Emerging Technologies Report on Wastewater Treatment (PDF)

Emerging Technologies Report on Wastewater Treatment (PDF)

Emerging Technologies Report on Wastewater Treatment (PDF)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

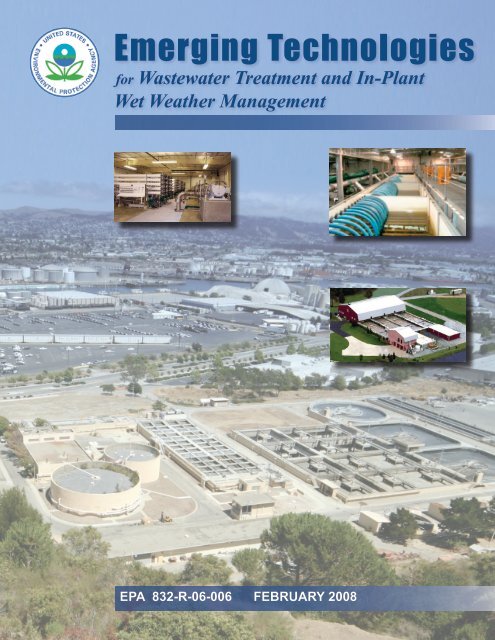

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

for <strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant<br />

Wet Weather Management<br />

EPA 832-R-06-006 FEBRUARY 2008

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> February 2008<br />

6-16<br />

This page intenti<strong>on</strong>ally left blank<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

for<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and<br />

In-Plant Wet Weather Management<br />

Prepared for:<br />

Office of <strong>Wastewater</strong> Management<br />

U.S. Envir<strong>on</strong>mental Protecti<strong>on</strong> Agency<br />

Washingt<strong>on</strong>, D.C.<br />

EPA 832-R-06-006<br />

Under C<strong>on</strong>tract<br />

68-C-02-111<br />

Prepared by:<br />

Pars<strong>on</strong>s Corporati<strong>on</strong><br />

Fairfax, Virginia<br />

February 2008

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> February 2008<br />

ii<br />

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> for <strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather<br />

Management<br />

EPA 832-R-06-006<br />

February 2008<br />

Produced under U.S. EPA C<strong>on</strong>tract No. 68-C-02-111<br />

Prepared by the Pars<strong>on</strong>s Corporati<strong>on</strong><br />

Fairfax, Virginia<br />

Technical review was provided by professi<strong>on</strong>als with experience in wastewater treatment.<br />

Technical reviewers of this document were:<br />

Dr. Charles Bott, Assistant Professor, Virginia Military Institute (VMI)<br />

Dr. Sudhir Murthy, Manager, Process Development, Washingt<strong>on</strong>, D.C. Water and Sewer<br />

Authority (WASA)<br />

Dr. Krishna Pagilla, Professor, Illinois Institute of Technology (IIT)<br />

Tyler Richards, Deputy Director of Operati<strong>on</strong>s and Envir<strong>on</strong>mental Services,<br />

Gwinnett County, GA<br />

Tom Sadick, CH2M HILL<br />

Terry Krause, CH2M HILL<br />

Mark Bishop, Hazen and Sawyer<br />

Recycled/Recyclable<br />

Printed with vegetable-based ink <strong>on</strong> paper that c<strong>on</strong>tains a minimum of 50 percent postc<strong>on</strong>sumer<br />

fiber c<strong>on</strong>tent, chlorine free.<br />

Electr<strong>on</strong>ic copies of this handbook can be downloaded from the<br />

U.S. EPA Office of <strong>Wastewater</strong> Management web site at:<br />

www.epa.gov/owm<br />

Cover photo credit: Veolia Water North America<br />

Photo inserts credit: Pars<strong>on</strong>s Corporati<strong>on</strong><br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management

February 2008<br />

Preface<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management<br />

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

The U.S. Envir<strong>on</strong>mental Protecti<strong>on</strong> Agency (U.S. EPA) is charged by C<strong>on</strong>gress with<br />

protecting the nati<strong>on</strong>’s land, air, and water resources. Under a mandate of envir<strong>on</strong>mental<br />

laws, the Agency strives to formulate and implement acti<strong>on</strong>s leading to a balance between<br />

human activities and the ability of natural systems to support and sustain life. To meet this<br />

mandate, the Office of <strong>Wastewater</strong> Management (OWM) provides informati<strong>on</strong> and<br />

technical support to solve envir<strong>on</strong>mental problems today and to build a knowledge base<br />

necessary to protect public health and the envir<strong>on</strong>ment well into the future.<br />

This publicati<strong>on</strong> has been produced, under c<strong>on</strong>tract to the U.S. EPA, by the Pars<strong>on</strong>s<br />

Corporati<strong>on</strong>, and it provides current state of development as of the publicati<strong>on</strong> date. It is<br />

expected that this document will be revised periodically to reflect advances in this rapidly<br />

evolving area. Except as noted, informati<strong>on</strong>, interviews, and data development were<br />

c<strong>on</strong>ducted by the c<strong>on</strong>tractor. Some of the informati<strong>on</strong>, especially related to embry<strong>on</strong>ic<br />

technologies, was provided by the manufacturer or vendor of the equipment or technology,<br />

and could not be verified or supported by full-scale case study. In some cases, cost data<br />

were based <strong>on</strong> estimated savings without actual field data. When evaluating technologies,<br />

estimated costs, and stated performance, efforts should be made to collect current and<br />

more up-to-date informati<strong>on</strong>.<br />

The menti<strong>on</strong> of trade names, specific vendors, or products does not represent an actual<br />

or presumed endorsement, preference, or acceptance by the U.S. EPA or Federal<br />

Government. Stated results, c<strong>on</strong>clusi<strong>on</strong>s, usage, or practices do not necessarily represent<br />

the views or policies of the U.S. EPA.<br />

iii

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> February 2008<br />

iv<br />

This page intenti<strong>on</strong>ally left blank<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management

February 2008<br />

C<strong>on</strong>tents<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management<br />

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

Page<br />

Preface .................................................................................................................................. iii<br />

List of Acr<strong>on</strong>yms and Abbreviati<strong>on</strong>s..................................................................................... viii<br />

List of <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> ...............................................................................................................xi<br />

Overview.............................................................................................................................O-1<br />

1. Introducti<strong>on</strong> and Approach .......................................................................................... 1-1<br />

1.1 Introducti<strong>on</strong> .....................................................................................................................1-1<br />

1.2 Approach .........................................................................................................................1-2<br />

1.2.1 Informati<strong>on</strong> Collecti<strong>on</strong> and New Process Identificati<strong>on</strong> .....................................1-3<br />

1.2.2 Initial Screened <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> ...........................................................................1-3<br />

1.2.3 Development of Technology Summary Sheets .................................................1-5<br />

1.2.4 Evaluati<strong>on</strong> of <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> .............................................................................1-15<br />

1.3 Guidance Document Format and Use ...........................................................................1-17<br />

1.4 Chapter References ......................................................................................................1-17<br />

2. Physical/Chemical <strong>Treatment</strong> Processes .................................................................... 2-1<br />

2.1 Introducti<strong>on</strong> .....................................................................................................................2-1<br />

2.2 Technology Assessment ..................................................................................................2-1<br />

3. Biological <strong>Treatment</strong> Processes .................................................................................. 3-1<br />

3.1 Introducti<strong>on</strong> .....................................................................................................................3-1<br />

3.2 Technology Assessment ..................................................................................................3-1<br />

4. In-Plant Wet Weather Management Processes .......................................................... 4-1<br />

4.1 Introducti<strong>on</strong> .....................................................................................................................4-1<br />

4.2 Technology Assessment ..................................................................................................4-1<br />

5. Process M<strong>on</strong>itoring <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> ............................................................................... 5-1<br />

