drinkworld Technology + Marketing 4/2022

drinkworld Technology + Marketing is the leading magazine for the entire drinks industry worldwide. Feature articles and short communications cover the whole spectrum of processing, bottling, raw materials, logistics, packaging and marketing of beverages. We also report on special topics of regional interest and the trends in the beverage industries worldwide. Readers are executives and decision-makers in the brewing, dairy and mineral water industries, manufacturers of non-alcoholic drinks, wine growers and bottlers.

drinkworld Technology + Marketing is the leading magazine for the entire drinks industry worldwide. Feature articles and short communications cover the whole spectrum of processing, bottling, raw materials, logistics, packaging and marketing of beverages. We also report on special topics of regional interest and the trends in the beverage industries worldwide. Readers are executives and decision-makers in the brewing, dairy and mineral water industries, manufacturers of non-alcoholic drinks, wine growers and bottlers.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ZKZ 62006<br />

ISSN 1433-1594 Vol. 26 No. 4 November <strong>2022</strong> US $ 12 · € 12<br />

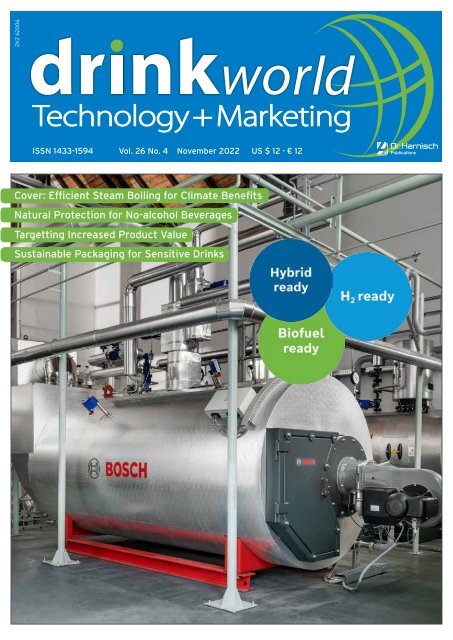

Cover: Efficient Steam Boiling for Climate Benefits<br />

Natural Protection for No-alcohol Beverages<br />

Targetting Increased Product Value<br />

Sustainable Packaging for Sensitive Drinks

INTERNATIONAL<br />

ENOLOGICAL<br />

AND BOTTLING<br />

EQUIPMENT<br />

EXHIBITION<br />

LEADER IN WINE & BEVERAGE TECHNOLOGY<br />

ORGANIZED BY<br />

29 th EDITION<br />

15 th -18 th November <strong>2022</strong><br />

Fiera Milano (Rho)<br />

info@simei.it / simei.it

Editorial<br />

Beverages Beyond Boundaries<br />

Who would have thought it? The<br />

Football World Cup is almost here.<br />

Leaving political topics aside, it is<br />

different this year. The expectations<br />

are muted, especially in some parts<br />

of the beverage industry. In the<br />

(European) summer, breweries and<br />

soft drink specialists would be fully<br />

occupied, getting everything ready<br />

for street parties, public viewing and<br />

the like. Nobody knows quite what<br />

to expect in winter. Mulled wine and<br />

cookies, instead of beer and pretzels?<br />

Sponsorship is also different in a<br />

country where alcohol is not consumed.<br />

Thankfully the beverage industry has<br />

many sides to it. There will always be<br />

consumers who would rather drink<br />

warm than cold drinks, and refreshing<br />

rather than relaxing. They all need to<br />

be pumped and processed, bottled<br />

and filled, as well as packaged and<br />

transported here and there. Athletes<br />

will need isotonic drinks to help<br />

recover and prepare for the next<br />

game. Fans will need to celebrate and<br />

commiserate and everybody is ready<br />

to drink the same thing they see their<br />

heroes have in their hands.<br />

An international event like this is, of<br />

course, still a boon for the beverage<br />

industry. It is certainly a major event<br />

for promotional and marketing<br />

opportunities, but it is impossible to<br />

predict how many extra portions of<br />

juice, water, softs drinks, beer and<br />

coffee or tea will be consumed. I<br />

for one, will be on the edge of my<br />

seat, kicking every ball and catching<br />

every shot at goal. In fact I have been<br />

practicing shooting penalty kicks, just<br />

in case my country needs me.<br />

No editorial about the World Cup<br />

is complete of course, without my<br />

personal tip. As always, almost my<br />

Ian D. Healey<br />

Editor-in-Chief<br />

Photo: BK<br />

whole life, I hope that England will be<br />

top of the pile in mid December, but I<br />

rather expect it will be Brazil, Belgium or<br />

Germany, with Senegal or Denmark as a<br />

dark horse. Let’s hope that sport will once<br />

again bring the world together. We can all<br />

drink our own preferred beverage to that!<br />

Cheers<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · November <strong>2022</strong> 3

Contents<br />

ZKZ 62006<br />

ISSN 1433-1594 Vol. 26 No. 4 November <strong>2022</strong> US $ 12 · € 12<br />

Cover: Efficient Steam Boiling for Climate Benefits<br />

Natural Protection for No-alcohol Beverages<br />

Targetting Increased Product Value<br />

Sustainable Packaging for Sensitive Drinks<br />

Issue 4 · November <strong>2022</strong><br />

The need to consume produced beverages and processed foods is constantly<br />

increasing. And so is the demand for steam, hot water and district<br />

heating. In many areas of the beverage industry, process heat in the form<br />

of steam is indispensable. In view of impending gas shortages, rising prices<br />

and for reasons of climate policy, many large companies need to reduce<br />

their energy consumption. Efficient boiler systems with optimally matched<br />

components reduce emissions, fuel use, consumption of water, chemicals,<br />

electrical power, and the cost of operation and monitoring.<br />

Our cover story starts on page 6.<br />

Cover: Bosch Industrial Boilers<br />

Ingredients<br />

10 Promises and Claims Beverages Make (and Break)<br />

14 Natural Preservatives for Alcoholfree<br />

Beverages<br />

16 Innovative Product Concepts for Yoghurts, Ice<br />

creams, Food services and Beverages<br />

17 Fi Europe Preview<br />

Processing<br />

6 Efficient Boiler Systems for a Climate-Neutral<br />

Future<br />

20 Three Factors That Affect Production Value<br />

Targets<br />

25 Covert Detection <strong>Technology</strong> Helps Identify<br />

Counterfeit Regional Wines<br />

27 Oat Milk Manufacture using High Shear Mixers<br />

28 Precise Results: New Analytical Instrument Unites<br />

3 Measuring Tasks in 1 Instrument<br />

30 Plant-based Drinks: Focussing on Oats<br />

LANXESS has received the <strong>2022</strong> World Beverage<br />

Innovation Award for its natural preservative Nagardo.<br />

”Receiving this award shows that Nagardo has already<br />

convinced beverage industry professionals. This reflects<br />

the voices of customers who are already successfully<br />

testing and using our new product,“ says Monika Ebener,<br />

Global <strong>Marketing</strong> Director Natural Antimicrobials. The<br />

full story is on page 14<br />

The quality of a diet beverage is largely influenced<br />

by three factors: process water, citric acid, and syrup<br />

ingredients. A recent study showed that these three<br />

factors have a negative impact on production target<br />

values. Because of this, analyzing these during the whole<br />

production process is best done with a system based on<br />

density measurement. Full details and study results can<br />

be found on page 20<br />

4

Contents<br />

Departments<br />

3 Editorial<br />

39 Fax<br />

42 Supplier's Guide<br />

Events<br />

41 Calendar of Events<br />

Packaging<br />

31 Maximum Flexibility in Product Labelling<br />

32 Cap Sterilization has Never Been Safer<br />

33 Riedel Chooses Unique on-the-go Packaging<br />

Innovation for Iconic Juice Brands<br />

34 The Future of Sustainable Packaging for<br />

Sensitive Drinks<br />

37 New Global Digital Label Material Swatchbook<br />

for Wine, Spirits and Beverage<br />

40 Food-Grade PET with Integrated rPET Supports<br />

Supply, Quality and Sustainability<br />

The new 1SKIN bottle is made to stand out on shelves in<br />

one of the fastest growing and most competitive beverage<br />

segments. The bottle is designed to deliver an appealing<br />

drinking experience, with an ergonomic grip for comfortable<br />

pouring. It has a wide neck and a cap lock feature to keep<br />

the open bottle top away from the consumer’s face. The<br />

surface is label-free but with texture options. See page 34<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · November <strong>2022</strong> 5

