food Marketing - Technology 4/2022

food Marketing & Technology is the international magazine for executives and specialists in the food industry.

food Marketing & Technology is the international magazine for executives and specialists in the food industry.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

4/22<br />

Vol. 36 • 31377<br />

ISSN 0932-2744<br />

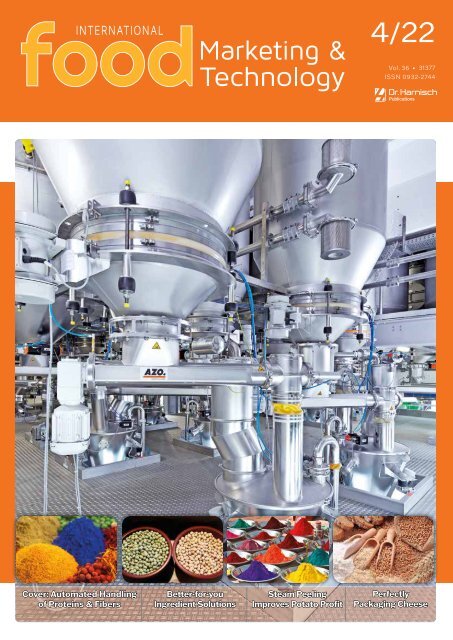

Cover: Automated Handling<br />

of Proteins & Fibers<br />

Better-for-you<br />

Ingredient Solutions<br />

Steam Peeling<br />

Improves Potato Profit<br />

Perfectly<br />

Packaging Cheese

We understand how you strive for constant<br />

product quality and optimized costs.<br />

CONSISTENT<br />

+ CONFIDENT<br />

You are poised to meet your safety and quality requirements<br />

while optimizing resources and securing process repeatability.<br />

Endress+Hauser helps you to improve your processes:<br />

• With a hygienic, robust product portfolio that meets<br />

international standards<br />

• With access to traceable, reliable and real-time data<br />

• With a network of industry application experts that help<br />

you ensure greater plant availability throughout the<br />

product life cycle<br />

Key No. 101574<br />

Do you want to learn more?<br />

www.endress.com/<strong>food</strong>-beverage

Editorial<br />

Fat People can Save the World<br />

It’s true to say that I am overweight.<br />

No real argument there. I have too<br />

many kilograms for my height. One<br />

problem is that I enjoy eating, tasting<br />

and sampling whatever I can find.<br />

Part of the job, so to say. Imagine<br />

my surprise after a recent trip when<br />

I came home after ten days travel<br />

3kg lighter than I had left. And I<br />

had enjoyed myself and not felt to<br />

be missing anything! This needed<br />

investigating, but is not to be taken<br />

too seriously.<br />

First of all, it was hot. Much as I love<br />

chocolate, it is not really practical<br />

on hot days. That meant I had<br />

automatically cut down on one of my<br />

staples; it also meant I drank a lot<br />

of water, because that is what you<br />

do on hot days! A little known fact<br />

is that water has fewer calories than<br />

chocolate…<br />

When I am travelling it usually means<br />

I stay in a hotel, without a kitchen or<br />

cooking area. There is no need to go<br />

<strong>food</strong> shopping, since I have no place<br />

to store anything. Except I do spend<br />

some time in supermarkets, trying<br />

to find differences in products and<br />

habits between different countries<br />

and regions. It also means I have<br />

to actively get up and hunt for my<br />

breakfast, as my forefathers did<br />

in times long gone. Having found<br />

something suitable, affordable and<br />

with coffee, I had to check my budget<br />

for the day.<br />

Being on the move all day, whether<br />

sightseeing or at an exhibtion<br />

or event is also quite distracting.<br />

There is a lot to do and see without<br />

necessarily thinking of <strong>food</strong> all the<br />

time. This is definitely an advantage<br />

for tubby tummies.<br />

What results and conclusions did I<br />

come to? Well, basically, if fat people<br />

like me don’t eat as much as they<br />

usually do, there will be proportionally<br />

more left over for other people. Fat<br />

people will get thinner and healthier,<br />

Ian Healey<br />

Editor-in-Chief<br />

need less medical care and will<br />

fit into older clothes they haven’t<br />

worn for years, thus saving other<br />

resources. I can only speak from<br />

personal experience. The key to this<br />

theory is to eat less on a long term<br />

basis, whether from being sensible,<br />

frugal or too busy. Maybe we should<br />

all talk to our fat friends and see if<br />

they agree?<br />

Photo: BK<br />

Sincerely,<br />

If you like it – subscribe!<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • August <strong>2022</strong><br />

3<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • August <strong>2022</strong>

International Magazine June 2020 ISSN 2628-5851<br />

<strong>Technology</strong> & <strong>Marketing</strong><br />

your easy way to stay updated<br />

2/20<br />

International Magazine October 2019 ISSN 2628-5851<br />

<strong>Technology</strong> & <strong>Marketing</strong><br />

2/19<br />

xxx<br />

Contents<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> August <strong>2022</strong><br />

1 Editorial<br />

58 Impressum<br />

Ingredients<br />

Ingredients: Hydrocolloids in Pet Food, Acacia Gum's Versatility, Antioxidants<br />

Processing: Optical Sorting, Gentle Cooling, Removing Risks in Food Safety<br />

International Magazine April 2020 ISSN 2628-5851<br />

1/20<br />

Ingredients Blueberries, Fiber, Sea<strong>food</strong>, Microencapsulation<br />

Processing Extrusion, Pumping and Dosing, Pellet Production<br />

Packaging Flexible Wet Packaging and Sleeving, Pouches for Treats<br />

<strong>Marketing</strong> Showcase India, Interzoo 2020 Preview<br />

FREE trial issue at <strong>food</strong>@harnisch.com<br />

Packaging: Pouches and Printing, Sustainability, Choosing the Right Bags<br />

<strong>Marketing</strong>: Ask the Vet, Company News, Updates From the Fairs<br />

PetFood PRO magazine<br />

wants to emphasize the<br />

high level of quality and<br />

care in the production<br />

of pet <strong>food</strong> through the<br />

choice of ingredients, the<br />

choice of technology and<br />

the choice of packaging<br />

materials.<br />

International Magazine April 2019 ISSN 2628-5851<br />

<strong>Technology</strong> & <strong>Marketing</strong><br />

1/19<br />

Recycling is<br />

teamwork<br />

10 IFT Food Focuses on Better-for-you and Better-forthe-planet<br />

Solutions<br />

14 Consumer Attitude Towards Sweeteners<br />

16 Healthy and Delicious Avocado: Price of the Bounty<br />

Processing<br />

6 Automated Handling of Plant-based Proteins, Fibers,<br />

Cellulose and Binders<br />

20 Spotlight on Sorting: How Potato Processors can<br />

Improve Profitability and Sustainability by Using the<br />

Latest Steam Peeling Solutions<br />

25 Semi-active Hygienic Wheel and Sole Cleaning<br />

26 Accelerating Impact Together<br />

28 Ultimate Processing of Proteins with New Dicer<br />

Generation<br />

29 Onboard Processing Plant for Antarctic Sea Krill<br />

Harvest Vessel<br />

30 The Right Dosage<br />

Packaging<br />

52 Perfectly packaged cheese – for lasting freshness<br />

and premium quality<br />

54 New Flowpacking Solution for Different<br />

Applications”<br />

Departments<br />

Ingredients Indispensable Fatty Acids, Dietary Fiber for Pets, Yeast<br />

Processing HPP <strong>Technology</strong>, Extruding Fish Feed, Encapsulation<br />