5.1 Introducti<strong>on</strong> .....................................................................................................................5-1<br />

v

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> February 2008<br />

vi<br />

C<strong>on</strong>tents<br />

Page<br />

5.2 Technology Assessment ..................................................................................................5-1<br />

6. Research Needs.......................................................................................................... 6-1<br />

6.1 Introducti<strong>on</strong> .....................................................................................................................6-1<br />

6.2 Research Needs .............................................................................................................6-1<br />

6.2.1 Upgrading Old WWTPs .....................................................................................6-1<br />

6.2.2 Removal of Nutrients and Other C<strong>on</strong>taminants ................................................6-2<br />

6.2.3 Use of Smart <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> ...............................................................................6-3<br />

6.2.4 Security of Water Systems ................................................................................6-3<br />

6.2.5 Other Research Focus and Developments .......................................................6-4<br />

6.2.6 Research Needs and Prioritizati<strong>on</strong> per<br />

Water Envir<strong>on</strong>ment Research Foundati<strong>on</strong> (WERF) ..........................................6-4<br />

6.3 Chapter References ........................................................................................................6-4<br />

Appendix A Trade Associati<strong>on</strong>s ........................................................................................A-1<br />

A.1 Introducti<strong>on</strong> .................................................................................................................... A-1<br />

A.2 Trade Associati<strong>on</strong>s ......................................................................................................... A-1<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management

February 2008<br />

List of Tables<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management<br />

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

Page<br />

Table 1.1 Summary of <strong>Treatment</strong> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

Chapter 2 – Physical/Chemical <strong>Treatment</strong> Processes .................................. 1-6<br />

Table 1.2 Summary of <strong>Treatment</strong> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

Chapter 3 – Biological <strong>Treatment</strong> Processes ................................................ 1-9<br />

Table 1.3 Summary of <strong>Treatment</strong> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

Chapter 4 – In-Plant Wet Weather Management Processes ...................... 1-13<br />

Table 1.4 Summary of <strong>Treatment</strong> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

Chapter 5 – Process M<strong>on</strong>itoring <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> ........................................... 1-14<br />

Table 1.5 Descriptive Evaluati<strong>on</strong> Criteria .................................................................... 1-16<br />

Table 2.1 Physical/Chemical <strong>Treatment</strong> Processes – State of Development ............... 2-2<br />

Table 3.1 Biological <strong>Treatment</strong> Processes – State of Development ............................. 3-2<br />

Table 4.1 In-Plant Wet Weather Management Processes – State of Development ..... 4-2<br />

Table 5.1 Process M<strong>on</strong>itoring <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> – State of Development ........................... 5-2<br />

List of Figures<br />

Page<br />

Figure 1.1 Flow Schematic for Guide Development....................................................... 1-2<br />

Figure 2.1 Evaluati<strong>on</strong> of Innovative Physical/Chemical <strong>Treatment</strong> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> .......... 2-3<br />

Figure 3.1 Evaluati<strong>on</strong> of Innovative Biological <strong>Treatment</strong> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> ........................ 3-4<br />

Figure 4.1 Evaluati<strong>on</strong> of Innovative In-Plant Wet Weather Management<br />

<str<strong>on</strong>g>Technologies</str<strong>on</strong>g> ................................................................................................. 4-2<br />

Figure 5.1 Evaluati<strong>on</strong> of Innovative Process M<strong>on</strong>itoring <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> .......................... 5-3<br />

List of Exhibit<br />

Page<br />

Exhibit 6.1 Paper from WERF Workshop <strong>on</strong> Nutrient Removal ...................................... 6-5<br />

vii

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> February 2008<br />

viii<br />

List of Acr<strong>on</strong>yms and Abbreviati<strong>on</strong>s<br />

Acr<strong>on</strong>ym/<br />

Abbreviati<strong>on</strong> Definiti<strong>on</strong><br />

A/O Anaerobic/Oxic (Phoredox)<br />

A2/O Anaerobic/Anoxic/Oxic<br />

AACE American Associati<strong>on</strong> of Cost Engineers Internati<strong>on</strong>al<br />

ABW ® Automatic Backwash Filters<br />

AEBR Anaerobic Expanded Bed Reactor<br />

AGAR ® Attached Growth Airlift Reactor<br />

AGRS Advanced Grit Removal System<br />

AGSP Aerobic Granular Sludge Process<br />

AIZ Air Intercept Z<strong>on</strong>e<br />

AMBR ® Anaerobic Migrating Blanket Reactor<br />

ANFLOW Anaerobic Fluidized Bed Reactor<br />

AN-MBR Anaerobic Membrane BioReactor<br />

AOP Advanced Oxidati<strong>on</strong> Process<br />

ASBR ® Anaerobic Sequencing Batch Reactor<br />

ASCE American Society of Civil Engineers<br />

atm Atmosphere<br />

AT3 Aerati<strong>on</strong> Tank 3<br />

AWTP Advanced <strong>Wastewater</strong> <strong>Treatment</strong> Plant<br />

AWWA American Water Works Associati<strong>on</strong><br />

BABE Bio-Augmentati<strong>on</strong> Batch Enhanced<br />

BAF Biological Aerated Filters<br />

BAR Bio Augmentati<strong>on</strong> Regenerati<strong>on</strong> and/or Reaerati<strong>on</strong><br />

BCFS Biological-Chemical Phosphorus and Nitrogen Removal<br />

BCDMH 1-Bromo-3 Chloro-5,5 DiMethylHydantoin<br />

BHRC Ballasted High Rate Clarificati<strong>on</strong><br />

BioMEMS Biological Micro-Electro Machine System<br />

BNR Biological Nutrient Removal<br />

BOD Biological/Biochemical Oxygen Demand<br />

BOD/N Biochemical Oxygen Demand Ratio to Nitrogen<br />

BOD/P Biochemical Oxygen Demand Ratio to Phosphorus<br />

CASS Cyclic Activated Sludge System<br />

CCAS CounterCurrent Aerati<strong>on</strong> System<br />

CDS C<strong>on</strong>tinuous Deflecti<strong>on</strong> Separator<br />

cfu Col<strong>on</strong>y forming unit<br />

CMAS Complete Mix-Activated Sludge<br />

CMF ® Compressed Media Filter (WWETCO CMF ® )<br />

CMOM Capacity, Management, Operati<strong>on</strong>s, and Maintenance<br />

COD Chemical Oxygen Demand<br />

CSO Combined Sewer Overflow<br />

CSS Combined Sewer System<br />

CWA Clean Water Act<br />

DAF Dissolved Air Flotati<strong>on</strong><br />

DEMON DEamMONificati<strong>on</strong><br />

DEPHANOX DE-nitrificati<strong>on</strong> and PHosphate accumulati<strong>on</strong> in ANOXic<br />

DF Disc Filter<br />

DO Dissolved Oxygen<br />

EBPR Enhanced Biological Phosphorus Removal<br />

EDC Endocrine Disrupting Compound<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management

February 2008<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management<br />

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

List of Acr<strong>on</strong>yms and Abbreviati<strong>on</strong>s (C<strong>on</strong>td)<br />