Cover Story<br />

Efficient Boiler Systems for a Climate-<br />

Neutral Future<br />

by SABINE STRAKA<br />

The need to consume produced beverages<br />

and processed foods is constantly<br />

increasing. And so is the demand for<br />

steam, hot water and district heating.<br />

In many areas of the beverage industry,<br />

process heat in the form of steam is<br />

indispensable. In view of impending gas<br />

shortages, rising prices and for reasons<br />

of climate policy, many large companies<br />

need to reduce their energy consumption.<br />

Efficient boiler systems with optimally<br />

matched components reduce emissions,<br />

fuel use, consumption of water, chemicals,<br />

electrical power, and the cost of operation<br />

and monitoring. Intelligent controls can<br />

also significantly increase efficiency,<br />

availability and the service life of the<br />

equipment. The use of modern industrial<br />

boilers can thus permanently reduce<br />

energy consumption and operating costs.<br />

From a small workshop to<br />

innovating an entire industry<br />

For more than 150 years, Bosch Industrial<br />

Boilers has been a leader in the field of<br />

large-scale thermal plants and system<br />

solutions. In 1865, the company was<br />

founded in Germany by Philipp Loos<br />

as a small boiler forge in Neustadt/<br />

Weinstrasse, and a new production site<br />

was established in Gunzenhausen in 1917.<br />

Already then Loos was the market leader<br />

for industrial boilers. In 1952 a patent was<br />

filed for the horizontal 3-pass flame tube<br />

smoke tube boiler with an internal watercooled<br />

reversing chamber, that became<br />

a global industry standard. Numerous<br />

production and plant expansions<br />

followed and the conventional boiler<br />

design as used in old steam locomotives<br />

was consistently replaced by innovative,<br />

safe and efficient new designs. In<br />

2009, Loos became part of the Bosch<br />

Group. More than 120,000 industrial<br />

boilers for steam generation have been<br />

produced in Gunzenhausen, Germany,<br />

and in Bischofshofen, Austria. In recent<br />

years, the company has developed into<br />

a leading global system supplier for<br />

industrial boilers and specializes in the<br />

customized development and equipment<br />

of reliable and efficient boilers and plants,<br />

of all sizes and performance classes<br />

with up to 38 megawatts per boiler. The<br />

technology is developed on customer<br />

request and depends on which energy<br />

source is available at the installation site.<br />

Due to the modular design of the boiler<br />

systems, individual components can be<br />

easily retrofitted. Each system is unique;<br />

it is configured according to customer<br />

specifications. Bosch also fulfils tailormade<br />

requests, the complete system<br />

consisting of boiler, tubes and layout.<br />

Depending on requirements, e.g. up to 7<br />

million variants of one single boiler type<br />

can be manufactured, differing from<br />

each other in terms of emission, nozzle,<br />

nominal value or position, depending<br />

on where the boiler is to be installed<br />

at the customer's site. The particular<br />

strength of Bosch Industrial Boilers is to<br />

manufacture individual products with the<br />

efficiency and quality of a large series.<br />

The Bosch group has been climateneutral<br />

since 2020.<br />

Manual work and precision<br />

The boilers have a weight of up to 120<br />

tons, even before they are filled with<br />

water. The core component in the<br />

production of boilers are flame tubes.<br />

With the specially developed corrugated<br />

tube machine, tubes up to 9 meters in<br />

length can be produced in one piece<br />

fully automatically. The corrugated<br />

tubes are manufactured with millimeter<br />

precision using laser technology. With<br />

the specialized production equipment in<br />

the factory sheets up to 3.5 meters wide<br />

can be processed. As a result, large boilers<br />

require fewer welds, which significantly<br />

increases their service life. Welding is<br />

performed horizontally using a modern,<br />

uniform welding process, which enables a<br />

homogeneous structure and high welding<br />

quality. Depending on the individual<br />

equipment of the boilers, the components<br />

are also joined together manually using<br />

a special welding process. Due to the<br />

customer-individual design of each boiler,<br />

large parts of the manufacturing process<br />

are performed by hand. In addition, more<br />

than a dozen semi- and fully automatic<br />

welding robots ensure consistent quality<br />

of safety relevant welds. An in-house<br />

laboratory for weld seam testing and<br />

material analysis ensures maximum<br />

safety. In three X-ray chambers, up to<br />

100 % of the weld seams are X-rayed and<br />

6

Cover Story<br />

evaluated. In the beverage industry, some<br />

companies order an outer cladding of<br />

stainless steel instead of aluminium.<br />

Specific requirements in the<br />

beverage industry<br />

The various processes in the beverage<br />

and brewing industries require high<br />

temperatures and pressures, consistent<br />

steam quality, reliability, energy efficiency,<br />

and flexibility. Depending on the application,<br />

boiler systems must easily cope not<br />

only with linear but also discontinuous<br />

production processes. Electric boilers can<br />

follow such processes, in which sometimes<br />

more and sometimes less steam is needed,<br />

much faster and more dynamically. They<br />

heat up faster and offer particularly<br />

high flexibility. In the food and beverage<br />

industry, steam quality is also especially<br />

important. When a food or beverage comes<br />

into contact with steam, culinary steam is<br />

used, which is produced and filtered from<br />

top quality drinking water. The residual<br />

moisture from the steam and the dosing<br />

agents in the boiler water must not contain<br />

any steam-volatile chemicals that would<br />

lead to contamination. Continuous and<br />

reliable operation of the boiler systems is<br />

also important. The redundancy of certain<br />

components ensures availability even if a<br />

component, such as a pump, fails once. The<br />

Bosch delivered the boiler house technology for GATEWAY plant of INTERNATIONAL BREWERIES<br />

PLC in Nigeria. The new boiler plant can generate 55 tons of steam per hour for the entire brewing<br />

process.<br />

power is then divided between two or more<br />

boilers. Pumps that are urgently needed<br />

are duplicated. One boiler runs, one can<br />

take over if a pump fails, for example.<br />

Multiple applications<br />

The boilers are used for all products<br />

produced with heat in various sectors: in<br />

the pharmaceutical, textile and building<br />

materials industries, for the production of<br />

car tires or foams, in the chemical industry<br />

and in the supply of district heating.<br />

Nowadays the first industrial boilers are<br />

operated with green hydrogen instead<br />

of natural gas or oil. There has also been<br />

an increase in demand for LNG (liquefied<br />

natural gas) terminals recently. About half<br />

to two thirds of the boilers are used in the<br />

food and beverage industry as well as in<br />

breweries. Thus, 8 out of 10 beers brewed<br />

Example illustration: Environmentally friendly electricity and hydrogen from renewable energy sources are used to generate steam.<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · November <strong>2022</strong><br />

