Panels & Furniture Asia January/February 2024

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

MATERIALS<br />

capacity and the maximum panel<br />

size. Regardless of the scale, two key<br />

components are essential: the CLT press<br />

and the finger jointing line. Additional<br />

specific equipment needed depends on the<br />

production capacity. For industrial-level<br />

production beginning at 5,000m 3 yearly<br />

production, additional equipment includes<br />

planers, cross-cut saws, mechanization<br />

systems, and board and panel handling<br />

systems. Moreover, a sander and a CNC<br />

machining centre designed for large<br />

format panels are necessary for a complete<br />

manufacturing process.<br />

and then finger joint whole CLT panels into<br />

the appropriate lengths with a unique finger<br />

jointing block press. This allows various<br />

possibilities and reduces the entry price as<br />

there is no need to finger joint lamellas, and<br />

the cold CLT press is only 6m long.<br />

According to Ledinek, new entrants can<br />

start with limited means and later modularly<br />

upgrade it to more automatic functions, and<br />

thus raise the capacity of the line. With fully<br />

equipped line they can achieve production<br />

volume of up to 100m 3 per shift. P<br />

For smaller workshops, Ledinek supplies<br />

production equipment for narrow CLT<br />

panels. The company has an automated<br />

production line that aims at smaller and<br />

medium-sized companies interested to<br />

enter the CLT market. The main advantage<br />

of the line is the possibility to press panels of<br />

the same length as boards in the packages<br />

2<br />

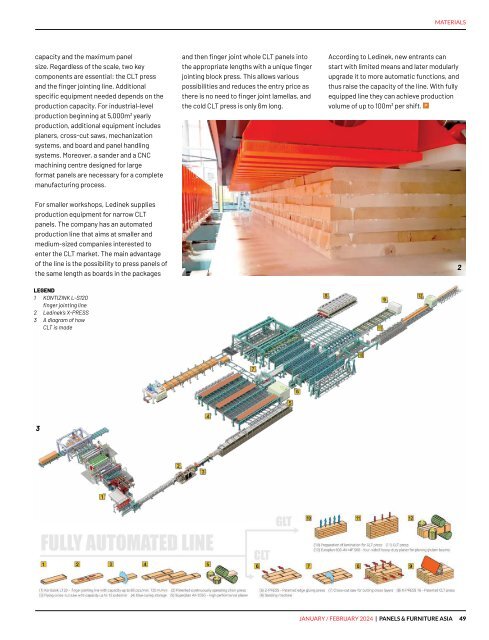

LEGEND<br />

1 KONTIZINK L-S120<br />

finger jointing line<br />

2 Ledinek’s X-PRESS<br />

3 A diagram of how<br />

CLT is made<br />

3<br />

JANUARY / FEBRUARY <strong>2024</strong> | PANELS & FURNITURE ASIA 49