Acr<strong>on</strong>ym/<br />

Abbreviati<strong>on</strong> Definiti<strong>on</strong><br />

ELISA Enzyme-Linked ImmunoSorbent Assay<br />

EMS Envir<strong>on</strong>mental Management Systems<br />

FBBR Fluidized Bed BioReactor<br />

FISH Fluorescence In Situ Hybridizati<strong>on</strong><br />

GAC Granular-Activated Carb<strong>on</strong><br />

GPD Gall<strong>on</strong>s per day<br />

gpm/ft 2 Gall<strong>on</strong>s per minute per square foot<br />

HANAA Handheld Advanced Nucleic Acid Analyzer<br />

HFMBfR Hydrogen-based hollow-Fiber Membrane Biofilm Reactor<br />

HFO Hydrous Ferric Oxide<br />

HPO High-Purity Oxygen<br />

HRC High-Rate Clarificati<strong>on</strong><br />

HRT Hydraulic Retenti<strong>on</strong> Time<br />

ICAAS Immobilized Cell-Augmented Activated Sludge<br />

ICEAS Intermittent Cycle Extended Aerati<strong>on</strong> System<br />

IFAS Integrated Fixed-film Activated Sludge<br />

IIT Illinois Institute of Technology<br />

ISE I<strong>on</strong> Selective Electrode<br />

LOT Limit Of Technology<br />

IWA Internati<strong>on</strong>al Water Associati<strong>on</strong><br />

MAB Multi-stage Activated Biological<br />

MABR Membrane-Activated BioReactor<br />

MAUREEN Main-stream AUtotrophic Recycle Enabling Enhanced N-removal<br />

MBR Membrane BioReactor<br />

MBRT Mobile-Bed Reactor Technology<br />

MFC Microbial Fuel Cell<br />

MGD Milli<strong>on</strong> Gall<strong>on</strong>s per Day<br />

mg/L Milligram per Liter<br />

MISS Moderate Isotope Separati<strong>on</strong> System<br />

MLE Modified Ludzack-Ettinger<br />

MLSS Mixed Liquor Suspended Solids<br />

mph Miles per hour<br />

MSABP Multi-Stage Activated Biological Process<br />

MUCT Modified University of Cape Town<br />

NACWA Nati<strong>on</strong>al Associati<strong>on</strong> of Clean Water Agencies<br />

NADH Nicotinamide Adenine Dinucleotide<br />

NF NanoFiltrati<strong>on</strong><br />

NOB Nitrite Oxidizing Bacteria<br />

ntu Nephelometric turbidity unit<br />

O&M Operati<strong>on</strong> and Maintenance<br />

ORP Oxidati<strong>on</strong> Reducti<strong>on</strong> Potential<br />

OWM Office of <strong>Wastewater</strong> Management (U.S. EPA)<br />

PAC Powdered Activated Carb<strong>on</strong><br />

PAO Phosphorus Accumulating Organisms<br />

PBDE PolyBrominated Diphenyl Ether<br />

PCR Polymerase Chain Reacti<strong>on</strong><br />

PeCOD Photo-electro Chemical Oxygen Demand<br />

PhACs Pharmaceutically Active Compounds<br />

ix

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> February 2008<br />

x<br />

List of Acr<strong>on</strong>yms and Abbreviati<strong>on</strong>s (C<strong>on</strong>td)<br />

Acr<strong>on</strong>ym/<br />

Abbreviati<strong>on</strong> Definiti<strong>on</strong><br />

POTW Publicly Owned <strong>Treatment</strong> Works<br />

PPCP Pharmaceutical and Pers<strong>on</strong>al Care Products<br />

ppm Parts per milli<strong>on</strong><br />

PVC Poly Vinyl Chloride<br />

psig Pounds per square inch (gauge)<br />

RAS Returned Activated Sludge<br />

RBC Rotating Biological C<strong>on</strong>tactor<br />

R-DN Regenerati<strong>on</strong> DeNitrificati<strong>on</strong><br />

rDON Refractory Dissolved Organic Nitrogen<br />

SBR Sequencing Batch Reactor<br />

SCFM Standard Cubic Feet per Minute<br />

SHARON Single reactor High-activity Amm<strong>on</strong>ia Removal Over Nitrite<br />

SHARON – ANAMMOX Single reactor High-activity Amm<strong>on</strong>ia Removal Over Nitrite –<br />

ANaerobic AMM<strong>on</strong>ia OXidati<strong>on</strong><br />

SNdN Simultaneous Nitrificati<strong>on</strong> deNitrificati<strong>on</strong><br />

SRBC Submerged Rotating Biological C<strong>on</strong>tactor<br />

SRT Sludge Retenti<strong>on</strong> Time; Solids Retenti<strong>on</strong> Time<br />

SSO Sanitary Sewer Overflow<br />

STRASS Similar to SHARON named after Strass, Austria<br />

SVI Sludge Volume Index<br />

TDH Total Dynamic Head<br />

TDS Total Dissolved Solids<br />

TF Trickling Filter<br />

TF/PAS Trickling Filter and Pushed Activated Sludge<br />

TF/SC Trickling Filter and Solid C<strong>on</strong>tactor<br />

TMP Trans Membrane Pressure<br />

TOC Total Organic Carb<strong>on</strong><br />

TSS Total Suspended Solids<br />

U.S. EPA United States Envir<strong>on</strong>mental Protecti<strong>on</strong> Agency<br />

UASB Upflow Anaerobic Sludge Blanket<br />

UCT University of Cape Town<br />

UV UltraViolet<br />

VIP Virginia Initiative Plant<br />

VIS Visibility<br />

VMI Virginia Military Institute<br />

VRM ® Vacuum Rotati<strong>on</strong> Membrane<br />

WAS Waste Activated Sludge<br />

WASA Water and Sewer Authority<br />

WEF Water Envir<strong>on</strong>ment Federati<strong>on</strong><br />

WEFTEC Water Envir<strong>on</strong>ment Federati<strong>on</strong>’s Annual Technical Exhibiti<strong>on</strong> and C<strong>on</strong>ference<br />

WERF Water Envir<strong>on</strong>ment Research Foundati<strong>on</strong><br />

WPAP Water Polluti<strong>on</strong> Abatement Program<br />

WPCF Water Polluti<strong>on</strong> C<strong>on</strong>trol Facility<br />

WRF Water Reuse Facility<br />

WWEMA Water and <strong>Wastewater</strong> Equipment Manufacturers Associati<strong>on</strong><br />

WWPF WasteWater Producti<strong>on</strong> Flow<br />

WWTF WasteWater <strong>Treatment</strong> Facility<br />

WWTP WasteWater <strong>Treatment</strong> Plant<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management

February 2008<br />

Physical/Chemical <strong>Treatment</strong> Processes<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management<br />

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

Compressible Media Filtrati<strong>on</strong> ............................................. Innovative .............................................................. 2-5<br />

Nanofiltrati<strong>on</strong> ....................................................................... Innovative .............................................................. 2-7<br />

Actiflo ® Process ................................................................... Innovative Use of Established Technology ........... 2-9<br />

DensaDeg ® Process ............................................................ Innovative Use of Established Technology ......... 2-11<br />

Microwave UV Disinfecti<strong>on</strong> .................................................. Innovative Use of Established Technology ......... 2-13<br />

Blue CAT .......................................................................... Embry<strong>on</strong>ic ........................................................... 2-15<br />

Blue PRO ......................................................................... Embry<strong>on</strong>ic ........................................................... 2-17<br />

CoMag ............................................................................. Embry<strong>on</strong>ic ........................................................... 2-19<br />

Solar Disinfecti<strong>on</strong>................................................................. Embry<strong>on</strong>ic ........................................................... 2-21<br />

Biological <strong>Treatment</strong> Processes<br />

List of <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

PROCESS TYPE PAGE<br />

Bioaugmentati<strong>on</strong>.................................................................. Innovative .............................................................. 3-5<br />

EXTERNAL BIOAUGMENTATION ..........................................Innovative .......................................................................3-5<br />

Seeding from Commercial Sources of Nitrifiers .......................Innovative .......................................................................3-5<br />

Tricking Filter and Pushed Activated Sludge (TF/PAS)<br />

Process ....................................................................................Innovative .......................................................................3-5<br />

Seeding from External Dispersed Growth Reactors<br />

Treating Reject Waters (Chemostat Type) ...............................Innovative .......................................................................3-6<br />

In-Nitri ® Process .......................................................................Innovative .......................................................................3-6<br />