7

Cover Story<br />

in Germany come into contact with heat<br />

from Bosch Industrial Boilers, for example<br />

during mashing, lautering, wort boiling,<br />

filtering, pasteurization, and CIP processes<br />

for cleaning and sterilizing bottles and<br />

kegs. In very large breweries, even doubleflame<br />

tube boilers are used, which operate<br />

with two burners. Two independent firings<br />

and flue gas paths ensure particularly<br />

high flexibility. In the beverage industry,<br />

hot water and steam are required for<br />

flash/tunnel pasteurization, distillation,<br />

sterilization, bottling and cleaning. Dairies<br />

use steam for ultra-high temperature<br />

heating, pasteurization, sterilization,<br />

thermalization, whey production, cheese<br />

production, and milk powder drying,<br />

as well as for cleaning and supplying<br />

CIP equipment. For many energyintensive<br />

processes involved in beverage<br />

production, Bosch offers energy systems<br />

that are particularly reliable, energyefficient,<br />

and automated.<br />

Flexible boiler technology<br />

Boiler technology is not necessarily fossil,<br />

but flexible as to which energy sources are<br />

used. Especially for the beverage industry,<br />

Bosch offers multivalent boiler systems<br />

that can be operated with different types<br />

of energy. The technology is customerspecific<br />

configured and depends on<br />

what type of energy is available at the<br />

site. Bosch Industrial Boilers’ focus is on<br />

switching to green energy sources. In<br />

the beverage sector, for example, biogas<br />

has been used for steam/hot water<br />

generation for many years, and now biooil<br />

is also used. Bosch Industrial Boilers<br />

is diversely positioned and has already<br />

experimented in many pilot plants. Today,<br />

operation boilers with nearly any liquid<br />

or gaseous energy sources is possible.<br />

Since this year, green power is also used.<br />

"In recent years, climate neutrality has<br />

become increasingly important. It is also<br />

important to customers to have security<br />

of supply independent of fossil fuels,"<br />

explains Daniel Gosse, Head of <strong>Marketing</strong><br />

at Bosch Industrial Boilers. "Despite<br />

external challenges many companies still<br />

adhere to their CO 2<br />

targets; for this green<br />

technology is needed. Even large wellknown<br />

retail brands are placing increasing<br />

Bosch Industrial Boilers Headquarters in Gunzenhausen Germany<br />

8

Cover Story<br />

emphasis on climate neutrality along the<br />

supply chain."<br />

Highly efficient operation: 100 %<br />

electric, 100 % climate-neutral<br />

The boiler is the largest energy consumer<br />

in many factories; in a dairy which includes<br />

milk powder production, for example,<br />

energy costs accounts up to 14 % of<br />

the total costs of production. A modern<br />

energy-saving boiler can make the<br />

operation much more efficient. Since this<br />

year, there has been strong demand for<br />

electric boilers, even in Germany, where<br />

electricity is relatively expensive. Here,<br />

energy from green power surpluses can be<br />

used by purchasing the electricity from the<br />

power supplier at a favorable price through<br />

flexible offtake. For energy-efficient<br />

operation, Bosch offers the new electric<br />

steam boiler ELSB. It has a capacity range<br />

of 350 to 7500 kg/h, an efficiency of up to<br />

99.6 % and produces no direct emissions.<br />

When operated with green power, steam<br />

generation with the new electric boiler<br />

is completely CO 2<br />

neutral. It can be<br />

configured individually for each application<br />

or integrated into existing boiler systems<br />

and enables multivalent operation. The<br />

new electric steam boiler responds<br />

quickly and accurately to fluctuating load<br />

reductions. It can be run at full load faster<br />

and has a wider, steplessly variable control<br />

range of 0 to 100 %. The ELSB delivers<br />

high steam quality with low residual steam<br />

moisture. Due to its continuously variable<br />

power control, it has a high efficiency over<br />

the entire power range. The power can be<br />

automatically adjusted to the respective<br />

demand. With the smart control system,<br />

available green power surpluses from<br />

energy suppliers or from the company's<br />

own power generation can be used in<br />

a targeted manner. With its high power<br />

density, the electric boiler is also much<br />

smaller than a steam boiler, and does not<br />

require a chimney or flue gas pipe. This<br />

reduces space requirements and costs.<br />

If, for example, fuel consumption increases,<br />

the digital assistant reports possible causes<br />

and provides recommendations for action.<br />

With predictive condition monitoring, it also<br />

makes predictions about the remaining<br />

service life of important components<br />

and assists with maintenance planning.<br />

Digital evaluation of the data enables<br />

increased energy losses to be detected<br />

and thus energy efficiency to be increased.<br />

Forecasts of wear optimize maintenance<br />

and thus the operational reliability and<br />

service life of a plant.<br />

In operation around the world<br />

Two thirds of all Bosch industrial boilers<br />

are exported to over 140 countries. For<br />

example for the production of ice-cold<br />

beers, INTERNATIONAL BREWERIES<br />

PLC, the largest brewery in Sagamu,<br />

Nigeria, and the second largest brewery<br />

in Africa, also uses process heat from<br />

Bosch. The new modern GATEWAY plant<br />

of INTERNATIONAL BREWERIES PLC is<br />

a model brewery of Anheuser-Bush, AB<br />

InBev in Africa. In the search for a steam<br />

generation system that could meet the<br />

high energy requirements in the brewery<br />

and for cleaning, the choice finally fell once<br />

again on Bosch Industrial Boilers, because<br />

of its product policy, its reliability, and the<br />

presence of a service team on site. To<br />

ensure that production does not come to<br />

a standstill anywhere, Bosch offers 24/7<br />

customer service with short response times<br />

worldwide, including in Nigeria. As a result,<br />

a new state-of-the-art multi-boiler system<br />

was ordered, that can generate 55 tons<br />

of steam per hour for the entire brewing<br />

Daniel Gosse, Head of <strong>Marketing</strong> at Bosch Industrial Boilers<br />

process. Bosch delivered the boiler house<br />

technology including all components for<br />

water treatment, degassing and energy<br />

recovery.<br />

The universal steam boilers supply<br />

consistently high steam quality on a<br />

high efficiency level of more than 95 %.<br />

Thanks to its optimal matched burners<br />

can use flexibly up to three different fuels<br />

to combust in one single boiler. That also<br />

increases operation reliability. In addition,<br />

the six heat recovery boilers can produce<br />

up to 20 % of the steam demand cost<br />

effectively by simply using process related<br />

waste heat. A variety of automation<br />

devices complete the system and ensure<br />

a highly reliable steam boiler operation.<br />

"As a manufacturing company, Bosch itself<br />

is also affected by rising energy prices or<br />

security of supply. For these issues we will<br />

need future-proof solutions in our more<br />

than 400 Bosch production locations.<br />

Therefore, we will continue to develop our<br />

boiler systems accordingly," says Daniel<br />

Gosse.<br />

The Author<br />

Sabine Straka is Assistant Editor at Dr. Harnisch<br />

Publicatiions<br />

Saving energy with smart boiler<br />

systems<br />

When operating industrial boilers intelligent<br />

components can help to maintain the high<br />

energy efficiency and to save energy costs.<br />

For example, a digital efficiency assistant<br />

can analyze boiler plant data and inform<br />

personnel about unfavorable operating<br />

conditions and ways to increase efficiency.<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · November <strong>2022</strong><br />