Packaging Canning, Recyclable Bags, Cartons<br />

<strong>Marketing</strong> The Vet's Corner, News from Fairs and Firms<br />

Ingredients Joint Health & Mobility, Yeast Extracts, Fiber<br />

Processing Batch & Continuous Mixing, Optical Sorting, Extrusion<br />

www.harnisch.com<br />

Packaging Pouches, Bags & Sacks, Tubs, Coding<br />

32 drinktec preview<br />

36 Fachpack preview<br />

44 PPMA preview<br />

56 all4pack preview<br />

57 Events

Cutting <strong>Technology</strong><br />

2/9/22 10:37 AM<br />

Vol. 36 • 31377<br />

ISSN 0932-2744<br />

Cover: AZO GmbH<br />

4/22<br />

In automated handling of bulk<br />

materials enormous challenges can<br />

quickly arise. Namely, when the raw<br />

material used turns out to be sticky,<br />

or lumpy for example in TVPs. To<br />

be able to face these challenges<br />

right from the start, you need a<br />

competent plant manufacturer at<br />

your side.<br />

Our Cover Story starts on page 6.<br />

your product.<br />

.urschel.com<br />

Cover: Automated Handling<br />

of Proteins & Fibers<br />

Better-for-you<br />

Ingredient Solutions<br />

Steam Peeling<br />

Improves Potato Profit<br />

Perfectly<br />

Packaging Cheese<br />

Key No. 102489<br />

Ingredients: Better Ingredients<br />

The Institute of Food Technologists’ (IFT) in-person annual<br />

convention took place in Chicago this past July after a twoyear<br />

pandemic hiatus. The show lived up to its rebranding of<br />

“IFT FIRST - where Food is Improved by Research, Science<br />

and <strong>Technology</strong>.” Each morning the day began with a fascinating<br />

keynote presentation featuring authorities across a<br />

range of <strong>food</strong> science disciplines. More on page 10.<br />

Processing: Profitable Potato Peeling<br />

Reducing <strong>food</strong> waste is one of the most important objectives<br />

of this generation. Equally important is energy use in production.<br />

The good news is that automated solutions are available<br />

to address both these issues. Solutions that are environmentally<br />

friendly and commercially savvy enhance processors’<br />

green credentials while also preventing waste from cutting<br />

away at the bottom line. See the full story on page 20.<br />

Events: Lasting Cheese Freshness<br />

Microorganisms generally play a key role during cheese<br />

production. But with packaged cheese, the aim is to avoid<br />

these microbes altogether, as they can spoil the cheese. Using<br />

packaging to protect cheese from microorganisms is beneficial<br />

to achieve the longest possible shelf life without forfeiting<br />

taste, appearance or quality. Find out more on page 44<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • February 2016<br />

Key No. 102158

Cover Story<br />

Automated Handling of Plant-based<br />

Proteins, Fibers, Cellulose and Binders<br />

The automated handling of bulk<br />

materials: What sounds trivial, can<br />

quickly become an enormous<br />

challenge. Namely, when the raw<br />

material used turns out to be sticky,<br />

building bridges, lumpy etc. Such<br />

raw materials are the order of the<br />

day, especially in the field of textured<br />

vegetable protein (TVP), high moisture<br />

extrusion (HME) and the used plantbased<br />

proteins, fibers, cellulose and<br />

binders. Especially Soy, pea or wheat<br />

proteins can be both sensitive and<br />

thus sometimes tend to be stubborn,<br />

means either stick or bridge easily.<br />

The produced TVP can also be quite<br />

stubborn, meaning it sticks easily and<br />

has poor flow characteristics. So, you<br />

can see, it is not as easy as it seems<br />

and needs a lot of know-how on how to<br />

lay out the whole plant.<br />

In order to be able to face possible<br />

challenges right from the start, you<br />

need a competent plant manufacturer<br />

at your side for the automation of such<br />

stubborn, free flowing or sensitive raw<br />

materials. And this is exactly where<br />

AZO comes in. The plant manufacturer<br />

from Osterburken, southern Germany,<br />

not only has more than 70 years<br />

of experience in the automation of<br />

raw materials, but with its in-house<br />

laboratory for raw material it also<br />

has the possibility to analyze the raw<br />

materials to be able to precisely<br />

determine their physical properties<br />

and derive the resulting storage<br />

properties, eligibility, etc. Furthermore,<br />

almost all products can be conveyed<br />

on a trial basis in the pilot plant. This<br />

creates the perfect basic conditions<br />

for an optimal plant design and for<br />

all the raw material characters and<br />

challenges, AZO has an appropriate<br />

solution.<br />

Artificial Meat: Already a<br />

permanent trend or still just a<br />

hype?<br />

The market potential of artificial meat<br />

is enormous and should certainly<br />

be seen as a permanent trend and<br />

not just as hype. Soy, pea or wheat<br />

proteins, fibers, cellulose and binders<br />

are usually used in the production of<br />

such meat substitutes. But producing<br />

these substitutes and automating their<br />

handling into the production process<br />

poses some challenges. The Goal is<br />

clear: Feed the extruder with the blend<br />

of raw materials continuously, in the<br />

right time with the right quantity in<br />

addition with a consistently quality.<br />

In the AZO Technical Center, more than 100 tests are carried out annually with more than 250 raw<br />

materials and analyzed in detail.<br />

Automated raw material handling<br />

of proteins: The vacuum weighing<br />

system<br />

Once, when the soybeans, pea or<br />

wheat are processed into a proteinflour,<br />

they get stored in big silos or big<br />

bags and are ready for the production<br />

of TVP or HME. This is where AZO’s<br />

expertise comes into play. The first<br />

challenge is to convey the proteins and<br />

additives out of silos or big-bags with<br />

a vacuum weighing system. But as<br />

already mentioned, some proteins and<br />

additives tend to flow poorly. A smooth<br />

and trouble-free unloading gets<br />

ensured by using discharge aids. The<br />

vibration bottom has become widely<br />

accepted as a discharge system since<br />

it is universally usable. It has smooth<br />

surfaces and no separate mechanically<br />

moved parts, making it very easy to<br />

clean as well as wear and maintenance<br />

free. Water condensation in the silo is<br />

avoided as no heated air is blown into<br />

bulk materials. In association with a<br />

correctly dimensioned silo cone, the<br />

vibration bottom provides symmetrical<br />

descent of the bulk material columns<br />

without funnel and bridge formation,<br />

thus guaranteeing “first in - first out”.<br />

A dosing device is located under the<br />

discharge equipment for challenging raw<br />

materials into the conveying line: Either<br />

a rotary valve or a product feeder with<br />

rotating rotor, or a dosing screw with<br />

worm thread continuously transfer the<br />

needed raw materials into the conveying<br />

line. Dosing screws dose poorly flowing<br />

products with more precision than<br />

rotary feeder, if necessary.<br />

But the job is not done yet:<br />

Since proteins are only one part of<br />

a whole mixture to produce TVP or<br />

HME, it is necessary to take a closer<br />

look at the other essential conveying<br />

lines. Next to the proteins, other minor<br />

and major ingredients of the recipe,<br />

like flours, flavors or spices, fibers,<br />

cellulose and binders have to get<br />

added in the right quantity and time<br />

into a pre mixer.<br />

6<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • August <strong>2022</strong>