Immobilized Cell-Augmented Activated Sludge (ICASS)<br />

Process ....................................................................................Innovative .......................................................................3-7<br />

Seeding from Parallel Processes.............................................Innovative .......................................................................3-8<br />

Seeding from Downstream Process ........................................Innovative .......................................................................3-9<br />

IN SITU BIOAUGMENTATION ................................................Innovative .......................................................................3-9<br />

DE-nitrificati<strong>on</strong> and PHosphate accumulati<strong>on</strong> in ANOXic<br />

(DEPHANOX) Process ............................................................Innovative .......................................................................3-9<br />

Bio-Augmentati<strong>on</strong> Regenerati<strong>on</strong>/Reaerati<strong>on</strong> (BAR) Process ..Innovative .....................................................................3-10<br />

Bio-Augmentati<strong>on</strong> Batch Enhanced (BABE) Process ..............Innovative ..................................................................... 3-11<br />

Aerati<strong>on</strong> Tank 3 (AT3) Process ................................................Innovative ..................................................................... 3-11<br />

Main stream AUtotrophic Recycle Enabling<br />

Enhanced N-removal (MAUREEN) Process............................Innovative ..................................................................... 3-11<br />

Regenerati<strong>on</strong>-DeNitrificati<strong>on</strong> (R-DN) .......................................Innovative .....................................................................3-12<br />

Cannibal ® ............................................................................. Innovative ............................................................ 3-15<br />

CATABOL ......................................................................... Innovative ............................................................ 3-17<br />

Deep Shaft Activated Sludge/VERTREAT ...................... Innovative ............................................................ 3-19<br />

Integrated fixed-Film Activated Sludge (IFAS)<br />

Systems ............................................................................... Innovative ............................................................ 3-21<br />

SUBMERGED MOBILE MEDIA IFAS ......................................Innovative .....................................................................3-21<br />

AGAR ® (Attached Growth Airlift Reactor) ................................Innovative .....................................................................3-21<br />

Captor ® ...................................................................................Innovative .....................................................................3-21<br />

xi

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> February 2008<br />

xii<br />

List of <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> (C<strong>on</strong>td)<br />

PROCESS TYPE PAGE<br />

Biological <strong>Treatment</strong> Processes (C<strong>on</strong>td)<br />

LINPOR ® .................................................................................Innovative .....................................................................3-21<br />

SUBMERGED FIXED MEDIA IFAS .........................................Innovative .....................................................................3-21<br />

CLEARTEC ® ...........................................................................Innovative .....................................................................3-21<br />

AccuWeb ® ...............................................................................Innovative .....................................................................3-22<br />

BioMatrix .............................................................................Innovative .....................................................................3-22<br />

HYBAS .................................................................................Innovative .....................................................................3-22<br />

BioWeb .................................................................................Innovative .....................................................................3-22<br />

RINGLACE ® ............................................................................Innovative .....................................................................3-22<br />

Membrane BioReactor (MBR) ............................................. Innovative ............................................................ 3-25<br />

Mobile-Bed Reactor Technology (MBRT) Process .............. Innovative ............................................................ 3-31<br />

Bardenpho ® (Three Stage) with Returned<br />

Activated Sludge (RAS) Denitrificati<strong>on</strong> ................................ Innovative Use of Established Technology ......... 3-33<br />

Biological-Chemical Phosphorus and Nitrogen Removal<br />

(BCFS) Process ................................................................... Innovative Use of Established Technology ......... 3-35<br />

Modified University of Cape Town (MUCT) Process ........... Innovative Use of Established Technology ......... 3-37<br />

Modified Anaerobic/Oxic (A/O) Process .............................. Innovative Use of Established Technology ......... 3-39<br />

Trickling Filter/Solids C<strong>on</strong>tactor (TF/SC) ............................. Innovative Use of Established Technology ......... 3-41<br />

Aerobic Granular Sludge Process (AGSP) ......................... Embry<strong>on</strong>ic .......................................................... 3-43<br />

ANaerobic Membrane BioReactor (AN-MBR) .................... Embry<strong>on</strong>ic ........................................................... 3-45<br />

Anaerobic Migrating Blanket Reactor (AMBR ® ) .................. Embry<strong>on</strong>ic ........................................................... 3-47<br />

DEamMONificati<strong>on</strong> (DEMON) ............................................. Embry<strong>on</strong>ic .......................................................... 3-49<br />

Hydrogen-based hollow-Fiber Membrane Biofilm .............. Embry<strong>on</strong>ic ........................................................... 3-51<br />

Reactor (HFMBfR)<br />

Membrane-Aerated BioReactor (MABR) ............................. Embry<strong>on</strong>ic ........................................................... 3-53<br />

Microbial Fuel Cell (MFC) Based <strong>Treatment</strong> System .......... Embry<strong>on</strong>ic ........................................................... 3-55<br />

Multi-Stage Activated Biological Process (MSABP) ......... Embry<strong>on</strong>ic ........................................................... 3-57<br />

Nerada ............................................................................. Embry<strong>on</strong>ic ........................................................... 3-59<br />

SHARON (Single reactor High-activity Amm<strong>on</strong>ia<br />

Removal Over Nitrate) ......................................................... Embry<strong>on</strong>ic ........................................................... 3-61<br />

SHARON – ANAMMOX (ANaerobic<br />

AMM<strong>on</strong>ia Oxidati<strong>on</strong>) ............................................................ Embry<strong>on</strong>ic ........................................................... 3-63<br />

STRASS Process (Nitritati<strong>on</strong> and Denitritati<strong>on</strong><br />

in SBR) ............................................................................... Embry<strong>on</strong>ic ........................................................... 3-65<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management

February 2008<br />

List of <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> (C<strong>on</strong>td)<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management<br />

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

PROCESS TYPE PAGE<br />

Vacuum Rotati<strong>on</strong> Membrane (VRM ® ) .................................. Embry<strong>on</strong>ic ........................................................... 3-67<br />

In-Plant Wet Weather Management Processes<br />

C<strong>on</strong>tinuous Deflecti<strong>on</strong> Separator (CDS).............................. Innovative .............................................................. 4-3<br />

HYDROSELF ® Flushing Gate .............................................. Innovative .............................................................. 4-5<br />

Tipping Flusher ® ................................................................. Innovative .............................................................. 4-7<br />

TRASHMASTER Net Capture System ............................ Innovative .............................................................. 4-9<br />

WWETCO Compressed Media Filtrati<strong>on</strong> ® or<br />

WWETCO CMF ® System .................................................... Innovative ............................................................ 4-11<br />

Alternative Wet Weather Disinfecti<strong>on</strong> .................................. Embry<strong>on</strong>ic ........................................................... 4-15<br />

Process M<strong>on</strong>itoring <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

Amm<strong>on</strong>ia and Nitrate Probes .............................................. Innovative .............................................................. 5-5<br />

ChemScan N-4000 ..................................................................Innovative .......................................................................5-5<br />

Hach Evita In Situ 5100 ...........................................................Innovative .......................................................................5-5<br />

Myratek Sentry C-2 ..................................................................Innovative .......................................................................5-5<br />

Hach NITRATAX ......................................................................Innovative .......................................................................5-5<br />

NitraVis ® System ......................................................................Innovative .......................................................................5-5<br />

Royce 8500 Series Multi-Parameter ........................................Innovative .......................................................................5-5<br />

Fluorescence In Situ Hybridizati<strong>on</strong> (FISH)<br />

for Filamentous and Nitrifying Bacteria ............................... Innovative .............................................................. 5-9<br />

Microwave Density Analyzer................................................ Innovative ............................................................ 5-11<br />

Microtox ® /Online Microtox ® ................................................. Innovative ............................................................ 5-13<br />