9

Ingredients<br />

Promises and Claims Beverages Make<br />

(and Break)<br />

by DONNA BERRY<br />

There’s a fine line separating a promise<br />

and a claim in the world of food and<br />

beverage marketing, and that fine<br />

line varies among regulatory agencies<br />

around the world. The USA has one<br />

of the more strict set of laws in place<br />

regarding statements on package<br />

labels, and when a consumer feels like<br />

it’s deceitful, off to court they go.<br />

That’s what happened in mid-October<br />

to Nestle USA Inc., a business unit of<br />

Nestle SA. The company is being sued<br />

for two claims printed on the packaging<br />

of its Ovaltine brand of flavored drink<br />

mix.<br />

The lawsuit identifies the statement<br />

“a good source of 12 vitamins and<br />

minerals” as a nutrient content claim<br />

under federal and state regulations.<br />

This means the product should provide<br />

between 10% and 19% of the daily<br />

recommended value of no less than 12<br />

vitamins and minerals. The problem<br />

is that Ovaltine itself is not a “good”<br />

source of 12 vitamins and minerals<br />

without adding other ingredients as<br />

specified in the directions. This matter<br />

is discreetly indicated by a dagger<br />

(†) accompanying the front label<br />

statement. The meaning of that dagger<br />

is identified in a smaller statement<br />

several lines below and reads: Ҡ when<br />

prepared as directed.” Those directions,<br />

as indicated in the third column of<br />

the Nutrition Facts label, require the<br />

consumer to “mix [it] with one cup lowfat<br />

vitamin A and D milk.” That promise<br />

of being a “good” source is broken if<br />

the consumer does not have the milk<br />

for mixing.<br />

The second item in dispute is the<br />

statement “no artificials.” The lawsuit<br />

explains that “consumers seeing the<br />

bigger font of ‘no artificials’ will expect<br />

this means the product does not<br />

contain artificial ingredients. However,<br />

upon closer reading of the label, one<br />

sees that the product contains artificial<br />

and bioengineered ingredients. This<br />

is disclosed a few lines beneath the<br />

ingredient list. Again, a promise is<br />

broken.<br />

The plaintiff further alleged that<br />

misleading symbols used on the front<br />

of the package “took advantage of<br />

consumers’ cognitive shortcuts made<br />

at the point-of-sale and their trust<br />

in defendant.” The one promise the<br />

defendant did not have an issue with is<br />

the phrase “supports immune health,”<br />

which is center front in a bold font on<br />

the package.<br />

In the US, and many other countries,<br />

there’s a line separating claims or<br />

promises that reference quantities of<br />

nutrients, quality of ingredients and<br />

direct health claims from suggestive<br />

references to physiological benefits,<br />

such as energizing, calming and antiaging,<br />

as well as subjective promises,<br />

like delicious, cooling and satiating.<br />

<strong>Marketing</strong> claims are a tricky business.<br />

New Joyba Bubble Tea, for example,<br />

is a line of ready-to-drink, bobashop<br />

inspired beverages. It makes<br />

the promise of containing “delicious<br />

popping boba.” Delicious is a subjective<br />

descriptor that could prove to be<br />

disappointing to someone who does<br />

not care for flavored and sweetened<br />

gelatinized balls exploding in the<br />

mouth.<br />

Another new product sporting a<br />

subjective claim is Juvee. Developed by<br />

Matthew “Nadeshot” Haag, a superstar<br />

gaming content creator and founder<br />

and CEO of the global gaming lifestyle<br />

brand 100 Thieves, Juvee is described as<br />

a rejuvenating energy drink formulated<br />

to boost your energy, increase your<br />

focus and improve overall well-being so<br />

you’re inspired to add more play to your<br />

every day.<br />

Short for “rejuvenation,” Juvee is<br />

made with a blend of ingredients that<br />

promises to provide invigorating and<br />

mood-lifting effects for longer-lasting,<br />

more sustainable energy. Each 12-<br />

ounce can of Juvee contains B vitamins,<br />

taurine and 128 milligrams of caffeine<br />

for energy. The addition of L-theanine<br />

10

Ingredients<br />

Online & In-Person<br />

28 Nov - 8 Dec <strong>2022</strong><br />

From Anywhere<br />

Online<br />

6 - 8 Dec <strong>2022</strong><br />

Paris, Expo Porte de Versailles<br />

France<br />

NEW<br />

VENUE<br />

Join<br />

the biggest<br />

EU ingredient event<br />

this December<br />

Learn<br />

more at<br />

bit.ly/fie-print<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · November <strong>2022</strong><br />

11

Ingredients<br />

is said to elevate mood, while the<br />

panax ginseng is for sustained focus.<br />

In addition, the drink has a boost of<br />

vitamin C for health and well-being and<br />

no sugar, with only 5 calories per can.<br />

As with allow- and no-sugar energy<br />

drinks, one may argue that this energy<br />

drink does not provide physical energy,<br />

which is also referred to as metabolic<br />

energy, as this comes from calories. It is<br />

produced via the Krebs cycle, a complex<br />

pathway that converts ingested<br />

carbohydrates, fats and proteins into<br />

a slow, steady stream of energy –<br />

adenosine triphosphate – during the<br />

process of aerobic respiration. This<br />

energy fuels the body’s cells to keep the<br />

body working, with the unit of energy<br />

measured in calories. In general, simple<br />

carbohydrates, namely refined sugars,<br />

tend to be quickly absorbed by the<br />

bloodstream after ingestion. They are<br />

responsible for a true quick metabolic<br />

energy boost.<br />

Again, it’s a fine line marketers walk<br />

with such promises. Imagine a gamer<br />

who drinks such an energy drink with<br />

hopes to stay up all night competing<br />

in a computer tournament, and then<br />

doses off in front of the screen. That’s<br />

a broken promise. Lawsuit worthy?<br />

Probably depends at how much was at<br />

stake and how sly of a lawyer one can<br />

retain to assist.<br />

Such fears of not delivering on promises<br />

have not stopped innovation in the<br />

burgeoning energy drink segment. Nor<br />

has it stopped the rollout of functional<br />

beverages making a range of purported<br />

benefits.<br />

Mude, for example, is a new line of allnatural,<br />

mood-supporting drinks. Mude<br />

is low in sugar – less than 6 grams per<br />

can – and only 40 calories. The brand<br />

claims to be one of the first beverages<br />

with vitamins and minerals that benefit<br />

mood and is sustainably sourced and<br />

packaged. One of the formulations<br />

– Mude Work – promises to help you<br />

focus and have mental clarity. It is<br />

formulated with “deep ocean” mineral<br />

salts, branched chain amino acids and<br />

ashwagandha.<br />

The deep ocean is generally defined<br />

as the depth at which light begins to<br />

dwindle, typically around 200 meters<br />

(656 feet), by the National Oceanic<br />

and Atmospheric administration of<br />

the US Department of Commerce. A<br />

quick internet search reveals that deep<br />

ocean minerals are recognized as being<br />

extracted from deep ocean water and<br />

are associated with superior hydration<br />

and recovery after a workout. When<br />

making such a formulation claim, a<br />

marketer should be well prepared to be<br />

fully transparent regarding sourcing.<br />

The brand also claims to be certified<br />

Carbon Neutral to naturally support<br />

mood without sacrificing health and<br />

wellness goals. Such sustainabilitytype<br />

claims are starting to gain<br />

traction. These claims promise the<br />

consumer that by choosing this<br />

product over another not making<br />

such a claim, they are supporting<br />

the health of the planet. Again, full<br />

12

Ingredients<br />

transparency is paramount in fulfilling<br />

this promise.<br />

While what is healthy for the planet<br />

remains subjective, in the US, the term<br />

“healthy,” as it relates to foods and<br />

beverages for humans, will likely be<br />

defined soon. In September, the US Food<br />

and Drug Administration proposed that<br />

manufacturers can label their products<br />

“healthy” if they contain a meaningful<br />

amount of food from at least one of<br />

the food groups or subgroups (such, as<br />

fruit, vegetable or dairy) recommended<br />

by the dietary guidelines. They must<br />

also adhere to specific limits for certain<br />

nutrients, such as saturated fat, sodium<br />

and added sugars.<br />

Of course, there are ways around this.<br />

One marketing term that suggests<br />

healthfulness is “superfood.” A new<br />

player in this space is RDCL Superfoods<br />

(pronounced radical). The brand<br />

promises to give ordinary drinks new<br />

“superpowers” with all plant-based<br />

ingredients and zero added sugar, all<br />

while making them healthier, tastier,<br />

more ethical and sustainable. Super<br />

Cocoa is a powder that can be mixed<br />

into hot or cold water or blended into<br />

a smoothie. Its rich chocolate-y taste<br />

comes from two kinds of premium cacao,<br />

according to the brand. It also contains<br />

pea protein, ancient grains and seeds,<br />

and greens. Radical Elements Superfood<br />

Blends is a powdered boost that is simply<br />

mixed into water, creating a functional<br />

beverage with immunity support and<br />

other benefits. The Passion Fruit variety<br />

promises to help boost focus and energy<br />

while Dragon Fruit Superberry helps<br />

alleviate stress and anxiety.<br />

Functional claims are often best alluded<br />

to simply by flagging the inclusion of<br />

the supposedly beneficial ingredient.<br />

Let the consumer do the homework and<br />

investigate what the promise may be.<br />

The Author<br />

Donna Berry is a food and beverage industry<br />

consultant and editor with over 25 years experience<br />

in tracking trends and advancements in<br />

product development.<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · November <strong>2022</strong><br />

