Panels & Furniture Asia January/February 2024

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FURNITURE MANUFACTURING<br />

Advanced manufacturing<br />

with HOMAG’s factory<br />

management system and<br />

full solution for automation<br />

the production process helps companies<br />

track and locate responsibilities and achieve<br />

standardisation.<br />

Most companies are aware of the importance<br />

of digitalisation in advanced furniture<br />

manufacturing, yet many generally give<br />

priority to the setting up of enterprise<br />

resource planning (ERP) systems to meet their<br />

needs.<br />

It is undeniable that ERP integrates much<br />

of the information within corporations and<br />

provides the management a platform for<br />

decision making, planning, control and the<br />

evaluation of business performance. However,<br />

at the shopfloor ERP alone cannot meet the<br />

needs of information processing, collection<br />

and exchange in the production process.<br />

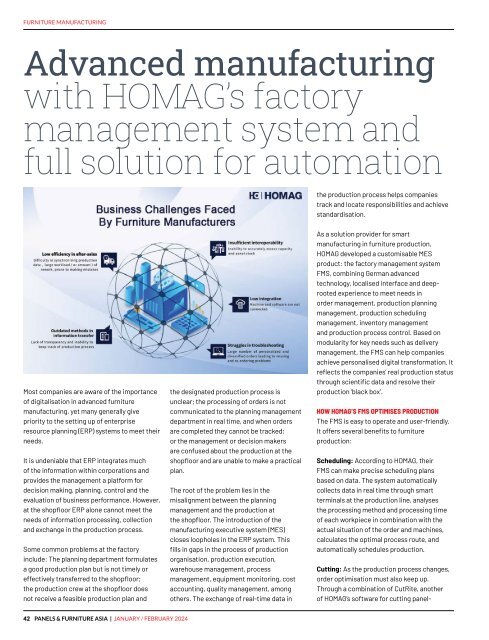

Some common problems at the factory<br />

include: The planning department formulates<br />

a good production plan but is not timely or<br />

effectively transferred to the shopfloor;<br />

the production crew at the shopfloor does<br />

not receive a feasible production plan and<br />

Cutting: As the production process changes,<br />

order optimisation must also keep up.<br />

Through a combination of CutRite, another<br />

of HOMAG’s software for cutting panelthe<br />

designated production process is<br />

unclear; the processing of orders is not<br />

communicated to the planning management<br />

department in real time, and when orders<br />

are completed they cannot be tracked;<br />

or the management or decision makers<br />

are confused about the production at the<br />

shopfloor and are unable to make a practical<br />

plan.<br />

The root of the problem lies in the<br />

misalignment between the planning<br />

management and the production at<br />

the shopfloor. The introduction of the<br />

manufacturing executive system (MES)<br />

closes loopholes in the ERP system. This<br />

fills in gaps in the process of production<br />

organisation, production execution,<br />

warehouse management, process<br />

management, equipment monitoring, cost<br />

accounting, quality management, among<br />

others. The exchange of real-time data in<br />

As a solution provider for smart<br />

manufacturing in furniture production,<br />

HOMAG developed a customisable MES<br />

product: the factory management system<br />

FMS, combining German advanced<br />

technology, localised interface and deeprooted<br />

experience to meet needs in<br />

order management, production planning<br />

management, production scheduling<br />

management, inventory management<br />

and production process control. Based on<br />

modularity for key needs such as delivery<br />

management, the FMS can help companies<br />

achieve personalised digital transformation. It<br />

reflects the companies’ real production status<br />

through scientific data and resolve their<br />

production ‘black box’.<br />

HOW HOMAG’S FMS OPTIMISES PRODUCTION<br />

The FMS is easy to operate and user-friendly.<br />

It offers several benefits to furniture<br />

production:<br />

Scheduling: According to HOMAG, their<br />

FMS can make precise scheduling plans<br />

based on data. The system automatically<br />

collects data in real time through smart<br />

terminals at the production line, analyses<br />

the processing method and processing time<br />

of each workpiece in combination with the<br />

actual situation of the order and machines,<br />

calculates the optimal process route, and<br />

automatically schedules production.<br />

42 PANELS & FURNITURE ASIA | JANUARY / FEBRUARY <strong>2024</strong>