SymBio – Nicotinamide Adenine Dinucleotide<br />

(NADH) Probes.................................................................... Innovative ............................................................ 5-15<br />

Online Respirometry ............................................................ Innovative ............................................................ 5-17<br />

NITROX – Oxidati<strong>on</strong> Reducti<strong>on</strong> Potential (ORP)<br />

Probe ................................................................................... Innovative ............................................................ 5-19<br />

Biological Micro-Electro-Mechanical Systems<br />

(BioMEMS) .......................................................................... Embry<strong>on</strong>ic ........................................................... 5-21<br />

Fluorescence In Situ Hybridizati<strong>on</strong> (FISH) for<br />

Phosphorus Accumulating Organisms (PAOs) .................... Embry<strong>on</strong>ic ........................................................... 5-23<br />

Handheld Advanced Nucleic Acid Analyzer<br />

(HANNA) .............................................................................. Embry<strong>on</strong>ic ........................................................... 5-25<br />

Immunosensors and Immunoassays .................................. Embry<strong>on</strong>ic ........................................................... 5-27<br />

Photo-electro Chemical Oxygen Demand<br />

(PeCOD) .......................................................................... Embry<strong>on</strong>ic ........................................................... 5-29<br />

xiii

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> February 2008<br />

xiv<br />

This page intenti<strong>on</strong>ally left blank<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management

February 2008<br />

Overview<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management<br />

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

In 2004, there were 16,583 municipal wastewater treatment plants operating in the United<br />

States. These plants ranged in size from a few hundred gall<strong>on</strong>s per day (GPD) to more<br />

than 800 milli<strong>on</strong> gall<strong>on</strong>s per day (MGD). Early efforts in water polluti<strong>on</strong> c<strong>on</strong>trol began in<br />

the late 1800s with c<strong>on</strong>structi<strong>on</strong> of facilities to prevent human waste from reaching drinking<br />

water supplies. Since the passage of the 1972 Amendments to the Federal Water Polluti<strong>on</strong><br />

C<strong>on</strong>trol Act (Clean Water Act [CWA]), municipal wastewater treatment facilities have been<br />

designed and built or upgraded to abate an ever-increasing volume and diversity of<br />

pollutants. The CWA requires that municipal wastewater treatment plant discharges meet<br />

a minimum of sec<strong>on</strong>dary treatment. However, in 2004, nearly 30 percent of the municipal<br />

facilities produced and discharged effluent at higher levels of treatment than the minimum<br />

federal standards for sec<strong>on</strong>dary treatment.<br />

This document provides informati<strong>on</strong> regarding emerging wastewater treatment and inplant<br />

wet weather management technologies organized into four categories of<br />

development:<br />

1. Embry<strong>on</strong>ic – <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> in the development stage and/or have been tested at<br />

a laboratory or bench scale <strong>on</strong>ly.<br />

2. Innovative – <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> that have been tested at a dem<strong>on</strong>strati<strong>on</strong> scale, have<br />

been available and implemented in the United States for less than five years, or<br />

have some degree of initial use (i.e., implemented in less than 1 percent of<br />

treatment facilities).<br />

3. Established – <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> that have been used at more than 1 percent of<br />

treatment facilities throughout the United States or have been available and<br />

implemented in the United States for more than five years.<br />

4. Innovative Uses of Established – Some wastewater treatment processes<br />

have been established for years, but they are not static. In some cases, an<br />

established technology may have been modified or adapted resulting in an<br />

emerging technology. In other cases, a process that was developed to<br />

achieve <strong>on</strong>e treatment objective is now being applied in different ways or to<br />

achieve additi<strong>on</strong>al treatment objectives. During the operati<strong>on</strong> of treatment<br />

systems using these established technologies, engineers, and operators have<br />

altered and improved their efficiency and performance. This document includes<br />

established technologies that have underg<strong>on</strong>e recent modificati<strong>on</strong>s or are used in<br />

new applicati<strong>on</strong>s.<br />

O-1

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> February 2008<br />

O-2<br />

This document also provides informati<strong>on</strong> <strong>on</strong> each technology, its objective, its descripti<strong>on</strong>,<br />

its state of development, available cost informati<strong>on</strong>, associated c<strong>on</strong>tact names, and<br />

related data sources. For each innovative technology, this document further evaluates<br />

technologies against various criteria, although it does not rank or recommend any <strong>on</strong>e<br />

technology over another. Research needs are also identified to guide development of<br />

innovative and embry<strong>on</strong>ic technologies and improve established <strong>on</strong>es.<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management

Chapter<br />

1<br />

Introducti<strong>on</strong> and Approach<br />

1.1 Introducti<strong>on</strong><br />

In 2004, there were 16,583 municipal wastewater treatment plants operating in the United<br />

States. These plants ranged in size from a few hundred gall<strong>on</strong>s per day (GPD) to more<br />

than 800 milli<strong>on</strong> gall<strong>on</strong>s per day (MGD). Early efforts in water polluti<strong>on</strong> c<strong>on</strong>trol began in<br />

the late 1800s with c<strong>on</strong>structi<strong>on</strong> of facilities to prevent human waste from reaching drinking<br />

water supplies. Since the passage of the 1972 Amendments to the Federal Water Polluti<strong>on</strong><br />

C<strong>on</strong>trol Act (Clean Water Act [CWA]), municipal wastewater treatment facilities have been<br />

designed and built or upgraded to abate an ever-increasing volume and diversity of<br />

pollutants. The CWA requires that municipal wastewater treatment plant discharges meet<br />

a minimum of sec<strong>on</strong>dary treatment. However, in 2004, nearly 30 percent of the municipal<br />

facilities produced and discharged effluent at higher levels of treatment than the minimum<br />

federal standards for sec<strong>on</strong>dary treatment.<br />

To meet the challenge of keeping progress in wastewater polluti<strong>on</strong> abatement ahead of<br />

populati<strong>on</strong> growth, changes in industrial processes, and technological developments,<br />

EPA is providing this document to make informati<strong>on</strong> available <strong>on</strong> recent advances and<br />

innovative techniques.<br />

The goal of this document is straight forward—to provide a guide for pers<strong>on</strong>s seeking<br />

informati<strong>on</strong> <strong>on</strong> innovative and emerging wastewater treatment technologies. The guide<br />

lists new technologies, assesses their merits and costs, and provides sources for further<br />

technological investigati<strong>on</strong>. This document is intended to serve as a tool for wastewater<br />

facility owners and operators.<br />

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> technologies typically follow a development process that leads from laboratory<br />

and bench-scale investigati<strong>on</strong>s to pilot studies and to initiate use or “full-scale<br />

dem<strong>on</strong>strati<strong>on</strong>s” before the technology is c<strong>on</strong>sidered established. Not all technologies<br />

survive the entire development process. Some fail in the laboratory or at pilot stages;<br />

others see limited applicati<strong>on</strong> in the field, but poor performance, complicati<strong>on</strong>s, or<br />

unexpected costs may cause them to lose favor. Even technologies that become<br />

established may lose favor in time, as technological advances lead to obsolescence. In<br />

short, technologies are subject to the same evoluti<strong>on</strong>ary forces present in nature; those<br />

that cannot meet the demands of their envir<strong>on</strong>ment fail, while those that adapt to changing<br />

technological, ec<strong>on</strong>omic and regulatory climates can achieve l<strong>on</strong>g-standing success and<br />

survival in the market.<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management<br />

1-1

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> February 2008<br />

1-2<br />

Some wastewater treatment processes have been established for many years, but that<br />

does not mean that they are static. During the operati<strong>on</strong> of treatment systems using<br />

these established technologies, engineers and operators have altered and improved<br />

efficiency and performance. In other cases, established technologies applied to <strong>on</strong>e<br />

aspect of treatment have been modified so that they can perform different objectives.<br />