13

Ingredients<br />

Natural Preservatives for Alcoholfree<br />

Beverages<br />

• Natural glycolipids from LANXESS honored as ”Best Beverage Ingredient“<br />

• Innovative preservative for non-alcoholic beverages<br />

• Expanded range opens up new preservation and energy-saving filling options for<br />

manufacturers<br />

LANXESS has received the <strong>2022</strong> World<br />

Beverage Innovation Award in the ”Best<br />

Beverage Ingredient“ category for<br />

its natural preservative Nagardo. The<br />

Awards honor innovation and excellence<br />

across all categories in the global<br />

beverage industry. The award ceremony<br />

took place on September 13, <strong>2022</strong>, during<br />

the drinktec trade fair in Munich. The jury<br />

had previously evaluated more than 150<br />

entries from 17 countries in 22 categories.<br />

Monika Ebener, Global <strong>Marketing</strong><br />

Director Natural Antimicrobials in<br />

the Beverage <strong>Technology</strong> business<br />

line at LANXESS, who accompanied<br />

the natural preservative from<br />

discovery to product launch, accepted<br />

the award. ”Receiving the World<br />

Beverage Innovation Award shows<br />

that Nagardo has already convinced<br />

beverage industry professionals. This<br />

reflects the voices of customers who<br />

are already successfully testing and<br />

using our new product,“ says Ebener.<br />

The preservative is already in use in<br />

the USA, Australia, New Zealand and<br />

Canada. With the recent EU approval,<br />

LANXESS is further expanding<br />

Nagardo’s global presence.<br />

Monika Ebener with the Best Beverage Ingredient Award, flanked by Jeanmarc Heitmann, Head of<br />

MPP’s Beverage <strong>Technology</strong> business (left) and Dr. Matthias Hüttl, Global <strong>Marketing</strong> Director,<br />

Beverage <strong>Technology</strong><br />

Active ingredient discovery by<br />

screening process<br />

Due to its high water content combined<br />

with potential nutrients such as sugars<br />

and fruit components, a beverage is an<br />

extremely sensitive product that can<br />

spoil within a few days if not treated<br />

with physical or chemical methods.<br />

Beverage-damaging microbes should<br />

ideally be controlled by naturally<br />

means. But natural ingredients, such as<br />

essential oils or certain extracts based<br />

on rosemary, cinnamon or onion, for<br />

example, provide microbial protection<br />

that is not nearly as effective as<br />

conventional preservatives. In addition,<br />

any influence on the taste of a beverage<br />

should be avoided.<br />

In its search for suitable products in the<br />

biosphere, Dortmund-based start-up IMD<br />

Natural Solutions GmbH (INS), which has<br />

been part of LANXESS’ Material Protection<br />

Products (MPP) business unit since 2017,<br />

has developed a program based on stateof-the-art<br />

research processes and search<br />

algorithms. One of the world’s largest<br />

screenable libraries of more than 100,000<br />

natural molecules from plants, bacteria,<br />

algae and fungi was searched for suitable<br />

active ingredients.<br />

In this extensive screening process,<br />

the most interesting results came from<br />

an edible fungus that had previously<br />

received little attention: the Dacryopinax<br />

spathularia, or commonly called “Sweet<br />

Osmanthus Ear”. This edible fungus is<br />

native to tropical and subtropical areas<br />

worldwide, is bright orange in color, and<br />

grows in the form of small ear-shaped<br />

spatulas similar to the osmanthus flower.<br />

The active ingredient is obtained<br />

fermentatively through a proprietary,<br />

solvent-free, food-grade process. It is<br />

composed of molecular congeners in a<br />

14

Ingredients<br />

specific ratio, all consisting of a sugar<br />

and a lipid moiety. This class of surfaceactive<br />

compounds that interfere with the<br />

cell membranes of microbes is therefore<br />

referred to as natural glycolipids.<br />

Consumer-friendly marketing<br />

options and reliable protection<br />

against spoilage<br />

Nagardo shows superior efficacy against<br />

typical beverage spoilage organisms<br />

compared to classical preservatives. In<br />

most cases, a dosage many times lower<br />

than that of conventional excipients is<br />

sufficient. The broad spectrum of activity,<br />

even at low application concentrations,<br />

also shows excellent activity against heatresistant<br />

spore-forming organisms such as<br />

Alicyclobacillus species or representatives<br />

of the genera Byssochlamys, Neosartorya<br />

as well as Talaromyces. It is also<br />

effective against organisms adapted<br />

to conventional preservatives, such as<br />

Zygosaccharomyces bailii.<br />

In the recommended dosage, Nagardo<br />

does not affect the sensory properties<br />

of a beverage: color, odor and, above all,<br />

taste are preserved as intended by the<br />

manufacturer. Therefore, the natural<br />

glycolipids can be used in a wide range<br />

of beverages. Carbonated products in<br />

particular benefit from Nagardo, as no<br />

second preservative is usually required.<br />

Special dosing technology is also not<br />

required: the powder is pre-dissolved<br />

in water and added to the beverage<br />

formulation during product mixing.<br />

Nagardo remains in the beverage and thus<br />

protects it naturally even after opening.<br />

Economical solution for filling<br />

sensitive products<br />

Nagardo natural preservative allows<br />

manufacturers to adapt their portfolio<br />

to changing consumer awareness<br />

and growing demand for natural<br />

ingredients. ”Our expanded offering<br />

opens up new possibilities for<br />

preservation. We want to participate<br />

even more in the global growth of<br />

the beverage market in the future<br />

with our brands Velcorin, which<br />

is one of the top technologies for<br />

antimicrobial beverage stabilization,<br />

and our new Nagardo,“ emphasizes<br />

Janmarc Heitmann, head of MPP’s<br />

Beverage <strong>Technology</strong> business.<br />

”Individually or in combination, our<br />

two technologies are an economical<br />

solution for microbiologically safe<br />

filling of sensitive products,“ Heitmann<br />

emphasizes. All filling systems, from<br />

glass/PET bottles to carton packs,<br />

cans, KEGs, and bag-in-box can be<br />

served with both technologies.<br />

The use of Nagardo and Velcorin can<br />

help achieve a company’s sustainability<br />

goals by reducing energy consumption<br />

by switching from hot fill or tunnel<br />

pasteurization to cold fill. Secondly,<br />

due to lower wall thicknesses, less<br />

PET is required for the beverage<br />

bottles than with hot filling. When both<br />

The Dacryopinax spathularia, or commonly<br />

called “Sweet Osmanthus Ear”<br />

Photo: AdobeStock_174797509<br />

products are combined, depending on<br />

the application, further microbiological<br />

hurdles, such as energy-intensive<br />

distribution and marketing in the cold<br />

chain, can be dispensed with.<br />

Criteria for selecting the<br />

appropriate technology<br />

In addition to the output efficiency,<br />

a holistic cost consideration for<br />

the producer is a decisive selection<br />

criterion for the suitable production<br />

platform. All costs incurred, i.e. one-off<br />

costs as well as running costs, must be<br />

taken into account. Cost drivers are,<br />

for example, heavy PET bottles for the<br />

hotfill process and rising energy prices.<br />

Factors such as the positioning of a<br />

brand, desired claims or the regulatory<br />

situation also influence the selection of<br />

a preservation technology.<br />

The great advantage of both Nagardo<br />

and Velcorin technology is that they<br />

can be used without any problems in<br />

new lines and also in combination with<br />

existing filling machines that were not<br />

originally intended for filling sensitive<br />

beverages. These are, for example, fillers<br />

for beer or classic soft drinks.<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · November <strong>2022</strong><br />

15

Ingredients<br />

Innovative Product Concepts for<br />

Yoghurts, Ice creams, Food services<br />

and Beverages<br />

The GULFOOD Manufacturing event in Dubai , from 8 – 10 November, is yet again the<br />

international venue for the food processing industry and the meeting point for experts,<br />

particularly from the Middle East, North and Central Africa as well as Asia. The global<br />

food industry player AGRANA will be presenting visitors from the dairy, bakery, ice cream<br />

and beverages sectors a wide range of new fruit and flavoring products at GULFOOD<br />

