draft beb rfp - TACOM Procurement Network - U.S. Army

draft beb rfp - TACOM Procurement Network - U.S. Army

draft beb rfp - TACOM Procurement Network - U.S. Army

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

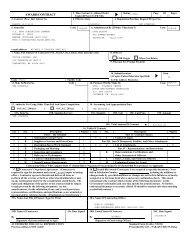

CONTINUATION SHEET<br />

Name of Offeror or Contractor:<br />

SECTION D - PACKAGING AND MARKING<br />

Reference No. of Document Being Continued Page 105 of 170<br />

PIIN/SIIN W56HZV-12-R-0445<br />

MOD/AMD<br />

Regulatory _______________ Cite ______________________________________________________________________ Title ____________ Date<br />

D-1 52.247-4016 HEAT TREATMENT AND MARKING OF WOOD PACKAGING MATERIALS AUG/2005<br />

(<strong>TACOM</strong>)<br />

Boxes/pallets and any wood used as inner packaging made of non-manufactured wood shall be heat-treated. All non-manufactured wood<br />

used in packaging shall be heat treated to a core temperature of 56 degrees Celsius for a minimum of 30 minutes. The box/pallet<br />

manufacturer and the manufacturer of wood used as inner packaging shall be affiliated with an inspection agency accredited by the board<br />

of review of the American Lumber Standard Committee. The box/pallet manufacturer and the manufacturer of wood used as inner packaging<br />

shall ensure traceability to the original source of heat treatment.<br />

Marking. Each box/pallet shall be marked to show the conformance to the International Plant Protection Convention Standard. The<br />

quality mark shall be placed on both ends of the outer packaging, between the end cleats or end battens; on two sides of the pallet.<br />

Foreign manufacturers shall have the heat treatment of non-manufactured wood products verified in accordance with their National Plant<br />

Protection Organization's compliance program. In addition, wood used as dunnage for blocking and bracing shall be ordered with ALSC<br />

certified marking for dunnage or the markings may be applied locally at two foot intervals.<br />

D.1 Preservation and Packaging<br />

[End of Clause]<br />

D.1.1 Required software, technical data, reports, etc. delivered under this contract shall be preserved and packaged to deter theft and<br />

assure safe arrival to the destination without damage to contents.<br />

D.1.2 The contractor shall preserve, package, pack and mark the BEBs and package, pack and mark all other items delivered under this<br />

contract in accordance with the approved packaging data as generated and submitted by the contractor and approved by the Government. If<br />

packaging data is not available at the time of delivery, the contractor shall preserve, package, pack and mark the items in accordance<br />

with the following requirements:<br />

D.1.2.1 If Shipping and Storage Instructions for the BEBs have not been developed by the contractor and approved by the Government; the<br />

BEBs shall be processed to Level B drive-on/drive-off requirements in accordance with MIL-STD-3003. Fuel tanks shall be one-half (1/2)<br />

filled with operational fuel and applicable biocide or JP8 fuel. All batteries shall be fully charged. Vehicles and mechanical<br />

equipment containing internal combustion engines or wet batteries are subject to requirements of Code of Federal Regulation Title 49<br />

(for truck and rail transport), International Maritime Dangerous Goods Code (for vessel transport) and the Joint Service Regulation<br />

AFMAN24-204/TM38-250 (for military air). All preventive maintenance shall be performed prior to Government acceptance. All components<br />

removed from the vehicle for reduction of cube including accessories shall be preserved, packaged, packed and marked to ensure safe<br />

delivery within the vehicle and minimize pilferage, corrosion and deterioration during shipment to receiving activity including<br />

temporary outdoor storage for up to 90 days.<br />

D.1.2.2 The Crew Protection Kit (CPK) shall be delivered and stored in a container that is new, weatherproof, non-collapsible, lockable,<br />

repairable, and suitable for repeated use. The container shall be warehouse stackable to sixteen feet when fully loaded to container<br />

rated gross weight without damage or permanent deformation. The container shall be configured such that all components of the armor kit<br />

are protected during shipment, and to facilitate quick inventory of the contents. When the armor kit is installed, the container shall<br />

store all items removed to facilitate armor installation. The container shall have forklift pockets that conform to STANAG 2828 that<br />

allow the container to be fork lifted from all four sides. In accordance with MIL-STD-209 the containers shall be capable of being<br />

transported by military and commercial vehicles, trailers, trains, marine vessels, aircraft, dolly sets and shall withstand the impact<br />

forces encountered in shipment without damage or permanent deformation. The containers shall be capable of being transported by C-130,<br />

C-5, and C-17 with or without supporting equipment existing in the DoD system. The container shall be painted the same color as the<br />

armor kit contained within. For container types existing in the DoD inventory, the modifications performed for this effort shall not<br />

void existing certifications.<br />

D.1.2.3 Consumable items, Training Aids, System Support Packages (SSP) and Special Tools scheduled for shipment shall be preservation,<br />

packaging, packing, unitization and marking furnished by the contractor to provide exceptional physical and mechanical protection,<br />

provide multiple handling, shipment by any mode, placed into storage for a period of one (1) year and meet or exceed the following<br />

requirements. It also shall provide for multiple handling, redistribution without additional repackaging and shipment by any mode.<br />

D.1.2.3.1 Cleanliness<br />

Items shall be free of dirt and other contaminants which would contribute to the deterioration of the item or which would require<br />

cleaning by the customer prior to use. Coatings and preservatives applied to the item for protection are not considered contaminants.<br />

D.1.2.3.2 Preservation<br />

DRAFT