Panels & Furniture Asia January/February 2024

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

IN PERSON<br />

wants to start a plywood mill with<br />

Chinglun’s help, Lee said that they<br />

are confident in providing what<br />

the customer wants “from A to Z”,<br />

tailored to their requirements.<br />

“First, we meet up with the customer<br />

and ask them what they need, to<br />

understand, for example, their target<br />

capacity, what kinds of products<br />

they are manufacturing, or what<br />

their working hours are like, because<br />

different factories have different<br />

working hours. Like in Indonesia,<br />

most factories are doing 10 hours<br />

a shift, with two shifts a day and 25<br />

days per month. Then we write up a<br />

proposal. Sometimes we ask them<br />

for a layout of their existing plan or<br />

factory, and we propose to them how<br />

it would be installed, so their flow of<br />

work would turn out smooth. Once<br />

everything is confirmed and after<br />

receiving the down payment, we<br />

will assign technicians to start the<br />

plant manufacturing and install the<br />

machines.”<br />

“DIFFERENT MARKETS REQUIRE<br />

DIFFERENT PROCESSING TECHNIQUES”<br />

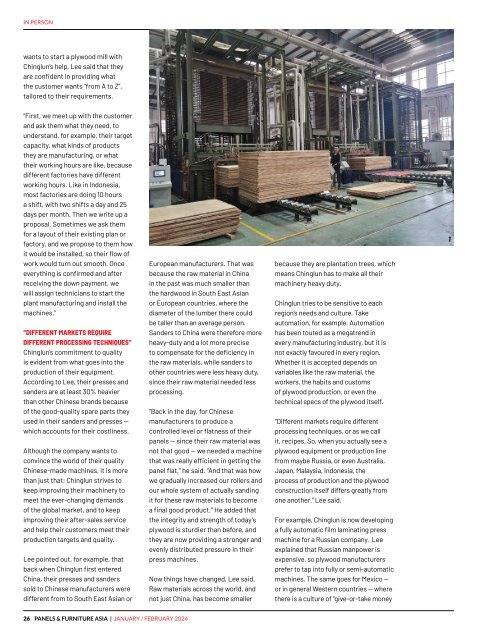

Chinglun’s commitment to quality<br />

is evident from what goes into the<br />

production of their equipment.<br />

According to Lee, their presses and<br />

sanders are at least 30% heavier<br />

than other Chinese brands because<br />

of the good-quality spare parts they<br />

used in their sanders and presses —<br />

which accounts for their costliness.<br />

Although the company wants to<br />

convince the world of their quality<br />

Chinese-made machines, it is more<br />

than just that; Chinglun strives to<br />

keep improving their machinery to<br />

meet the ever-changing demands<br />

of the global market, and to keep<br />

improving their after-sales service<br />

and help their customers meet their<br />

production targets and quality.<br />

Lee pointed out, for example, that<br />

back when Chinglun first entered<br />

China, their presses and sanders<br />

sold to Chinese manufacturers were<br />

different from to South East <strong>Asia</strong>n or<br />

European manufacturers. That was<br />

because the raw material in China<br />

in the past was much smaller than<br />

the hardwood in South East <strong>Asia</strong>n<br />

or European countries, where the<br />

diameter of the lumber there could<br />

be taller than an average person.<br />

Sanders to China were therefore more<br />

heavy-duty and a lot more precise<br />

to compensate for the deficiency in<br />

the raw materials, while sanders to<br />

other countries were less heavy duty,<br />

since their raw material needed less<br />

processing.<br />

“Back in the day, for Chinese<br />

manufacturers to produce a<br />

controlled level or flatness of their<br />

panels — since their raw material was<br />

not that good — we needed a machine<br />

that was really efficient in getting the<br />

panel flat,” he said. “And that was how<br />

we gradually increased our rollers and<br />

our whole system of actually sanding<br />

it for these raw materials to become<br />

a final good product.” He added that<br />

the integrity and strength of today’s<br />

plywood is sturdier than before, and<br />

they are now providing a stronger and<br />

evenly distributed pressure in their<br />

press machines.<br />

Now things have changed, Lee said.<br />

Raw materials across the world, and<br />

not just China, has become smaller<br />

because they are plantation trees, which<br />

means Chinglun has to make all their<br />

machinery heavy duty.<br />

Chinglun tries to be sensitive to each<br />

region’s needs and culture. Take<br />

automation, for example. Automation<br />

has been touted as a megatrend in<br />

every manufacturing industry, but it is<br />

not exactly favoured in every region.<br />

Whether it is accepted depends on<br />

variables like the raw material, the<br />

workers, the habits and customs<br />

of plywood production, or even the<br />

technical specs of the plywood itself.<br />

“Different markets require different<br />

processing techniques, or as we call<br />

it, recipes. So, when you actually see a<br />

plywood equipment or production line<br />

from maybe Russia, or even Australia,<br />

Japan, Malaysia, Indonesia, the<br />

process of production and the plywood<br />

construction itself differs greatly from<br />

one another.” Lee said.<br />

For example, Chinglun is now developing<br />

a fully automatic film laminating press<br />

machine for a Russian company. Lee<br />

explained that Russian manpower is<br />

expensive, so plywood manufacturers<br />

prefer to tap into fully or semi-automatic<br />

machines. The same goes for Mexico —<br />

or in general Western countries — where<br />

there is a culture of “give-or-take money<br />

1<br />

26 PANELS & FURNITURE ASIA | JANUARY / FEBRUARY <strong>2024</strong>