Manufacturing alongside AUSTRIA JUICE, a joint venture between AGRANA and Raiffeisen<br />

Ware Austria.<br />

Healthy and conscious nutrition is<br />

becoming increasingly important.<br />

Consumers are attaching greater<br />

importance to the positive effects of<br />

food on their own well-being and immune<br />

systems. At the same time however<br />

demands in terms of taste and enjoyment<br />

remain high. “All-natural nutrition is a<br />

trend which we are increasingly taking<br />

into account through our innovative<br />

product concepts for the downstream<br />

food processing industry. That’s why<br />

AGRANA is focusing at the GULFOOD<br />

Manufacturing fair on ‘good-for-you’<br />

products since this trend is also on the<br />

rise in the Gulf Region”, stresses AGRANA<br />

CEO Markus Mühleisen.<br />

AGRANA integrates these demands into<br />

functional concepts such as yoghurts<br />

based on various new taste combinations.<br />

One of these novel drinkable yoghurts<br />

is a kiwi-lime, immunity-boosting drink:<br />

This concept is rich in Vitamin C and zinc,<br />

both of which are known to support the<br />

body’s own immune system. The high<br />

concentration of fiber, which is good<br />

for the metabolism, makes this drink a<br />

refreshing, all-round indulgence between<br />

meals.<br />

Another new product development from<br />

AGRANA is a spoonable yoghurt with<br />

large, firm-to-the-bite pieces of dates.<br />

Dates are one of the most popular<br />

fruits in Arabian countries and also<br />

becoming more popular internationally.<br />

Until now, however, there has not been<br />

a spoonable yoghurt with firm pieces of<br />

dates since the dates tend to dissolve<br />

during pasteurisation due to their<br />

innate properties. At the GULFOOD<br />

Manufacturing fair, AGRANA is this<br />

year presenting a dessert with a high<br />

concentration of fruit which combines<br />

the best properties of both yoghurt and<br />

dates.<br />

Proudly presenting the Watson<br />

Says beverage brand created<br />

specially for baristas<br />

The Watson Says product brand from<br />

AGRANA Fruit has been specially<br />

developed as a product line of premium<br />

syrups, sauces and fruit blends for use<br />

in coffee creations, tea-based drinks,<br />

cocktails, mocktails, frappes and numerous<br />

other beverages. Smooth in texture, with a<br />

natural taste and color, these products are<br />

based on premium formulations so that<br />

these are available ready-for-use in cafés,<br />

fast-food restaurants and bars. These<br />

attractively designed brand<br />

16

Events<br />

Leading ingredients trade show Fi & Hi<br />

Europe all set to welcome more than<br />

20,000 visitors from around the world<br />

Fi & Hi Europe returns to France this year. From December 6 to 8, the leading ingredients<br />

fair will be held for the first time at the Paris Expo Porte de Versailles exhibition centre.<br />

More than 1,200 exhibitors – from leading ingredients manufacturers to highly specialized<br />

startups – will present themselves in four halls. The face-to-face exhibition will be<br />

complemented by a comprehensive online offering. A broad conference programme, as well<br />

as the renowned Innovation Awards and Startup Innovation Challenge, will complete the<br />

trade show experience.<br />

In the heart of Paris, Fi & Hi Europe is set to attract exhibitors<br />

and attendees from more than 135 countries around the<br />

world. The new Paris Expo Porte de Versailles location is<br />

within walking distance of many hotels, restaurants and bars,<br />

making logistics easier and the event more visitor-friendly<br />

than ever before. Many leading ingredient manufacturers<br />

have already confirmed their participation in Paris, including<br />

ADM, Beneo, Brenntag, Cargill, DSM and Ingredion. In addition<br />

to well- established companies, many new players have also<br />

announced their intention to present their solutions to the<br />

industry. In addition, there will be more country pavilions this<br />

year than ever before.<br />

Digitally enabled event concept<br />

This year, Informa Markets is focusing on a technologically<br />

enhanced hybrid show concept. The combination of online<br />

and face-to-face events offers participants the best of both<br />

worlds, including a wide variety of live and on-demand<br />

content as well as data-driven networking options. All<br />

exhibiting companies have their own online profile, allowing<br />

them to find relevant contacts, network and set up virtual or<br />

face-to- face meetings before the event. A smartphone app<br />

also facilitates on-site lead generation.<br />

the conference programme includes more than 55 expert<br />

sessions on-site and online, giving global audiences access<br />

to invaluable knowledge.<br />

The platform Fi Global insights provides a lot of additional<br />

information as well as exclusive reports covering the<br />

following topics:<br />

• Protein<br />

• Dairy and Dairy Alternatives<br />

• Snacks, Backery and Confectionery<br />

• Plant-based<br />

• Sustainability<br />

• Beverages<br />

"We look forward to welcoming visitors and exhibitors from<br />

around the world to an event that no one in the ingredients<br />

industry should miss," says Julien Bonvallet, Group Brand<br />

Director at Informa Markets. "After months of restriction and<br />

uncertainty, many people have a great need for face-to-face<br />

meetings. But even those who prefer to participate online<br />

can do so easily thanks to our technical solutions. "<br />

Multifaceted conference programme<br />

The online event will begin on 28 November, the week<br />

before doors open at Paris Expo Porte de Versailles. It<br />

offers an extensive conference programme covering the<br />

hottest topics in the industry, with a focus on plant-based<br />

nutrition, health & wellness, and reformulation. In addition,<br />

interested participants will find a wealth of information on<br />

application areas that are currently trending – such as baked<br />

goods, snacks, dairy products and dairy alternatives. Overall,<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · November <strong>2022</strong> 17

