-:><br />

\_ 1 s7r,,<br />

corner to corner and release the long blank first, then cutting it into fin wax along the inside corners<br />

waste part (Figure 4). Remember, individual blocks (Figure 5). Drill where the rails travel (Figure 6).<br />

these cutouts allow the support two screw holes through each This will help them slide a little<br />

rails to slide back and forth<br />

through the platform, so make<br />

block, just below the rabbet. Add a<br />

countersink. too - the screw<br />

easier. Then feed the rails through<br />

the cutouts in the end caps and fas-<br />

sure there's plenty of clearance at heads won't compress the hard ten the guide blocks in place -<br />

those corners. Then drill and plastic the way they do wood. one in the center and one at each<br />

countersink the screw holes, Three guide blocks along each corner (Figure 7). Don't apply a<br />

spread glue on each end of the<br />

plafform assembly, and fasten the<br />

support rail turned out to be plenty,<br />

and I found it easier to position<br />

lot of pressure to the guide blocks<br />

or overtighten the screws - it<br />

end caps. Once they're secure, them with the rails in place. To doesn't add any critical precision,<br />

slide the pegboard tray bottom in install the blocks, flip the plafform and anything more than a snug fit<br />

and fasten the front beam in place. upside-down and rub some paraf- will make the rail travel stubborn.<br />

Fitting the Support Rqils<br />

At this stage you've still got the<br />

riser blocks and other accessories<br />

to make, but detour for a few minutes<br />

to cut and install the plastic<br />

guide blocks for the support rails<br />

(Guide Block DetaiD. I chose a<br />

high-density polyethylene called<br />

UHN/ilV (for ultra-high molecular<br />

weight) because it slides so easily<br />

against other smooth surfaces.<br />

Though it's denser than most Use a jig saw to cut between the three<br />

woods, it cuts well with regular holes and free the waste piece. Prccision<br />

carbide blades. Besides cutting isn't critical - just leave clearance room.<br />

the blocks to size, the only<br />

machining required is adding a<br />

shallow rabbet on one face, where<br />

the aluminum rail will nest. I felt<br />

safer machining this rabbet on a<br />

Guide Block Detail<br />

Wih the wood platftrm upsidedown, rub<br />

some paraffin wax along the inside cornen<br />

wherc the supprt rails will track.<br />

center to center<br />

Cut the shallow rabbet on a 20"+ piece of<br />

UHMW plastic first, then cut it into shorter<br />

lenghs tor the individual guide blocls.<br />

Let the guide blocls rcst naturally in place<br />

as you fasten them to the beams. Too<br />

much prcssure will bind the rail action.<br />

\Torkbench r December 1997 +><br />

t

![Til]tl](https://img.yumpu.com/45878240/1/190x245/tiltl.jpg?quality=85)