Cover Story<br />

Whether these raw materials are stored<br />

in silos, big bags or sacks – AZO has the<br />

right dispensing stations and discharge<br />

aids for every type of raw material. Due<br />

to the fact that major raw materials are<br />

usually easier to handle, it´s worth to<br />

have a closer look on the automation<br />

of minor and micro components for an<br />

economical production line.<br />

System for minor ingredients<br />

automation and pre-mixing: AZO<br />

COMPONENTER® Family<br />

The AZO COMPONENTER® in<br />

circular design is recommended<br />

when a small number of components<br />

need to be automatically weighed.<br />

Following this principle, the surge<br />

bins, such as feeding hoppers for<br />

sacks, pneumatically fed receivers<br />

or small silos are arranged in a circle<br />

above the collection vessel. They<br />

can be fed by vacuum or pressure<br />

conveying. Each component has its<br />

own discharge, dosing and scale unit,<br />

optimized to the specific raw material.<br />

Thus, parallel weighing processes<br />

and feeding of several mixing lines<br />

are possible.<br />

The vibration bottom employed here<br />

ensures reliable transfer even for<br />

small components with poor flowing<br />

characteristics. The vibration dosing<br />

screw with locking device guarantees<br />

highly accurate dosing. The rotating /<br />

tipping scales project into a common<br />

collection vessel and empty into<br />

The AZO COMPONENTER® in circular design for automatically weighing.<br />

Vibration bottom is an universally usable discharge aid.<br />

it. From this point, the product is<br />

pneumatically transferred into the<br />

conveying scale, or depending on the<br />

application, transferred directly to the<br />

mixer. This AZO COMPONENTER®<br />

version can be used where<br />

intermixture of related products is<br />

permitted.<br />

The AZO COMPONENTER® Step<br />

allows effective production<br />

planning<br />

This system makes it possible to<br />

weigh minor and micro components<br />

automatically with accuracies down<br />

to a gram, such as colorings, flavoring<br />

agents, spices, fibers, cellulose and<br />

binders and numerous other micro<br />

quantities. The system improves<br />

product safety while simultaneously<br />

boosting production efficiency by<br />

reducing individual manual production<br />

steps to a minimum.<br />

The system comprises two levels. The<br />

components are held ready in raw<br />

material storages on the upper level.<br />

Prior to filling, the raw materials can<br />

be identified using the barcode and<br />

allocated to the correct hoppers. This<br />

rules out mix-ups of a high numerous<br />

of products and ensures that raw<br />

materials can be traced back. The raw<br />

material storage can be filled from<br />

sacks or big bags; pneumatic filling is<br />

also feasible.<br />

The target containers are positioned<br />

below the dosing points using a<br />

pneumatic drive. After the product is<br />

dosed with the quantity determined<br />

in the recipe, the target container is<br />

transported one step forward to the<br />

next dosing point. There are separate<br />

scales provided for each component for<br />

simultaneously weighing of components.<br />

This results in maximum time gain and<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • August <strong>2022</strong> 7

Cover Story<br />

a nearly infinity number of recipes that<br />

can get produced.<br />

Once all raw materials are in the target<br />

container in accordance with the recipe,<br />

it is ready for the next process: The<br />

premixing of all your used components.<br />

Get your all your components<br />

together<br />

No matter in which way all the<br />

needed raw materials get dosed<br />

and conveyed: They get all together<br />

in the right quantity and time into<br />

a pre mixer. After all ingredients<br />

have been mixed, the finished blend<br />

is transferred to the next process<br />

step. This means that the mixer can<br />

produce a new batch immediately<br />

after emptying - regardless of the<br />

subsequent process. The buffer tank<br />

is again equipped with a discharge<br />

aiding vibrating floor and conveys<br />

the mixture further to a magnetic<br />

sieve and the proven AZO screening<br />

machine. In this way, possible<br />

impurities are immediately separated<br />

without the blend being segregated.<br />

A great advantage to ensure the<br />

quality of your end products.<br />

Before the production of the TVP or<br />

HME can finally begin, another AZO<br />

system has to be used: The AZODOS®<br />

dosing system for volumetric dosing of<br />

products.<br />

Time to feed the extruder with the<br />

AZODOS® system<br />

The unit can be used in the <strong>food</strong> industry<br />

wherever production processes require<br />

Feeding the mixer with the needed raw materials.<br />

The AZO COMPONENTER® Step for producing a high number of different recipes.<br />

coarse/fine flow at a uniform mass flow<br />

rate in connection with a weighing device.<br />

But how does it work? A weigh feeder<br />

consists of the basic unit mounted on<br />

a platform load cell or integrated in<br />

a 3-point weighing frame. The dosing<br />

screw meters the bulk material in<br />

coarse/fine flow to the downstream<br />

process. If the blend is still badly flowing,<br />

double screws can be used to aid. The<br />

amount of product that is metered out<br />

of the AZODOS® is weighed.<br />

The system operates gravimetrically in<br />

accordance with the negative weighing<br />

principle. The AZODOS® becomes a<br />

loss-in weight feeder (DDW) when it<br />

is paired with a corresponding control<br />

system. The bulk material is discharged<br />

by the dosing screw. The actual loss<br />

in weight per unit of time (actual<br />

Feeding the TVP/HME extruder by using an<br />

AZODOS.<br />

throughput) is compared against the<br />

required setpoint, which is defined by<br />

the downstream process, e.g. extruder.<br />

Differences between the actual loss in<br />

weight per unit of time and the setpoint<br />

are corrected by changes in the screw<br />

speed.<br />

The control process is briefly interrupted<br />

when the product in the AZODOS®<br />

reaches a preset minimum level and<br />

the surge bin is replenished. During<br />

the refill time the dosing screw output<br />

is set to a value based on empirical<br />

weight and output data gained from<br />

previous metering cycles. This leads<br />

to a maximum dosing accuracy with<br />

simultaneous easy to clean solution by<br />

means of an extraction device. Now it´s<br />

time to feed the extruder with the blend<br />

of raw materials continuously, in the<br />

right time with the right quantity. This<br />

all leads to a perfect quality of the final<br />

product<br />

So it doesn’t matter what challenges<br />

arise when storing, conveying, mixing<br />

or dosing proteins, fibers, cellulose,<br />

binders and other raw materials:<br />

With an experienced and competent<br />

plant engineer like AZO, most<br />

problems can be eliminated before<br />

they even arise. “Don’t think in<br />

terms of problems. Think in terms of<br />

solutions,” as Johann Wolfgang von<br />

Goethe already knew.<br />

fmt<br />

8<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • August <strong>2022</strong>

Cover Story<br />

A WORLD OF PACKAGING SOLUTIONS<br />

DESIGNED FOR SUSTAINABILITY.<br />

BROUGHT TO LIFE BY SCHUBERT.<br />

FACH PACK<br />

NÜRNBERG<br />

SEPTEMBER 27. – 29.; <strong>2022</strong><br />

HALL 1 BOOTH 1-219<br />

WELCOME<br />

Key No. 102249<br />

How can packaging be both environmentally friendly and cost-effi cient? With our<br />

TLM packaging machines. They enable you to use the thinnest materials possible,<br />

cutting them to size to reduce consumption and dramatically decrease your use<br />

of resources. It’s great for the planet and you benefi t from a real competitive edge.<br />

We call it Mission Blue and we promise: The mission goes on.<br />

www.mission-blue.com<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • August <strong>2022</strong><br />