Events<br />

Market products in the spotlight<br />

On-site, the New Product Zone in cooperation with Innova<br />

Market Insights offers an extensive selection of the most<br />

innovative products, showcased alongside insightful<br />

information. It features product innovations from leading<br />

industry players and provides the perfect opportunity to<br />

give new ingredients the introduction to the market that<br />

they deserve. A popular area for visitors and the press, this<br />

feature has become a trendsetting spot for the nutrition<br />

industry.<br />

www.harnisch.com<br />

Fi Europe Innovation Awards<br />

The renowned Fi Europe Innovation Awards will once again be<br />

adding extra value to the trade show. With one exception, the<br />

awards will only be presented among Fi Europe exhibitors:<br />

The new "Food Training & Education" category is also open<br />

to non-exhibitors. This award is intended to recognise a<br />

company, institution or organisation that contributes to<br />

better consumer health, for example, through an educational<br />

initiative or a pioneering approach. The "Sustainability<br />

Innovation Award" recognises environmentally, economically<br />

or socially sustainable approaches and practices in the food<br />

and beverage industry.<br />

Companies that create equal opportunities in the work<br />

environment receive the "Diversity & Inclusion Innovation<br />

Award". The "Plant-based Innovation Award" acknowledges<br />

alternatives to animal products and is given for the best<br />

ingredient or application. In the "Sensory Innovation"<br />

category, the award is for an ingredient or process that<br />

improves the overall sensory properties of foods or<br />

beverages. The "Health Innovation Award" honours an<br />

ingredient or process that provides a health benefit. The<br />

"Food Tech Innovation Award" goes to companies that<br />

have developed innovative processes, packaging or waste<br />

reduction solutions.<br />

The decision as to who receives awards is made by industry<br />

experts from the fields of consulting, management, product<br />

development and trade media. Prof. Colin Dennis, Chairman<br />

of the Board of Trustees of the IFIS organization and member<br />

of the Board of Trustees of the British Nutrition Foundation,<br />

will again chair the jury this year. The winners of all categories<br />

will be announced during Fi & Hi Europe at a ceremony on<br />

December 6.<br />

Award for innovative startups<br />

The Fi Global Startup Innovation Challenge also enables<br />

young companies to present their innovative concepts,<br />

products and ideas to an international audience of experts,<br />

major companies and sponsors. All companies founded no<br />

more than five years ago are eligible to participate. They can<br />

apply in one or more of the following categories:<br />

• Most innovative ingredient for food or beverage<br />

• Most innovative plant-based or alternative ingredient<br />

• Most innovative processing technology<br />

• Most innovative service, technology or digital solution for<br />

the food and beverage industry<br />

- <strong>Technology</strong> & <strong>Marketing</strong> -<br />

18

Events<br />

Finalists and winners will have access to the Startup Lounge,<br />

where they can present their products and solutions on<br />

the Innovation Hub stage, and network with industry<br />

representatives. Both the pitches and the award ceremony<br />

will also be streamed via the Fi Europe online platform and<br />

remain permanently available. Winners will have a choice of<br />

several attractive prizes: A fully equipped booth at Fi Europe<br />

next year, a comprehensive online marketing package or an<br />

individual mentoring programme. The latter can be coaching,<br />

for example, or the implementation of a pilot project, or it<br />

can include access to corporate collaborations and business<br />

accelerator programmes.<br />

Prebiotic Dietary Fiber Enrichment Range<br />

Among the latest additions to Taiyo's product lines are special<br />

Sunfiber® variants. They are suitable as prebiotic dietary<br />

fiber enrichment for baby food, pet food and applications<br />

such as fortified gummies or bakery products. Furthermore,<br />

the expert for natural-based functional ingredients presents<br />

health-promoting green tea catechins from the Sunphenon®<br />

range.<br />

In addition to the Innovation Hub, visitors will find the<br />

new Sustainability Hub at the exhibition, which focuses on<br />

sustainable food solutions along the entire value chain. Here<br />

visitors will find information on food waste, circular economy,<br />

regenerative agriculture and many other topics. Finally, the<br />

Women’s Networking Breakfast, sponsored by DSM, Lunch &<br />

Learn and other events are perfect for building a professional<br />

network.<br />

Future-Focused Concepts and Solutions that<br />

Meet Evolving Consumer Demands at Fi<br />

Europe <strong>2022</strong><br />

Today’s consumers are increasingly looking for foods and<br />

beverages that not only proactively support their personalized<br />

wellness goals, but also support their communities and the<br />

planet. This holistic evolution of conscientious shopping is driving<br />

food and beverage innovation. At this year’s Fi Europe, ADM will<br />

take a deeper dive into what’s motivating consumers’ shopping<br />

behaviors, showcasing full-service platforms and systems,<br />

transparently sourced ingredients, cutting-edge solutions and<br />

technical expertise that bring on-trend, consumer-preferred<br />

concepts to life. Highlights include a variety of plant-based savory<br />

and dairy alternative offerings, lifestyle beverages, baked goods<br />

and snacks with gut microbiome-supporting solutions, as well as<br />

interactive sensorial stations.<br />

Sunfiber® is a soluble prebiotic dietary fiber produced from<br />

the guar bean which promotes the acitivity and multiplication<br />

of beneficial probiotics in the gastro-intestinal tract.<br />

Sunfiber® VB can be utilized in baby food. Because of its<br />

slow fermentation, Sunfiber® does not cause uncomfortable<br />

bloating, cramps or other digestive discomfort. All variants<br />

of Sunfiber® decrease the glycemic index of food products,<br />

which helps to stabilize blood sugar levels. Furthermore, the<br />

prebiotic dietary fiber supports the health and function of the<br />

intestinal tract, and increases overall wellbeing. Sunfiber®<br />

VC is characterized by its low viscosity which perfectly suits<br />

technological requirements. It also dissolves well in fluids<br />

such as milk beverages or supplements in the form of syrups<br />

and shots.<br />

Green tea catechins in the Sunphenon® range are innovative<br />

ingredients. Their health-promoting properties differ<br />

depending on the catechin: Sunphenon XLB can be used<br />

in oral hygiene and disinfectant products to make it more<br />

difficult for viruses to penetrate. Sunphenon® EC is a<br />

myostatin blocker that can positively contribute to muscle<br />

growth. In sufficient doses, it can also have beneficial effects<br />

against diabetes and obesity. The Sunphenon® EGC variant<br />

is an amylase and glucosidase blocker that can also have a<br />

health-promoting effect in type 2 diabetes and obesity.<br />

"Consumers are increasingly questioning a product's ingredients<br />

and looking for natural and plant-based alternatives with added<br />

health benefits," says Dr. Stefan Siebrecht, managing director<br />

of Taiyo's German subsidiary. "Taiyo is therefore presenting<br />

innovative solutions and products that enable the industry to<br />

meet these demands."<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · November <strong>2022</strong> 19

Processing<br />

Three Factors That Affect Production<br />

Value Targets<br />

by CLEMENS PRÖBSTING<br />

Diet soft drinks and other mid-calorie<br />

alternatives make up a growing<br />

segment of today’s soft drink industry.<br />

Along with ingredients like acids and<br />

artificial flavors, typical diet soft drinks<br />

also contain sweeteners. While other<br />

ingredients cannot be overlooked, it is<br />

mostly sugar that affects the density of<br />

the soft drink. This effect is expressed<br />

in sugar concentration (°Brix), which<br />

can easily be analyzed by measuring<br />

density.<br />

To demonstrate the effectiveness<br />

of this technology compared with<br />

traditional methods, Anton Paar, along<br />

with a selection of soft drink production<br />

plants, carried out a comparative study<br />

in which it conducted more than 1,800<br />

measurements over several batches of<br />

diet beverages with a PBA-SD analyzing<br />

system from 2011 and a new PBA 5001<br />

Soft Drink Diet system. The study<br />

aimed to explore whether the PBA<br />

Figure 1: Anton Paar’s PBA 5001 Soft Drink<br />

5001, a measuring system based only<br />

on density, could out-perform Anton<br />

Paar’s older system, which was based<br />

on density and color measurements,<br />

in analyzing the most important<br />

influencing factors for guaranteeing inspec<br />

production of diet products and<br />

%Diet.<br />

Results showed that the new system<br />

could indeed be used for this style of<br />

measurement. Due to its new patented<br />

measuring principle (an oscillating<br />

U-tube principle called the Pulsed<br />

Excitation Method) as well as continuous<br />

technological improvements that have<br />

been made over the years, the system<br />

was effective.<br />

Measuring density for %Diet<br />

monitoring<br />

Traditionally, the perfect diet drink has<br />

been linked to a laboratory reference<br />

method. For this, a lead substance<br />

(e.g., phosphoric acid) is picked to<br />

determine the concentration of a diet<br />

drink, and the reference lab analysis<br />

specifies if the target reference<br />

value for the lead component can be<br />

reached and how much it deviates.<br />

A major disadvantage of reference<br />

methods is that they are timeconsuming<br />

procedures and require<br />

skilled operators and chemicals.<br />

20

Processing<br />

Beverage Monitored substance Laboratory reference method<br />

Cola diet beverage Phosphate Photometric method or ion chromatography<br />

Cola diet beverage Caffeine HPLC<br />

Most diet beverages Total acids Titration<br />

Table 1: Overview of reference methods for different diet beverages<br />

The influence of process water<br />

Process water is the main ingredient<br />

of a diet soft drink and is different<br />

at every soft drink plant. Small<br />

density variations during production<br />

are possible, depending on the<br />

pretreatment. The following table and<br />

figure show measuring results from the<br />

PBA 5001 Soft Drink Diet. A 500 mL<br />

Analyzing the three factors<br />

that negatively influence diet<br />

concentration<br />

All steps in this study were performed<br />

with the PBA 5001 Soft Drink Diet from<br />

Anton Paar, which measures %Diet<br />

based on density with an accuracy of<br />

0.5 %Diet.<br />

Sample preparation procedure<br />

The soft drink package (glass, can, or PET<br />

bottle) was placed into a PFD Piercing<br />

and Filling Device without any sample<br />

preparation having occurred. The<br />

package was then pierced by the device<br />

and the sample directly transferred to<br />

the measuring system.<br />

Sample Measured diet conc. [%] Density [g/cm 3 ] Added water [mL]<br />

Diet cola 1 100.00 1.00098 0<br />

Diet cola 2 92.21 0.99919 50<br />

Diet cola 3 84.92 0.99912 100<br />

Diet cola 4 77.84 0.99904 150<br />

Table 2: The influence of process water<br />

diet cola was diluted with water. The<br />

same water was used for the process<br />

water adjustment.<br />

Figure 2 shows that the low density<br />

of process water changes the density<br />

of the final beverage. Due the<br />

influence of process water, the actual<br />

measurement no longer agrees with<br />

the adjustment and leads to a lower<br />

diet concentration. Consequently,<br />

it can be assumed that if the diet<br />

concentration result is below the<br />

reference value, there is too much<br />

process water in the final beverage.<br />

As a result, operators know that<br />

they have to adapt their production<br />

process.<br />

The influence of citric acid<br />

Density measurement is not a selective<br />

measuring technique. Because diet syrup<br />

has a lot of ingredients, it is difficult to<br />

determine whether the syrup dosing is<br />

wrong or if a specific syrup ingredient<br />

causes the wrong diet concentration. In<br />

the table and figure below, an example<br />

is shown. Citric acid was added to a 500<br />

mL diet orange beverage.<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · November <strong>2022</strong><br />

