National Hardwood Magazine - September 2022

The September 2022 issue of National Hardwood Magazine is full of fascinating features and news updates from the hardwood industry. This month's issue includes stories on PRS Guitars Limited Partnership, Thompson Appalachian Hardwoods, BID Group and much more.

The September 2022 issue of National Hardwood Magazine is full of fascinating features and news updates from the hardwood industry. This month's issue includes stories on PRS Guitars Limited Partnership, Thompson Appalachian Hardwoods, BID Group and much more.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

BID Group: Driving Solutions With Artificial Intelligence<br />

AI Gains Consistency And More Through-Put On Grade<br />

Mirabel, QC – While Artificial Intelligence (AI) was<br />

founded as an academic discipline in 1956, its<br />

various sub-fields of usage have required decades<br />

of experimentation and have been implemented<br />

with various tools in differing industries. The lumber industry<br />

is no exception to that, with the BID Group leading<br />

the way in AI development.<br />

The privately-owned BID Group, established in 1983,<br />

has been providing industry-leading solutions for its<br />

highly valued customers in the wood processing industry.<br />

BID is a leader in Operational Lifecycle Excellence,<br />

transformational wood processing technologies, and integrated<br />

solutions. It’s at the forefront of Artificial Intelligence<br />

and Digital Solutions in the industry, empowering<br />

customers to achieve their best overall performance.<br />

BID Group is the umbrella company that owns a multitude<br />

of brands, providing turnkey operations from the<br />

ground up.<br />

BID adds strategic value for its customers through its<br />

ability to provide complete, smart-connected, turnkey<br />

manufacturing systems that include engineering, project<br />

management, equipment, software, installation, startup,<br />

and after-sales parts and services. BID is dedicated to<br />

delivering its customers superior performance, innovation,<br />

remarkable service, and results through continuous<br />

improvement of its products and services. The company<br />

has offices in 18 locations with over 2,000 employees<br />

throughout North America and is situated to serve its<br />

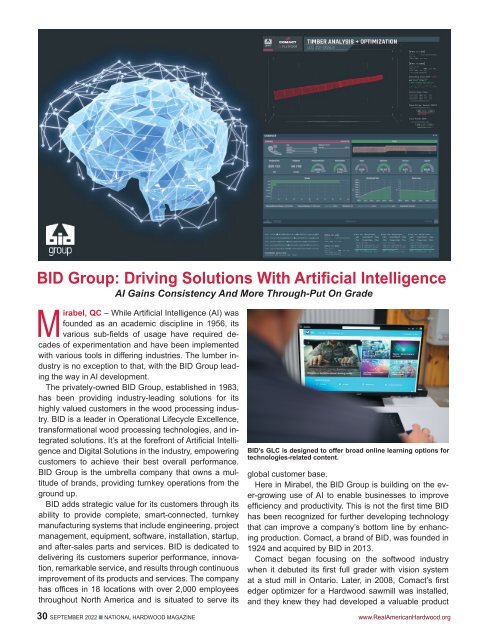

BID’s GLC is designed to offer broad online learning options for<br />

technologies-related content.<br />

global customer base.<br />

Here in Mirabel, the BID Group is building on the ever-growing<br />

use of AI to enable businesses to improve<br />

efficiency and productivity. This is not the first time BID<br />

has been recognized for further developing technology<br />

that can improve a company’s bottom line by enhancing<br />

production. Comact, a brand of BID, was founded in<br />

1924 and acquired by BID in 2013.<br />

Comact began focusing on the softwood industry<br />

when it debuted its first full grader with vision system<br />

at a stud mill in Ontario. Later, in 2008, Comact’s first<br />

edger optimizer for a <strong>Hardwood</strong> sawmill was installed,<br />

and they knew they had developed a valuable product<br />

Here are some of the BID team members who are dedicated to providing superior optimization products.<br />

In the <strong>Hardwood</strong> industry, BID’s Comact TrimExpert (pictured) is the most commonly<br />

utilized AI optimizer.<br />

for the <strong>Hardwood</strong> side of the industry based on the results of the optimizer’s<br />

performance.<br />

Senior Vice President of Optimization at BID, Stephane Desjardins, said,<br />

“In 2008, we completed a good project with a good outcome but quickly saw<br />

that we had to put in more effort as there is always room for improvement.”<br />

From 2008 to 2018, they installed more <strong>Hardwood</strong> and Softwood systems<br />

and with each one, they found ways to improve as the industry evolved. “In<br />

2018, we began work on our AI platform,” explained Desjardins. “Our first<br />

test was wood species identification. You want to sort species because you<br />

want to dry them differently. In the beginning, it was difficult to get over 80<br />

percent of good detection, but then as we tried Deep Learning, within a few<br />

weeks we were able to get to 98-99 percent detection. So, with that, we saw<br />

opportunities with the AI system for both <strong>Hardwood</strong> and Softwood.”<br />

He commented further that AI is “similar to the human brain in the way<br />

it figures things out and the more times it is shown something, like a wood<br />

defect, the more accurately it recognizes it each time. We have 30 wood<br />

processing engineers who teach the system how to detect what is needed.<br />

Each project is assigned a wood processing engineer, a software engineer<br />

and a project manager.”<br />

Patrick Lepage, Manager of Sales Support of the Optimization Group,<br />

added, “Our wood processing engineers have either a bachelor’s degree in<br />

forestry or wood technology. There are different levels of expertise on each<br />

team, with some being more hands-on at the mill.”<br />

“These guys are really the face of<br />

the optimization team during startup.”<br />

Anne-Marie Levesque, Vice<br />

President of Digital Technologies<br />

and Marketing, added, “The wood<br />

processing engineers are part of<br />

the preparation process and are<br />

the ones training the customer, so<br />

they are part of the whole project to<br />

assist the customer before, during<br />

and after startup so the customer<br />

can take ownership of the machine.”<br />

Sawmill product consistency is<br />

a result of the optimization and AI<br />

products developed by BID, too.<br />

“A big value of our system is that<br />

the machine gives you a consistent<br />

product – every day, every time,”<br />

commented Lepage. “With the ongoing<br />

labor shortage, good graders<br />

are hard to find, and human graders<br />

can be very proficient at what<br />

they do, or they can be average.<br />

With our machine, the product is<br />

stable. This consistency also gives<br />

you greater flexibility.”<br />

Desjardins concurred, adding,<br />

“you can do proprietary grades on<br />

the production line. For example,<br />

if you put a new product down the<br />

line, a human grader may find it difficult<br />

to switch between products.<br />

However, our systems are not challenged<br />

by that.”<br />

Please turn to page 46<br />

30 SEPTEMBER <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.org<br />

www.RealAmerican<strong>Hardwood</strong>.org<br />

SEPTEMBER <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE 31