9

Ingredients<br />

IFT Food Focuses on Better-for-you and<br />

Better-for-the-planet Solutions<br />

by Donna Berry<br />

The Institute of Food Technologists’<br />

(IFT) in-person annual convention<br />

took place in Chicago this past July<br />

after a two-year pandemic hiatus. The<br />

show lived up to its rebranding of “IFT<br />

FIRST--where Food is Improved by<br />

Research, Science and <strong>Technology</strong>.”<br />

Each morning before the expo floor<br />

opened to attendees, the day began<br />

with a keynote presentation featuring<br />

authorities across a range of <strong>food</strong><br />

science disciplines.<br />

The first keynote centered around<br />

“Should We Eat More Processed<br />

Foods?” There are two sides to this<br />

story when you consider that new<br />

technologies enable formulators to<br />

create <strong>food</strong>s that can’t be made in<br />

home kitchens, <strong>food</strong>s that are far<br />

from the junk <strong>food</strong> many categorize<br />

as processed <strong>food</strong>s. Advocates<br />

say “a substantial increase in <strong>food</strong><br />

processing is the best way to feed<br />

growing human populations while also<br />

reducing <strong>food</strong> waste. We should trust<br />

and invest in <strong>food</strong> technology that can<br />

make our global <strong>food</strong> supply healthier<br />

and more sustainable, including highly<br />

or ultra-processed <strong>food</strong>s.” Opponents<br />

argue that “these kinds of <strong>food</strong>s<br />

are often less nutritious, and are<br />

commonly linked to adverse health<br />

indices, particularly when it comes to<br />

ultra-processing.”<br />

Michael Gibney, emeritus professor of<br />

Food and Health at University College<br />

Dublin, a supporter of more processed<br />

<strong>food</strong>s and one of the speakers pointed<br />

out how “you can’t make plantbased<br />

<strong>food</strong>s without processing and<br />

processing aids.”<br />

And, indeed, plant-based innovation<br />

was a focal point for many ingredient<br />

suppliers. Ingredion Inc., for example,<br />

featured an entire menu of plantbased,<br />

sustainably packaged <strong>food</strong>s<br />

and beverages, including treats for<br />

dogs.<br />

“Our 360 Value approach to innovation<br />

helps brands achieve holistic value<br />

creation by increasing margins and<br />

meeting consumer well-being demands,<br />

all while decreasing environmental<br />

impacts,” said Janelle Litel, manager of<br />

content and communications.<br />

Prototypes sampled included a<br />

butterfly jasmine plant-based milk tea,<br />

which is a higher protein, reducedsugar<br />

beverage that is a good source<br />

of fiber. It is made with pea protein<br />

isolate and soluble prebiotic fiber,<br />

and sweetened with allulose and<br />

fermented sugarcane Reb M.<br />

“The ‘puppy power biscuits’ were loaded<br />

with good-for-them ingredients,” said<br />

Litel. “They included a combination of<br />

Kerr by Ingredion’s fruit and vegetable<br />

concentrates and prebiotic fiber.”<br />

The company created gluten-free,<br />

vegan “cheez” crunchy snack chips.<br />

The base was made with faba bean<br />

protein concentrate, pea flour, tapioca<br />

flour and varied starches. The chips<br />

relied on vegan cheese-type flavors.<br />

Many suppliers chose to sample their<br />

plant-based prototypes in prepared<br />

<strong>food</strong> applications in order to provide<br />

attendees with real-world application<br />

ideas.<br />

“We created an assortment of greattasting<br />

concepts to showcase how our<br />

experts can help optimize production<br />

by substituting existing ingredients<br />

with plant-based equivalents to<br />

give better process efficiency,” said<br />

Octavio Diaz de Leon, president<br />

of AAK USA and AAK North Latin<br />

America. “Prototypes included plantbased<br />

pepperoni on flatbread pizza<br />

and plant-based butter that is perfect<br />

Photo: Ingredion<br />

Photo: AAK<br />

10 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • August <strong>2022</strong>

Ingredients<br />

for cooking and baking and is stable at<br />

room temperature.<br />

ChickP, Ltd., a <strong>food</strong>-tech startup based<br />

in Israel, used IFT FIRST to introduce<br />

its chickpea protein isolates in dairyalternative,<br />

barista-style coffee drinks.<br />

This system was designed specifically<br />

for milk analogs to be used in creamy<br />

beverages.<br />

“Plant-based barista drinks set new<br />

challenges,” said Liat Lachish Levy,<br />

chief executive officer. “Consumers<br />

want a holistic, better-for-you, yet fullflavor<br />

experience. Our technologists<br />

took full advantage of our new stateof-the-art<br />

application lab to overcome<br />

organoleptic and technical challenges<br />

in creating creamy, dairy-free ‘milk’ for<br />

the perfect cappuccino.”<br />

antithesis of the norm,” said Yoon.<br />

“Our products are low in calories, net<br />

carbs and sugar, yet high in fiber<br />

and protein. We use ingredients like<br />

chickpeas and other pulses, which are<br />

highly regarded by experts in nutrition<br />

and sustainability.”<br />

The company sampled gluten-free<br />

chocolate chip cookies and pita chips,<br />

both having chickpeas as the numberone<br />

ingredient. There were also two<br />

better-for-you toppings—strawberry Photo: ChickP<br />

dots and vanilla crumbles—made with kind ingredients. Canadian start-up<br />

resistant starch and a pulse protein Chinova Bioworks introduced Chiber<br />

blend.<br />

Mushroom Fiber. It is derived from<br />

the upcycled stems of white button<br />

The expo included a number of firsttime<br />

exhibitors featuring first-of-their-<br />

preservative 1 29.04.22 to improve 20:07 Seite the 3<br />

mushrooms and functions as a natural<br />

R+K_AZ_<strong>2022</strong>_Food_<strong>Technology</strong>_137x187.qxp_Layout quality,<br />

Maor Dahan, application manager,<br />

said, “Our chickpea isolates are the<br />

most refined form of protein with the<br />

advantage of matching color, flavor<br />

and functional properties to <strong>food</strong> and<br />

beverage applications. This protein has<br />

great solubility, exhibiting excellent<br />

water dispersion properties across a<br />

wide range of pH. It has a low viscosity<br />

and an optimized flavor.”<br />

Antithesis Foods Inc., Ithaca, N.Y.,<br />

made its debut at IFT FIRST in the<br />

Startup Pavilion. The company is<br />

all about making processed <strong>food</strong>s<br />

healthier by using the best <strong>food</strong><br />

science.<br />

“We develop nutritionally dense lowcalorie<br />

alternatives to classic crunchy<br />

snacks and ingredients, all based on<br />

legumes,” said Jason Goodman, chief<br />

executive officer. “If it crunches, we<br />

make it healthier.”<br />

Founded in 2017, Antithesis Foods<br />

was started by Goodman and Ashton<br />

Yoon, chief operating officer, who were<br />

then both graduate <strong>food</strong> scientists at<br />

Cornell University. They were united by<br />

their shared passion for using science<br />

to address critical problems in the <strong>food</strong><br />

system.<br />

“At Antithesis, we thrive on solving<br />

problems, care deeply about <strong>food</strong> and<br />

nutrition, and aren’t afraid to do the<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong><br />