21

Processing<br />

Since citric acid has a very high density,<br />

the density of the final beverage changes<br />

drastically. Diet concentration increases<br />

significantly (above 200% with 3g added<br />

citric acid). Such a strong increase in diet<br />

can usually only be triggered by an acid.<br />

Sample Measured diet conc. [%] Density [g/cm 3 ] Added water [mL]<br />

Diet orange 1 100.00 1.00066 0<br />

Diet orange 2 109.92 1.00090 0.3<br />

Diet orange 3 129.28 1.00137 1.0<br />

Diet orange 4 169.65 1.00235 2.0<br />

Diet orange 5 209.98 1.00333 3.0<br />

Table 3: The influence of acids<br />

The influence of syrup<br />

ingredients<br />

Syrup dosing is a critical taste and<br />

cost factor. Syrup was added to 500<br />

mL diet cola. The results are shown<br />

below.<br />

In this example, too much syrup was<br />

added to the process water, which<br />

led the density of the final beverage<br />

to increase and no longer match the<br />

adjustment. Since the density change<br />

is not as strong as with citric acid, the<br />

increase in diet concentration can easily<br />

be related to syrup dosage.<br />

One system covers it all<br />

Since, as was shown above, a highly<br />

accurate density measurement is the<br />

most reliable way to monitor quality<br />

in terms of diet concentration (%Diet,<br />

mL NaOH, etc.) during the production<br />

process for diet beverages, using one<br />

system for all samples of a production<br />

plant is beneficial.<br />

A system for quality checks on<br />

all products from a soft drink<br />

factory<br />

With its PBA 5001 Soft Drink Diet, Anton<br />

Paar now offers an analyzing system<br />

that is not only capable of measuring<br />

diet soft drinks and energy drinks, but<br />

also mid-calorie drinks, regular drinks,<br />

and bottled water. Since the sample<br />

is transferred directly from the final<br />

package with the help of a special<br />

filling device, no sample preparation is<br />

required for analysis.<br />

All key parameters analyzed in<br />

one run<br />

Besides density, the system simultaneously<br />

selectively determines the pH value and<br />

amount of dissolved O 2<br />

and CO 2<br />

in the<br />

package. Analyzing all key parameters in<br />

one run from a single sample helps soft<br />

drink producers optimize their blending<br />

process and ensure ideal carbonation<br />

levels. PBA 5001 systems that are already<br />

22

Processing<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · November <strong>2022</strong><br />

23

Processing<br />

Sample Measured diet conc. [%] Density [g/cm 3 ] Added water [mL]<br />

Diet cola 1 100.00 0.99918 0<br />

Diet cola 2 109.90 0.99929 2.0<br />

Diet cola 3 119.70 0.99938 5.0<br />

Diet cola 4 128.00 0.99947 7.5<br />

Diet cola 5 135.94 0.99969 10.0<br />

Table 4: The influence of syrup dosage<br />

being used can easily be upgraded due<br />

to their modular setup. Since there is<br />

automatic filling error detection in the<br />

density and CO 2<br />

meters, users can be<br />

confident that their sample filling has<br />

been done correctly.<br />

Less reference analysis in daily<br />

work routines<br />

For anyone still using the complex<br />

molybdenum blue or titration methods<br />

for diet drink analysis, Anton Paar’s new<br />

beverage analyzing system can help. It is<br />

easily adjusted and operated. A reference<br />

for %Diet measurements is only set<br />

at the beginning of batch production,<br />

which reduces the demand for reference<br />

analysis by 75 % and saves users money<br />

on costly chemicals and consumables.<br />

Conclusion<br />

The quality of a diet beverage is largely<br />

influenced by three factors: process water,<br />

citric acid, and syrup ingredients. This<br />

study showed that these three factors<br />

have a negative impact on production<br />

target values. Because of this, analyzing<br />

these during the whole production<br />

process is best done with a system based<br />

on density measurement.<br />

24

Processing<br />

Covert Detection<br />

<strong>Technology</strong> Helps Identify<br />

Counterfeit Regional Wines<br />

The National Office of Vine and<br />

Vitivinicultural Products (ONVPV) in<br />

Romania, is using Eluceda’s covert<br />

taggant marker with a unique machinereadable<br />

signature, to authenticate<br />

the provenance of its regional wines<br />

and protect drinkers from potential<br />

counterfeits.<br />

The ONVPV oversees national vineyard<br />

management and winemaking in Romania<br />

and supports the traditional production<br />

of wine in this designated geographical<br />

area. The security labels provide a clear<br />

brand identity for the ONVPV, which is<br />

easily recognizable on labelled bottles<br />

and products within a retail environment.<br />

Working closely with security label<br />

manufacturer Eltronis, Eluceda provided<br />

a tailored taggant to ensure that ONVPV<br />

wine labels were protected by the latest<br />

covert security technology, helping<br />

producers to stay one step ahead of the<br />

counterfeiters.<br />

By adding authentication technology<br />

to wine bottles, the ONVPV is helping<br />

to counter this trend, promoting the<br />

provenance of the region, and building<br />

protection against potential counterfeit<br />

through the ability to identify genuine<br />

products.<br />

Richard Burhouse, Commercial Director<br />

for Eluceda, said: “We’re seeing growth<br />

in the use of our covert markers to<br />

help protect products of geographic<br />

importance, as they provide discrete and<br />

instant verification of genuine goods for<br />

enforcement officers working in the field.<br />

“We are delighted to be involved in<br />

this project and support progressive<br />

organisations such as the ONVPV who<br />

continue to invest in security technologies<br />

in order to promote their wines and take<br />

a clear stand against fraud.”<br />

The new labels build on ONVPV’s<br />

existing design and combine an overt<br />

hologram with high-level covert security.<br />

Eluceda’s taggant marker with its unique<br />

machine-readable signature provides an<br />

instant unambiguous response to the<br />

pocket-sized Reveal detectors used by<br />

enforcement officers in the field.<br />

The Reveal range of readers work in<br />

hand in glove with Eluceda’s MicroTagg<br />

and Securitagg inorganic taggant<br />

materials and are configured according<br />

to the ONVPV’s needs to identify genuine<br />

wines quickly and securely.<br />

Wine fraud is on the rise in all markets,<br />

helped in part by the growth of<br />

ecommerce. This poses significant<br />

dangers to both consumers and<br />

producers alike, as fraudsters will<br />

sometimes include dangerous additives<br />

and trust in a brand can often be broken<br />

if customers fall foul of counterfeiters.<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · November <strong>2022</strong><br />

25

Processing<br />

State-of-the-Art Filtration Technologies<br />

for a High-Quality and Efficient Wine<br />

Production at SIMEI <strong>2022</strong><br />

The Filtration Division of power<br />

management company, Eaton, will present<br />

an extensive range of filtration and<br />

biotechnology products at the SIMEI trade<br />

show in Milan, Italy, from November 15<br />