Often, better performance can be achieved by linking established processes in innovative<br />

ways. This document includes established technologies that have underg<strong>on</strong>e recent<br />

modificati<strong>on</strong>s or are used in new applicati<strong>on</strong>s. These technologies are evaluated in the<br />

chapters al<strong>on</strong>gside the innovative and embry<strong>on</strong>ic technologies.<br />

1.2 Approach<br />

To develop this guide, the investigators sought informati<strong>on</strong> from a variety of sources,<br />

identified new technologies, prepared cost summaries, where informati<strong>on</strong> was available,<br />

for all technologies, and evaluated technologies deemed to be innovative. This method is<br />

described below and in Figure 1-1.<br />

Collect Informati<strong>on</strong><br />

Identify Process<br />

Screen<br />

Prepare Process<br />

Summary Sheets<br />

Screen<br />

Prepare Process<br />

Evaluati<strong>on</strong> Matrix<br />

Established<br />

Embry<strong>on</strong>ic or Innovative<br />

Innovative<br />

Embry<strong>on</strong>ic<br />

No Further Acti<strong>on</strong><br />

No Further Acti<strong>on</strong><br />

Has Innovative<br />

Modi�cati<strong>on</strong>s<br />

Figure 1.1—Flow Schematic for Guide Development<br />

745043_WWT-01..ai<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management

February 2008<br />

1.2.1 Informati<strong>on</strong> Collecti<strong>on</strong> and New Process Identificati<strong>on</strong><br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management<br />

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

The collecti<strong>on</strong> of informati<strong>on</strong> and identificati<strong>on</strong> of new technology provided the foundati<strong>on</strong><br />

for subsequent work. To identify new treatment process technologies, investigators<br />

gathered informati<strong>on</strong> and focused <strong>on</strong> relevant Water Envir<strong>on</strong>ment Federati<strong>on</strong> (WEF) and<br />

American Society of Civil Engineers (ASCE) c<strong>on</strong>ference proceedings, as well as m<strong>on</strong>thly<br />

publicati<strong>on</strong>s from these and other organizati<strong>on</strong>s such as Internati<strong>on</strong>al Water Associati<strong>on</strong><br />

(IWA).<br />

“Gray” Literature – Vendor-supplied informati<strong>on</strong>, Internet research, and c<strong>on</strong>sultants’<br />

technical reports comprise the informati<strong>on</strong> collected in this category.<br />

Technical Associati<strong>on</strong>s – Investigators c<strong>on</strong>tacted a variety of professi<strong>on</strong>al and<br />

technical associati<strong>on</strong>s in the United States to identify emerging wastewater treatment<br />

technologies.<br />

Interviews and Corresp<strong>on</strong>dence – Individuals known to the project investigati<strong>on</strong><br />

team, including c<strong>on</strong>sultants, academics, and municipal wastewater treatment plant<br />

owners and operators, were c<strong>on</strong>sulted.<br />

<str<strong>on</strong>g>Technologies</str<strong>on</strong>g> identified through search of the above sources were screened to determine<br />

their classificati<strong>on</strong> as described below.<br />

1.2.2 Initial Screened <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

This project focuses <strong>on</strong> emerging technologies that appear to be viable, but have not yet<br />

been accepted as established processes in the United States. Specific screening criteria<br />

used to define the state of development for processes are described in the following<br />

paragraphs. This screening resulted in:<br />

� 23 embry<strong>on</strong>ic technologies<br />

� 52 innovative technologies<br />

� 8 established technologies with innovative modificati<strong>on</strong>s<br />

Embry<strong>on</strong>ic – These technologies are in the development stage and/or have been tested<br />

at laboratory or bench scale. New technologies that have reached the dem<strong>on</strong>strati<strong>on</strong><br />

stage overseas, but cannot yet be c<strong>on</strong>sidered to be established there, are also c<strong>on</strong>sidered<br />

to be embry<strong>on</strong>ic with respect to North American applicati<strong>on</strong>s.<br />

Innovative – <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> that meet <strong>on</strong>e of the following criteria were classified as<br />

innovative:<br />

� They have been tested as a full-scale dem<strong>on</strong>strati<strong>on</strong>.<br />

� They have been available and implemented in the United States for less than five<br />

years.<br />

�<br />

They have some degree of initial use (i.e., implemented in less than 1 percent of<br />

municipalities throughout the United States).<br />

1-3

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> February 2008<br />

1-4<br />

�<br />

They are established technologies from overseas.<br />

Established – In most cases, these processes are used at more than 1 percent of fullscale<br />

facilities in North America; but there are some excepti<strong>on</strong>s based up<strong>on</strong> specific<br />

c<strong>on</strong>siderati<strong>on</strong>s. The established category may include technologies that are widely used<br />

although introduced more recently in North America. Due to the extensive number of<br />

established technologies and variati<strong>on</strong>s in each technology, <strong>on</strong>ly established technologies<br />

are listed. N<strong>on</strong>e are described in depth in this document and Technology Summary sheets<br />

are not provided for established technologies.<br />

Innovative Uses of Established – In some cases, an established technology such<br />

as the UCT (University of Cape Town) process may have been modified or adapted,<br />

resulting in an emerging technology such as the Modified UCT. In other cases, a process<br />

like Actiflo ® was developed to remove solids from wet weather flows but is now also being<br />

used to polish final effluent.<br />

The focus of this document is <strong>on</strong> Innovative <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> al<strong>on</strong>g with preliminary<br />

informati<strong>on</strong> of Embry<strong>on</strong>ic <str<strong>on</strong>g>Technologies</str<strong>on</strong>g>. Early in the development process (the laboratory<br />

stage), data was usually insufficient to prove or disprove technology viability at full scale.<br />

Available informati<strong>on</strong> <strong>on</strong> these embry<strong>on</strong>ic technologies is presented in this document.<br />

<str<strong>on</strong>g>Technologies</str<strong>on</strong>g> <strong>on</strong> the other end of the developmental scale, those defined as established<br />

in North America, are excluded from the detailed assessments <strong>on</strong> the assumpti<strong>on</strong> that<br />

they are proven, although still relatively new.<br />

The differentiati<strong>on</strong> between technologies established in Europe or Asia and those that<br />

have reached similar status in the United States can be critical since technologies that<br />

have been applied successfully in other countries have not always flourished here in the<br />

United States. Because the viability of imported technologies is not guaranteed,<br />

established processes from overseas are classified as innovative technologies for this<br />

project, unless they are proven in North American applicati<strong>on</strong>s.<br />

Some technologies fall into a “gray area” between the embry<strong>on</strong>ic and innovative<br />

categories. <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> that fall into this category are incorporated into the innovative<br />

category. The screening assessment is summarized by chapter in Tables 1.1 through<br />

1.4.<br />

�<br />

�<br />

�<br />

�<br />

Table 1.1 summarizes the treatment technologies for Chapter 2 – Physical/Chemical<br />

<strong>Treatment</strong> Processes.<br />

Table 1.2 summarizes the treatment technologies for Chapter 3 – Biological<br />

<strong>Treatment</strong> Processes.<br />

Table 1.3 summarizes the treatment technologies for Chapter 4 – In-Plant Wet<br />

Weather Management Processes.<br />

Table 1.4 summarizes the treatment technologies for Chapter 5 – Process M<strong>on</strong>itoring<br />

<str<strong>on</strong>g>Technologies</str<strong>on</strong>g>.<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management

February 2008<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management<br />

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

All the cost estimates provided in this document c<strong>on</strong>tain a certain degree of expert<br />

judgment or educated guesswork c<strong>on</strong>cerning the various cost elements that comprise<br />

the estimates. This is true when cost estimates are based <strong>on</strong> limited or no informati<strong>on</strong><br />

where in some cases little more than process type, locati<strong>on</strong>, and plant capacity are known.<br />