11<br />

Key No. 102794

Ingredients<br />

freshness and shelf-life of various<br />

<strong>food</strong> and beverage products, including<br />

cottage cheese, plant-based meats<br />

and hummus.<br />

role of <strong>food</strong> in the life of an astronaut<br />

and why human travel to Mars won’t<br />

happen until technology is available to<br />

feed them.<br />

“Mushrooms have long been overlooked<br />

by our <strong>food</strong> system for their incredible<br />

functional properties, but we have<br />

found a great use for this mushroom<br />

fiber as a natural replacement<br />

for artificial preservatives,” said<br />

David Brown, co-founder and chief<br />

operations officer.<br />

Two weeks after IFT FIRST, Chinova<br />

received a No Questions Letter from<br />

the U.S. Food and Drug Administration<br />

(FDA) regarding their application<br />

for Chiber Mushroom Fiber to be<br />

Generally Recognized As Safe<br />

(GRAS). A No Question Letter is FDA’s<br />

communication showing an ingredient<br />

is permitted for use. FDA GRAS status<br />

is recognized in many countries<br />

outside the U.S. and aids in garnering<br />

regulatory ingredient acceptance<br />

abroad.<br />

This is the type of <strong>food</strong> science that<br />

one may describe as being “out of<br />

this world.” Speaking of beyond our<br />

planet, the second keynote panel<br />

discussion—R&D at the Edges of<br />

Human Experience—included current<br />

and former <strong>food</strong> science teams from<br />

the U.S.’s National Aeronautics and<br />

Space Administration (NASA). They<br />

discussed the need for advanced<br />

technologies to better understand the<br />

“Food is so important. It’s not only<br />

sustenance. It can be life support,” said<br />

Scott Parazynski, a panelist and former<br />

astronaut. “It’s also a bridge between<br />

cultures, and it’s a tie to home.”<br />

He pleaded for innovators to develop<br />

products that replicate the tastes<br />

astronauts crave from space. But<br />

that’s just one small problem for<br />

mankind. To get to Mars, there’s a lot<br />

more to consider in terms of nutrition.<br />

Panelist Michele Perchonok, a past<br />

IFT president who managed the<br />

NASA Space Food Systems Lab<br />

before her retirement, identified<br />

some of the challenges of space <strong>food</strong><br />

development. In addition to safety and<br />

preserving nutrient density, shelf-life<br />

is paramount, as well as minimizing<br />

packaging waste.<br />

It will be about a six-month journey to<br />

Mars. Then there’s about a two-year<br />

stint exploring the planet followed by<br />

a six-month return trip. With current<br />

technology, feeding a crew of six for<br />

three years would require more than<br />

26,000 pounds of <strong>food</strong>, of which 17%<br />

is packaging waste. Further, the shelflife<br />

requirement is more than three<br />

years because it is impossible for the<br />

vehicle transporting the astronauts<br />

Photo: Ingredion<br />

to also transport the <strong>food</strong>. There will<br />

be about a six-month supply on their<br />

ship, and the rest will have to be prepositioned<br />

on Mars prior to takeoff.<br />

And jokingly, Perchonok said, they<br />

have to know Martians won’t take it.<br />

But seriously, she explained, it has to<br />

be pre-positioned safely so that it is<br />

available when the astronauts arrive.<br />

Food scientists have a major role to<br />

play in advancing space <strong>food</strong> product<br />

development, according to Dorit<br />

Donoviel, executive director at the<br />

Translational Research Institute for<br />

Space Health, who moderated the<br />

panel. “We’re looking to you,” she said.<br />

“We’re here to ask you to please engage<br />

and help us solve these problems.”<br />

These needs put a whole new<br />

perspective on why advanced<br />

technologies—everything from<br />

bioengineering to 3-D printing to<br />

cellular meat—are important. The<br />

beauty of all this work by NASA is that<br />

it can be adapted to <strong>food</strong> production<br />

on Earth and help feed the growing<br />

population.<br />

Photo: K emin<br />

But to get there, thinking out of the<br />

box is paramount. The final keynote<br />

left attendees eager to get back to the<br />

lab. “Cultivating Curiosity: The Key<br />

to Unlocking Innovative Solutions to<br />

Complex Problems,” was addressed by<br />

Evette Cordy, chief executive officer of<br />

12 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • August <strong>2022</strong>

Ingredients<br />

Agents of Spring. She explained that<br />

organizations are often too focused on<br />

the short term and then jump quickly<br />

to provide solutions.<br />

“…what is the customer problem you<br />

are trying to solve?” asked Cordy. “That<br />

is why we must first learn to problem<br />

find before we problem solve. Curiosity<br />

is the tool we can use to solve our most<br />

problems.”<br />

Companies need to step back and<br />

answer this question before they jump<br />

on the latest trend, which right now,<br />

is everything plant based. The world<br />

does not need any more plant-based<br />

burgers, nuggets or cheese. It is time<br />

to take it to the next level.<br />

Sugar reduction was also big business<br />

at IFT FIRST. And while stevia and<br />

allulose dominated the conversation, a<br />

number of exhibitors showcased new<br />

sugar-reduction technologies. Some<br />

are based on real cane sugar formatted<br />

into sensory-enhanced crystals, others<br />

are real cane sugar blended with fibers<br />

and natural flavors.<br />

director and brand partnership. “This<br />

allows for a higher concentration<br />

of sucrose to dissolve around<br />

the receptors and enhances the<br />

perception of sweetness.”<br />

Deproteinized whey, also known as<br />

whey permeate, is a concentrated<br />

source of minerals along with lactose.<br />

It allows for a reduction in total<br />

sugar and added sugars in many<br />

formulations. Agropur used it in lowersugar<br />

cheesecake bites.<br />

Whey permeate is also considered an<br />

upcycled ingredient, as it is the liquid<br />

stream that remains after whey protein<br />

ingredient manufacturing. In fact, you<br />

might even call it a double upcycled<br />

ingredient, as whey is the waste stream<br />

from cheese production and permeate<br />

is the waste stream of whey ingredient<br />

production.<br />

A final recurring them at IFT FIRST<br />

was about upcycling and sustainability,<br />

with the latter coming from many<br />

different directions. Kemin, for example,<br />

introduced Proteus V functional<br />

proteins, which are designed for<br />

breaded fried applications. With this<br />

ingredient, less oil is absorbed into<br />

the product. By limiting the amount<br />

of oil used, manufacturers reduce the<br />

amount of oil waste. This ingredient also<br />

helps the coating adhere more cleanly<br />

to the product, reducing the amount of<br />

coating waste that would otherwise be<br />

thrown away, along with the oil. fmt<br />

The Author<br />

Donna Berry is a <strong>food</strong> and beverage industry<br />

consultant and editor with over 25 years<br />

experience in tracking trends and advancements<br />

in product development.<br />

Lycored, for example, showcased<br />

its unique plant-based solution<br />

for sodium and sugar reduction to<br />

help support cleaner and healthier<br />

ingredient and recipe strategies<br />

for prepared <strong>food</strong>s. The company’s<br />

tomato-derived taste-enhancer was<br />

used in plant-based meatballs offering<br />

40% reduced sodium and pizza sauce<br />

with 50% reduced sodium and sugar.<br />

“The idea of wellness is fast becoming a<br />

dietary staple and a trend driving much<br />

of the <strong>food</strong> and beverage industry’s<br />

natural, clean-label recipe innovation,”<br />

said Tammi Higgins, senior vice<br />

president of product and applications.<br />

DouxMatok showed how its patented<br />

Incredo Sugar reduces sugar in a range<br />

of products. The ingredient is made<br />

from real cane sugar and achieves the<br />

same level of sweetness with up to<br />

50% less sugar and no compromise on<br />

taste or texture.<br />

“Incredo Sugar works by improving<br />

the efficiency of sucrose delivery and<br />

dissolution to the sweet receptors,”<br />

said Shiri Ranot, global marketing<br />

Join us in<br />

our next:<br />

Hydrocolloid Information Center<br />

Publisher of:<br />

The Quarterly Review of Food<br />

Hydrocolloids<br />

Food Hydrocolloid Conference<br />

MALTA<br />

April 23-25, 2023<br />

Nesha Zalesny – nzalesny@hydrocollid.com<br />

Dennis Seisun – dseisun@hydrocollid.com<br />

www.hydrocolloid.com<br />

Key No. 102333<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • August <strong>2022</strong><br />

13

Ingredients<br />

Consumer Attitude Towards Sweeteners<br />

The ongoing war on sugar has shaped consumer attitude towards sugar and what excessive sugar intake<br />

is associated with. As more consumers have become conscious about their health and wellbeing in the last<br />

couple of years this is something that has amplified. As many consumers view sugar as a cause of obesity<br />

and link excessive consumption with health problems, sugar intake is something that people are looking to<br />

