LRyIrue LnuINATEI USS CoruSrIruTION SNIM I ... - Wood Tools

LRyIrue LnuINATEI USS CoruSrIruTION SNIM I ... - Wood Tools

LRyIrue LnuINATEI USS CoruSrIruTION SNIM I ... - Wood Tools

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

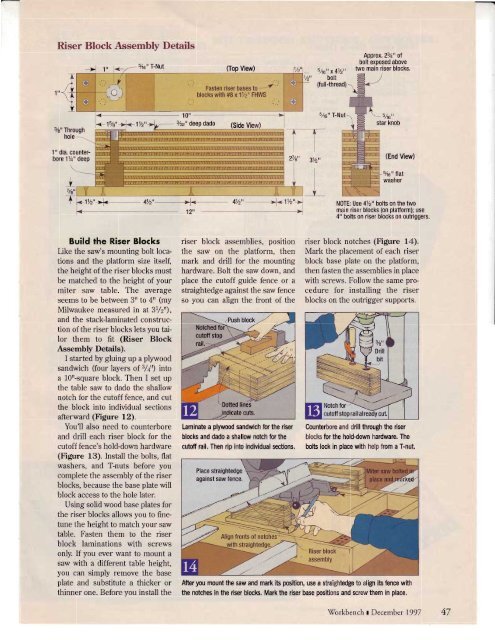

Riser Block Assembly Details<br />

3/s" Through<br />

hole ----\<br />

l " dia. counterbore<br />

17+" deep<br />

#rr<br />

TFE<br />

Build the Riser Blocks<br />

Like the saw's mounting bolt locations<br />

and the platform size itself,<br />

the height of the riser blocks must<br />

be matched to the height of your<br />

miter saw table. The average<br />

seems to be between 3rr to 4" (my<br />

Milwaukee measured in at 3l/z'r),<br />

and the stacklaminated construction<br />

of the riser blocks lets you tailor<br />

them to fit (Riser Block<br />

Assembly Details).<br />

I started by gluing up a pl1'wood<br />

sandwich (four layers of 3/+rr) into<br />

a l0rlsquare block. Then I set up<br />

the table saw to dado the shallow<br />

notch for the cutoff fence, and cut<br />

the block into individual sections<br />

afterward (Figure 12).<br />

You'll also need to counterbore<br />

and drill each riser block for the<br />

cutoff fence's hold-down hardware<br />

(Figure 13). Install the bolts, flat<br />

washers, and T-nuts before you<br />

complete the assembly of the riser<br />

blocks, because the base plate will<br />

block access to the hole later.<br />

Using solid wood base plates for<br />

the riser blocks allows you to finetune<br />

the height to match your saw<br />

table. Fasten them to the riser<br />

block laminations with screws<br />

only. If you ever want to mount a<br />

saw with a different table height,<br />

you can simply remove the base<br />

plate and substitute a thicker or<br />

thinner one. Before you install the<br />

riser block assemblies, position<br />

the saw on the platform, then<br />

mark and drill for the mounting<br />

hardware. Bolt the saw down, and<br />

place the cutoff guide fence or a<br />

straightedge against the saw fence<br />

so you can align the front of the<br />

Approx. 23l+" of<br />

bolt exoosed above<br />

sAa', x 4lz,'<br />

two main riser blocks.<br />

bolt<br />

(full-thread) -<br />

3Y2"<br />

L<br />

5lo" T-Nut<br />

5/rc"<br />

star knob<br />

(End View)<br />

sla" tlat<br />

wasner<br />

N0TE: Use 472" bolts on the two<br />

main riser blocks (on platform); use<br />

4" bolts on riser blocks on outriggers.<br />

riser block notches (Figure 14).<br />

Mark the placement of each riser<br />

block base plate on the platform,<br />

then fasten the assemblies in place<br />

with screws. Follow the same procedure<br />

for installing the riser<br />

blocks on the outrigger supports.<br />

Laminate a plywood sandwich for the riser Counterbore and drill through the riser<br />

blocls and dado a shallow notch for the block for the hold-down hardware. The<br />

cutoff rail, Then rip into individual sections. bolts lock in place with help from a T-nut.<br />

Place straightedge<br />

against saw fence.<br />

After you mount the saw and mark ib position, use a straightedge to align ib fence with<br />

the notches in the riser block. Ma* the riser base positions and screw them in place.<br />

Workbench I December 1997 +/

![Til]tl](https://img.yumpu.com/45878240/1/190x245/tiltl.jpg?quality=85)