Therefore, cost estimates are at best order-of-magnitude level per American Associati<strong>on</strong><br />

of Cost Engineers (AACE) Internati<strong>on</strong>al classificati<strong>on</strong>. However, numerous peripheral<br />

factors that could also interfere with the accuracy of the order-of-magnitude level cost<br />

estimates. C<strong>on</strong>sidering these facts, the reader should keep in mind that site-specific<br />

applicati<strong>on</strong>s and local requirements should be c<strong>on</strong>sidered to increase the accuracy of<br />

cost estimates provided in this document.<br />

1.2.3 Development of Technology Summary Sheets<br />

<str<strong>on</strong>g>Technologies</str<strong>on</strong>g> defined as embry<strong>on</strong>ic or innovative are each summarized <strong>on</strong> an individual<br />

Technology Summary sheet. Each process includes the following informati<strong>on</strong>:<br />

� Objective – Descripti<strong>on</strong> of the goal of the technology.<br />

� State of Development – Where and how the technology has been applied (i.e.,<br />

laboratory study, dem<strong>on</strong>strati<strong>on</strong> scale, full scale, etc.).<br />

� Descripti<strong>on</strong> – A brief overview of the technology.<br />

� Comparis<strong>on</strong> to Established <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> – Advantages and disadvantages<br />

of innovative and embry<strong>on</strong>ic technologies are compared to more comm<strong>on</strong>ly used<br />

technologies.<br />

� Available Cost Informati<strong>on</strong> – Approximate range of capital and operati<strong>on</strong>s and<br />

maintenance costs, and assumpti<strong>on</strong>s made in developing them (when reliable<br />

informati<strong>on</strong> was available).<br />

� Vendors Name(s) – Name, address, teleph<strong>on</strong>e numbers, web address, and other<br />

c<strong>on</strong>tact informati<strong>on</strong> for equipment manufacturers and suppliers.<br />

� Installati<strong>on</strong>(s) – Name, address, teleph<strong>on</strong>e numbers, and other c<strong>on</strong>tact<br />

informati<strong>on</strong> for utilities and facilities where the technology has been used (full or pilot<br />

scale).<br />

� Key Words for Internet Search – Because this document is not intended to<br />

provide a comprehensive list of vendors for these technologies, key words have<br />

been added to aid the reader in finding additi<strong>on</strong>al vendors and current product<br />

informati<strong>on</strong> <strong>on</strong> the Internet.<br />

�<br />

Data Sources – References used to compile the technology summary.<br />

1-5

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> February 2008<br />

Technology and Advancements<br />

(Listed in process flow sequence)<br />

Established <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

1-6<br />

Table 1.1—Summary of <strong>Treatment</strong> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

Chapter 2 – Physical/Chemical <strong>Treatment</strong> Processes<br />

C-BOD Removal<br />

Phosphorus Removal<br />

Nitrificati<strong>on</strong>-Amm<strong>on</strong>ia<br />

Removal<br />

Denitrificati<strong>on</strong> – Nitrogen<br />

Removal<br />

Applicati<strong>on</strong>s<br />

Air Stripping<br />

Screening<br />

l l<br />

� Fine Screening<br />

l<br />

� Micro Screening<br />

l<br />

� Rotary Screening<br />

l<br />

� Step Screening<br />

l<br />

� Microsieves<br />

l l l<br />

Grit Removal<br />

� Travelling Bridge<br />

l<br />

Fine/Advanced Grit Removal System (AGRS)<br />

HEADCELLTM � l<br />

GRITKINGTM � l<br />

PISTAGRITTM � l<br />

HYDROGRITTM � l<br />

Flocculati<strong>on</strong><br />

Chemical Precipitati<strong>on</strong>*<br />

l<br />

� Alum Additi<strong>on</strong><br />

l l<br />

� Ir<strong>on</strong> Salts Additi<strong>on</strong><br />

l l<br />

� Zeolite<br />

l<br />

High Rate Dissolved Air Flotati<strong>on</strong> (DAF) <strong>Treatment</strong>/Settling l<br />

Chemically Enhanced Primary <strong>Treatment</strong> l l<br />

Solids C<strong>on</strong>tact Clarifier for P Removal l l l<br />

I<strong>on</strong>-Exchange<br />

Chemical Oxidati<strong>on</strong>*<br />

l<br />

� Hydroxyl Radical<br />

l l<br />

� Oxygen (Atomic and Molecular)<br />

l l<br />

� Oz<strong>on</strong>e<br />

l l<br />

� Hydrogen Peroxide<br />

l l<br />

� Hypochlorite/Chlorine/Chlorine Dioxide<br />

l l<br />

Note:<br />

* Chemical phosphorus removal is limited by kinetic factors as well as stoichiometric factors and excessive inorganic precipitant<br />

requirements need to be reduced.<br />

Solids – Liquid<br />

Separati<strong>on</strong> (TDS and TSS)<br />

Targeted C<strong>on</strong>taminants<br />

Removal<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management<br />

Disinfecti<strong>on</strong><br />

Physical/Chemical<br />

M<strong>on</strong>itoring<br />

Biochemical M<strong>on</strong>itoring

February 2008<br />

Technology and Advancements<br />

(Listed in process flow sequence)<br />

Established <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> (C<strong>on</strong>td)<br />

Advanced Oxidati<strong>on</strong> Processes<br />

Table 1.1—Summary of <strong>Treatment</strong> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> (C<strong>on</strong>td)<br />

Chapter 2 – Physical/Chemical <strong>Treatment</strong> Processes<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management<br />

C-BOD Removal<br />

Phosphorus Removal<br />

Nitrificati<strong>on</strong>-Amm<strong>on</strong>ia<br />

Removal<br />

Denitrificati<strong>on</strong> – Nitrogen<br />

Removal<br />

Applicati<strong>on</strong>s<br />

� Supercritical Water Oxidati<strong>on</strong><br />

l l<br />

� Catalytic Oxidati<strong>on</strong><br />

l l<br />

� Photo Catalysis (UV + TiO2) l l<br />

� Fent<strong>on</strong>’s Reagent (H2O2 + Ferrous I<strong>on</strong>)<br />

l l<br />

Electodialysis<br />

Filtrati<strong>on</strong> through Membranes<br />

l l<br />

� Reverse Osmosis<br />

l l l<br />

� Microfiltrati<strong>on</strong><br />

l l l<br />

� Ultrafiltrati<strong>on</strong><br />

l l l<br />

Filtrati<strong>on</strong> through Media<br />

� Cloth Media<br />

– Disc Filter (DF)<br />

l l<br />

– Drum Filter<br />

l l<br />

– Diam<strong>on</strong>d-Shaped Filters<br />

l l<br />

� Silica Media (One- and Two-Stage)<br />

– C<strong>on</strong>venti<strong>on</strong>al Downflow<br />

l l<br />

– Deep-Bed Downflow Filters<br />

l l<br />

– Deep-Bed Upflow C<strong>on</strong>tinuous Backwash Filters<br />

l l<br />

� Activated Alumina Media<br />

l<br />

� Powdered Activated Carb<strong>on</strong> (PAC)<br />

l l<br />

� Granular-Activated Carb<strong>on</strong> (GAC)<br />

l l l<br />

Denitrificati<strong>on</strong> Filters l l l<br />

Automatic Backwash Filters (ABW ® ) l l<br />

Pulsed Bed Filter<br />

Disinfecti<strong>on</strong><br />

l l<br />

� Oz<strong>on</strong>e<br />

l<br />

� Chlorine/Chlorine Dioxide/Liquid Chlorine/Dechlorinati<strong>on</strong><br />

l<br />

� Halogens (Bromine)<br />

l<br />

� UltraViolet (UV) Disinfecti<strong>on</strong><br />

l<br />

Solids – Liquid<br />

Separati<strong>on</strong> (TDS and TSS)<br />

Targeted C<strong>on</strong>taminants<br />

Removal<br />

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

Disinfecti<strong>on</strong><br />

Physical/Chemical<br />

M<strong>on</strong>itoring<br />

Biochemical M<strong>on</strong>itoring<br />

1-7

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> February 2008<br />

Technology and Advancements<br />

(Listed in process flow sequence)<br />

Innovative <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

1-8<br />

Table 1.1—Summary of <strong>Treatment</strong> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> (C<strong>on</strong>td)<br />