reduce.<br />

Why turn to sweeteners?<br />

FMCG Gurus consumer insights found<br />

that 66% of global consumers seek out<br />

products containing sweeteners as an<br />

attempt to avoid or moderate sugar<br />

intake. With a greater focus on improving<br />

diet and lifestyle to aid healthy ageing,<br />

more consumers are making efforts to<br />

reduce the amount of sugar in their diet.<br />

Additionally, plant-based sweeteners<br />

with free-from claims can appeal to<br />

health-conscious consumers looking<br />

for better-for-you options in their diets.<br />

This, alongside organic and sustainability<br />

claims, can help products containing<br />

sweeteners instead of sugar be seen by<br />

consumers as a guilt-free alternative.<br />

Many consumers are simply not<br />

educated enough about the different<br />

types of sweeteners on offer. Only<br />

27% of global consumers regularly<br />

conduct research into different types of<br />

natural sweeteners. This highlights that<br />

consumers will seek out products where<br />

information is clearly available on the<br />

packaging about the sweetener content.<br />

The industry should address this and<br />

look for ways to encourage consumers<br />

to research and educate themselves on<br />

natural sweeteners. This can help avoid<br />

confusion where consumers might label<br />

a sweetener as artificial if they believe<br />

the ingredient sounds chemical, even if<br />

this is not the case.<br />

However, it is interesting to note that<br />

FMCG Gurus consumer insights found<br />

that 50% of consumers deem natural<br />

sweeteners to be healthy, but only one<br />

in four consumers are making active<br />

attempts to seek out products that<br />

contain them. This suggests that there<br />

is not enough motivation alone from<br />

natural sweetener claims on packaging<br />

and this is something that brands need<br />

to address.<br />

Barriers for the sweetener market<br />

One of the main barriers for the<br />

sweetener market is a lack of education.<br />

Another issue to address is cost.<br />

FMCG Gurus consumer insights found<br />

that only 29% of consumers were<br />

willing to pay a premium for <strong>food</strong> and<br />

drink containing natural sweeteners.<br />

In a time of reduced financial<br />

confidence with living costs on the<br />

rise, consumers are looking to cut they<br />

amount they spend on <strong>food</strong> and drink.<br />

Consumers can associate betterfor-you<br />

products with a higher price<br />

point and may avoid products with<br />

sweeteners due to this preconception.<br />

This also demonstrates that natural<br />

sweetener claims alone are not<br />

enough to influence consumers to pay<br />

a premium price. Again, brands should<br />

encourage consumers to understand<br />

about individual sweeteners rather<br />

than natural sweeteners as a collective.<br />

This can help them make informed<br />

decisions about the products they<br />

consume and the sustainability,<br />

heath and quality benefits of these<br />

ingredients.<br />

Most importantly, the biggest<br />

barrier that sweetener brands<br />

need to overcome is the sensory<br />

appeal of sweeteners. Globally, 57%<br />

of consumers state that natural<br />

sweeteners lack in taste and 36% state<br />

that they regularly experience a bitter<br />

taste when eating or drinking products<br />

that contain natural sweeteners. This<br />

is something that the sweetener<br />

market has been faced with for a<br />

long time. Consumers will want to<br />

seek out products that are guilt-free<br />

and healthier, but will not want to<br />

compromise on taste. The industry<br />

should continue to innovate and work<br />

on improving the taste of ingredients<br />

so consumers are more likely to turn<br />

to products containing sweeteners. fmt<br />

14 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • August <strong>2022</strong>

Ingredients<br />

Online & In-Person<br />

28 Nov - 8 Dec <strong>2022</strong><br />

From Anywhere<br />

Online<br />

6 - 8 Dec <strong>2022</strong><br />

Paris, Expo Porte de Versailles<br />

France<br />

NEW<br />

VENUE<br />

Key No. 103367<br />

Join<br />

the biggest<br />

EU ingredient event<br />

this December<br />

Learn<br />

more at<br />

bit.ly/fie-print<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • August <strong>2022</strong> 15

Ingredients<br />

Healthy and Delicious Avocado:<br />

Price of the Bounty<br />

by Rico R. Magda<br />

There has been a silent contest among<br />

the major producers of this unique<br />

‘green-gold’ avocado as to who<br />

would be on the top list of suppliers<br />

or exporters. There have been many<br />

contenders but the production of<br />

this ‘green-gold’ fruit is creating<br />

some drawbacks like droughts or<br />

scarcity of useable domestic water,<br />

deforestation, etc. to name a few.<br />

Producer countries, however, deny<br />

such bad effects and claim otherwise<br />

that sales have been beneficial to<br />

national economic development. The<br />

controversy surrounding the stuff<br />

seems unabated though one thing<br />

is sure: Avocado will remain as the<br />

mainstay export crop and a favorite<br />

domestic diet.<br />

Avocado, a very thirsty tree<br />

In 500 BC, the Aztecs in Mexico<br />

named ‘avocado’ as ‘ahuacatl’ fruit<br />

as it hangs from the tree as testicle,<br />

which greatly resemble the male<br />

part. Avocado (Persea americana)<br />

appears as a common fare for trendy<br />

magazines and social media. Its<br />

growing practices, however, have<br />

griping disadvantages to the exporting<br />

countries due to its gargantuan needs<br />

for irrigation water during the fruiting<br />

stage, reducing the growing countries<br />

with depleted or scarce water supply.<br />

Despite this apparent drawback, the<br />

popularity of this stuff marches on.<br />

A report has it that avocado exports<br />

have increased from 230 million kg<br />

in1990 to 1,300 million kg in 2000<br />

despite some precautions of water<br />

scarcity.<br />

Due to lucrative international trade<br />

of avocado, more forestlands in<br />

Mexico have been converted to<br />

avocado plantations. In 2000 to 2010,<br />

an estimateof 20,000 hectares of<br />

forestlands are converted in Mexico<br />

resulting to1,700 acres of deforested<br />

lands each year.<br />

It takes more water to produce, let’s<br />

say a kilo of avocado in comparison<br />

with other fruits. One kilo of avocado<br />

needs about four times (about 20<br />

gallons) of irrigation water than<br />

producing the same weight of<br />

oranges, and 10 times that of tomato.<br />

Facing reality, avocado-growing<br />

countries have been experiencing<br />

dryness and scarce water resources.<br />

This experience has been enhanced<br />

by climate-change factors, which led<br />

them prospecting for potable water<br />

even up to 100 meters or more down.<br />

Water scarcity model<br />

A water scarcity model is used to<br />

estimate the impact of water usage.<br />

For example, this shows that Mexico<br />

where half of the world trade for<br />

avocado takes place, has the highest<br />

WSF (Water Scarcity Footprint) rate<br />

of 27%. Chile follows Mexico with<br />

22%; then Israel with 12%; USA 11%;<br />

Australia 7%; South Africa 5.6%;<br />

Rwanda 5%; Peru 3.6%; Spain 3%; and<br />

Morocco 1%.<br />

Despite of all the infringement of basic<br />

rights for water and the destruction of<br />

natural habitats, tenacious producer<br />

countries are not giving up.<br />

Here’s a brief UN report on Chile’s<br />

water scarcity. As Chile’s ‘greengold’<br />

fruit booms, some looming tensions<br />

brought by water scarcity (big<br />

producers vs local residents) loom on<br />

the horizon.<br />

Let’s use Chile as a frame for<br />

‘successful’ raising of avocados for<br />

the international market. The world’s<br />

demand for the fruit has been on<br />

tremendous rise. Zeroing on Petorca<br />

City, Chile’s north of the capital<br />

Santiago, is a booming avocado<br />

business. This site produces most<br />

of the avocado fruits, which makes<br />

Chile as the world’s third largest<br />

exporter. Lately, however, residents<br />

have noticed that the backside of this<br />

booming trade has a gloomy result<br />

surfacing: local water supply has<br />

considerably dried up.<br />

With water scarcity arising from<br />

water use manipulation and the<br />

prevaling climate change, Chile may<br />

be facing hunger.They attribute the<br />

increasing water depletion to big<br />

16 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • August <strong>2022</strong>