Chapter 2 – Physical/Chemical <strong>Treatment</strong> Processes<br />

C-BOD Removal<br />

Phosphorus Removal<br />

Nitrificati<strong>on</strong>-Amm<strong>on</strong>ia<br />

Removal<br />

Denitrificati<strong>on</strong> – Nitrogen<br />

Removal<br />

Applicati<strong>on</strong>s<br />

Compressible Media Filtrati<strong>on</strong> l l l<br />

Nanofiltrati<strong>on</strong><br />

Innovative Use of Established <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

Ballasted High Rate Clarificati<strong>on</strong> (BHRC) Processes*<br />

l l l<br />

Actiflo ® � Process<br />

l l<br />

Densadeg ® � Process<br />

l l<br />

Microwave UV Disinfecti<strong>on</strong><br />

Embry<strong>on</strong>ic <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

l<br />

Blue CATTM l l l<br />

Blue PROTM l l<br />

CoMagTM l l<br />

Solar Disinfecti<strong>on</strong><br />

Note:<br />

l<br />

* Chemical phosphorus removal is limited by kinetic factors as well as stoichiometric factors and excessive inorganic precipitant<br />

requirements need to be reduced.<br />

Solids – Liquid<br />

Separati<strong>on</strong> (TDS and TSS)<br />

Targeted C<strong>on</strong>taminants<br />

Removal<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management<br />

Disinfecti<strong>on</strong><br />

Physical/Chemical<br />

M<strong>on</strong>itoring<br />

Biochemical M<strong>on</strong>itoring

February 2008<br />

Technology and Advancements<br />

(Listed in process flow sequence)<br />

Established <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

BOD Removal and Nitrificati<strong>on</strong><br />

Table 1.2—Summary of <strong>Treatment</strong> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

Chapter 3 – Biological <strong>Treatment</strong> Processes<br />

<strong>Wastewater</strong> <strong>Treatment</strong> and In-Plant Wet Weather Management<br />

C-BOD Removal<br />

Phosphorus Removal<br />

Nitrificati<strong>on</strong>-Amm<strong>on</strong>ia<br />

Removal<br />

Denitrificati<strong>on</strong> – Nitrogen<br />

Removal<br />

� Biolac-Aerated Lago<strong>on</strong><br />

l l<br />

� Complete Mix-Activated Sludge (CMAS) Process<br />

l l<br />

� C<strong>on</strong>tact Stabilizati<strong>on</strong><br />

l l<br />

� C<strong>on</strong>venti<strong>on</strong>al Extended Aerati<strong>on</strong><br />

l l<br />

� Countercurrent Aerati<strong>on</strong> System (CCAS)<br />

l l l<br />

� Cyclic Activated Sludge System (CASS)<br />

l l l<br />

� High-Purity Oxygen (HPO)<br />

l l<br />

Intermittent Cycle Extended Aerati<strong>on</strong> System (ICEASTM � ) l l l<br />

� Kraus Process<br />

l l<br />

� Oxidati<strong>on</strong> Ditch/Aerated Lago<strong>on</strong>s<br />

l l<br />

� Sequencing Batch Reactor (SBR)<br />

l l l<br />

� Staged Activated-Sludge Process<br />

l l<br />

� Step Feed<br />

l l<br />

� Step Feed (Alternating Anoxic and Aerobic)<br />

l l l<br />

Biological Nutrient Removal (BNR)<br />

Bardenpho ® � (Four Stage)<br />

l l l<br />

BiodenitroTM � l l l<br />

� Ludzack-Ettinger<br />

l l l<br />

� Modified Ludzack-Ettinger (MLE)<br />

l l l<br />

OrbalTM � Process<br />

l l l<br />

SchreiberTM � Process<br />

l l l<br />

� Simultaneous Nitrificati<strong>on</strong> denitrificatioN (SNdN) Process l l l<br />

� Step Feed BNR Process<br />

l l l<br />

� Wuhrman<br />

l l l<br />

Enhanced Biological Phosphorus Removal (EBPR)<br />

� Anaerobic/Anoxic/Oxic (A2/O)<br />

l l l l<br />

Bardenpho ® � (Five Stage)<br />

l l l l<br />

� Johannesburg Process<br />

l l l l<br />

� Phoredox (Anaerobic/Oxic [A/O])<br />

l l<br />

� Phostrip<br />

l l<br />

� University of Cape Town (UCT)<br />

l l l l<br />

� Virginia Initiative Plant (VIP)<br />

l l l l<br />

Applicati<strong>on</strong>s<br />

Solids – Liquid<br />

Separati<strong>on</strong> (TDS and TSS)<br />

Targeted C<strong>on</strong>taminants<br />

Removal<br />

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

Disinfecti<strong>on</strong><br />

Physical/Chemical<br />

M<strong>on</strong>itoring<br />

Biochemical M<strong>on</strong>itoring<br />

1-9

<str<strong>on</strong>g>Emerging</str<strong>on</strong>g> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> February 2008<br />

Technology and Advancements<br />

(Listed in process flow sequence)<br />

Established <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> (C<strong>on</strong>td)<br />

Other Biological Processes<br />

1-10<br />

Table 1.2—Summary of <strong>Treatment</strong> <str<strong>on</strong>g>Technologies</str<strong>on</strong>g> (C<strong>on</strong>td)<br />

Chapter 3 – Biological <strong>Treatment</strong> Processes<br />

C-BOD Removal<br />

Phosphorus Removal<br />

Nitrificati<strong>on</strong>-Amm<strong>on</strong>ia<br />

Removal<br />

Denitrificati<strong>on</strong> – Nitrogen<br />

Removal<br />

� Fluidized Bed Bioreactor (FBBR)<br />

l l<br />

� Rotating Biological C<strong>on</strong>tractor (RBC)<br />

l l<br />

� Submerged Rotating Biological C<strong>on</strong>tactor (SRBC) l l<br />

� Trickling Filter (TF)<br />

l l<br />

Anaerobic Processes<br />

� Anaerobic Attached Growth System<br />

– Upflow Packed-Bed Attached Growth Reactor l<br />

– Upflow Attached Growth Anaerobic<br />

l<br />

– Expanded-Bed Reactor (Anaerobic Expanded Bed<br />

Reactor [AEBR])<br />

l<br />

– Downflow Attached Growth Process<br />

l<br />

� Anaerobic C<strong>on</strong>tact Process<br />

l<br />

Anaerobic Sequencing Batch Reactor (ASBR ® � )<br />

l<br />

� Upflow Anaerobic Sludge Blanket (UASB)<br />

l<br />

� ANFLOW (ANaerobic FLuidized Bed Reactor)<br />

l<br />

Biological Aerated Filters (BAF)<br />

Biofor ® � l l l<br />

Biostyr ® � l l l<br />

Innovative <str<strong>on</strong>g>Technologies</str<strong>on</strong>g><br />

Bioaugmentati<strong>on</strong><br />

� External Bioaugmentati<strong>on</strong><br />

– Seeding from Commercial Sources of Nitrifiers l l l<br />

– Trickling Filter and Pushed Activated Sludge (TF/PAS)<br />

Process<br />

l l l<br />

– Seeding from External Dispensed Growth Reactors<br />

Treating Reject Waters (Chemostat)<br />