Ingredients<br />

avocado companies manipulating<br />

water use that cause severe shortage.<br />

As free water becomes scarce in<br />

local communities, villagers now just<br />

rely on the weekly rationed water<br />

by government trucks. Residents,<br />

however, have commented on the<br />

safeness of the said water. Noticeably,<br />

some families have left Petorca’s<br />

community due to this problem.<br />

Chile’s Water Code of 1981 says that<br />

individuals, companies, and producers<br />

can request government allocation<br />

and extraction of water. Such Code,<br />

however, seems not doable in poor<br />

communities.<br />

Climate change and avocado farming<br />

The onset of climate change with fewer<br />

rainfalls contributes to the scarcity of<br />

water in the plantation site of Petorca.<br />

In 2006, big avocado companies came<br />

up with a good promise for economic<br />

benefits in uplifting the community<br />

life. But the rising drought has oiled<br />

a potential conflict between the<br />

community and the big firms. Initially,<br />

economic growth was observed<br />

from big investment in the ‘greengold’<br />

farming. But common avocado<br />

farmers have not been satisfied<br />

with the selective improvements as<br />

they reasoned out that only the big<br />

avocado companies are the only ones<br />

that reap huge benefits. Common<br />

workers, on the other hand, have only<br />

benefited by short-term or seasonal<br />

employment.<br />

water. Some avocado advocates<br />

have suggested building big water<br />

reservoirs in Petorca for immediate<br />

and emergency use particular on<br />

drier months. According to a report,<br />

local farmers have been continuously<br />

harping the water authority on<br />

building some water reservoirs. And<br />

one of the current projects has on its<br />

program of building bigger reservoir<br />

costing some two billion US dollars.<br />

Recently, a mass inspection has<br />

been carried out in some Petorca’s<br />

plantation sites to monitor some illegal<br />

extraction and building of illegal wells.<br />

Some companies were identified<br />

resorting to illegal connections and<br />

were fined.<br />

Is avocado farming has really caused<br />

water scarcity or drought in Chile’s<br />

central district? An 18-month long<br />

study by the UN in Chile is negating<br />

that effect. The study, on the contrary,<br />

has even concluded that the avocado<br />

industry has contributed to the<br />

environment and the community.<br />

According to a report, from the<br />

Water Centre for Arid and Semi-<br />

Arid Zones of Latin America and<br />

Refinery refined<br />

the Carribean (CAZALAC-UNESCO)<br />

basing on the study results, shows<br />

that the avocado industry complies<br />

with the UN’s Convention to<br />

Combat Desertification and Drought<br />

while contributing to biodiversity,<br />

conserving humidity, preventing soil<br />

erosion, and providing economic<br />

development to the community. The<br />

study leader of that report said that<br />

saying avocado is responsible for<br />

drought is ‘irresponsible’ since there<br />

is water scarcity in Chile since 1540.<br />

Accusing that avocado farming as the<br />

cause of water scarcity was based on<br />

‘wrong vision and emotion’ according<br />

to an account of the report.<br />

The spiralling demand for more and<br />

more avocados in China, USA, and<br />

in Europe has put more demand<br />

on irrigation water between local<br />

residents and big firms on water<br />

rights. The situation creates tension<br />

and serious felony threats between<br />

local players and international firms.<br />

Some conflicts have been recorded by<br />

the California-based Pacific Institute<br />

from 16 cases in 1990 to 73 in 1995.<br />

Big water reservoirs, the solution?<br />

The indiscriminate avocado<br />

farming in Petorca as revealed by<br />

satellite images some illegal ways<br />

of diverting water from rivers to<br />

plantation sites managed by private<br />

companies. Literally, the hills have<br />

become orchard with all the needed<br />

Palm oil<br />

free<br />

Sensory<br />

competence<br />

Pesticide free<br />

Chocolate<br />

Omega-3<br />

Tailormade<br />

Infant<br />

formula<br />

Give us a call:<br />

+41 32 387 48 48<br />

nutriswiss.ch<br />

Key No. 103029<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • August <strong>2022</strong><br />

17

Ingredients<br />

Currently, the domestic price of avocado<br />

in Chile is higher than the export price,<br />

which makes companies to tone down<br />

their export programmes. Production<br />

has been down by 40-50% due to<br />

prevailing drought. High temperature<br />

during flowering stage also greatly<br />

affected the production phase. Retail<br />

price has reached to $6.50 per kg. Since<br />

avocado in the domestic market has<br />

become expensive, Chile has turned<br />

to Mexico and Peru to fill the current<br />

domestic supply. Meanwhile, Peru<br />

floods the European markets while<br />

Mexico sends substantial volume to<br />

US, China, and South Korea at bottom<br />

prices. Chile’s avocado has not failed,<br />

however, shipping out successfully air<br />

and seafreighted fruits to Australia with<br />

prices on level with the domestic market.<br />

So far, Chilean exporters expect that<br />

avocado production will be normalized<br />

for the next cropping as shown by<br />

vigorous flowering and fruit setting.<br />

Brief focus on global avocado markets<br />

So far, the export of avocados from<br />

Peru has been declining same as<br />

for other suppliers from South<br />

Africa, Kenya, and California (USA).<br />

The supply comes now from other<br />

exporting countries like Columbia,<br />

Italy, Spain, and Mexico. The price has<br />

been on the rise.<br />

Due to oversupply caused by the<br />

pandemic, the Mexican avocado has<br />

been pushed back by two months. So<br />

instead of shipping in July, exportation<br />

started in May. So far, the supply and<br />

demand have been stabilized and<br />

growers expect higher volumes in the<br />

coming months.<br />

At the start, Peru avocados had low<br />

demand due to pandemic and now<br />

recovering. Currently, Peru plans to<br />

expand its market to US and Europe<br />

starting the spring of 2021.<br />

Columbia plans to be one of the big<br />

producers and potentially has the<br />

capability of producing the year round.<br />

Currently, its market is focussed on<br />

Europe while eyeing possible markets<br />

worldwide.<br />

Meanwhile, in the Dominican Republic,<br />

they dubbed now the ‘green-skin’<br />

avocado as the green-skinned which<br />

they currently export as ‘tropical<br />

avocados’ with the aim of expanding<br />

the market to US. The Semil-34<br />

variety dubbed as tropical avocado<br />

has a long shelf-life aimed at Texas<br />

and West Coasts markets.<br />

The European market has a limited<br />

supply and expectedly, prices to rise.<br />

Supplies from Peru, South Africa,<br />

South Africa, Kenya, and Chile will<br />

soon decline and Israel has been<br />

coming to the rescue with large<br />

volumes of Ettinger variety to deliver.<br />

Despite the decreasing demand,<br />

summer prices have soared from 20<br />

to 23 Euro per pack for ready-to-eat<br />

Hass variety.<br />

In Germany, the avocado trade has<br />

been stabilizing during summer<br />

characterized by some oversupply<br />

and low prices due to lack of demand<br />

from the catering industry brought<br />

by the pandemic. France has same<br />

market scene. As supplies from Peru<br />

declines, France market has been<br />

switching to Chilean avocados.<br />

In UK, when the last batch of Peruvian<br />

avocado is coming, UK now switches<br />

to Mexican and Columbian products.<br />

In Italy, the demand for avocado has<br />

increased despite the pandemic.<br />

Peru supplies the Hass variety.<br />

Sizes of 10, 12, 14 and 16 are the<br />

sought-after but with a limited supply.<br />

Despite the pandemic, consumption<br />

in Italy has grown by as much as<br />

500%. Consumers see avocado as<br />

a super<strong>food</strong>. Sicilian avocado farms<br />

are not yet in full production this<br />

year and they’re on just 50% capacity.<br />

This season’s fruits are mostly Hass<br />

variety with some small amount of<br />

Fuerte variety. South African avocado<br />

and rhe Peruvian Hass have surfaced<br />

on the market place. Hass costs about<br />

€21/4kg.<br />

18 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • August <strong>2022</strong>

Ingredients<br />

In China, as young generation now<br />

with health-oriented lifestyle, prefers<br />

nutrient-rich <strong>food</strong> like avocado.<br />

Although China produces avocado<br />

domestically, buyers still rely on<br />

imports from Chile, Peru, and Mexico.<br />

Currently, the price of avocado is on<br />

the rise.<br />

Japan has found a new avocado<br />

import partners in Indonesia. As<br />

Japan does not grow the fruit itself, it<br />

heavily relies on imports from Chile,<br />

Peru, US, New Zealand and Vietnam.<br />

Japan is known to have astringent<br />

requirements when they come to<br />

importing fruits and vegetables. Strict<br />

rules, however, are not observed as<br />

more avocado supply is needed by<br />

Japanese consumers. Japan avocado<br />

imports have increased steadily to<br />

74,000 tons in the last five years.<br />

In California, USA, yield of 77,000<br />

tons have been estimated. Prices<br />

may start at $1.70 in April and could<br />

sharply increase to $2.30 per half<br />

kilo. US imports avocado from<br />

Mexico and Peru. When the price of<br />

Mexican avocado has risen sharply<br />

on the US market, Peru would ship a<br />

large portion intead of Europe. When<br />

avocado supply from California and<br />

Peru has slowed down, a sharp price<br />

increase is expected and the supply<br />

now comes from Mexico.<br />

Nutritional benefits of avocado<br />

Fruit lovers consider avocado not<br />

a simple fruit. While most table<br />

fruits are loaded with cabohydrates,<br />

avocado, on the other hand, is very<br />

rich in healthy and safe fats. In facts,<br />

avocado has great benefits backed up<br />

by research.<br />

Avocado has intrinsic nutients<br />

with excellent flavor and texture<br />

that enhance various dishes like<br />

guacamole. It has been given the<br />

‘super-<strong>food</strong>’ status due to its popularity<br />

and nutritional composition. In the<br />

fruit market, you’ll find avocado in<br />

different shapes and color from green<br />

to black. They weigh from 8 ounces<br />

(220g) to 8 pounds (1.4kg).<br />

Alligator pear or the Hass variety is the<br />

most popular type of avocado. Hass<br />

has green rough skin like alligator with<br />

yellow-green flesh inside. In a single<br />

3.5- ounce (100g) slice, the following<br />

nutrients are found: Vitamin K, 26%<br />

of the daily value; Vitamin C, 17% of<br />

the DV; Potassium, 14% of the DV;<br />

Folate, 20% of the DV; Vitamins B5,<br />

B6, E, with 14, 13, and 10% of the DV<br />

respectively. Some trace amounts<br />

of copper, iron, zinc, phosphorous,<br />

manganese, magnesium, Vitamins A,<br />

B(thiamine), B2 (riboflavin), and B3<br />

(niacin) are found. The 3.5-ounce slice<br />

gives 160 calories, 2g of protein and<br />

15g of healthy fats. Avocados have no<br />

cholesterols or sodium but with low<br />

saturated fats.<br />

Sometimes consumers don’t get<br />

enough Potassium in their diet.<br />

With avocado, high amount of this<br />

substance becomes available, which<br />

could maintain healthy blood pressure<br />

level. This fruit has monounsaturated<br />

fatty acid good for the heart in the<br />

form of oleic acid with health benefits<br />

similar to olive oil.<br />

A 3.5-ounce serving gives 7g of fiber,<br />

both soluble and insoluble, which is<br />

27% of RDA. Fibers are important in<br />

the body’s weight loss and metabolic<br />

health. Consuming avocado can<br />

reduce bad cholesterol of up to 28%<br />

and triglycerides level of up to 20%<br />

while increasing the good cholesterol<br />

of up to 11%. Remember that heart<br />

disease is the common cause of death.<br />

In a study, analyzing data from 17,<br />

567 participants of dietary habits and<br />

health of people who eat avocado,<br />

researchers have found out that<br />

avocado consumers have higher<br />

nutrient intake and much healthier<br />

than people who are not avocado<br />

eaters. They also have lower risk of<br />

metabolic syndrome.<br />

Other nutritional benefits of avocado<br />

Avocado oil mixed with salad or salsa<br />

can increase antioxidant absorption in<br />

the body some 2.6 to 15 fold. When you<br />

eat fat-soluble nutients like Vitamins<br />

A, D, K, and E, they need fat or oil for<br />

the body to absorb. Or else, these<br />

nutrients are wasted into the drain.<br />

Beside helping the body in absorbing<br />

antioxidants, avocado in itself<br />

contains high antioxidants like lutein<br />

and zeaxanthin. These carotenoids<br />

can reduce the risk of having cataracts<br />

and macular degeneration associated<br />

with aging.<br />

Though avocados have limited<br />

evidence of benefits for cancer<br />

treatment, test-tube studies suggest<br />

that they may be beneficial for patient<br />

having chemotheraphy in human<br />

lympocytes. It also suggests inhibition<br />

of growth of prostate cancer cells<br />

in the laboratory test. More humanbased<br />

research, however, is needed.<br />

There’s also a strong suggestion<br />

that avocado extract may mitigate<br />

the symtoms of arthritis. It has the<br />

same effects as soybean oil extract in<br />

reducing osteoarthritis.<br />

Avocados are a weight-loss <strong>food</strong>,<br />

which can help one to lose weight.<br />

People given with avocado in meal<br />

have 23% satisfaction with lower<br />

desire to eat over the next five hours<br />

than people who did not eat the fruit.<br />

It is naturally rich in fiber and low in<br />

carbs, which is good for trimming<br />

extra weight.<br />

Avocados are healthy, delicious,<br />

and blendable with many kind of<br />

<strong>food</strong> preparations like salads, and<br />

other dishes making them easy to<br />

incorporate in your favorie diet. Being<br />

an excellent <strong>food</strong> with incredible taste<br />

and nutrients not found in ordinary<br />

diet, avocado makes itself a unique<br />

one.<br />

fmt<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • August <strong>2022</strong><br />

19

Processing<br />

Spotlight on Sorting: How Potato<br />

Processors can Improve Profitability and<br />

Sustainability by Using the Latest Steam<br />

Peeling Solutions<br />

Peeling potatoes on potato processing<br />

lines can be a bit like peeling notes from<br />

a wad of dollar bills and then throwing<br />

them away. Because mechanized peel<br />

removal also removes potato flesh, a<br />

high quantity of saleable raw material<br />

gets discarded. This is lost value and<br />

margin for a business, and over time<br />

it adds up to sums of money that <strong>food</strong><br />

processors cannot afford to lose.<br />

Reducing <strong>food</strong> waste is one of the most<br />

important objectives of this generation.<br />

Processors, retailers and consumers<br />

increasingly focus on the origin of<br />

<strong>food</strong> and expect <strong>food</strong> producers to<br />

adopt sustainable business practices.<br />

Thankfully much of the product loss<br />

incurred during potato peeling is<br />

preventable, and this not only increases<br />

the utilization of the precious potato,<br />

but also enables <strong>food</strong> processors to<br />

produce high-quality flavorsome dishes.<br />

Another important sustainability<br />

concern is energy use in production and<br />

associated greenhouse gas emissions.<br />

By increasing the yield from every piece<br />

of raw material entering the production<br />

process, businesses can operate for<br />

a shorter time to achieve the same<br />

required output, hence saving energy<br />

costs and water usage.<br />

The good news is that automated<br />

solutions are available to address<br />

these issues. Solutions that are<br />

both environmentally friendly<br />

and commercially savvy enhance<br />

processors’ green credentials while<br />

also preventing waste from cutting<br />

away at the bottom line.<br />

As the world changes, so must<br />

processors<br />

Though it has always made good<br />

business sense to eliminate waste, this<br />

necessity is now more important than<br />

ever because of the legislative and<br />

consumer led changes facing the <strong>food</strong><br />

industry.<br />

For one thing, demand for frozen potato<br />

products for <strong>food</strong>service is increasing,<br />

meaning that there’s greater pressure<br />

to increase volumes and throughputs,<br />

and more business for processors to<br />

win or lose. For example, the growth in<br />

production capacity of frozen French<br />

fries in new regions is growing each<br />

year rapidly, with each new processing<br />

line in China, Africa, and Brazil capable<br />

of delivering 150,000 tons each year.<br />

Recently we have seen supply chain<br />

issues in North America resulting<br />

in shortages in Asia. Reducing <strong>food</strong><br />

miles is another important challenge<br />

for the potato processing industry and<br />

challenges in logistics are discouraging<br />

businesses from shipping frozen<br />

products over long distances, meaning<br />

that new potato processing facilities<br />

are being built closer to local retailers.<br />

For another, the consumer expectations<br />

of quality, flavor, and taste around the<br />

world are increasing. Consumers are<br />

getting fussier about the quality of the<br />

<strong>food</strong>s they buy, meaning that retailers<br />

are also becoming less tolerant of<br />

product imperfections.<br />

Achieving high-quality potato products<br />

from locally grown raw materials<br />

becomes essential. Innovation in<br />

potato seed has resulted in producing<br />

a wider range of new potato varieties<br />

that are more resistant to drought and<br />

wet, which is necessary due to climate<br />

change. This has helped improve the<br />

raw material consistency and quality<br />

delivered to <strong>food</strong> processors, enabling<br />

them to improve their business and<br />

product quality. But this is only part of<br />

the solution. <strong>Technology</strong> and steam<br />

peeling solutions need to be adaptable<br />

to extract the maximum benefit of the<br />

available raw material.<br />

As the world continues to change and<br />

adapt to challenges, we see that <strong>food</strong><br />

processors need to install new lines<br />

incorporating the latest technical<br />

solutions. And aging lines will need to<br />

20 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • August <strong>2022</strong>

Processing<br />

be replaced to ensure the business<br />

stays competitive and survives.<br />

Increasing demand for quantity<br />

and quality<br />

Potato processors might be tempted<br />

to dismiss market forces as something<br />

that only retailers need to worry<br />

about, but this would be a mistake:<br />

just as retailers must meet changes in<br />

consumer demand, so processors must<br />

meet the subsequent changes in retailer<br />

requirements. And those requirements<br />

are not only for greater quantities, but<br />

also for greater product quality and a<br />

responsible approach to sustainability.<br />

Potatoes are a staple <strong>food</strong>, of course,<br />

ranked fourth in global production<br />

after wheat, rice, and maize. But what’s<br />